Upside down reverse threading

| Danny M2Z | 11/05/2019 15:05:20 |

963 forum posts 2 photos | I have noticed that a few gunsmiths advocate this technique. They are cutting a barrel tenon away from a fixed shoulder and I must admit that it is new to me but it seems to make sense - here is a linky UDRT Any thoughts on this as a general technique considering that most forum members to not thread barrels? |

| duncan webster | 11/05/2019 16:08:18 |

| 5307 forum posts 83 photos | Don't try this on a lathe with a screwed on chuck, for obvious reasons |

| JasonB | 11/05/2019 16:27:45 |

25215 forum posts 3105 photos 1 articles | I do it quite often except I have a tool the right way up behind the work and just run in reverse, have suggested it a few times on here as you can run at a decent speed due to having miles of room to stop.

Edited By JasonB on 11/05/2019 16:57:54 |

| Nick Hughes | 11/05/2019 16:49:10 |

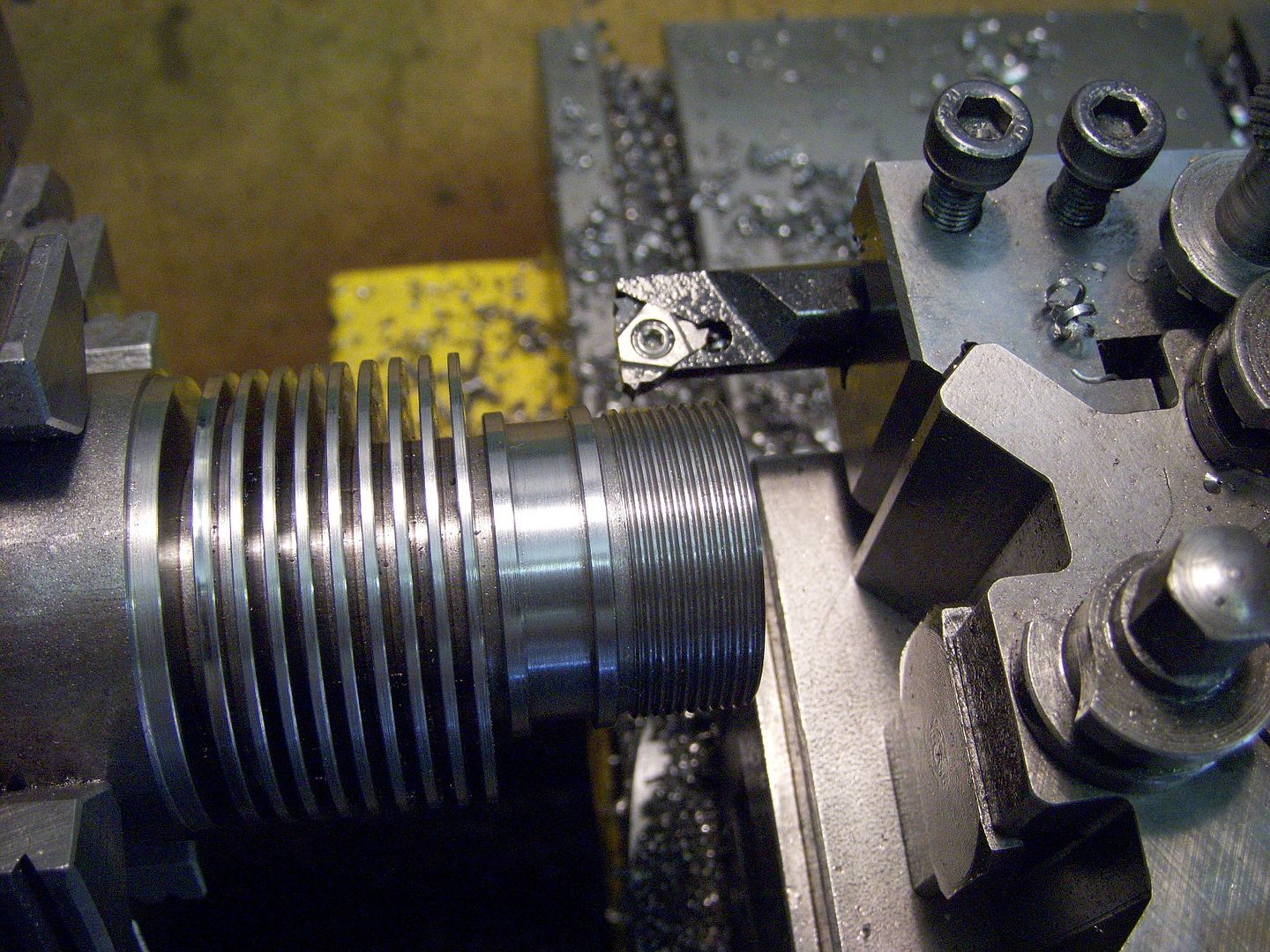

307 forum posts 150 photos | No problem with the Myford screwed on chuck when I did it:- Edited By Nick Hughes on 11/05/2019 16:50:29 |

| ega | 11/05/2019 17:12:14 |

| 2805 forum posts 219 photos | Jason B: You have not mentioned this in vain. However, the direct import Chinese tool-holder I used to try this would, I think, only be usable with relatively short threads. I was surprised by how well this method worked given that the tool seems to be working the wrong way round in relation to the helix angle of the thread. I found also that the work is more difficult to see working like this and it was obviously necessary to be very disciplined about moving switches and levers in the appropriate direction. |

| I.M. OUTAHERE | 12/05/2019 06:58:21 |

| 1468 forum posts 3 photos | Also used for threading blind holes like threaded end caps etc . |

| ega | 12/05/2019 08:35:11 |

| 2805 forum posts 219 photos | Posted by Nick Hughes on 11/05/2019 16:49:10:

No problem with the Myford screwed on chuck when I did it:- Edited By Nick Hughes on 11/05/2019 16:50:29 Light bulb moment: running the tool upside down at the front would deal with my visibility problem - thank you! |

| not done it yet | 12/05/2019 08:57:01 |

| 7517 forum posts 20 photos | Posted by Nick Hughes on 11/05/2019 16:49:10:

No problem with the Myford screwed on chuck when I did it:- Edited By Nick Hughes on 11/05/2019 16:50:29 Yes, that was clearly so - but would you accept the blame when someone ends up with his chuck on his/her toes? |

| Hopper | 12/05/2019 10:54:58 |

7881 forum posts 397 photos | Posted by not done it yet on 12/05/2019 08:57:01:

Posted by Nick Hughes on 11/05/2019 16:49:10:

No problem with the Myford screwed on chuck when I did it:- Edited By Nick Hughes on 11/05/2019 16:50:29 Yes, that was clearly so - but would you accept the blame when someone ends up with his chuck on his/her toes? There is a simple safeguard to stop the chuck unscrewing: A length of threaded rod through the spindle hole with a large washer or even a piece of flat bar with hole drilled in it holding the chuck in place. Other end of the threaded rod has a nut and washer that is nipped up. Simples. |

| not done it yet | 12/05/2019 13:00:36 |

| 7517 forum posts 20 photos | So it is no good for any workpiece which might pass through the chuck and into the spindle? Special cases can often be contrived, but simply stating that screw on chucks can be used in reverse is not good information for new starters - who are more likely to get the chuck on their toes. |

| Nick Hulme | 12/05/2019 17:18:35 |

| 750 forum posts 37 photos | Posted by duncan webster on 11/05/2019 16:08:18:

Don't try this on a lathe with a screwed on chuck, for obvious reasons Done it on a Myford Super 7 for 15 years, you have to cut a massive thread in one pass to dislodge a well fitted Myford chuck. |

| Nick Hulme | 12/05/2019 17:20:48 |

| 750 forum posts 37 photos | Posted by not done it yet on 12/05/2019 13:00:36:

So it is no good for any workpiece which might pass through the chuck and into the spindle? It's fine, all the "experts" haven't actually done it, or if they have and hit this problem they had left their chuck loose :D |

| Alan .204 | 13/05/2019 00:07:21 |

| 304 forum posts 14 photos | I do all my threading with an inverted tool away from the chuck, no need for thread relief either, I just go straight into the finished depth pull back out then thread in stages as normal just in reverse, works a treat and more importantly for me safer. Alan. |

| thaiguzzi | 13/05/2019 05:00:19 |

704 forum posts 131 photos | Posted by not done it yet on 12/05/2019 08:57:01:

Posted by Nick Hughes on 11/05/2019 16:49:10:

No problem with the Myford screwed on chuck when I did it:- Edited By Nick Hughes on 11/05/2019 16:50:29 Yes, that was clearly so - but would you accept the blame when someone ends up with his chuck on his/her toes? Not at screwcutting speeds. Screwcutting on my Boxford in reverse @ 50 rpm and a low DOC is not going to unscrew a chuck. |

| Hopper | 13/05/2019 05:24:09 |

7881 forum posts 397 photos | It's probably like welding petrol tanks, maybe one in a thousand goes wrong. Just don't be that one... |

| Circlip | 13/05/2019 12:00:05 |

| 1723 forum posts | In a similar vein, left an American ME site after arguing with a colonial about NOT using a milling cutter in a drill chuck. "I've been doing it for years" was the retort.

Regards Ian. |

| Jon | 13/05/2019 20:03:55 |

| 1001 forum posts 49 photos | Posted by Alan .204 on 13/05/2019 00:07:21:

I do all my threading with an inverted tool away from the chuck, no need for thread relief either, I just go straight in How are you plunging in to the metal with no relief? Most blind hole have no relief |

| Jon | 13/05/2019 20:06:51 |

| 1001 forum posts 49 photos | Posted by Circlip on 13/05/2019 12:00:05:

In a similar vein, left an American ME site after arguing with a colonial about NOT using a milling cutter in a drill chuck. "I've been doing it for years" was the retort. Whats the problem with that? Is it because its not a drill or a D bit or any other kind. |

| SillyOldDuffer | 13/05/2019 20:41:45 |

| 10668 forum posts 2415 photos | Posted by Nick Hulme on 12/05/2019 17:18:35:

Posted by duncan webster on 11/05/2019 16:08:18:

Don't try this on a lathe with a screwed on chuck, for obvious reasons Done it on a Myford Super 7 for 15 years, you have to cut a massive thread in one pass to dislodge a well fitted Myford chuck. Perhaps your chuck is jammed, it's a well known Myford problem... |

| Alan .204 | 13/05/2019 21:30:45 |

| 304 forum posts 14 photos | John, when the tip of the insert is where I want it I set a DTI on the bed way so every time I come back I start in the same place, I have brocken tips yes but not doing it like this, as for plunging what ever the finished depth is I go to depth in full then come back to the start of the depth so to speak and add more depth each time I make another pass, I’ve had no problems at all, give it go if you don’t believe me, I will be making some collet holders soon I’ll put it on my ytube channel you can have a look if you want to, just because you haven’t done something a certain way yourself doesn’t mean you should dismiss it ? Alan. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in