Imperial V Metric

Boring sizes Imp V Metric

| Garry Smith 7 | 01/05/2020 22:16:20 |

| 26 forum posts 7 photos | I need to cut the steam ways in a steam chest on a cylinder. The sizes on the plans are Imperial but I am working in metric because all my tooling is metric. steam way size converts to 2.4 mm. I only have 2 mm and 3 mm drills and milling cutters. Which is the preferred option, to drill undersize or the next size up please. Edited By Garry Smith 7 on 01/05/2020 22:24:25 |

| Brian H | 01/05/2020 22:21:28 |

2312 forum posts 112 photos | Hello Garry, going up a size would be preferable but you need to ensure that a bigger drill is not going to break out somewhere it shouldn't. Having said that, a change from 2,7mm to 3.0mm should not make a lot of difference. Brian |

| Garry Smith 7 | 01/05/2020 22:25:15 |

| 26 forum posts 7 photos | Thank you Brian. Just noticed my size was wrong and should read 2.4 mm |

| Howard Lewis | 01/05/2020 22:37:59 |

| 7227 forum posts 21 photos | If you are worried that a 3 mm drill will ,break through aw all, buy a 2.4 mm or 2.5 mm drill (It will probably cut slightly over size anyway! A couple of drills must be cheaper than having to buy another casting! Howard Edited By Howard Lewis on 01/05/2020 22:38:26 |

| Hopper | 01/05/2020 23:05:46 |

7881 forum posts 397 photos | Buy a set of metric drills in .5mm increments should do you for the whole project and onwards. You can get sets in .1mm increments too which is handy for exact tapping sizes etc but more expensive. With your steam ports, if the 3mm is too big and going to break through, you could use 2mm in a pinch. It just means maximum performance might be reduced by the restricted steam flow. Which probably wont matter on a demonstration model not doing any actual work. |

| Pete. | 01/05/2020 23:19:29 |

910 forum posts 303 photos | Invest in some drill bits, they're not expensive, unless you're giving up engineering after this project, you're going to need them again at some point. |

| not done it yet | 01/05/2020 23:24:51 |

| 7517 forum posts 20 photos | 3/32” on the plans possibly means that a 1/8” drill was considered too big or, more, likely too risky. I just looked at the prices on the Arceurotrade site. Even with postage one is not talking a fortune! Even for several at a time for the standard length drills. As Hopper says, these drills will come in handy sooner or later. I pick my drills for pilot holes for instance. I would rather wear out a size I have several of than use one which is the last on my inventory. I buy one set and replace small drills, as they are almost considered as consumables - I don’t expect them to drill to size after a quick sharpening. |

| Pete. | 02/05/2020 00:47:00 |

910 forum posts 303 photos | I just had a quick look on ebay, you can buy a box of 50 presto Sheffield made bits from RDG tools, 1 to 5.9mm in 0.1mm increments, ground steam tempered £33.71 posted. I have quite a few of these presto drill bits, very good quality for little more than imports of dubious quality, and you get to support our industry in this country. |

| JasonB | 02/05/2020 07:00:11 |

25215 forum posts 3105 photos 1 articles | Depening on the metal available in the casting you could drill two 2.0mm holes side by side if there is a risk of a 3mm breaking through. What do you do about metric threading when you want a tapping drill for M3? Similar multi hole drillings

|

| not done it yet | 02/05/2020 07:14:50 |

| 7517 forum posts 20 photos | 2 x 2mm drillings will increase the cross sectional drilling area by almost 40%, so for the same area one only needs 2 x 1.7mm drillings (but there will be more pumping losses, I suppose...) |

| JasonB | 02/05/2020 07:26:27 |

25215 forum posts 3105 photos 1 articles | But he has not got a 1.7mm drill, he wanted options for the drills that he has. better than a 60% increase from using a single 3mm hole too. Plus as a beginner a 2mm drill will be a bit less likely to break in his GM casting when drilling at an angle than a 1.7mm

Edited By JasonB on 02/05/2020 07:38:36 |

| JasonB | 02/05/2020 07:37:09 |

25215 forum posts 3105 photos 1 articles | regarding milling the ports then use the 2mm cutter and just move it over to get the required 2.4mm width otherwise you start having to look into redesigning the valve cavity etc. |

| Garry Smith 7 | 02/05/2020 11:55:30 |

| 26 forum posts 7 photos | Thank you Gentlemen I didn’t make myself clear. I have a full set of drills offering the minor point sizes between the 2-3-4 mm etc. I was asking in relationship to Milling cutters. My preferred supplier is ARC Euro and they only sell milling cutters in the full mm sizes and not in sizes between the 2-3-4 mm etc. The steam way I want to cut are not holes in the steam chest but are ports ie the size I require is 2.4 mm wide x 9.25 mm long hence my question do I go up a size or down if I only have milling cutters to the whole mm sizes. |

| Les Jones 1 | 02/05/2020 12:07:18 |

| 2292 forum posts 159 photos | If I was cutting a 2.4 mm wide slot I would not use a 2.4 mm cutter even if I had one. I would use a 2mm cutter to cut a slot that would probably be a little over 2mm wide. I would then clean up the sides taking light cuts until the slot was 2.4 mm wide. Les. |

| Keith Long | 02/05/2020 12:07:51 |

| 883 forum posts 11 photos | Garry - down in size and then move the work sideways to open up to the required finished size, ie take 2 or 3 cuts to get where you want to be. You can't cut a 2.4 wide slot with a 3mm dia cutter. |

| SillyOldDuffer | 02/05/2020 12:52:15 |

| 10668 forum posts 2415 photos | Posted by Pete. on 02/05/2020 00:47:00:

... I have quite a few of these presto drill bits, very good quality for little more than imports of dubious quality, and you get to support our industry in this country. Are Presto Drills still made in the UK? These days it's not obvious who owns what or where anything is made, though China is often a good bet. Easterbrook and Allcard were sold to the James Wilkes Group in 1989, Suter plc in 1993, Ascot Holdings in 1995, Kennametal Hertel Ltd in 1997 and most recently Suncraft International in 2006. Suncraft 'is 'one of largest power-tool accessories manufacturers and exporters in China'... Beware of trusting brand-names without checking. They don't guarantee anything. As far as I know Presto products have always been well-made, but I don't think Presto equates to 'Made in England'. Dave

|

| Michael Gilligan | 02/05/2020 13:22:18 |

23121 forum posts 1360 photos | Good question, Dave ^^^ I was looking last night: Presto has a ‘presence’ in Penistone ... but the Heritage statement does seem a little woolly: https://www.presto-tools.co.uk/History MichaelG. . Edit: https://www.28dayslater.co.uk/threads/presto-tools-penistone-road-offices-sheffield-oct-09.43910/ Edited By Michael Gilligan on 02/05/2020 13:25:52 |

| Pete. | 02/05/2020 16:17:10 |

910 forum posts 303 photos | Posted by SillyOldDuffer on 02/05/2020 12:52:15:

Posted by Pete. on 02/05/2020 00:47:00:

... I have quite a few of these presto drill bits, very good quality for little more than imports of dubious quality, and you get to support our industry in this country. Are Presto Drills still made in the UK? These days it's not obvious who owns what or where anything is made, though China is often a good bet. Easterbrook and Allcard were sold to the James Wilkes Group in 1989, Suter plc in 1993, Ascot Holdings in 1995, Kennametal Hertel Ltd in 1997 and most recently Suncraft International in 2006. Suncraft 'is 'one of largest power-tool accessories manufacturers and exporters in China'... Beware of trusting brand-names without checking. They don't guarantee anything. As far as I know Presto products have always been well-made, but I don't think Presto equates to 'Made in England'. Dave

They advertise as being made in Sheffield, and they have Sheffield on each individual drill, so why wouldn't they be? Surely there are laws that determine you can't make blatant lies about this? But if you know otherwise, feel free to share |

| Nick Hulme | 06/05/2020 09:06:50 |

| 750 forum posts 37 photos | Posted by Garry Smith 7 on 02/05/2020 11:55:30:

Thank you Gentlemen I didn’t make myself clear. I have a full set of drills offering the minor point sizes between the 2-3-4 mm etc. I was asking in relationship to Milling cutters. My preferred supplier is ARC Euro and they only sell milling cutters in the full mm sizes and not in sizes between the 2-3-4 mm etc. The steam way I want to cut are not holes in the steam chest but are ports ie the size I require is 2.4 mm wide x 9.25 mm long hence my question do I go up a size or down if I only have milling cutters to the whole mm size If slots required "On Size" cutters we would all end up with an infinite number of cutters, you use the next size cutter down but you cut the slot or pocket to the correct size! |

| SillyOldDuffer | 06/05/2020 10:34:45 |

| 10668 forum posts 2415 photos | Posted by Pete. on 02/05/2020 16:17:10:

Posted by SillyOldDuffer on 02/05/2020 12:52:15:

Posted by Pete. on 02/05/2020 00:47:00:

... I have quite a few of these presto drill bits, very good quality for little more than imports of dubious quality, and you get to support our industry in this country. Are Presto Drills still made in the UK? These days it's not obvious who owns what or where anything is made, though China is often a good bet. Easterbrook and Allcard were sold to the James Wilkes Group in 1989, Suter plc in 1993, Ascot Holdings in 1995, Kennametal Hertel Ltd in 1997 and most recently Suncraft International in 2006. Suncraft 'is 'one of largest power-tool accessories manufacturers and exporters in China'... Beware of trusting brand-names without checking. They don't guarantee anything. As far as I know Presto products have always been well-made, but I don't think Presto equates to 'Made in England'. Dave

They advertise as being made in Sheffield, and they have Sheffield on each individual drill, so why wouldn't they be? Surely there are laws that determine you can't make blatant lies about this? But if you know otherwise, feel free to share I can't see anything on the Presto website claiming any of the current range of tools are made in Sheffield or the UK. 'Sheffield' can be put on packaging and tools because this arm of Suncraft is registered there, but I don't think it confirms anything is made in Sheffield. Certainly Presto tools were made in Sheffield for decades and the Heritage section of their website shows a modernish Guehring CNC machine, but when was the photo taken? It could be 20 years ago. Anyone been inside recently? The original Presto works is discussed here, depressing. At Companies House Presto's purpose of business is '46620 - Wholesale of machine tools'. Likewise, on Yell, Presto International UK are listed under 'Tool Suppliers and Services'. I'm afraid neither 'Wholesale of machine tools' or 'Tool Suppliers and Services' imply manufacturing. Does it matter? It's a shame the world has moved on. But if it became impossible for old Presto to operate profitably in Sheffield as a tool-maker, well done them for moving on to something that does provide jobs. As far as I know Presto tools are as good as they've ever been, wherever they're made. Dave |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

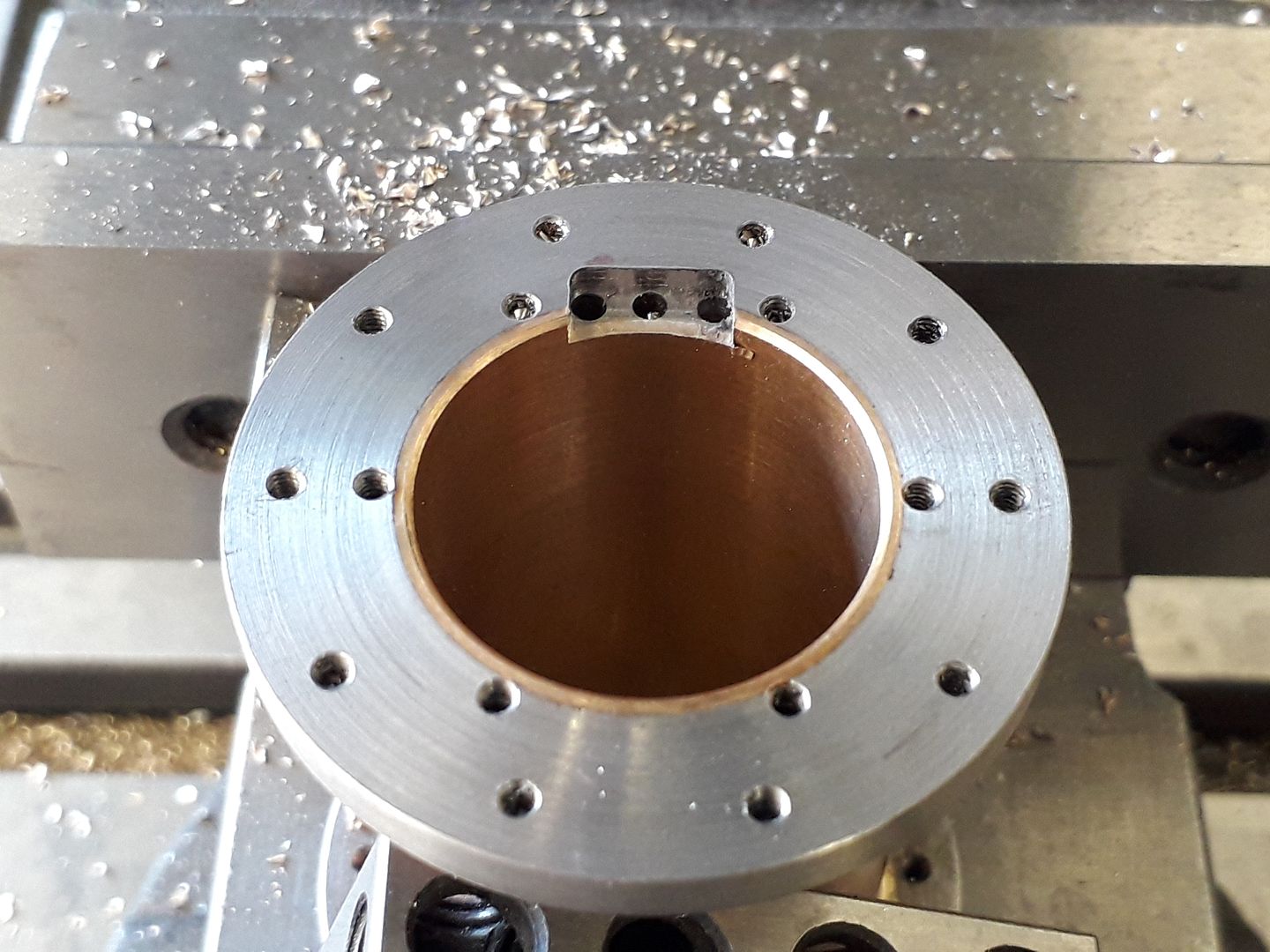

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in