slow speed attachment for Unimat SL

| David Costello | 18/05/2011 18:58:40 |

| 79 forum posts 9 photos | Where can i buy this attachment DB1280 in the Uk?

Dave |

| JasonB | 18/05/2011 19:10:35 |

25215 forum posts 3105 photos 1 articles | Probably have to resort to US e-bay and a seller that will do deal to UK then get hit for import duty & VAT

For the same sort of money you could get a vari speed motor, not sure what teh slowest speed is but worth asking here

Jason Edited By JasonB on 18/05/2011 19:17:22 |

| David Costello | 18/05/2011 19:31:02 |

| 79 forum posts 9 photos | Thanks Jason,but not at that price

.yes ebay has a US seller but again a bit steep.I need to turn some 50mm od steel which the book tells me 350rpm,my slowest is 900rpm,so will try that first. .yes ebay has a US seller but again a bit steep.I need to turn some 50mm od steel which the book tells me 350rpm,my slowest is 900rpm,so will try that first.Dave. |

| JasonB | 18/05/2011 19:44:22 |

25215 forum posts 3105 photos 1 articles | Didn't realise the slowest speed was that high, thought it would be about the same as my old Unimat 3.

You may just get away with very fine cuts, hope you have not got too much metal to remove.

J Edited By JasonB on 18/05/2011 19:45:48 |

| Martin W | 18/05/2011 19:50:38 |

| 940 forum posts 30 photos | David

Any merit in trying an electronic speed controller similar to that used in mains operated drills etc. There will be a certain loss of power but it may do at a pinch with very light cuts.

Cheers

Martin

Try Maplin they may have a unit/kit. |

| David Costello | 18/05/2011 20:02:27 |

| 79 forum posts 9 photos | Thanks Martin

Yes could be an option,will have a think on that.

Dave |

| Roderick Jenkins | 18/05/2011 21:08:02 |

2376 forum posts 800 photos | David, Your book speed of 350rpm for 2" (50mm) gives a surface speed of about of about 180 ft/min. Your lowest speed of 900rpm gives a surface speed of about 470fpm. The tables in Machinery's Handbook (admittedly as a guide for production) give a speed of 150fpm for HSS on plain carbon steel but for coated carbide the recommended speeds are between 400 and 800 fpm. You should be able to get away with a sharp coated QC tip, though the swarf could well be coming off blue and smoking, depending on the feed. I appreciate that the your motor power is limited but I reckon it is worth a try. Rod |

| dcosta | 18/05/2011 21:22:02 |

| 496 forum posts 207 photos | Hello David! I have with me a number of accessories (never used) for small Emco machines. My first lathe (1982) was an Emco Unimat 3 and at that time I bought two small boxes with accessories from a closing shop. Though some of the accessories were usable in my Unimat 3, most of them were for an older Unimat (I think Unimat SL) I could use some of them in Unimat 3 (e.g.: the 3 jaw chuck, the 4 jaw chuck, the faceplate, a drill chuck, the fixed steady, etc.). Among the items I have, there are two DB202-21 (Motor bracket). Comparing it with the one originally proposed for speed reduction, it looks to me it will be a non dificult operation to add support for another pair of wheels...

Follows the URL for the Double speed reduction picture. http://www.model-engineer.co.uk/albums/member_photo.asp?a=14817&p=264699 and for the Motor bracket http://www.model-engineer.co.uk/albums/member_photo.asp?a=14817&p=264700

Good luck with Your endeavour Dias Costa Edited By Dias Costa on 18/05/2011 21:41:54 |

| ady | 18/05/2011 22:45:13 |

| 612 forum posts 50 photos | The original motor power is extremely limited on the wee unimat sl, belting is a big big issue as well. The motor usually needs resting every 10 minutes or so to prevent overheating. (going back a bitty now) I ended up removing the original motor and getting a 1450rpm off ebay, then getting some of that 4mm red belting and fixing the lot to a baseboard. The difference was like night and day for lathe work, she actually made hot swarf! The original motor was still needed for the drilling configuration though. They are pretty amazing little units and highly versatile but quite limited for serious work because they really do lack stiffness, especially when that little weeny carriage is hanging out over thin air for a side cut, too much flexing. If the ways/bars had been 16mm instead of 12mm this would have made a huge difference. Watchmakers use units like Cowells lathes, which have a 'proper' bed and even have backgear. If you do continue down the slow speed attachment route invest in some decent belting to transmit as much power as possible to the spindle for a decent cut. Without decent belting you can't do much work on a unimat sl. |

| Ian S C | 19/05/2011 03:24:50 |

7468 forum posts 230 photos | You could use an old 1/4 hp 1450rpm motor, I don't know about your side of the world, but here you would pay about $NZ20 for a good one, and with the right pullies, and a counter shaft, you can have what ever speed you want. You could hang the motor under the bench top,and bring the belt up to the counter shaft on top. The heat fused belting is a good way to go, I use it on my Super Adept, 5 mm I think. Ian S C |

| Richard Parsons | 19/05/2011 07:13:05 |

645 forum posts 33 photos | David, I bought my Unimat SL in the mid-60’s. I still use it (with its original motor). They are nice little machines if used within their limitations. One of the strength (and weaknesses) is the motor. The original motor is what I know of is a ‘universal motor’. It has brush gear and can run on either AC or DC. This being the case it can run on ‘pulsed DC’. A pulsed DC speed controller provides a 230 volt DC pulse and controls the motor speed by the length and frequency of the pulses. I bought my speed controller kit about the same time as the Unimat. It is still working and is used to control the Russian spin drier motor which drives my tool grinder. I have had a look see on Google and have found this at http://www.quasarelectronics.com/smart-kit/1074-ac-motor-speed-controller-230vac.htm (usual disclaimer). But there are loads of circuits to choose from. Your motor is 100 watt I would go for the 350 watt unit. (it is more complex than mine but seems to have a speed range of 5% to 95% of full speed output). These units can have problems at low speed where high torque is required. I had a mill which at low speed caused ‘surging’ when taking anything but the lightest of cuts. Regards Dick Edited By Richard Parsons on 19/05/2011 07:15:32 |

| Ian S C | 19/05/2011 13:36:57 |

7468 forum posts 230 photos | To get low speed its always better to keep the revs up and use mechanical speed reduction, electric motors do not like low speeds, the fan for cooling becomes innafective. A bigger motor would be a help. Ian S C |

| CJW | 19/05/2011 14:26:54 |

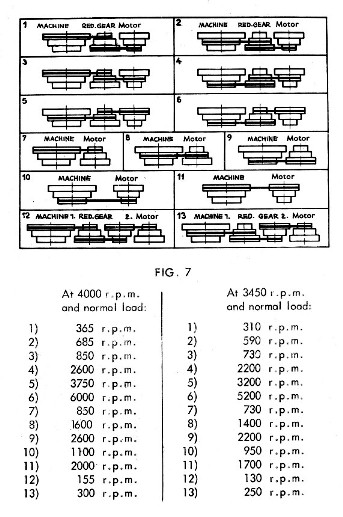

| 10 forum posts | David, I thought the lowest speed on a Unimat SL with the standard UK motor and speed reduction was 365 rpm. Do you have a different setup? Regards, Chris |

| David Clark 1 | 19/05/2011 15:31:12 |

3357 forum posts 112 photos 10 articles | Hi There

There was an attachment available that added another pulley to the Unimat SL to give a lower speed.

regards David

|

| CJW | 19/05/2011 15:36:16 |

| 10 forum posts | Hi, I found this which has details of the speeds with standard pulley and motor combinations. All the best, Chris |

| JasonB | 19/05/2011 17:07:05 |

25215 forum posts 3105 photos 1 articles | David the attachment you mention is the DB 1280 that Davy is asking about.

Lathes.co.uk give speeds of 900 to a rather hair raising 7200!! on a MK 1A machine.

Jason |

| Richard Parsons | 19/05/2011 17:15:03 |

645 forum posts 33 photos | Ian SC From memory The Unimat SL motor has a vestigial fan. When I used it as a work centre I had a little battery driven fan which allowed me to run for more than the 10 minutes described in the book. Dick |

| David Costello | 25/05/2011 20:44:13 |

| 79 forum posts 9 photos | Update to my original post.

50mm steel turns ok at 900rpm,no problem as envisaged.

Dave.  |

| JasonB | 25/05/2011 20:47:19 |

25215 forum posts 3105 photos 1 articles | That will be the plough wheels made then  |

| David Costello | 25/05/2011 21:02:20 |

| 79 forum posts 9 photos | A start on one Jason

Dave |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in