ME vertical boiler

| geoff walker 1 | 15/01/2018 18:23:35 |

| 521 forum posts 217 photos | Hi All Model engineer issue 4576 has part one of a project by Martin Gearing on a vertical boiler for beginners. Can anyone tell me if this is continued in issue 4577? I've searched online for information but am unable to find anything. Called in W.H. Smith at the weekend but they had sold out. I will order a copy online but only if part two of the boiler project is featured. cheers geoff |

| Frances IoM | 15/01/2018 18:32:42 |

| 1395 forum posts 30 photos | not in my copy - guess ME has reverted to its old habit of continuations every other issue |

| JasonB | 15/01/2018 18:36:43 |

25215 forum posts 3105 photos 1 articles | Part 2 is in 4578

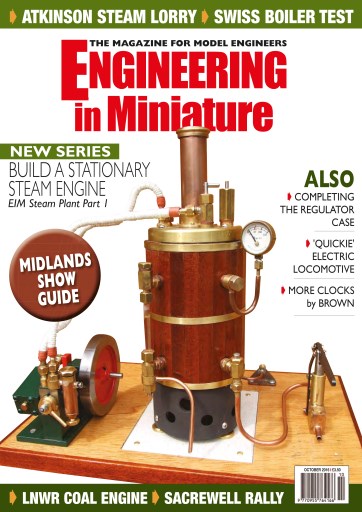

Anyone know if this is going to be a duplicate of the EiM vertical steam plant?

Edited By JasonB on 15/01/2018 19:57:25 |

| geoff walker 1 | 15/01/2018 18:40:53 |

| 521 forum posts 217 photos | Thanks Frances, Jason. 4578 is out on Friday, so not long to wait. geoff

|

| Robin King | 15/01/2018 19:28:28 |

| 137 forum posts 1 photos | Perhaps I've missed something but I have to admit to being a bit perplexed by this series. Why would a beginner be encouraged to equip themselevs with a milling machine (not necessarily a small investment) in order to build a simple boiler? I can't recall this ever being proposed in the past sixty odd year that I've been reading M.E. and I've never needed one for that purpose. If you want to encourage beginners wouldn't it be better to show them how to achieve results at least cost, to start with?

|

| geoff walker 1 | 15/01/2018 19:43:20 |

| 521 forum posts 217 photos | Perhaps I've missed something but I have to admit to being a bit perplexed by this series. Why would a beginner be encouraged to equip themselevs with a milling machine (not necessarily a small investment) in order to build a simple boiler? I have to say that the use of milling machine puzzled me. That's not a criticism just an observation and I look forward to part 2 in issue 4578. As I have no milling machine I will have to improvise. I assume the use of a rotary table is for setting out the hole positions in the top flange plate? In due course all will be revealed. Geoff |

| geoff walker 1 | 19/01/2018 18:45:29 |

| 521 forum posts 217 photos | Anyone know if this is going to be a duplicate of the EiM vertical steam plant?

Looks very much like the same boiler Jason. Have you got the eim issue numbers? I may need them I have just bought today M.E. 4578 today eagerly anticipating part 2 of the M.E. boiler article. I can't believe what I'm reading, preparing blanks and datum locations, understanding working drawings, axis conventions and locations and checking a machine head and vice alignment. Absolutely nothing to make and it looks very much like part 3 will have nothing to make as well. In part 3, quote, we will look at the bill of materials you will need. Three parts, well two at least and nothing to make? Do me a favour!!! Rant over |

| Clive Foster | 19/01/2018 19:19:02 |

| 3630 forum posts 128 photos | geoff I think you have completely misunderstood the focus and reasoning behind this series. As I read it the articles are more a "school / apprentice type project" than "amateur builds a simple boiler project". The author appears to be using the boiler build as a vehicle for explaining many of the skills and concepts a neophyte needs to get to grips with if they are to make successful working models from drawings with minimal frustration along the way. A boiler is an interesting choice for this sort of thing. Usually small tools, work holding and marking out equipment tend to be the subjects. A good example of the conventional approach being the SouthBend book no 39B "Machine Shop Course for Apprentices". Given the modern trend towards CNC, the greater emphasis on CAD and general tendency towards more complex models using a boiler may well be a better approach here and now. I suspect much, if not all, of the generally applicable learning value could be got armchair wise by careful reading and re-reading. When it comes to marking out, dimensioning reading drawings et al boiler components provide a very clear subject. Probably only the specific constructional skills and techniques need the actual practice of making a real boiler. The old style way is much more geared to learning by doing with considerable scope for just winging it. Nowt wrong with just winging it. I learned near enough everything that way. But overall its a slow way of going about things. Plenty of complaints about the old school way books too. "I don't need to make these tools. If I want them I'll buy them for thruppence three farthin' (plus postage) on line. I need useful things to get going on my 7 1/2" gauge Big Boy project." But then it was ever thus. Think of the guys who bought a cheap Machine Mart welder expecting to fix their rusty MoT failed car just-like-that. Clive. Edited By Clive Foster on 19/01/2018 19:19:26 Edited By Clive Foster on 19/01/2018 19:20:13 Edited By Clive Foster on 19/01/2018 19:20:49 |

| JasonB | 19/01/2018 19:31:36 |

25215 forum posts 3105 photos 1 articles | Sorry Geoff but I don't usually take EiM, does look like it could be quite a while until steams up I think I read somewhere that the pump will be detailed and made first and then presumably the boiler.

As has been said, it looks like everything on there could be made on the lathe and possibly not even a vertical slide needed so with the series Lathes & More in ME and Neil's in MEW that would have covered the theory so this could have got straight down to putting things into practice.

Maybe Martin could comment on the order and length of the vertical Boiler Articles? |

| John Purdy | 19/01/2018 20:53:17 |

431 forum posts 252 photos | Geoff The series in EIM is by the same author and started in Oct.'16 and is still going. It started with a similar preamble then detailed the making of the engine, which finished in Nov. '17. The latest serial (part 11 Dec. '17) details the displacement lubricator. He hasn't got to the boiler yet. John Purdy |

| John Purdy | 19/01/2018 21:35:47 |

431 forum posts 252 photos | Geoff Further to my last, to quote from part one of the EIM series " The project is divided into six parts #1, Engine, #2 Displacement Lubricator, #3, Hand Pump, #4, Boiler, #5, Boiler fittings, and #6, Gas Burner." John |

| geoff walker 1 | 20/01/2018 10:29:22 |

| 521 forum posts 217 photos | Hi Gents, Thank you a for your replies. Clive as you say I may have misunderstood the reasoning on this project although the introduction states, quote, " A project aimed at beginners wishing to develop there skills OR those requiring a requiring a robust vertical boiler for the running or testing of small steam engines." I suppose it all depends how you interpret that introduction. I saw it as for complete beginners and also amateurs who just want a boiler. I'm just an amateur who wants a boiler so I see myself in the latter category. My gut feeling is that the remaining articles will be heavily biased towards the complete beginner with a lot of instructional preamble which is not for me. I'll keep an eye on the progress, I'm in no hurry. I'll just cherry pick the parts of value to me. thanks again geoff

|

| Steamcoalnz | 18/03/2018 18:33:29 |

| 32 forum posts |

Hello. The I have received the first part of this series but ask if anyone who has received the following copies can list the materials required for the drawn tubes and the firetubes, number, lengths, dia and gauge. It would be good to assemble these parts before receiving the boiler construction issues later. Thank you.

|

| JasonB | 18/03/2018 19:00:25 |

25215 forum posts 3105 photos 1 articles | As welll as the following tubes you wil need a piece of 16swg C106 copper sheet 4" x 12" |

| Steamcoalnz | 19/03/2018 09:30:44 |

| 32 forum posts |

Guess if I order and have the material parts shipped by sea to New Zealand the construction issues might be to hand.

No really ..just being sarcastic chaps and thanks for the list Jason. I am sure amongst friends we could scrap together the materials and give it a go. Maybe I should start on the boat first.I quite like stationary boilers and the other half seems at ease now with the 8" dia one sitting in the living room. I'll squeek a few more in when she is away. Thanks. |

| fizzy | 19/03/2018 09:38:46 |

1860 forum posts 121 photos | What is the intended heat source - curious as to why there are so many holes around the base - cant be coal and the holes would be very counter productive to gas?

|

| JasonB | 19/03/2018 10:07:11 |

25215 forum posts 3105 photos 1 articles | Gas As you say any air needed for combustion would be drawn in as part of the burner in most cases so not sure what the holes are for. |

| Neil Wyatt | 19/03/2018 11:41:59 |

19226 forum posts 749 photos 86 articles | LOL! I put holes in my boiler stand, I even went as far as making a punch from silver steel just for the job. Never occurred to me that they might not be doing anything... I suppose they make it less exciting to light than putting a lighter to the top of the chimney Neil |

| geoff walker 1 | 19/03/2018 13:41:53 |

| 521 forum posts 217 photos | I find the materials list interesting. I know very little about boiler design and cannot visualise the internal layout of this boiler from the list. Can anyone explain to me what the arrangement is LIKELY to be inside the 3" diameter shell. I've been looking at the 3" Tubal Cain vertical boiler in M.E. feb/april 1977 and it would appear from the materials list that the internal structure of the current M.E. Boiler is completely different. The Tubal Cain design has conical firebox with 3 crossing and angled fire tubes. Issue numbers 3555 to 3558 over a period of 6 weeks cover the whole design with detailed and informative diagrams and building notes all aimed at the beginner to boiler making making their first boiler. geoff |

| JasonB | 19/03/2018 15:59:12 |

25215 forum posts 3105 photos 1 articles | I think it will have a flanged plate at the bottom and a second flanged plate about 1" down from the top. one ring of 5/16" tubes running vertically and an outer ring of 7/16" tubes running vertically. Heat will pass up through the firetubes into the space at the top and then out up the chimney. Don't think this is a centre flue boiler like the TC one. Edited By JasonB on 19/03/2018 16:15:05 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in