Cheap gear cutters from China

| Douglas Johnston | 29/12/2019 14:54:20 |

814 forum posts 36 photos | I have just received a set of 8 gear cutters from China via ebay and I must say they look rather nice. I have wanted to try gear cutting for a while but could not bring myself to pay up a lot of money for something that would not get a huge amount of use. I took a punt at the Chinese ones, not expecting anything great, but I must say they do seem well made. I have not used them yet so this is just a first impression, but at about £38 for a set of 8 cutters they do represent good value provided they cut well. The workshop is a bit cold at this time of year so I will have to wait a bit before trying them out, but at least I can sit in the warmth and look at them! Doug |

| Jens Eirik Skogstad | 29/12/2019 15:02:46 |

400 forum posts 22 photos | I has a set of gear cutter, Module 1, 0.7, 0.5 from Alibaba, really cheap to buy. I'm satisfied the quality of the gear cutter, precise as i can see when i created the gear wheels. |

| Douglas Johnston | 29/12/2019 15:10:34 |

814 forum posts 36 photos | I forgot to mention the ebay number which is 162447654385 Doug |

| Brian Selby | 29/12/2019 15:25:27 |

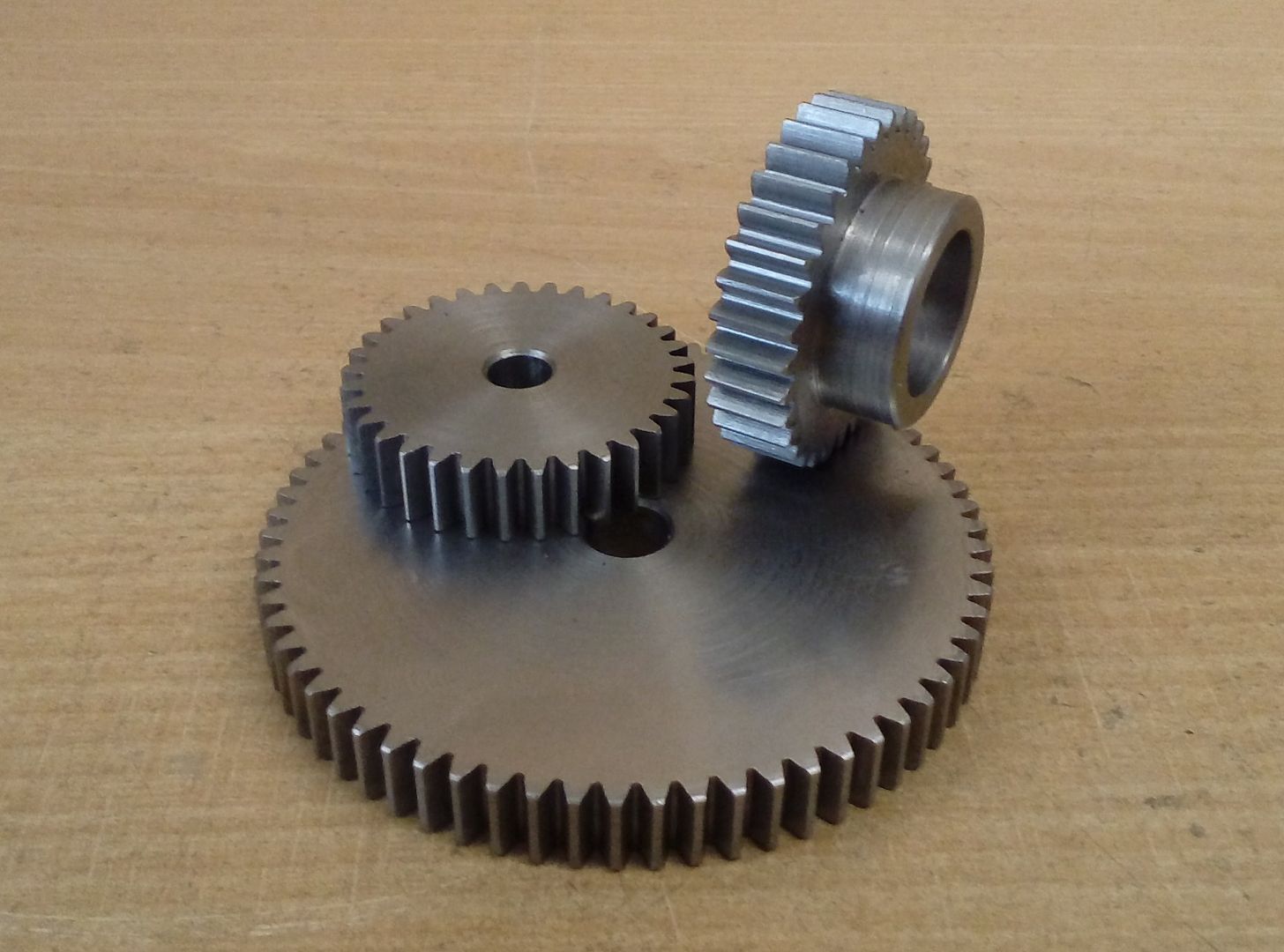

9 forum posts 19 photos | I bought set of 1.25 mod cutters from banggood. I have used them to cut a set of gears for my Mastiff powered Charlatan I'm building. I am really pleased by the quality. the only problem being me in counting the holes on the dividing head plate, must remember in future don't include the hole the peg is in, as I now have two practice gears that don't quite mesh. |

| Jens Eirik Skogstad | 29/12/2019 15:43:55 |

400 forum posts 22 photos | Brian Selby.. As rule in the dividing plate for indexing head: counts of hole + 1 hole for pin |

| JasonB | 29/12/2019 15:45:03 |

25215 forum posts 3105 photos 1 articles | I bought a couple of similarly priced MOD1 cutters and although they did the job they were starting to loose their edge after about 70T each in 1/4" wide steel so you get what you pay for.

|

| Jens Eirik Skogstad | 29/12/2019 15:51:24 |

400 forum posts 22 photos | Douglas Johnston.. I has the gear cutter same factory as your gear cutter where there is marked on gear cutter: 上 Homepage Shang Gong: http://www.cccme.org.cn/shop/cccme0467/introduction.aspx

Edited By Jens Eirik Skogstad on 29/12/2019 15:54:33 |

| Douglas Johnston | 29/12/2019 16:01:02 |

814 forum posts 36 photos | Posted by JasonB on 29/12/2019 15:45:03:

I bought a couple of similarly priced MOD1 cutters and although they did the job they were starting to loose their edge after about 70T each in 1/4" wide steel so you get what you pay for.

That is interesting Jason, as long as I stick to aluminium they should be fine for letting me try out gearcutting. They do also look quite easy to sharpen, so even if they do blunt quickly they can be touched up to give extended service. Doug |

| Douglas Johnston | 29/12/2019 16:11:44 |

814 forum posts 36 photos | Posted by Jens Eirik Skogstad on 29/12/2019 15:51:24:

Douglas Johnston.. I has the gear cutter same factory as your gear cutter where there is marked on gear cutter: 上 Homepage Shang Gong: **LINK**

Edited By Jens Eirik Skogstad on 29/12/2019 15:54:33

Thanks for that link Jens Eirik, it looks as if the cutters are made in a decent factory rather than some backstreet outfit.Have you tried cutting steel with your cutters, and if so how well have they stood up with regard to wear? Doug |

| Jens Eirik Skogstad | 29/12/2019 16:37:08 |

400 forum posts 22 photos | Tried to cut in steel, cutter seem fine. I'm cutting mostly in cast iron, brass and aluminium. Use right rpm and cutting fluid to keep cutter cooled and sharp enough. It's not difficult to resharpen the cutter if worn out. |

| Enough! | 29/12/2019 16:56:13 |

| 1719 forum posts 1 photos | Posted by Douglas Johnston on 29/12/2019 15:10:34:

I forgot to mention the ebay number which is 162447654385

|

| Michael Gilligan | 29/12/2019 17:03:05 |

23121 forum posts 1360 photos | Posted by Bandersnatch on 29/12/2019 16:56:13:

Posted by Douglas Johnston on 29/12/2019 15:10:34:

I forgot to mention the ebay number which is 162447654385

. Try just copying and pasting that number into ebay search [it’s not a hyperlink] ... works fine on ebay UK MichaelG. |

| Pete Rimmer | 29/12/2019 18:23:17 |

| 1486 forum posts 105 photos | Posted by Douglas Johnston on 29/12/2019 16:01:02:

That is interesting Jason, as long as I stick to aluminium they should be fine for letting me try out gearcutting. They do also look quite easy to sharpen, so even if they do blunt quickly they can be touched up to give extended service. Doug The simple rule for sharpening them is always sharpen the face so it remains in line with the centre. This means you have to rotate the cutter to grind more off, rather than moving it. |

| Douglas Johnston | 29/12/2019 18:47:08 |

814 forum posts 36 photos | Posted by Pete Rimmer on 29/12/2019 18:23:17:

The simple rule for sharpening them is always sharpen the face so it remains in line with the centre. This means you have to rotate the cutter to grind more off, rather than moving it.

Thanks for that tip Pete, every day is a learning day. It makes sense when you think about it, the trouble is it is so easy to jump in without thinking. Doug

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

As usual newbeginners did fault when they count the hole with pin in the hole to example 5 hole instead 5 hole + 1 hole for pin at dividing plate for indexing head.

As usual newbeginners did fault when they count the hole with pin in the hole to example 5 hole instead 5 hole + 1 hole for pin at dividing plate for indexing head.

Register

Register Log-in

Log-in