Silver soldering question

| Sam Longley 1 | 03/12/2016 11:55:42 |

| 965 forum posts 34 photos | I am silver soldering a large & a small sprocket onto a bush to sit on a layshaft. i wanted to drill the bush between the two for a grub screw just to locate the bush on the shaft rather than place collars each side of it. I do not need any keyway & have no facility to cut one anyway. i have to drill & tap the hole before I silver solder the sprockets onto the bush as the diameter of the largest bush is 100mm & the grubscrew is 4mm from it with the smaller sprocket another 6mm from that so there is only a 10mm gap. My problem is how to prevent the silver solder filling the grub screw hole. If I place the screw in , sod's law dictates that it will solder itself in place. if I do not then the hole will fill with dross Is there a simple trick to prevent this? Do I have to re think the process & forget the grubscrew hole altogether? |

| mechman48 | 03/12/2016 12:30:19 |

2947 forum posts 468 photos | FWIW - IIRC from other members comments / posts if you coat the areas you do not want to solder with Tippex correction fluid then the solder won't adhere, include the tapped grub screw hole...

|

| Philip Rowe | 03/12/2016 12:37:31 |

| 248 forum posts 33 photos | Sam, a trick that I have used successfully in the past is to put a rusty screw of the same thread in the threaded hole before you carry out the silver soldering. This will prevent the solder from adhering although you might get some of the flux sticking to the screw but that will be easily removed by the pickling after soldering, or at worst by mechanical means ie wire brush or scaping. Phil |

| MW | 03/12/2016 12:45:34 |

2052 forum posts 56 photos | Not so much a trick but a point to remember that may help is that the solder tends to follow the hottest point, I would use something like mechman said to "mask off" the area so to speak, but it would be easier to avoid overspill, if you can control where the hottest point is with a smaller burner head. And a "softer" hard solder like 55% silver will make it easier to flow and therefore use less solder. Michael W

|

| JasonB | 03/12/2016 13:22:01 |

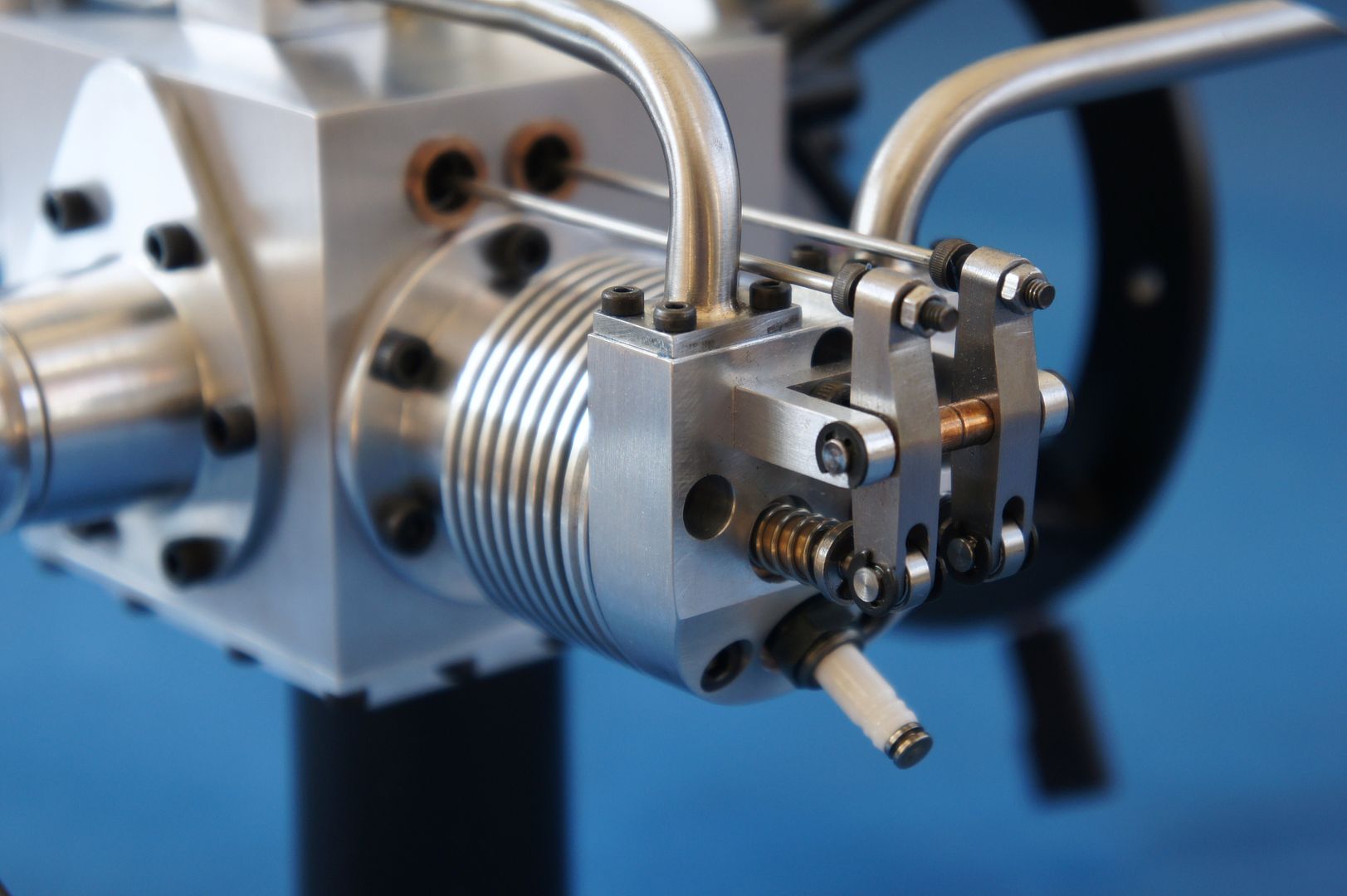

25215 forum posts 3105 photos 1 articles | As Mechman says tippex correction fluid will keep the solder off, must be the solvent based one. Here are some bits pegged to a steel plate to keep them in place while soldering, you can see the tippexed areas

All came off the jig OK

Same again stainless steel parts screwed to a steel jig

And finished part

|

| Adam Phillips | 03/12/2016 16:27:10 |

47 forum posts | A trick I use all the time to stop silver and gold solder running where you don't want it is to paint the area with rouge powder mixed with a little water into a paste. Its also good at stopping an already soldered joint from coming undone or the solder flowing out of an already soldered joint |

| Philip Rowe | 03/12/2016 16:40:56 |

| 248 forum posts 33 photos | Adam, thats very interesting would you provide a little more information on "rouge" powder, is it something that is obtainable from jewellery suppliers? I particularly like the sound of its use to stop previously soldered joints from coming undone. Thanks, Phil |

| Adam Phillips | 03/12/2016 17:51:14 |

47 forum posts | Hi Phil Rouge powder is obtainable from Cousins who sell watch parts and tool,Cooksons gold. and H S Walsh in hatton garden. It realy comes into is own when soldering next to an already soldered joint. Paint it on and then warm the job but be careful when you put on any flux if the Rouge mixes into the flux your solder won't flow. I bought a 120 gram jar about 10 years ago and I'm not even 1/4 of the way through. Item no p8984 from cousinsuk.com |

| fizzy | 03/12/2016 18:20:44 |

1860 forum posts 121 photos | This is a good page for beginers **LINK** |

| steamdave | 03/12/2016 21:04:46 |

| 526 forum posts 45 photos | Another mask if you can't get solvent Tippex or rouge is a simple lead pencil. Just rub it where you don't want the solder to run. Dave |

| Sam Longley 1 | 03/12/2016 21:29:32 |

| 965 forum posts 34 photos | Thanks Parts suitably tippexed ready for a go tomorrow |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in