Velocette

32DP / 0.8 mod

| Graham Williams 11 | 16/08/2019 11:31:37 |

| 80 forum posts 41 photos | What's the consensus on the use of a 0.8mod cutter using 32dp specs i.e. depth of tooth and outside diameter on a magneto drive gear for a Velo MAC, alloy engine, 92 teeth? Cheers Graham W |

| Michael Gilligan | 16/08/2019 11:35:27 |

23121 forum posts 1360 photos | They are very, very, close Assuming of course that the Velo uses 20° pressure angle !! [which I cannot remember] MichaelG. . Can you post a flat-bed scanner image, or a good photo, of a Velocette gear please. |

| Graham Williams 11 | 16/08/2019 11:47:29 |

| 80 forum posts 41 photos | It is 20 degree pa, tried to include a photo but the method eludes me I'm afraid. Understand that 32dp is about 0.794 mod but if I work out the outside diameter on module it equates to 2.961" ((94x0.8) x 0.03937) but the automatic advance retard unit with tufnol gear i'm looking to replace is 3.055" and have been told previously that the diameter should be 3.063" which is I assume what Velo used way back. Couldn't find a 32DP cutter at a price I could afford but did find a 0.8mod cutter on ebay hence the question Edited By Graham Williams 11 on 16/08/2019 12:10:09 |

| JasonB | 16/08/2019 11:59:17 |

25215 forum posts 3105 photos 1 articles | I cut a couple last week the other way round eg to 0.8MOD sizes using 32DP cutters as I had the cutters

Are RDG's prices too high?

|

| Graham Williams 11 | 16/08/2019 12:07:32 |

| 80 forum posts 41 photos | No Jason, I find RDG an ok supplier but when I last checked they only did 14 1/2 degree pa cutters |

| Roderick Jenkins | 16/08/2019 15:55:30 |

2376 forum posts 800 photos | Graham, Sets of gear cutters only produce the true tooth profile for the number of teeth at the bottom end of the range stamped on the cutter but the system works fine. Bearing this in mind I can see no problem in your original plan, I'm sure the gear will mesh adequately. Since Jason is showing off, here's a pair of 0.8 MOD gears I cut for my Farm Boy last week. I bought my set of cutters from CTC. Cheers, Rod |

| Chris Evans 6 | 16/08/2019 16:04:12 |

2156 forum posts | Graham, please let us know how you get on. I have a bit of a collection of knackered tufnol gears..... |

| John MC | 16/08/2019 16:32:20 |

464 forum posts 72 photos | Posted by Graham Williams 11 on 16/08/2019 11:31:37:

What's the consensus on the use of a 0.8mod cutter using 32dp specs i.e. depth of tooth and outside diameter on a magneto drive gear for a Velo MAC, alloy engine, 92 teeth? Cheers Graham W Sorry to say no good at all, assuming you are forming rather than generating the gear. These gears need hobbing (generating the tooth form), although not transmitting any great load the formed tooth will probably be quite noisy, defeating Veloce's use of helicals to keep thing quiet. Why not buy a gear (£59 from the VOC) intended for the manual advance/retard and modify that? John |

| Roderick Jenkins | 16/08/2019 17:01:47 |

2376 forum posts 800 photos | Whoa... If we really are talking about helical gears then that's a whole different problem.. Helical gears can be cut using form cutters but it takes a bit of fiddling around to produce the necessary lead on the blank. Rod |

| Michael Gilligan | 16/08/2019 17:02:38 |

23121 forum posts 1360 photos | Posted by John MC on 16/08/2019 16:32:20:

Posted by Graham Williams 11 on 16/08/2019 11:31:37:

What's the consensus on the use of a 0.8mod cutter using 32dp specs i.e. depth of tooth and outside diameter on a magneto drive gear for a Velo MAC, alloy engine, 92 teeth? Cheers Graham W Sorry to say no good at all, assuming you are forming rather than generating the gear. These gears need hobbing (generating the tooth form), although not transmitting any great load the formed tooth will probably be quite noisy, defeating Veloce's use of helicals to keep thing quiet. Why not buy a gear (£59 from the VOC) intended for the manual advance/retard and modify that? John . Arghh ... Nobody mentioned helical gears 'til now ... did they ? MichaelG. . Oops ... 'ere we go : http://velobanjogent.blogspot.com/2008/10/349-cc-mac-velocettethe-so-called-alloy.html Edited By Michael Gilligan on 16/08/2019 17:09:06 |

| Michael Gilligan | 16/08/2019 17:08:15 |

23121 forum posts 1360 photos | Posted by Graham Williams 11 on 16/08/2019 11:47:29:

... tried to include a photo but the method eludes me I'm afraid. . https://www.model-engineer.co.uk/forums/postings.asp?th=103028&p=1 |

| Graham Williams 11 | 16/08/2019 17:19:26 |

| 80 forum posts 41 photos | John. There are quite a few suppliers, Tank Classics, Grove as well as VOC (I'm a member) and they all go for around the same price + P&P and did exactly that for a friend's bike but I just wanted to make my own using my vert. mill, going the manual mag route and made a simple jig to set the mag shaft taper., taper is 11mm to 13mm over 11.5 mm length.EN3 sourced from local machine shop for the price of a pint and disregarding the electric used much cheaper to make and kept me entertained, the cutter cost me £12 delivered from China and trying it today it cuts well. CRT ? in Sheffield want around £90 for the correct cutter and Tap & Die want £120 so more than I wanted to lay out. Bit disconcerting that you suggest there will be a noise problem making it this way, had whines in the past from the timing gears on a Viper but the adjustment on the intermediate gear put that right (thank you Mr. Dodkin). Will have to give it some thought as to completing number 2 methinks. Wonder what a small gear hobber will cost to make........... where is this going? Rod. How do you put photo into the post, it's not working for me. Made a gear today but the 'not' deliberate mistake gave me RH helix, 92 teeth cut, what fun, must pay more attention.. LoL |

| JasonB | 16/08/2019 18:20:59 |

25215 forum posts 3105 photos 1 articles | Graham As you now have some photos in an album all you do while posting a reply is click the little black camera icon at teh top of the box you are typing in and select the image from there. Michael's link earlier also gives details |

| Graham Williams 11 | 16/08/2019 18:22:00 |

| 80 forum posts 41 photos | |

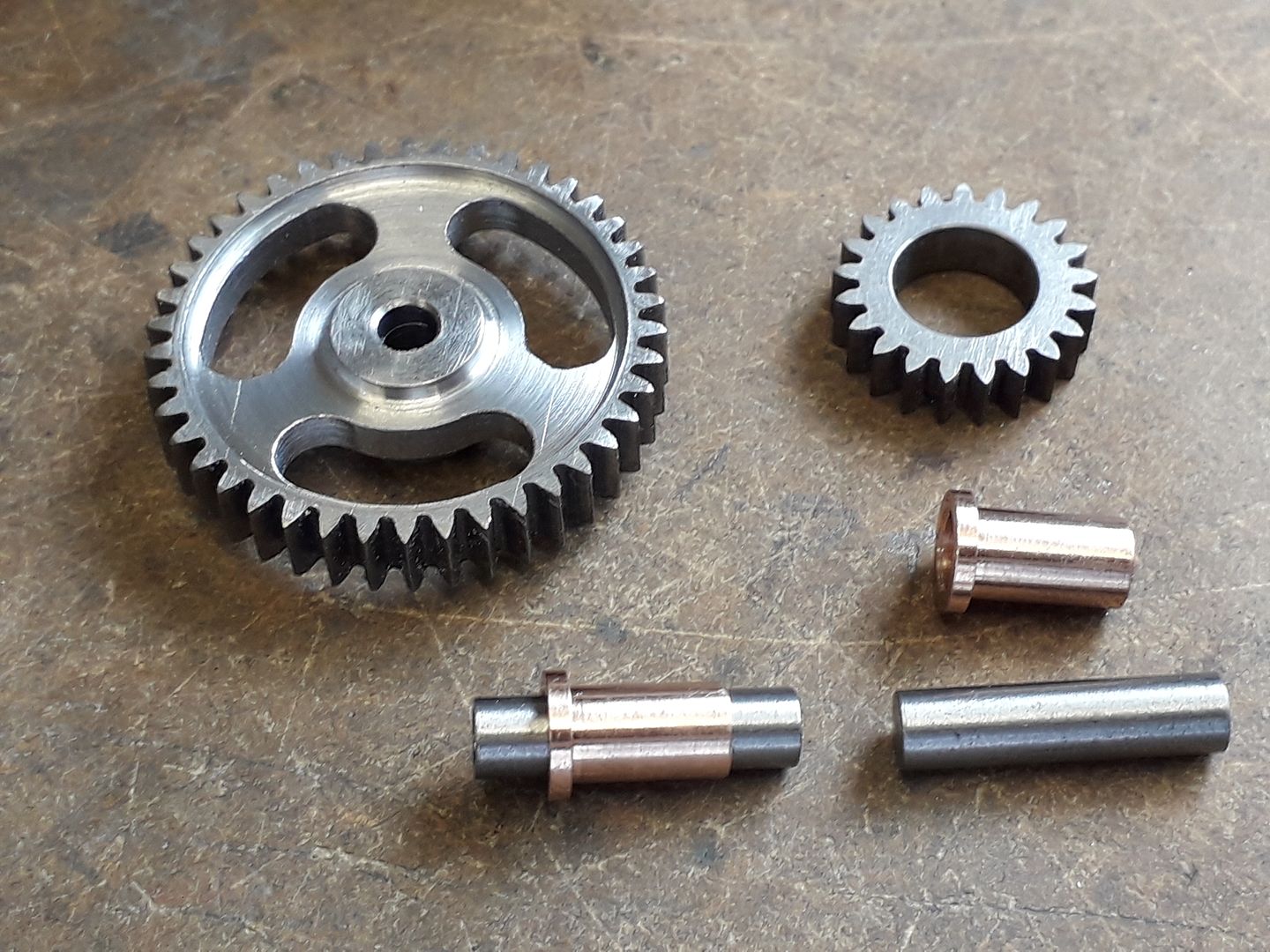

| Graham Williams 11 | 16/08/2019 18:23:07 |

| 80 forum posts 41 photos | Thanks for the 'how to' so put a couple of photos of the one I made (incorrectly) today. |

| Graham Williams 11 | 16/08/2019 18:24:51 |

| 80 forum posts 41 photos | Thanks Jason, just need to find out how to put a comment up with the pictures................. need the grandson here LoL |

| Roderick Jenkins | 16/08/2019 23:27:08 |

2376 forum posts 800 photos | Graham, That's a good looking gear and, frankly, I wonder if for a gear with that many teeth and such a shallow angle one would really be able to tell the difference between one that has been cut straight across at an angle and one that has been cut in the correct helical fashion. Rod |

| Graham Williams 11 | 17/08/2019 06:19:38 |

| 80 forum posts 41 photos | Rod. In the Velobanjoagent link posted above you can see what Velocette's thinking was at the time, i.e they believed it gave quieter running but that with more modern gear manufacturing methods the same result could be achieved. However having said that they didn't change the gears on any of the singles at all as far as I'm aware once having made the change to helical teeth from the early straight teeth gears. Very quirky bikes are Velocettes, I won't get into the 'famous' clutch as many Velo fans will well know LoL |

| not done it yet | 17/08/2019 09:51:26 |

| 7517 forum posts 20 photos | My thoughts. You are replacing a tufnol gear with a steel gear? Tufnol might either ‘deform’, ‘run in’ or simply get chewed away in short time if the incorrect tooth form is adopted. At least the magneto drive is beyond the cam and is, of course, only half engine revs. I think I would be making it in aluminium if it has to be metal - more chance of it ‘conforming’ rather than wearing the cam gear as well. I’m surprised that the gears are 20 degree pressure angle, but maybe they were introduced long before I thought... I might be concerned when considering RJ’s comment re straight cut and helical, but I don’t know enough about gears to compromise too much - at least for fast rotating ones. One of our experts (Andrew) is unfortunately ‘on holiday’ from the forum. Might be worth sending him a personal message? Is the engine ‘safe’ if the cam drive were to fail? Just a thought... ... Likely to go noisy before failure, if it were to wear, I suppose. |

| Graham Williams 11 | 17/08/2019 12:11:45 |

| 80 forum posts 41 photos | Don't know when exactly that Velocette made the change to helical cut gears, it may well have been pre WW2 when the MAC was introduced, I believed the early ones (early 30's) had straight cut gears so that might give a reason for 20 degree pa. Commercially available mag gears are steel as far as I know no-one has offered Alum gears and think the wear factor s a consideration, Tufnol doesn't seem to wear that badly, the gear usually strips mostly by the kick back when the starting drill is slightly off, that's my experience when Velos were my daily transport anyway, prompting change to manual a/r with steel gear which was the standard for bikes so equipped from the factory, perhaps anodising might toughen them up, just a thought. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in