Horizontal engine

| richard 2 | 29/08/2017 11:09:38 |

| 127 forum posts | HI Does any one know of a published design for a simple horizontal steam engine about half as big again as the "Potty" engine. I'm finding 2mm screws and their taps etc., a bit too small at my advanced age. Many thanks. Richard 2. |

| Nick_G | 29/08/2017 11:26:18 |

1808 forum posts 744 photos | . Are you thinking of a bar-stock construction or a casting kit engine.? Nick |

| JasonB | 29/08/2017 11:33:15 |

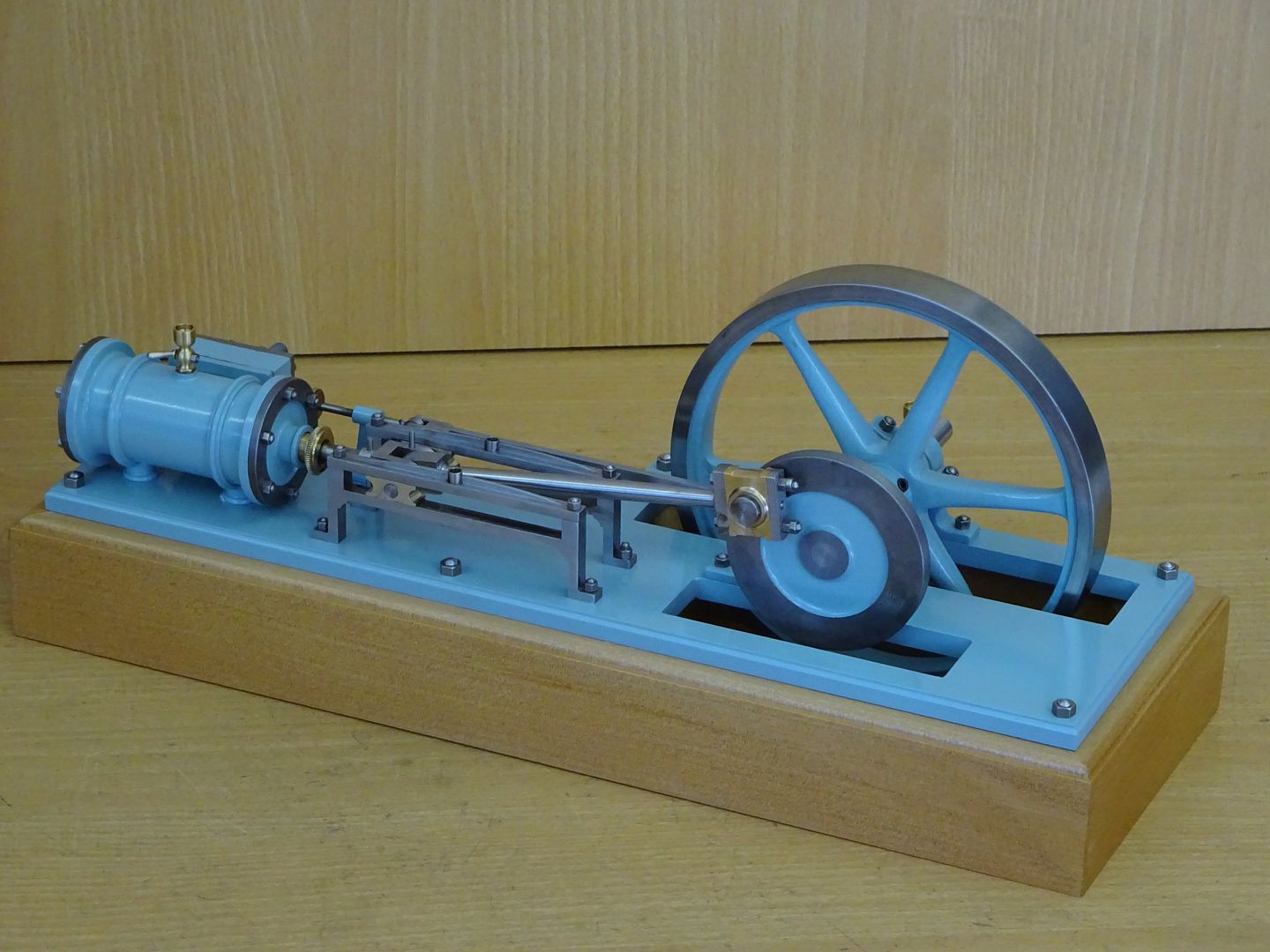

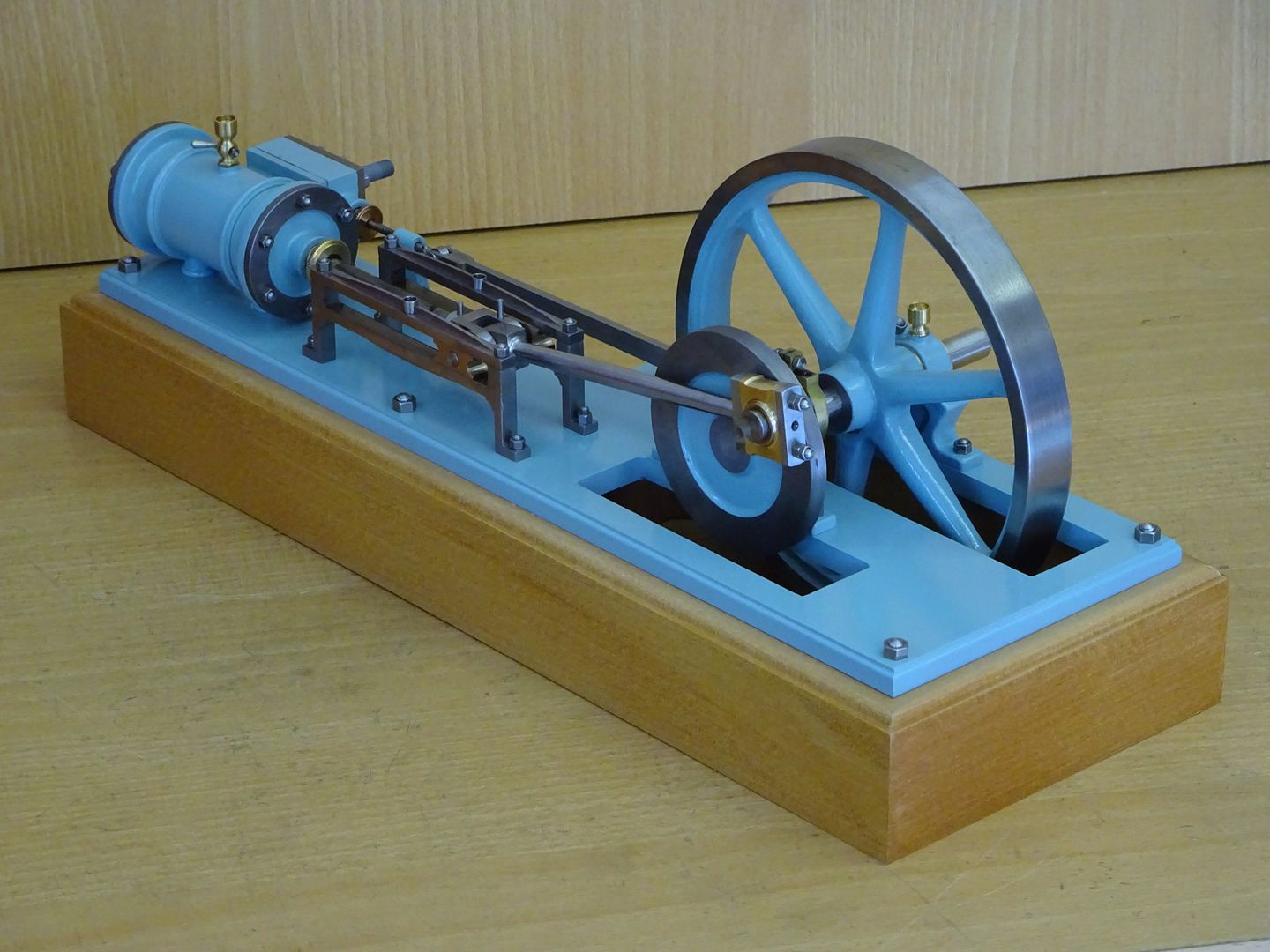

25215 forum posts 3105 photos 1 articles | Just about any published design can be made larger just by multiplying all the measurements by a common number, metric drawings can be made 50 % or 100% larger. Same for imperial or you can take imperial designs and make them metric quite easily by allowing 1/32" = 1mm and so on. I have seen the Potty Horizontal made larger. I do have a design for a 24mm bore horizontal but not published it yet no castings needed and being a bit more refined than the average bar stock engine does still have a couple of M2 fixings though most are M2.5 or M3 |

| Nige | 29/08/2017 16:32:27 |

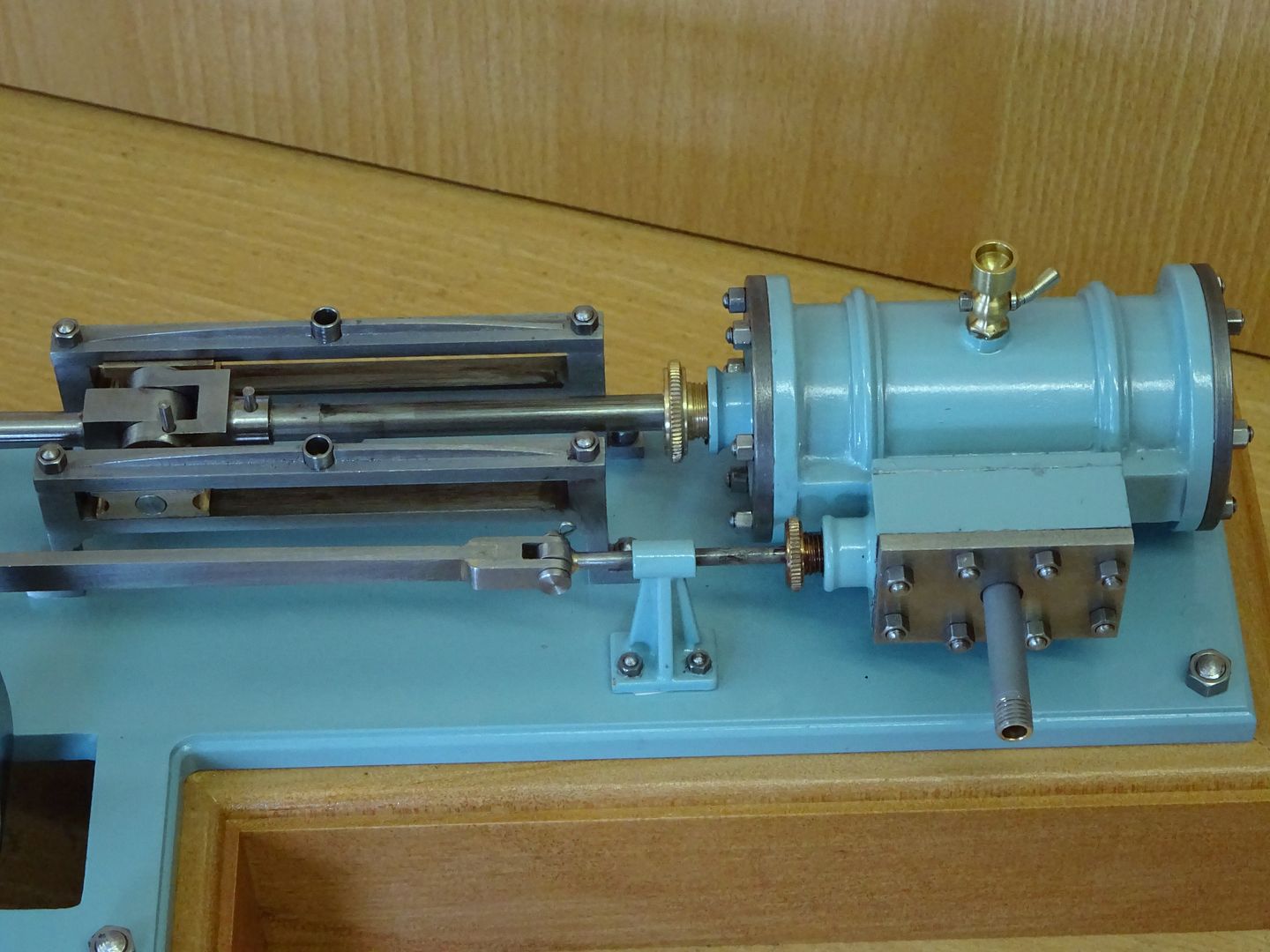

370 forum posts 65 photos | JasonB: Do you have any more pictures of that engine please, I am interested to see the 'gubbins' on the other side where the reciprocating takes place |

| Nick_G | 29/08/2017 16:42:25 |

1808 forum posts 744 photos | . I am one of his 'stalkers' on youtube. |

| JasonB | 29/08/2017 16:45:11 |

25215 forum posts 3105 photos 1 articles | A few shots of the gubbins sorry about the poor colour need to take some better ones.

And the gubbins in motion which probably shows things better particularly if you blow it upto full screen Looks like the Fan Boy beat me to it

Edited By JasonB on 29/08/2017 16:46:10 |

| richard 2 | 02/09/2017 08:35:17 |

| 127 forum posts | Many thanks everyone. I like the look of the Thompstone workshop engine but it seems there are castings for the cylinder and valve spindle guides. Other than that I think it would be an ideal job for me if not too large. Workshop unusable for this week as I am replacing the "bits and pieces" shelving with decent shelving bays. Richard 2. |

| JasonB | 02/09/2017 10:22:35 |

25215 forum posts 3105 photos 1 articles | The only casting I used was the flywheel but at 5" dia could be cut from solid, fabricated or buy in a casting. There is some silver soldering needed on the cylinder. |

| Nige | 02/09/2017 18:54:21 |

370 forum posts 65 photos | JasonB: Thank you for the extra photos and the video, very nice. I have plans for Stewart's Pottymill now and planning on making a start on that once we get moved and the new workshop sorted out |

| BW | 02/03/2019 08:17:30 |

| 249 forum posts 40 photos | what do I have to put into a google search to find somewhere where I can buy the blue hose and the brass fittings that connect the steam to the engine in the video ? Thanks Bill |

| BW | 02/03/2019 08:18:23 |

| 249 forum posts 40 photos | ............. and by the way nice engine ..... looking forward to being able to do something similar one day in the distant future.

|

| JasonB | 02/03/2019 08:25:10 |

25215 forum posts 3105 photos 1 articles | Push fit pneumatic hose and fittings will find it. That is 4mm hose in the video, 1/8" BSP fitting and than a home made adaptor to get from the BSP to M5 x 0.5 The other end of the hose goes back to a regulator, one of several screwed into a manifold that is fed from the compressor. Different hose sizes to suit the size of engine. Edited By JasonB on 02/03/2019 08:31:18 |

| Ian McVickers | 02/03/2019 09:25:19 |

| 261 forum posts 117 photos | Jason, did you ever publish drawings for that engine? |

| Ron Laden | 02/03/2019 10:30:25 |

2320 forum posts 452 photos | Posted by JasonB on 29/08/2017 16:45:11:

A few shots of the gubbins sorry about the poor colour need to take some better ones.

ed By JasonB on 29/08/2017 16:46:10 I do like the extra detail you put into your engines Jason, for example how the con rod tapers down at each end rather than just a piece of round bar and the curved webs on top of the guide bars, it makes all the difference and very pleasing to the eye. Great stuff Ron |

| JasonB | 02/03/2019 10:49:38 |

25215 forum posts 3105 photos 1 articles | Ian, not yet. Martin has the article for the Entablature engine shown in the video I posted earlier today, if that goes down OK then I'll do this one for the mag if not probably do it as a build on here and MEM. |

| Niloch | 04/03/2019 12:24:51 |

| 371 forum posts | Jason, is your design for the manifold shown anywhere? |

| JasonB | 04/03/2019 12:55:32 |

25215 forum posts 3105 photos 1 articles | It's nothing special. Just a piece of aluminium approx 20 x 25 x 150 drilled most of the way through from one end with a 1/4" BSP tapping drill and the first part of the hole tapped 1/4" BSP for connector to compressor (I've now got a quick realease coupling on it) Then 5 holes drilled down from the top into the long hole which are tapped to suit the valves, I think the ones for 4 and 6mm OD pipe are M5 and the one for 8mm pipe 1/8" BSP. That's all there is to it.

Edited By JasonB on 04/03/2019 12:56:18 |

| Niloch | 04/03/2019 13:03:59 |

| 371 forum posts | Thank you Jason, much obliged. |

| Andy_C | 23/06/2019 18:38:44 |

| 66 forum posts 13 photos | Did the entablature build get published and are the horizontal plans available or published? |

| JasonB | 23/06/2019 19:04:11 |

25215 forum posts 3105 photos 1 articles | Entablature is with the Editor and has been since the end of last year, hopefully it may get an airing now that the ME Boiler series has ended. Not done the working drawings for the horizontal yet as I was waiting to see how the Entablature was received. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in