Cutting long tapers using homemade top/compound slide

| Square Peg | 02/04/2020 14:52:34 |

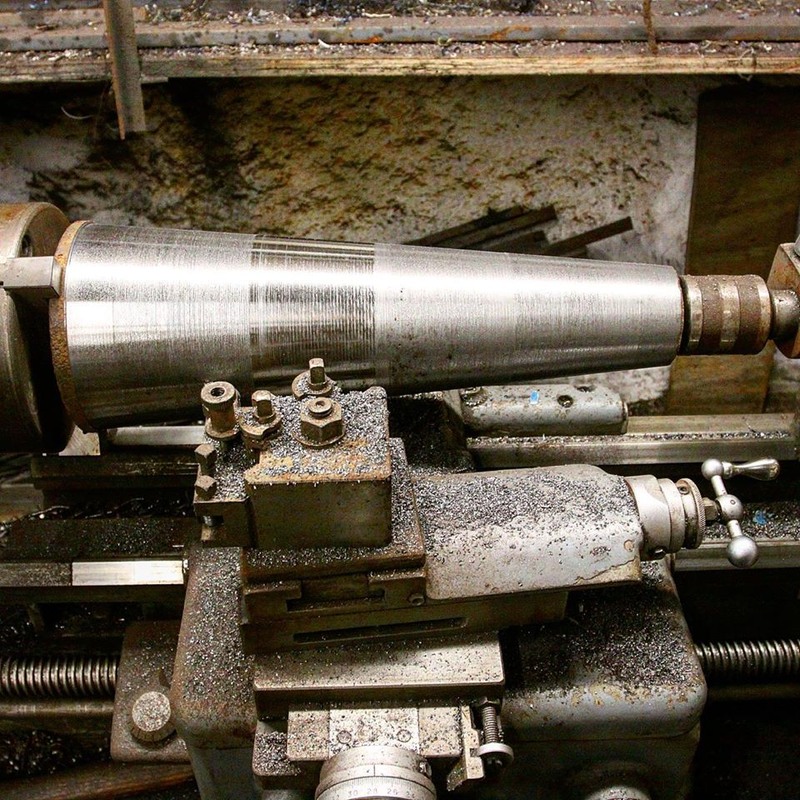

| 12 forum posts 2 photos | I often need to clean up tapered tools for jewelers and silversmiths and am limited by the 3" of travel on my topslide. I was wondering if making a longer top slide was a viable solution. I was thinking of powering the slide by using a small 3-phase motor and VFD. It seems simple enough but was wondering why nobody seems to use that method.

|

| Mick B1 | 02/04/2020 15:03:20 |

| 2444 forum posts 139 photos | From your last pic, you seem to me to be doing nicely wiv wotcha got. I'm guessing that the drawback to an extra long topslide is the potential mutual obstruction between topslide handwheel at full retraction and tailstock, unless you have a chatter-prone tool projection at the toolpost, or some special toolholding arrangment to counter that. |

| Alan Waddington 2 | 02/04/2020 15:31:36 |

| 537 forum posts 88 photos | Unless im misunderstanding the problem, why not just make a taper turning attachment ? |

| Square Peg | 02/04/2020 15:57:26 |

| 12 forum posts 2 photos | Posted by Alan Waddington 2 on 02/04/2020 15:31:36:

Unless im misunderstanding the problem, why not just make a taper turning attachment ?

Cuz I've got no idea how they work!

|

| old mart | 02/04/2020 15:59:53 |

| 4655 forum posts 304 photos | I think you are already using the best method that your lathe is capable of. A longer top slide will run into problems of lack of stiffness. That leaves the possibility of making a taper turning attachment, it might be feasible if you have milling facilities. For a taper turning attachment to work, you have to disconnect the cross slide leadscrew. The cross slide has an extension to the rear which slides along a track angled the required amount to be parallel to the taper. When you move the saddle, the tool follows the required taper. The link might help to visualise how they work. Ignore the tailstock types, they will not do what you require.

Edited By old mart on 02/04/2020 16:11:15 |

| ega | 02/04/2020 16:18:47 |

| 2805 forum posts 219 photos | In default of a TTA I have fitted a spare ML7 cross slide to my S7 cross slide: Fine adjustment of the "top slide" is via the gadget installed in the front tee slot. Edited By ega on 02/04/2020 16:19:18 |

| ega | 02/04/2020 16:28:45 |

| 2805 forum posts 219 photos | PS I haven't used this setup for some time but, looking at the photo, I can see that the "top slide" gib is on the wrong side for taper boring, something to bear in mind for the future. That said, I don't recall any problem of lack of adequate stiffness. |

| Alan Waddington 2 | 02/04/2020 18:41:24 |

| 537 forum posts 88 photos | Posted by Square Peg on 02/04/2020 15:57:26:

Posted by Alan Waddington 2 on 02/04/2020 15:31:36:

Unless im misunderstanding the problem, why not just make a taper turning attachment ?

Cuz I've got no idea how they work!

Google is your friend........got to be easier than what your doing now. Is it a Harrison L5 or L5a ? If so pretty sure iv’e got a genuine Harrison taper turning attachment tucked away somewhere.

|

| Spurry | 02/04/2020 19:01:31 |

| 227 forum posts 72 photos | Although not extending the range of the top slide, I have used an allen screw into the handle retaining shaft, powered by a bit of allen key in a variable speed electric drill. Much less tedious than turning by hand. Pete |

| Square Peg | 02/04/2020 19:29:41 |

| 12 forum posts 2 photos | Posted by Alan Waddington 2 on 02/04/2020 18:41:24:

Posted by Square Peg on 02/04/2020 15:57:26:

Posted by Alan Waddington 2 on 02/04/2020 15:31:36:

Is it a Harrison L5 or L5a ? If so pretty sure iv’e got a genuine Harrison taper turning attachment tucked away somewhere.

It's a new fangled 140... |

| DC31k | 02/04/2020 20:35:04 |

| 1186 forum posts 11 photos | How accurate does the taper need to be? A great deal of the complexity of a full-blown taper attachment is in the adjustment mechanism. If you do not need such fine control of the angle, a much simplified version is reasonably easy to make. It would be more like a copy turning attachment where the pattern is straight-edged. I would use some of the cheap round rail and bearing/slider that you see on low end CNC machines. Glue it to the back of the bed, set the angle good enough, disconnect the cross-slide feedscrew and have at it. Put on the cut with the compound slide. Even simpler is just to spring load the cross slide against a straight piece of flat bar set at the correct angle. You might be able to set up the straight bar such that it is clamped to the bed just above the cross slide and let the non-moving part of the compound ride along it. |

| DC31k | 02/04/2020 20:45:17 |

| 1186 forum posts 11 photos | Sorry to follow up so soon, but it might be worth perusing this thread: https://www.model-engineer.co.uk/forums/postings.asp?th=110851 Our very own Jason makes some very relevant points that will greatly assist your situation. |

| Square Peg | 07/04/2020 13:20:39 |

| 12 forum posts 2 photos | Thanks for the replies, I think I may have a go at making one if I can't find one to buy... |

| Neil Wyatt | 07/04/2020 19:05:56 |

19226 forum posts 749 photos 86 articles | Posted by Spurry on 02/04/2020 19:01:31:

Although not extending the range of the top slide, I have used an allen screw into the handle retaining shaft, powered by a bit of allen key in a variable speed electric drill. Much less tedious than turning by hand. Pete Me too Steadier as well Neil |

| Howard Lewis | 07/04/2020 22:47:57 |

| 7227 forum posts 21 photos | If you want to turn a long taper, you can offsetb the tailstock (Don't forget to realign it afterwards ) Or you could fit a Boring head in then Tailstock With the slide horizontal ) and use the adjuster to offset a small, specially made centre. No Boring Head,? There have been designs for a Tailstock mounted slide which does the same thing. I think that Dave Clark made one up for his mini lathe and featured it in an narticle in MEW, some time ago. It might be worth doing a dummy run to ensure that the offset is correct to produce the taper that you require. Howard |

| Mick B1 | 07/04/2020 22:55:18 |

| 2444 forum posts 139 photos | Posted by Howard Lewis on 07/04/2020 22:47:57:

If you want to turn a long taper, you can offsetb the tailstock (Don't forget to realign it afterwards ) ... OK, but the OP's illustrated piece would need a pretty big offset and also present what look like serious issues gripping the headstock end on the slant. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in