Stirling Engine : Laura

A premilled kit by Bengs

| Brian John | 21/12/2015 11:38:13 |

| 1487 forum posts 582 photos | Hopper : so the gap between the piston and the glass tube is necessary so I will make the piston 12.5mm as per the drawings. It looks like the displacement brass cylinder can be anything though ; it is marked as 14mm so I assume that this is not crucial at all (part #25). Does the piston have to be aluminium and if so, why ? I have seen many Stirling engines that do not use glass ; they use a metal tube. What metals are best for this job ? Edited By Brian John on 21/12/2015 11:41:41 |

| Ian S C | 21/12/2015 12:20:42 |

7468 forum posts 230 photos | Brian, what is the displacer piston made of? These are usually made hollow, and thin walled stainless steel is the ideal. I have seen some actually made from a smaller test tube, as long as you have a gap of (say) a mm. The best of my engines have thin walled stainless steel for the hot cap, and the displacer, the final dimensions often(in my case)depend on what materials I have in the junk box. If the piston is aluminium, it's for weight (you don't want weight), aluminium is not the best stuff to use here, it conducts heat too fast, so that too much heat arrives as the cold end. This is what happens to hollow aluminium displacers when you start to get some heat into things. |

| Brian John | 21/12/2015 12:39:23 |

| 1487 forum posts 582 photos | Ian : the displacer piston is aluminium. |

| JasonB | 21/12/2015 13:07:06 |

25215 forum posts 3105 photos 1 articles | I think I said early on in this thread that a bit of freehand turning and a file applied to the revolving work will do fine for rounding over the end of teh piston, you could do it faster than you could set up a ball/radius attachment. An alternative is to grind a HSS toolbit with a 1/4 circle anmd apply that to the piston

Or buy a bit of gauge plate (ground flat stock) drill a 12.5mm hole in it, cut away what you don't want and the heat & quench.

Edited By JasonB on 21/12/2015 13:12:56 |

| Brian John | 22/12/2015 00:58:06 |

| 1487 forum posts 582 photos | I have not had much luck with freehand work in the past but aluminium is cheap so I will give it a go once I finish boring the cylinders. |

| Brian John | 22/12/2015 07:22:46 |

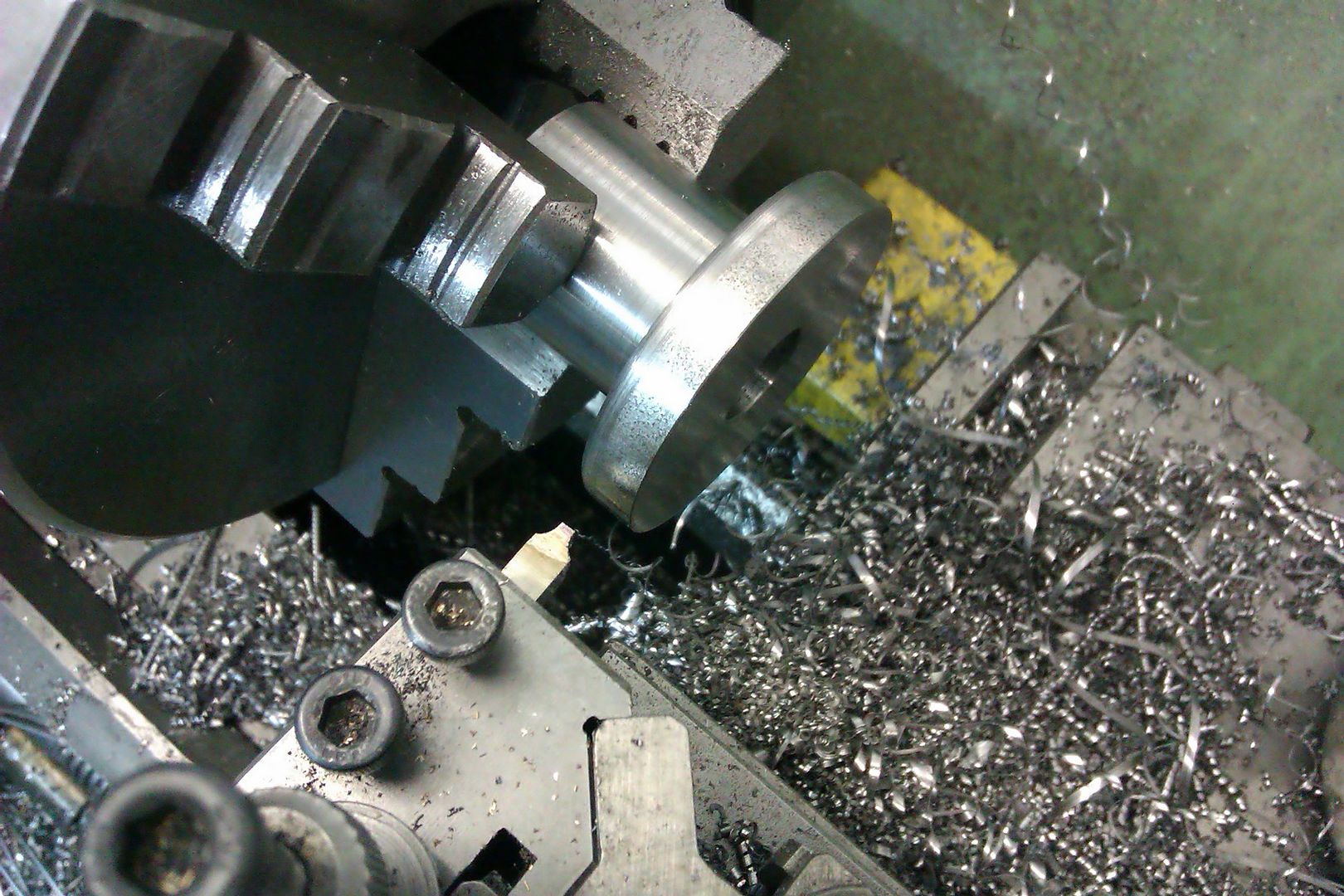

| 1487 forum posts 582 photos | I bored out the three work cylinders (part #26) today. Yes, I made three because I needed to practise my recess cuts ! The first one I attempted to drill and ream using my newly arrived 10H7 reamer...what a mess. It must be a poor quality reamer as it did not leave a smooth finish on the inside. I have bought smaller reamers (2H7, 3H7 and 6H7) from this Chinese company before and had no problems. Maybe smaller sizes are easier to make ? I found that it had reamed undersize anyway (9.8mm) so I was lucky and cleaned it up with the boring bar to finish at 10mm. I did the other two with the boring bar after drilling out to 9mm with stub drills. The boring bar is the way to go although I have to use auto feed. I cannot get a smooth finish on manual feed. |

| Martin Connelly | 22/12/2015 09:18:28 |

2549 forum posts 235 photos | You could use stepped roughing to get the basic curve done on the piston then finish with a file. See ballcut.zip here: Martin |

| Brian John | 23/12/2015 05:37:46 |

| 1487 forum posts 582 photos | The parts list show the working piston (part #15) as ''Rotguss'' which I have googled and come up with ''red brass'' This is also classified as a type of both bronze and brass according to Wikipedia. All the other brass parts are listed as Ms58. Why is this piston made of this type of brass/bronze ? Edited By Brian John on 23/12/2015 05:42:16 Edited By Brian John on 23/12/2015 05:42:38 |

| Andy Holdaway | 23/12/2015 09:01:27 |

167 forum posts 15 photos | Red brass is a gunmetal. I presume from the inclusion of lead and tin it provides an amount of lubrication for the piston. |

| pgk pgk | 23/12/2015 09:29:18 |

| 2661 forum posts 294 photos | Posted by Andrew Holdaway on 23/12/2015 09:01:27:

Red brass is a gunmetal. I presume from the inclusion of lead and tin it provides an amount of lubrication for the piston. ..when the q was posed i looked up 'red brass' as a gunmetal but nothing re lead in it and couldn't see why the difference with brass would help lubrication. Logic suggested perhaps better able to cope with condensation/corrosion compared to brass but then often the power side cylinders are made of brass which negates that theory? Is gunmetal more or less prone to 'tarnish' than brass? Edit... a carbon piston makes for sense.. Edited By pgk pgk on 23/12/2015 09:30:42 |

| Ajohnw | 23/12/2015 10:16:55 |

| 3631 forum posts 160 photos | It's the fit the drawings indicate between cylinders and pistons that is most important Brian not the precise sizes some slight variation on those wont matter. The other aspect that matters on stirling engines is the phasing of the pistons. That usually corresponds to the distance between holes in linkages. Stainless is sometimes used for the hot cylinder but borosilicate test tubes have lower thermal conductivity so may well be a better choice. Red brass etc - it's more capable of running in close proximity to a cylinder than say aluminium or even mild steel which might well pick up and bind. I assume that little program some one posted a link to calculates the step sizes to produce a radius. It's an easy way of doing it pretty precisely and finishing with a file after that is done is easy. Some people do the same thing on milling machines for the same reason. I might be tempted to buy a cutter. It's also possible to produce a decent rad by turning various angle chamfers and then smoothing with a file. Best for situations where the actual value doesn't matter too much. John - |

| Brian John | 23/12/2015 11:03:08 |

| 1487 forum posts 582 photos | I tried to buy a single cut smooth file for the final shaping of the aluminium displacement piston but I could not find one anywhere in Cairns. I will just rough it out with my double cut files and finish off with wet and dry sandpaper if I get the shape right. |

| Andy Holdaway | 23/12/2015 11:28:00 |

167 forum posts 15 photos | pgk pgk, I know you shouldn't believe everything you read on the internet, but this from Wikipedia: "Red brass used to produce pipes, valves, and plumbing fixtures, and is considered to offer a good mixture of corrosion resistance, strength, and ease of casting.[6] It typically contains 85% copper, 5% tin, 5% lead, and 5% zinc." |

| Ajohnw | 23/12/2015 11:45:29 |

| 3631 forum posts 160 photos | Posted by Brian John on 23/12/2015 11:03:08:

I tried to buy a single cut smooth file for the final shaping of the aluminium displacement piston but I could not find one anywhere in Cairns. I will just rough it out with my double cut files and finish off with wet and dry sandpaper if I get the shape right. With aluminium you are probably better off not using a super smooth file. It's rather soft so can clog up the file. The actual size of the cut on a file can vary with the size of the file too. Smaller - finer. I need to get a couple of coarser cut small files off Aminster. A drop of oil will help with the wet and dry. If I'm feeling manic I sometimes finish with a little abrasive rubber like block that is used for cleaning pcb contacts. Quick and easy and they last a long time. It's a very fine abrasive as pcb contacts are often gold plated. Metal polish will do it too but rags can catch in chucks which can result in lost fingers. John - |

| steamdave | 23/12/2015 14:47:59 |

| 526 forum posts 45 photos | Posted by John W1 on 23/12/2015 11:45:29:

snip ... With aluminium you are probably better off not using a super smooth file. It's rather soft so can clog up the file. The actual size of the cut on a file can vary with the size of the file too. Smaller - finer. I need to get a couple of coarser cut small files off Aminster. John Chalk rubbed on a file helps to prevent clogging. Oh for the good old schooldays days with chalk and a blackboard! Dave |

| Brian John | 24/12/2015 06:17:38 |

| 1487 forum posts 582 photos | I made the cylinder covers for the work and displacement cylinders today. I made two for the work cylinder because things were going so well ! I also treated myself to a new Trademaster bench drill. It was the display model and the last one they had so I thought I had better grab it now. The improved quality over my last bench drill is obvious. When I turn it on the drill bit does not wobble all over the place : a 1.5mm drill bit will actually drill a 1.5mm hole unlike the last machine. At some stage I am going to have to cut the glass test tube to size. What is your favourite way of cutting glass tubing ? I was think of doing it in the lathe with a triangular file. Edited By Brian John on 24/12/2015 06:18:28 Edited By Brian John on 24/12/2015 06:20:02 Edited By Brian John on 24/12/2015 06:22:10 |

| maurice bennie | 24/12/2015 09:59:24 |

| 164 forum posts 1 photos | Hi Brian , The easy way is to scratch the tube ONE third the way round , we had what we called a glass knife, made I think of tungsten carbide but anything that will scratch the tube will work,this will work on tube up to half inch. wear leather gloves,or as I did a duster in each hand and grip the tube ,one hand on each side of the mark and the mark on top, thumbs on top then pull and bend at the same time downwards (each thumb close to the mark) wear goggles just in case . I have broken off pieces from a five foot tube 3/8 " diameter and four inches long . This all depends on diameter and length to be broken .I was once working as a glass blower making apparatus for a laboratory. Hope this helps ,and do not be frightened of it . best wishes and a happy yuletide Maurice. . Edited By maurice bennie on 24/12/2015 10:02:06 |

| Bob Unitt 1 | 24/12/2015 10:05:36 |

323 forum posts 35 photos | Posted by John W1 on 23/12/2015 11:45:29:Metal polish will do it too but rags can catch in chucks which can result in lost fingers.

Woodturners use something called 'safety cloth' for polishing, it tears if it catches rather than dragging you into the chuck. I see no reason why this shouldn't work with metal polish too. |

| maurice bennie | 24/12/2015 10:07:50 |

| 164 forum posts 1 photos | Hi Brian again ,The only other way is to use a diamond wheel .Not got mind in gear this morning. Maurice. |

| Michael Gilligan | 24/12/2015 10:30:13 |

23121 forum posts 1360 photos |

This is probably a question for Ian SC ... Apart from manufacturing convenience; is there any good reason why that displacer is made solid ? MichaelG. . P.S. ... Glad to see you have found a useable drilling machine, Brian ... Project and Workshop are both looking good. Edited By Michael Gilligan on 24/12/2015 10:32:06 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in