Ball Nose Cutters

| Alan Girvan | 08/07/2016 20:37:34 |

| 40 forum posts 3 photos | Hi, Trying to purchase 15mm (£40) ball nose milling cutters and 22mm (£70) or 78 can only find one site with these but they are very expensive and wouldn't justify the outlay for something you are only going to use occasionally. My biggest collet is 20mm, I was using these for making farming wheels for pipe benders. I am using them for cutting aluminium. Thanks in advance for any information you may be able to provide me with. Regards, Lynne. |

| Michael Gilligan | 08/07/2016 20:56:18 |

23121 forum posts 1360 photos | For occasional use on Aluminium, you would probably get away with woodworker's Router Bits. MichaelG. |

| Richard S2 | 08/07/2016 21:06:05 |

237 forum posts 135 photos | May be worth having a good look at the Stock these people carry. They are local (walking distance) to me and they carry a vast range. Usual disclaimer. - http://www.drill-service.co.uk/Product.asp?Parent=100120300000&Tool=113 Regards. |

| Andrew Johnston | 08/07/2016 21:43:36 |

7061 forum posts 719 photos | Personally I wouldn't bother. Unless you have a large and rigid mill (and for reference that doesn't mean a Bridgeport) you'll find it difficult to get a good finish with a large ball mill.. One the cutter will be working over a long length, inviting chatter, and two the centre of the cutter isn't cutting, it's rubbing. Depending upon the shape of the wheels I'd turn them, or mill them, in steps and clean up the form with a file or similar. We're not talking precision shapes for a pipe bender. If you don't want to eyeball the shape it is simple enough to make a template from sheet steel. Andrew |

| Neil Wyatt | 08/07/2016 21:49:17 |

19226 forum posts 749 photos 86 articles | For grooving pulleys/roller just feed the side of an ordinary endmill into the work, then rotate it. That way you are left with a usable big endmill with a pristine end. Or rough out and use a form tool on the lathe. Neil |

| Andrew Johnston | 09/07/2016 00:00:55 |

7061 forum posts 719 photos | Posted by Neil Wyatt on 08/07/2016 21:49:17:

For grooving pulleys/roller just feed the side of an ordinary endmill into the work, then rotate it. That's a good alternative. Andrew |

| Clive Foster | 09/07/2016 00:13:48 |

| 3630 forum posts 128 photos | Even using the side of an end mill requires a decently rigid machine. Diameter of the wheel is limited by the length of the end mill too. If the wheel diameter is large enough to need a long series end mill a sidelock (Weldon) type in a holder would probably be more rigid. I've used a similar technique on a large square column bench mill with R8 spindle a few years back. Keeping chatter under control proved difficult. I'm very glad there was only a short arc to do. I think I took several bites at it cutting first one side then the other before finishing off with a centralised cut. Clive. |

| frank brown | 09/07/2016 06:50:12 |

| 436 forum posts 5 photos | How about turning the recess in the quadrant by making a template with a 15mm recess in it and fixing it at centre height in place of your fixed steady. Now make a follower the same shape as your lathe tool fixed in the right hand position of your toolpost. This now limit your lathe tool position to that require. Mount the quadrant on your face plate. Should work but will be a be clunky. Frank |

| JasonB | 09/07/2016 07:14:52 |

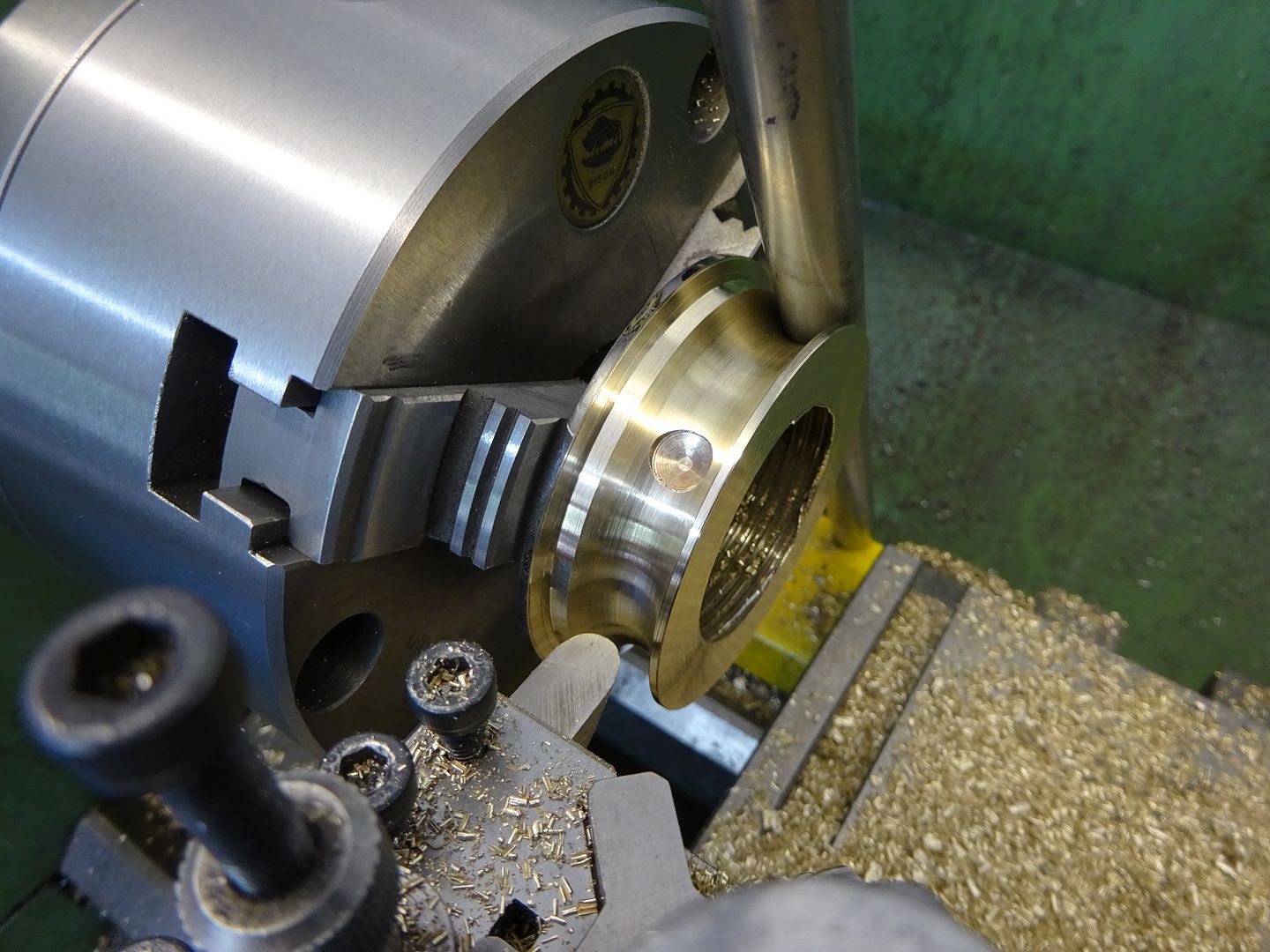

25215 forum posts 3105 photos 1 articles | Set the wheel on the Rotary table mounted vertically, use the boring head set to size to first drop down to ctr height and then rotate the work. If you advance the work in in several stages you won't be taking a lot off per cut and no need to buy 15 & 22mm cutters.

For teh 15mm you could probably do that on teh lathe with a form tool that is slightly smaller so you are not cutting over the whole width of teh tool, just offer up a bit of pipe to test the fit. I did this one a month or so ago from some scrap brass to bend 1/2" stainless

|

| JasonB | 09/07/2016 07:40:15 |

25215 forum posts 3105 photos 1 articles | A 6mm button tool and a few offsets is another option with a bit of freehand knob twiddling to blend the final shape |

| Chris Evans 6 | 09/07/2016 18:43:22 |

2156 forum posts | If possible when using a ball nose cutter I tip the machine head over a few degrees to eliminate the rubbing when cutting on centre. |

| Nigel McBurney 1 | 09/07/2016 19:59:34 |

1101 forum posts 3 photos | I have a good selection of ball nose cutters some new some used,all donated, When I was apprenticed I never saw or used one,years later I have found that they will chatter even on a large turret mill and they will break,first one that went was 1/2 inch and it surprised me how easily it broke,and long series ones are even more fragile,I think that they were used a lot when we had an aircraft industry on aluminium alloy and prototype work, I have found a use for them,should you need to turn a very accurate radius on the lathe ,place the ball nose cutter in the toolholder and use it as a turning tool, I have also collected a number of one inch bore horizontal form milling cutters which cut full rads, I made a tool holder too mount these cutters in the lathe and again use one of the teeth as a lathe form tool,these cutters were made very accurate ,there are also usually have about ten teeth to get blunt before sharpening the cutter. |

| MW | 09/07/2016 22:26:14 |

2052 forum posts 56 photos | Good hint Nigel, sounds like quite an interesting lot. I do well believe the rigidity argument, when i used to side face aluminium to get a work piece square on a bridgeport turret mill i found you couldn't be too aggressive with the cut even on soft material like ally. When you think about it they aren't designed to take huge amounts off in one go, especially with really small sizes, doesn't matter if it's made of carbide if it gets too hot n dug in deep it'll either break or warp, you're better off using a horizontal for that kind of work.

Michael W Edited By Michael Walters on 09/07/2016 22:27:59 |

| Neil Wyatt | 10/07/2016 10:36:50 |

19226 forum posts 749 photos 86 articles | > I have found that they will chatter even on a large turret mill They seem to be more prone to chip welding on aluminium than normal cutters, I think the rake is less. The other day I machined a nice groove, but ran the cutter back along at the same setting and it picked up and spoilt the finish Neil |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in