Rubbish Milling Finish in Aluminium

| Avon | 28/03/2021 17:52:42 |

| 71 forum posts 26 photos | The phot below shows the poor finish I'm achieving when milling a piece of aluminium. Its not just cosmetic either, it feels rough to the touch. The setup I've tried is as follows: Milling Machine: Centec 2A fitted with a Clarkson Autolock. No discernible movement in the cutter or the work. Cutters: various 5/8" 2 and 3 flute cutters, which may not be as sharp as they could be as they're my fathers old ones and I don't have the means (knowledge) to sharpen them. Cutter RPM: I've tried 400rpm and 600rpm with a slow feed rate, cutting depth of about 15-20 thou, I suspect the problem is blunt cutters, but want to be sure before buying new ones. If I have to buy new ones what would be recommended - I'd like to keep the clarkson autolock, but don't know whether the thread would be the same on new cutters. Any advice gratefully received. Peter |

| SillyOldDuffer | 28/03/2021 18:10:46 |

| 10668 forum posts 2415 photos | Do you know what Aluminium alloy it is? Looks pretty manky on the outside, which may not signify, but it may not be a machinable grade. Also a possible combination problem: blunt cutters, poor material, and no cutting fluid. First thing to try is wetting the cutter and rod with paraffin or WD40 with a brush. I'd also try faster rpm and feed rate. Also, holding round sticky out rod in a vice like the photo is highly likely to vibrate and move. Try inverting the rod so the vice grips the flat you've already cut: the flat is much less likely to move. (I'd hold a round object in that configuration in a V-Block) Few of us can sharpen milling cutters, so no shame in replacing them. Buy a new one to compare known good with what you have before assuming they're all past it, but if they belonged to your dad... Can't answer the Clarkson question, I'm sure someone else will! Dave

|

| Journeyman | 28/03/2021 18:11:38 |

1257 forum posts 264 photos | Well the cutter certainly looks old and well used in the photo. The white/silver line at the cutting edge would tend to suggest bluntness, there should be no reflection from the edge. The material may also be suspect as it looks home cast and may be soft and sticky. Most purchased alloys have had some form of heat treatment which improves machinability. New cutter threads will still fit you Clarkson chuck. John |

| JasonB | 28/03/2021 18:13:36 |

25215 forum posts 3105 photos 1 articles | Looks like an odd bit of cast Aluminium so could be just about anything thrown into the mix and if not heat treated can be less than ideal to machine, you could try eliminating the unknown buy practicing on an known alloy such as 6082. Any metal won't like dull or blunt cutters particularly non ferrous so investing in some new ones if changing alloy does not cure the problem will help. using the now outdated Clarkson which requires threaded cutters will limit your choice these days but HSS 2 flue would be your best bet for aluminium. |

| Avon | 28/03/2021 18:16:54 |

| 71 forum posts 26 photos | HI Dave, Its a scrap bit of casting which is why it looks manky. Foundry & Fabrication at Totnes have cast the baseplate (aluminium) for my hot air engine and its Flyweheel (ali-bronze). Its the same material as they use for casting gearboxes for cranes and having seen the quality of their finished product this is a very machinable alloy. (I collected them yesterday and their Production Manager was kind enough to show me the foundry and workshop - its such a pleasure to talk with a knowledgeable and enthusiastic professional). I confess I didn't detect any vibration, but I'll try holding it differently - I've nothing to loose and lots and lots to learn. You make a good point about buying a new and comparing - I thought they would be expensive, but just seen one for about £6.00 which is not extravagant. Thanks for your help. |

| JasonB | 28/03/2021 18:35:23 |

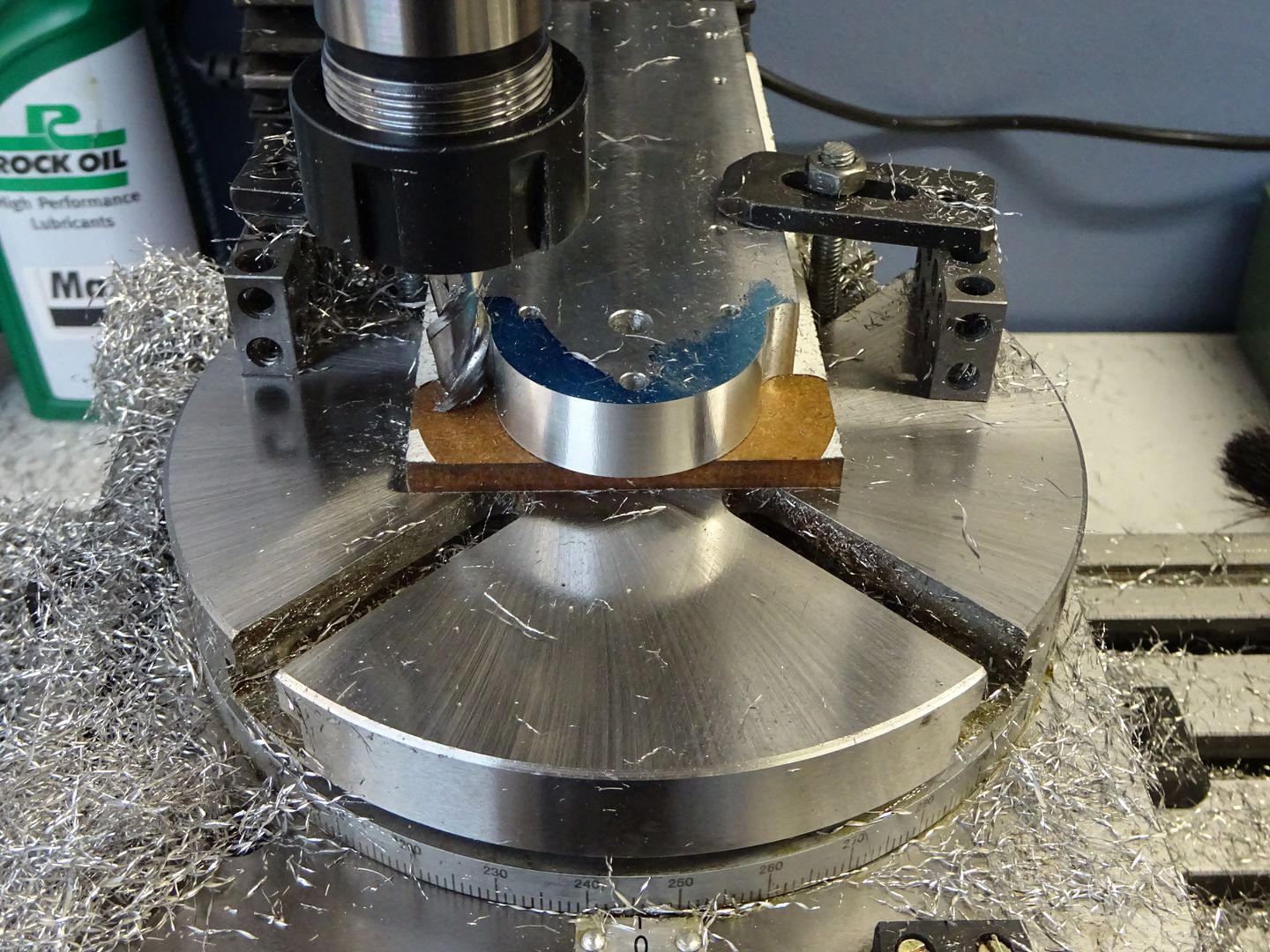

25215 forum posts 3105 photos 1 articles | This is the sort of finish you can get with reasonably priced import cutters, not the swarf is the full length of the cut not crumbs, unfortunately the ARC ali specific ones don't come with screwed shank. Also up your speed, 5/8 HSS can be run at about 2000rpm on Ali if the old Centec is upto it.

Edited By JasonB on 28/03/2021 18:41:11 |

| Avon | 28/03/2021 18:51:27 |

| 71 forum posts 26 photos | thats more like the finish I want to achieve! I don't think it can achieve 2000rpm, but it can do considerably more than I've been using - I looked for advice on figures in book I have. I'll give it a go. I'll also investigate getting new cutters - do you think they need to be threaded on could plain shank be held effectively just by the collett? |

| JasonB | 28/03/2021 18:54:51 |

25215 forum posts 3105 photos 1 articles | You need threaded ones in the Clarkson otherwise they will pull or wander out, that is why I said your choice will be limited. I think there are adaptors available or could even be made that would let you hold a "weladon" shank cutter (parallel with a flat for grub screw) of a smaller diameter which will open up the choices of available modern cutters. Hopefully a Clarkson user will show you what they are like. |

| Avon | 28/03/2021 19:09:38 |

| 71 forum posts 26 photos | Thanks Jason, I think I've seen the sort of thing on the Zoro website. I'm going to check with them tomorrow and hopefully get some new cutters before next weekend! (when I have time to enjoy my workshop). |

| old mart | 28/03/2021 19:41:32 |

| 4655 forum posts 304 photos | As already mentioned, that cutter looks blunt. New threaded shank cutters are easy to get hold of, but beware, metric sizes need metric collets and inch sizes need inch collets. Keep the new sharp ones exclusively for non ferrous metals. Edited By old mart on 28/03/2021 19:43:34 |

| Bob Rodgerson | 28/03/2021 19:47:31 |

| 612 forum posts 174 photos | Use coolant. It will make a big difference. I agree with other comments regarding the material itself, it looks pretty rough stuff.

|

| old mart | 28/03/2021 19:54:53 |

| 4655 forum posts 304 photos | If you have a MT2 fitting spindle, you could get an er25 collet holder which runs up to 16mm shank diameter. That would hold plain shank cutters as well as threaded shank ones. That would allow a much greater range of tooling. Selling the Clarkson would go most, if not all the way to financing an er system. |

| Stuart Bridger | 28/03/2021 20:30:05 |

| 566 forum posts 31 photos | Tracy Tools have a good range of threaded shank milling cutters |

| Brian Howett 2 | 28/03/2021 21:34:46 |

| 3 forum posts | Hello out there,

One piece of advice missing? When cutting aluminium the cutter should rotate "climb milling" - as shown in the more recent picture, the rotary table should be rotating Anti-clockwise, or as shown - cut completed. |

| Martin Kyte | 28/03/2021 22:11:56 |

3445 forum posts 62 photos | As above regarding sharp cutters. Also I would like to see that workpiece held in a more rigid fashion such as in the V of a Vee block and then held in the milling vice which gives three lines of contact with the workpiece. I don't recognise that milling vice either so cannot comment on the rigidity of that either. Cutters should cut not rub especially on aluminium. All that said, try it with some WD40 as a lubricant. regards Martin |

| Marcus Bowman | 28/03/2021 22:53:50 |

| 196 forum posts 2 photos | I use, and can thoroughly recommend, the ACCUPRO single-flute solid carbide 'router' cutters for aluminium, sold by MSC Industrial, BUT, they are breathtakingly expensive, and they have plain, metric, shanks. Wickedly sharp, so watch your fingers. I endorse the comments by Brian Howett 2, re: climb milling, which is essential for the best finish. Lubricant helps too, but can be neat cutting oil if the stink from WD40 or paraffin is too strong. The earlier comments about material grade and provenance are spot on. Run the cutter as fast as you can, and apply a decent feed rate, for a finish as shown by JasonB.

|

| duncan webster | 29/03/2021 00:32:23 |

| 5307 forum posts 83 photos | Top speed on centec vertical head is 1400 rpm, be warned it will get pretty warm if used at this speed for long runs. This is normal, but I usually chicken out and run a bit slower. |

| Bill Pudney | 29/03/2021 04:02:39 |

| 622 forum posts 24 photos | Cannot recommend the use of sharp cutters and some sort of fluid enough. My preference is for paraffin/kero on al alloy. WD40 is ok but leaves a waxy finish in the overspray areas. Fantastic for displacing water though!! Kero is probably cheaper as well. cheers Bill |

| JasonB | 29/03/2021 07:28:38 |

25215 forum posts 3105 photos 1 articles | I should say that finish I showed was done with conventional cutting not climb cutting. I would also suggest OP sticks with conventional until he gets a feel for the machine which could have a lot of backlash due to it's age. If you do want to climb then start by just using it for a final light finish pass. As I said at the start sticking with the Clarkson will limit your options for cutters as most suppliers just do basic 2 & 4 flute and 2-flute ball nose in screwed shank so you will be stuck with old technology and not be able to take advantage in advances in cutter design such as high helix, ctr cutting on all flute counts, material specific cutters, carbide and so on. |

| Martin Connelly | 29/03/2021 08:42:29 |

2549 forum posts 235 photos | Look at the size of Jason's chips and then at yours. Jason is feeding fast enough to be cutting, I think you are feeding too slowly and probably rubbing as much as you are cutting. Plus the other points regarding sharp tools and fluid to help. Find a speed and feed calculator on line and learn how fast to turn the handwheel for the suggested feeds. For a 3 flute cutter Ø5/8" with rpm at 600 you need to be feeding in at about 3.5" (90mm) per minute as a starting point then adjust feed up or down to suit the actual conditions. For a 2 flute cutter the feed would be 2/3 of that required for a 3 flute cutter, 60mm/minute. Rubbing produces heat that can cause the aluminium to become tacky and help it stick to the cutter which adds to poor finishes. Rigidity of workpiece holding is also very important. Looking at your picture the vice has serrated jaws. To me this makes it look like a drilling vice and not a milling vice which usually have smooth jaw faces. if it is not a milling vice that may also contribute to a poor finish. Martin C Edited By Martin Connelly on 29/03/2021 08:46:30 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in