Machine vice recommendations?

| Scottmk1 | 16/07/2013 18:39:24 |

| 25 forum posts | Hi folks, I am after a vice to go with my old Axminster ZX 25 Milling machine. Ideally, I am after something with a decent jaw opening, over 100mm, without costing the earth (obviously) and that has a decent grip. Budget is probably about £100, this is going to be a gift from someone so cant dictate the price too much if at all.So far I have seen the Axminster Accu-Lock 5" here **LINK** And the Precision Tool Vice 100mm wide from Arc Euro Trade as seen here **LINK** Which would you guys go for out of these two? If you have any other suggestions please let me know.

Scott |

| JasonB | 16/07/2013 18:50:23 |

25215 forum posts 3105 photos 1 articles | Vertex K4 works for me, try Chronos for them. Take it off the swivel to get a bit more head room as you don't need the angle much Edited By JasonB on 16/07/2013 18:52:34 |

| Scottmk1 | 16/07/2013 18:54:03 |

| 25 forum posts | Thanks for the reply Jason, the K4 looks decent but seems the jaw opening is very restricted at 62mm? Do you find that to be an obstacle? |

| NJH | 16/07/2013 19:10:11 |

2314 forum posts 139 photos | Hi Scott I have the same as Jason and have not found it a problem - however my interest is mostly in making smaller things and I've not found the need to take the vice off its swivel base - the swivelling facility has been useful on occasion. What I also find useful is a clamping set so that I can work directly from the table and this has always catered for those items too large for the vice. Cheers Norman Edited By NJH on 16/07/2013 19:10:51 |

| Scottmk1 | 16/07/2013 19:13:00 |

| 25 forum posts | Hi Norman, at the minute all I have is a clamping set, and sometimes it would be plain handy to have a fairly versatile vice, especially for those jobs that dont require highly accurate results. My main worry with the cheaper vices is jaw lift, that is really what I'm aiming to avoid.

Scott |

| JasonB | 16/07/2013 19:18:50 |

25215 forum posts 3105 photos 1 articles | Like Norman I find if it won't fit in the vice then a couple of angle plates and clamp set go a long way, I have done 2" traction engines, large hit & miss & steam engines and not missed the larger capacity often. The K4 also seems about the right size for my X3 which has about the same size table as your axi and can fit ontop of a 6" rotary table if needed |

| mechman48 | 16/07/2013 21:17:39 |

2947 forum posts 468 photos | Hi Scott I have the 4" radial milling vice from Arc Euro & find it fits most of my needs at the moment, & is slightly cheaper to boot. If I were to go for another vice my preference would be the 4" precision vice type 2 from Arc Euro, but at the moment the vice I have is quite adequate. George |

| Scottmk1 | 16/07/2013 21:21:20 |

| 25 forum posts | Hi George, does the 4" precision type 2 vice have lugs on the body to bolt it to the machine table? |

| mechman48 | 16/07/2013 21:33:49 |

2947 forum posts 468 photos | The type 2 has machined slots on the sides to clamp to use clamping dogs on your table, apart from the two smallest, the type 1 has holes for the same method, have a look at your link for Arc Euro. G |

| _Paul_ | 17/07/2013 09:21:05 |

543 forum posts 31 photos | Scott,

I have both vices, the precision vices from Arc are The Axminster "Kurt" clone is an "eastern" manufactured item of suspect quality see this thread for some detail **LINK** Regards Paul

|

| Steambuff | 17/07/2013 09:31:52 |

544 forum posts 8 photos | Hi, I use the Precision Vice from Arc, and have had no problems Dave |

| Scottmk1 | 17/07/2013 09:34:24 |

| 25 forum posts | Hi Dave, thanks for your input. It looks like the one from Arc is going to be my choice due to its wide opening ability. |

| _Paul_ | 17/07/2013 09:34:38 |

543 forum posts 31 photos |

Posted by Scottmk1 on 16/07/2013 21:21:20:

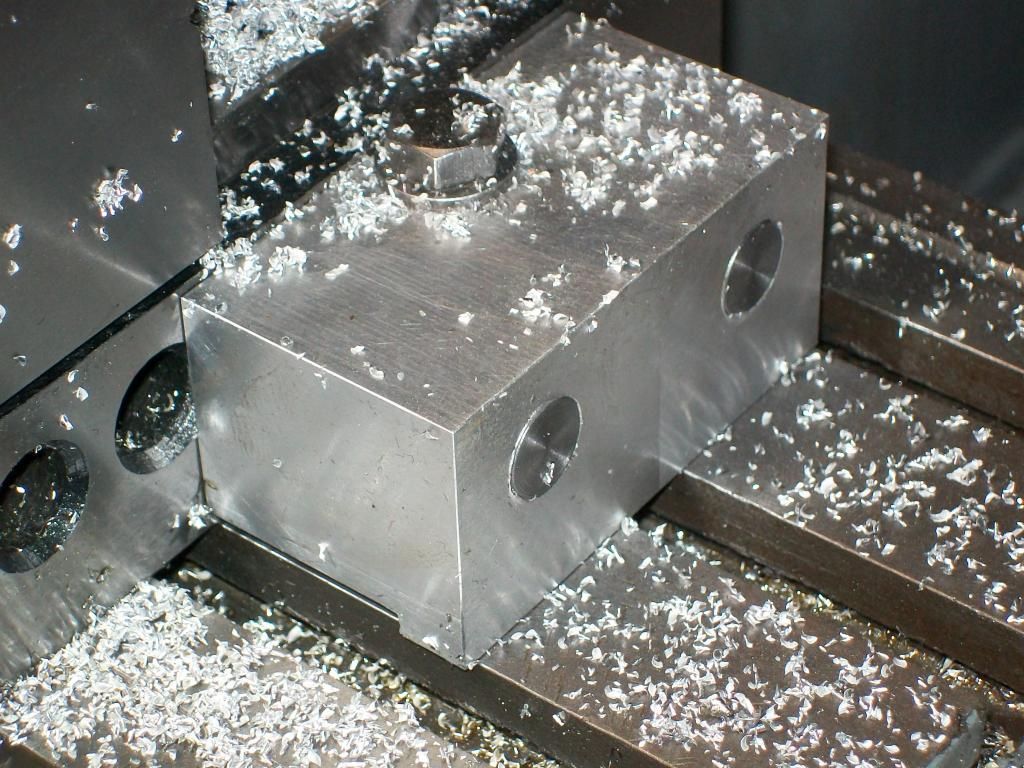

Hi George, does the 4" precision type 2 vice have lugs on the body to bolt it to the machine table? I have the type with holes in the side but made some of these to mount it on my milling machines and shapers, here is an Arc 100mm precision vice mounted on my small Taylor Mill (18 x 6" table)

|

| Scottmk1 | 17/07/2013 09:55:14 |

| 25 forum posts | Hi Paul, thats a neat solution, are the blocks made from aluminium billet? |

| _Paul_ | 17/07/2013 10:23:49 |

543 forum posts 31 photos | Scott, a chunk of aluminium from the scrapbox of unknown type, the pins are recovered printer shafting pressed in with an interference fit of around 0.0005" ish I didn't even case harden them and they have worked fine for years. No plans just machined to what looked like reaonably sturdy dimensions, something worthy of note though the hole centre spacing in the vice wasn't as accurate as you might expect with on average 0.020" difference. Regards Paul

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in