Member postings for Michael Horner

Here is a list of all the postings Michael Horner has made in our forums. Click on a thread name to jump to the thread.

| Thread: Mini lathe |

| 19/01/2019 20:43:12 |

Hi Jeff I suspect they are for the threading dial, you should have three, one may be already fitted under the dial marked 1 to 12. They have different number of splines depending what pitch thread you are cutting. Cheers Michael. |

| Thread: Mini lathe speed and tailstock question |

| 14/10/2018 19:31:05 |

Hi Jack The white dot looks off white and the sensor bracket doesn't look like it is at 90 degrees to the dot. My RPM display is an extra and uses a reflective opto and if things aren't just right can give wacky readings. Cheers Michael |

| Thread: Bench grinder improvement mod. |

| 08/10/2018 07:36:51 |

For this, I added larger flanges, using adhesive, to the grinders spindles and turned these true with the grinder running whilst fixed to the lathes bed. The advantage of this, together with the accurately made adaptors, is that the wheels can be interchanged and only need truing up the first time they are run. The above is from Harold Halls website of how he dealt with the issue. Cheers Michael |

| Thread: Automatic Centre Punches |

| 23/09/2018 08:01:13 |

Hi Terry I have. Wish I had seen Michael G's info. Went all round the houses trying to get it to work. To me shaft 17 canted over is the key. I put a ball bearing on the left hand side, the right hand side wants to be flat and so does 23. As the spring is compressed the 2 cones come together and make shaft 17 drop down the hole, this is the hammer action. On my punches the wear made it drop down the hole to soon. HTH Cheers Michael. |

| Thread: Yet another parting tool question... |

| 27/08/2018 12:08:11 |

Posted by JasonB on 27/08/2018 10:13:31:

I don't understand why the first type is advertised as a parting tool only, but the second as a parting and grooving tool. Can anyone enlighten me about the functional differences of these two designs of bit holder? Robin Michael, Neil and Andrew,that holder that Michael shows is not what the OP shows. The tip are different and have better side cutting geometry and can therefor cut sideways which is why the MGEH is also described as suitable for profiling, even more so with the round nose inserts.

The QA-GTN that the OP posted just uses a standard GTN parting insert but due to the holder being stiffer (sideways) will be better able to cut sideways but at the expense of not parting as deep as the blade type will allow. Edited By JasonB on 27/08/2018 10:16:47

Hi Jason Must have misread the post. Robin went on to mention the second type which I presumed was the profiling one. Cheers Michael. |

| 27/08/2018 08:51:56 |

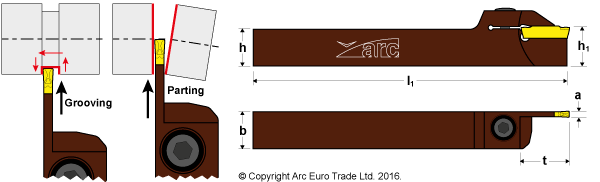

ARC MGEH one piece clamp type Parting & Grooving Tool Holders Suitable for external grooving, parting, turning, relieving, profiling. Each tool holder includes:

Can you see the left arrow above the grooving arrow? This tool can take small cuts side to side. Cheers Michael. |

| Thread: What did you do Today 2018 |

| 15/08/2018 23:30:09 |

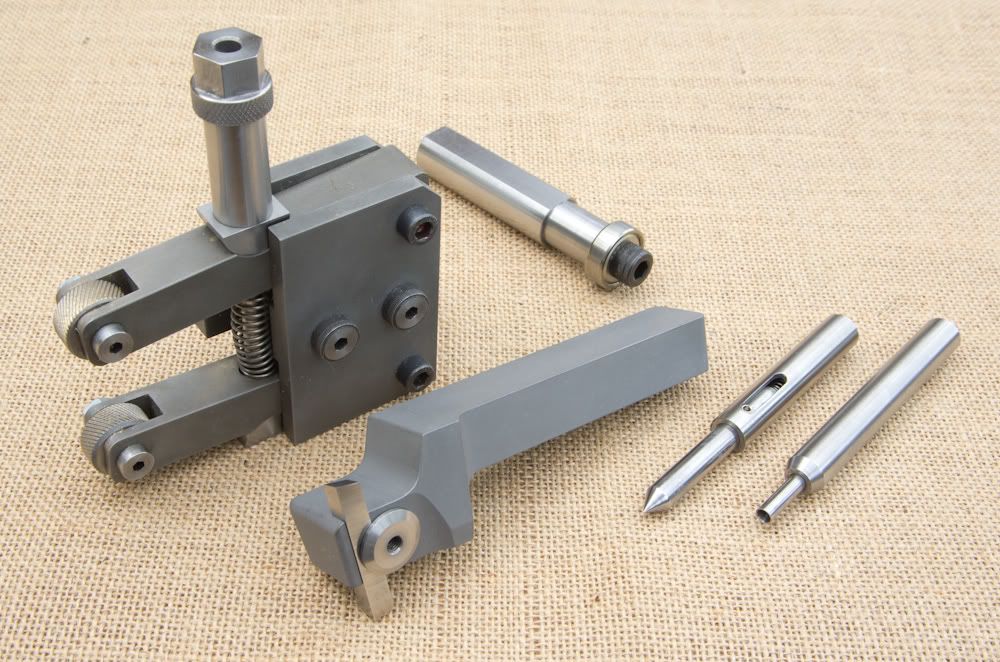

Made a straight knurler along the lines of Vics' design. Slipped up with the lower pivot and have now corrected the oversight. Need to finish of the top. Maybe put a big knurled knob on it! |

| Thread: Knurling Tools |

| 30/07/2018 19:44:56 |

Posted by Vic on 09/07/2016 19:20:18:

I bought a knurling tool and had the same problem, very wobbly arms. I made my own in the end which works fine.

Hi Vic Came across this whilst researching knurling tools, it looks good. Are the side pieces about 5mm thick? Going to cheat and use 2 push knurls with 0.5" shafts should be just enough metal in them to drill the holes for the pivots and the clamp. Cheers Michael.

|

| Thread: Shingle bells |

| 18/07/2018 06:59:20 |

Why do people always want to ban things? I am grateful for the information. I have a blood disorder which will eventually affect my immune system. It has already pushed my holiday insurance up 300%! Wife got it down from 700%. I am the kind of guy who doesn't go to the doctor, so would have been too late for the vaccine to be effective! So thank you. Cheers Michael

|

| Thread: Oilite Bearing with through oil hole |

| 15/07/2018 11:44:13 |

"Cutting tools must be sharp. For this reason tungsten

carbide tooling is highly recommended since they

hold a cutting edge much longer".

Selected quote from Hoppers post. Does this mean carbide tooling can be sharp? Or have I misread excerpt?

Cheers Michael.

|

| Thread: What could possibly go wrong!? |

| 13/04/2018 14:38:03 |

Geoff Surely time to beef up your security! Cheers Michael

|

| Thread: Spotting Drill or Centre drill. |

| 09/02/2018 15:15:29 |

Spotting drill . Usually I'm repairing a shaft by drilling and tapping. Go in deep enough so when I thread it doesn't pull the surface up. 1 less operation! Cheers Michael. |

| Thread: What did you do Today 2018 |

| 28/01/2018 21:08:40 |

Cheers Michael. |

| Thread: A DIY Spot welder finally done - aka R2D2... |

| 21/01/2018 08:46:26 |

Posted by Joseph Noci 1 on 26/03/2017 16:42:24:

I made a video, but the motion from one button to another and to the tool tip, and the thread start and end - makes me ill !!!!!

Joe I do so wish some of the other posters on here will take heed of Joe's words.

" To say that a lot of the members here can make such marvelous models and jobs the fact that the tripod was invented at least 400 years ago seems to escape them" . Hi Joe If the above is what you are referring to it was JS RIP. I just wish I had 10% of your energy! Spend far too long in the arm chair! Cheers Michael. |

| Thread: What did you do Today 2018 |

| 01/01/2018 07:43:36 |

Cheers Michael. |

| Thread: cl 300 lathe problems |

| 31/12/2017 16:31:22 |

Hi Ernie This the Gadget Builder link for removing excess play in the hand wheel **LINK**. Apron Handwheel Backlash Not done the mod myself yet, only had the lathe 15 years! Do make sure the screw in the handle is tight. I have had that come loose and you get lots of free play! Enjoy Cheers Michael. |

| Thread: In praise of angle grinders |

| 10/10/2017 07:03:32 |

Posted by Mike E. on 05/10/2017 10:44:45:

Chop saw attachments for 4" angle grinders have been available for awhile now. I bought one from Lidl a few years ago, and set it up to make my own French Drains for leaching rain water from behind my retaining walls. If I recall correctly, the price was under ten pounds. Thanks for this Mike. Looks like an idea to try to drain my soggy garden. Cheers Michael. |

| Thread: UK supplier of 1mm T section parting blades |

| 24/09/2017 20:03:38 |

Posted by Nick_G on 24/09/2017 14:08:18:

. The ones I have purchased from Eccentric engineering are of excellent quality but have a flat top to them without the groove Graham is requesting.

"T" Type Parting Off BladesThe premium quality blades we stock are sourced from the largest manufacturer of repetition lathe tooling in the USA. The blades have a slight hollow grind along the top (bottom) cutting edge which assists in curling the chip for easier ejection from the cut. The industry standard height for 1/2" "T" type parting blades is actually close to 12mm.

This is what EE's advert says Cheers Michael. |

| 24/09/2017 13:55:34 |

Hi Graham Have a look at the Exccentric Engineering add on this page near the bottom. He sells them and has a UK distributer. Cheers Michael.

|

| Thread: What Did You Do Today (2017) |

| 14/08/2017 00:18:30 |

Posted by Bazyle on 13/08/2017 19:57:52:

Is that a battery drill providing the power lift?

Hi Bazyle Yes, seems to work ok. Bike's not very heavy. The thread is M16 on 2mm pitch, time will tell how well it wears. Michael. |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Hi Robin

Hi Robin

I repurposed a clamp or is that dual purposed a clamp into a Bultaco clutch spring compressor.

I repurposed a clamp or is that dual purposed a clamp into a Bultaco clutch spring compressor.

high and will not fit the FoR inverted parting tool holder.

high and will not fit the FoR inverted parting tool holder.

Register

Register Log-in

Log-in