Workshop Electrics

| Vic | 28/08/2014 10:26:44 |

| 3453 forum posts 23 photos | I'd like to put the ring main (and lighting circuit) in the workshop inside 20mm PVC conduit for safety (and neatness!) and I know it should be done with single 2.5mm cables. The problem is I'll only need about 25M max of each of the three cables and I've only seen them sold in 100M reels. I don't fancy having 225M of "spare" cable sitting on the shelf so is there any technical reason I can't use T&E for the job? Actually if I include the lighting circuit cable as well it's going to be an awful lot of conduit cable sitting around doing nothing after the jobs done. I should add I'd prefer to use conduit cable so if anyone knows where I can get 25M reels without paying silly money let me know! |

| Mike Poole | 28/08/2014 11:01:44 |

3676 forum posts 82 photos | Mechanical protection of the cables in a workshop should be a consideration, the conduit solution covers this nicely with metalclad switches and outlets. Conduit cable should be multistranded for flexability and ease of wiring. If you are proposing putting T&E in conduit you will struggle as it is solid cores and most uncooperative. You maybe be able to buy cable by the metre but other than for very short lengths it soon becomes economical to buy a drum. Maybe an electrical contractor would have some short drums he would sell you for a reasonable price. You could sell on what you have leftover even if you take a hit at least it won't be in the way doing nothing. Mike Edited By Michael Poole on 28/08/2014 11:04:53 |

| Bob Brown 1 | 28/08/2014 11:12:00 |

1022 forum posts 127 photos | As far as I'm aware using twin and earth is not a problem for running the cable around a workshop in PVC conduit and is what I intend to get my tame sparky to do although I will do first fix. I would be inclined to use 25mm conduit at it gets tight when trying to feed two 2.5 T&E cables down 20mm conduit. Do not forget that in the UK the rules regarding electrics have change and wiring the wiring you purpose will either need to be done by a qualified electrician or building control will need to be notified and the installation checked on completion and a certificate issued. see **LINK** Bob

|

| Vic | 28/08/2014 11:14:04 |

| 3453 forum posts 23 photos | Thanks Mike, T&E is most "uncooperative" as you put it at the best of times, I can't stand the stuff. As it's only one run in the conduit it's doable I think but I take your point. I'll see if I can source some single cable, might save my knuckles and my temper! |

| David Jupp | 28/08/2014 11:14:17 |

| 978 forum posts 26 photos | I used T&E in my garage - with the vertical drops from eaves height inside conduit.. You can't squeeze as many wires in conduit using T&E, and I wouldn't like to try to route it round corners. |

| Brian Wood | 28/08/2014 11:18:49 |

| 2742 forum posts 39 photos | Hello Vic, Twin and Earth will sit quite happily inside rectangular PVC trunking, the kind with the clip on lid. I think you would then be able to buy what you need, including the trunking, from a wholesaler who at most might insist on selling you 50 metre reels. I don't think technically you need metal clad outlets either, trunking can be fitted tight up to the usual boxes and as with conduit, it is very visible while still looking neat and business like. I would hang on to surplus cable from 50 metre rolls, it will find a home somewhere. Regards Brian |

| Clive Foster | 28/08/2014 11:24:44 |

| 3630 forum posts 128 photos | I just pushed ordinary household cable in. Actually the amount of cable I used, 4 normally rated 13 amp 12 socket rings and 4 motor power rated 4 socket rings installed, single cable would have been justified. Made the big mistake of listening to idiot electrician who insisted on putting main cable runs and lighting feeds in the shop loft household style with conduit drops and horizontal runs for each ring. If I'd had any sense I'd have insisted on min-trunking just under the ceiling which would have saved mega hassle later. Never quite bad enough to tear it all out and start over. Eventually fired sparky for wanting to do something that would have been 'kin dangerous under certain fault conditions. Why so many rings. I use old style metal clad 6 way switched distribution boards as my wall sockets for ordinary 13 amp supplies. Puts plenty of sockets in reach for hand held tooling, bench lights, computer etc in the office section yadda yadda purposes. I hate long trailing leads. But two boards add up to 12 sockets which is the maximum I consider acceptable on any ring. Hence several rings and a proper Consumer unit on the incomer. Machine motor power comes through separate with appropriately rated RCD and MCBs. Clive |

| Bob Brown 1 | 28/08/2014 12:28:44 |

1022 forum posts 127 photos | I am really surprised that people seem to be advocating a DIY approach to electrics, under UK current regulations only minor work is allow without informing Building control or using a qualified sparky who is registered. A new ring main is notifiable work and if you do opt for the DIY route building control need to be informed before the work starts and tested on completion, the latter may be problematical as most sparks do not like or want to sign off work they have not done. Bob |

| Nigel McBurney 1 | 28/08/2014 14:13:47 |

1101 forum posts 3 photos | if its only a garden shed workshop one sneaky way round the wiring regs is to use good condition old stock red /black wiring and keep your mouth shut and you can always claim that it was done prior to the new regs, |

| Johnboy25 | 28/08/2014 15:30:42 |

260 forum posts 3 photos | Vic... If you go down the conduit and single cables route, the spec for conduit cables in single colours is 6491X for normal PVC insulation or 6491B for low smoke requirements. For a ring main for an area of up to 100 square metres (if you're lucky enough to have a large workshop!) it can be wired in 2.5 sq. mm with a 32 Amp MCB overload protection device. You can have as many 13 Amp socket outlets you want as diversity considerations assume that you won't be able to draw more than 32 Amp load at anyone time! I much favour separate supplies to motor circuits but there's no reason why you couldn't drop off a spur to the lathe or mill. Again you're not likely to to drawing much current at anyone time unless you have multiple heaters and a kettle! It mainly common sense really to know what you can an can't run at anyone time. If you're going to be using an arc welder I certainly would recommend a separate supply outlet in correctly rated cable & MCB to suit. One more point, if your using inverter drives be aware that RCD's don't like the inrush current which can trip them out. This can be overcome by separate circuit to the inverter not being fed via the RCD. As mention end previously - it should be installed or a least certified & tested by a competent electrician. It bugs me that as I'm a qualified electrical engineer I still need to have my work inspected to meet with the Part P building regs! I hope all of this may be helpful. John |

| Vic | 28/08/2014 16:56:31 |

| 3453 forum posts 23 photos | Yes John, very helpful thank you. And the rest of you guys, I appreciate it. I used to work with a qualified electrician and although I let him fit a nice new HD consumer unit in our old house I didn't much like a lot of the work he did for our employer. Most of it was just untidy due to not using the right tools or rushing to get the job done. I only plan to do the first fix and then get a sparks to finish off. I've seen an awful lot of really untidy work carried out by "qualified" tradesmen over the years, including electricians and plumbers. I'd like this job done to a decent standard even if I'm only running the conduit and fitting the boxes.

|

| duncan webster | 28/08/2014 18:20:20 |

| 5307 forum posts 83 photos | I did mine by running cable tray right round the workshop at high level (out of harm's way) and having droppers in 20 mm conduit to the sockets. No problem getting 2 T&E down the droppers, they are dead straight and not that long. I put a separate 15A socket on a spur for the welder. |

| the artfull-codger | 07/09/2014 21:12:33 |

304 forum posts 28 photos | I suspect a large number of [us] have wired our own workshops to a safe standard, so If I wire my workshop up to the 17th edition perfectly & test it out with no faults, who is going to prosecute me for doing it right because I'm not ''part p approved''?? Insurance?? well if it's done correctly it won't be the cause any problem, selling your house?? just get a periodic test from the national inspection council,[or now get a part p electrician to do a test [about £150 for a certificate] It doesn't matter how large your electrical firm is you only need 1 employee to be part p, the rest don't need to be as long as he signs it off. |

| Bob Brown 1 | 07/09/2014 22:01:21 |

1022 forum posts 127 photos | I think the thing to remember in England it is now a criminal offence not to have electrical work certified. Gone are the days that will do, OK some of us are quite capable of wiring a house and I include myself in that but I'm not prepared to risk the costs that could be incurred if I did it or made a mistake better the mistake fall in someone else's lap so I can sue them if they make a mistake. On the other side of that coin is the numpty that wires his workshop with 1mm cable just because he had reel that was given him in 1961. I do get a bit miffed at times, building control would not accept roof calculations from me as I do not have the correct accreditation so £300 later job done. Even to the point with the guy who came to quote on some scaffolding would not take my word or the drawings for the dimensions of the work he had to get his tape measure out. Bob |

| the artfull-codger | 08/09/2014 20:25:22 |

304 forum posts 28 photos | Bob, point taken, especially about ''the numpty'' doing a bit of diy [I hate that phrase] electrical work, & doesn't have a clue, but I'll stick with my own wiring as I know it's up to standard [especially when you get good guidance from your electrician mate. It reminds me of a couple of yrs ago when gas fitters came round to work to fit valves to the gas supply pipes to our boilers for regular testing purposes, both qualified &''gas safe'' or corgi registered as it was then, armed with said valves tap,tap wrench & drillbit well after struggling it was obvious they hadn't a clue, so I had a look & the drill was the wrong size for the tap so after loaning them the right size I showed them how to use a tap wrench & tap & all went well after that. [corgi registered?? hmmnn] Graham. |

| Phil Whitley | 08/09/2014 20:28:39 |

1533 forum posts 147 photos | I think the thing to remember in England it is now a criminal offence not to have electrical work certified.. No Bob , it isn't. There is much work that can be done that is outside part P, and I am afraid to tell you that quite a number of those "part P certified electricians" are unemployed window cleaners who have been on a FIVE WEEK!!! course. I am a fully qualified electrician, five year apprenticeship, 3 years tech college, City& Guilds National Diploma in electrical engineering, plus 40 years in the industry, and yet I cannot now wire a house without having my work checked by another and certified....or I can pay some money to join one of the "clubs" (£600-£800) and then pay them a yearly fee( £300) for nothing so that I can keep wiring houses (part P ONLY applies to domestic premises) Part P has already been watered down after much protest from the electrical industry, and most of the restrictions on kitchen work have gone, although bathrooms are still a restricted area. Having said that the requirements are not particularly onerous, you can get many online guides to part P requirements, and you can "do it yourself" If there was already a ring main in your workshop, even if it only had two sockets, you can extend it. If there is already a lighting circuit, you can add to it. There is no requirement to bring existing installations up to the latest standards, as long as they complied with the regs in force when they were installed and are in good condition they are fine. Domestic wiring is not rocket science, it is the very BOTTOM of the electrical skills level, and the overall effect of part P has been to make electrical installations in domestic premises less safe, not more safe as was supposed to the claimed reason for their introduction. For your personal protection I would use an RCD to protect the whole installation, and make sure that your machines are earthed , but I would still have rewireable fuses. The reason for this is simple, and it seems to have occurred to no one in the IET that RCD's and MCB's are not fail safe. In other words, if they become faulty in use, THEY DO NOT SWITCH OFF! Be careful out there people! I think I would proceed as follows, if there is already a feed to the shed and a consumer unit in place, and you are confident you can do it safely, do it yourself and say nowt. If you need to obtain a feed from your existing consumer unit and run a new sub main, I would look for a friendly sparks who will do the connecting up for you and certify what you have done (they can do this now, another part of "P" that has been dumped) You could get your local electrical building inspector to come round, they inspect, but do not test or sign off work, you would have to do that yourself as a "competent person", and the new testing regime requires expensive equipment, and the knowledge to use it., and of course there is a fee! any advice needed< let me know. Phil |

| Bazyle | 09/09/2014 21:20:24 |

6956 forum posts 229 photos | I know the original queston was about thin conduit but wouldn't a girdle of 4x1 conduit right round be better to enable sockets to be fitted direct to it and added easily as required? lots of room for wires then, Thinking in advance of my new workshop next year. Anyone know if it is it ok to put 3 phase and 1 phase in the same run when it is that big? |

| Oompa Lumpa | 09/09/2014 21:41:53 |

| 888 forum posts 36 photos | There is a fairly simple - and reasonably priced - dodge around most of this certification malarkey. Just take out a maintenance contract with British Gas. They will be straight 'round doing a "survey" and not only will they certify your electrics, they will check the gas too and certify that. As Paul says, if the installation is already there, there is nothing stopping you "repairing" it, say by replacing the old wire with new. I too have my C&G part III Electrical Engineering (somewhere) and yet I need a window cleaner sans ladder to "certify" it. graham. |

| Nick_G | 09/09/2014 23:08:06 |

1808 forum posts 744 photos | Posted by Bazyle on 09/09/2014 21:20:24:

Anyone know if it is it ok to put 3 phase and 1 phase in the same run when it is that big?

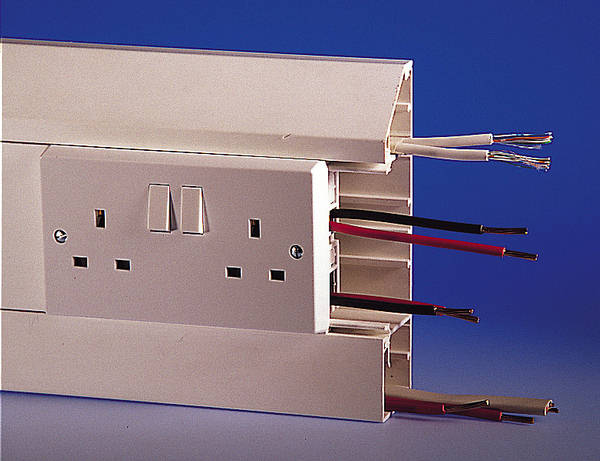

Yes that's fine providing the insulation value of both is high enough. Which it will be unless you start running door bell and telephone / data cables in the same compartment. If you wish to be uber posh in your workshop and attach sockets directly to the wiring runs as you hint at, do a search for 'Dado trunking'. They even do versions with several segmented compartments. Nice stuff but not the cheapest option. It would however make alterations and additions at a later stage a piece of cake.! Nick e.g. The lid just clips on and off and you can add outlet boxes where and when you need them. The above image is just a sample type. There are many different forms, sizes and profiles available.

Edited By Nick_G on 09/09/2014 23:17:20 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in