Shop made Knurling Tool

| Vic | 19/11/2015 15:39:11 |

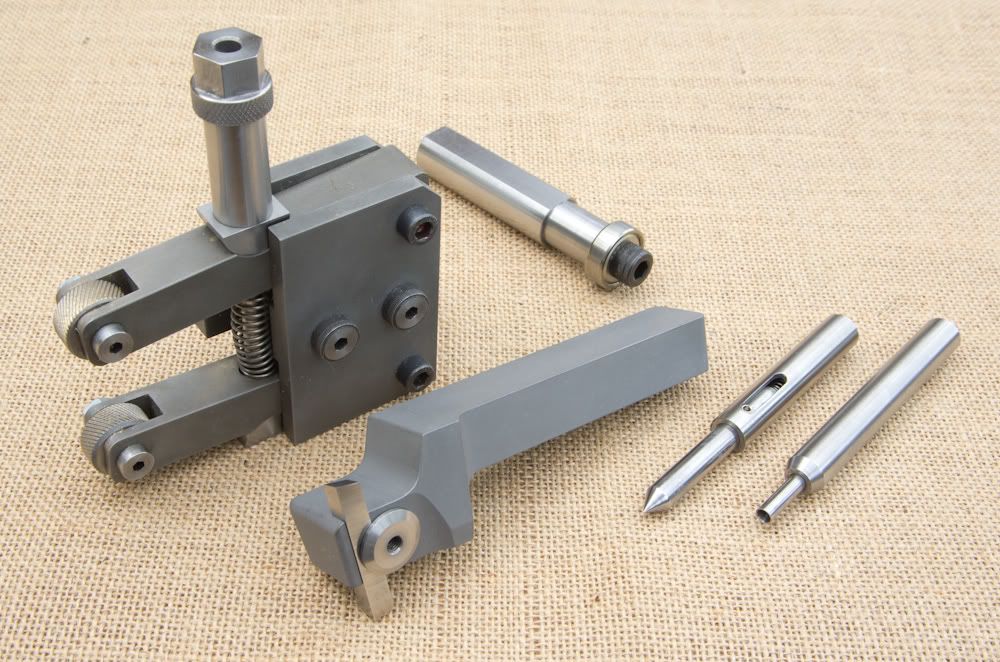

| 3453 forum posts 23 photos | I noticed on another thread that other folks have also made their own shop made Knurling tools so I thought this thread might be a nice reference for anyone thinking of making their own as well. So, post of pictures of your shop made knurlers here if you like. This is my effort.

|

| Neil Wyatt | 19/11/2015 17:01:02 |

19226 forum posts 749 photos 86 articles | Just in case anyone is likely to be put off by sophistication and fine finish. This one had given about ten year's good service before it was adapted to fit my QCTP. Capacity about 1". Neil |

| pgk pgk | 19/11/2015 17:20:31 |

| 2661 forum posts 294 photos | I made this one..**LINK** Simple enough, rigid etc. I'll try to take and upload a pic but with rural internet speeds.... |

| Involute Curve | 19/11/2015 17:39:06 |

337 forum posts 107 photos | I made this as an apprentice, must have been used thousands of times over the years.....

Edited By Involute Curve on 19/11/2015 17:40:07 |

| John Stevenson | 19/11/2015 18:39:16 |

5068 forum posts 3 photos | Don't laugh but here's mine.

Looks weird but it's a cut knurling tool for straight knurls, cut knurling tools for diamond knurls have straight wheels. Yes I know doesn't make sense but it's the geometry and the action.

This one get some serious action when doing straight knurls on motor shafts which have to be dead straight. In the first picture there are two vertical jacking screws that allow you to twist the main spindle carrying the wheel and by this action you can 'steer' it.

Works very well and being a cutting action you don't need the pressures that are normal with crush type tools. When doing steel I run at about 350 revs and a feed of "Jesus H Christ with a Bridgeport - that was fast "

This is what you get.

So it's not all about looking pretty.

Edited By John Stevenson on 19/11/2015 18:40:46 |

| Involute Curve | 19/11/2015 18:48:04 |

337 forum posts 107 photos | John, Do you have drawings for this cut knurl tool? Shaun |

| Thor 🇳🇴 | 19/11/2015 18:50:18 |

1766 forum posts 46 photos | Here is the knurking tool I made years ago, it has served me well. Thor |

| pgk pgk | 19/11/2015 22:22:47 |

| 2661 forum posts 294 photos | Finally managed to get pics of mine to upload: |

| John Stevenson | 20/11/2015 00:17:22 |

5068 forum posts 3 photos | Posted by Involute Curve on 19/11/2015 18:48:04:

John, Do you have drawings for this cut knurl tool? Shaun Sorry no, I never used any, it was a weld it where it touches exercise [ as usual ] I could get some principle dimensions but all that is really needed is to get the centre of the leading edge of the wheel on the centre hight of the machine and get the angle right so that the teeth are horizontal. Away tomorrow and over the weekend but could strip it on Monday and get some better photos so you can see the build up. |

| Roger Head | 20/11/2015 00:29:29 |

| 209 forum posts 7 photos | JS - I'm not laughing. That's the same action/geometry as in the Quick range of knurlers, but at about 1/1000th of the cost. I've watched these in use (the 2-wheel types), and marvel at the beautifully clean cuts they make. [quote} "Yes I know doesn't make sense but it's the geometry and the action." [\quote] Sometimes I think I have it straight in my head, then I start to question myself, and it becomes a circle Is yours a LH or RH tool? Reason I ask is because Quick's typical illustrations of their single-wheel products have the wheel canted in the opposite direction, and as most manufacturers typically show their RH products, well...

|

| Gary Wooding | 20/11/2015 07:15:13 |

| 1074 forum posts 290 photos | Here's mine that I made years ago. I did an article about it in MEW #72. Edited By Gary Wooding on 20/11/2015 07:16:34 |

| Neil Wyatt | 20/11/2015 09:06:26 |

19226 forum posts 749 photos 86 articles | I hope all these different approaches encourage beginners to devise their own solution, as the likelihood of success is high and that's a great encouragement to tackling other projects. One thing we haven't discussed here that beginners need to know, is the need for the spindles to be able to cope with the high loads and hard steel of the knurling rollers. I've made mine from phosphor bronze, and I know others have used hardened and tempered silver steel or hardened dowel pins. Neil |

| Vic | 20/11/2015 10:31:34 |

| 3453 forum posts 23 photos | Some great Knurling tools here folks. Don't be shy if anyone else has made one, keep the pictures coming! Edited By Vic on 20/11/2015 10:31:54 |

| Involute Curve | 20/11/2015 10:40:32 |

337 forum posts 107 photos | Posted by John Stevenson on 20/11/2015 00:17:22:

Posted by Involute Curve on 19/11/2015 18:48:04:

John, Do you have drawings for this cut knurl tool? Shaun Sorry no, I never used any, it was a weld it where it touches exercise [ as usual ] I could get some principle dimensions but all that is really needed is to get the centre of the leading edge of the wheel on the centre hight of the machine and get the angle right so that the teeth are horizontal. Away tomorrow and over the weekend but could strip it on Monday and get some better photos so you can see the build up. JS, you take the pics and Ill create a 3D model and send a .step and .iges files to Neil it can then be downloaded by whoever wants it.

Shaun |

| Neil Wyatt | 20/11/2015 13:12:44 |

19226 forum posts 749 photos 86 articles | Hi Shaun, Not sure I can host those types of file here Neil

|

| Involute Curve | 20/11/2015 13:25:29 |

337 forum posts 107 photos | We can sort it, I could host it on my site if necessary.

Shaun |

| clivel | 20/11/2015 18:02:43 |

| 344 forum posts 17 photos | Posted by Roger Head on 20/11/2015 00:29:29:

Sometimes I think I have it straight in my head, then I start to question myself, and it becomes a circle The Aug/Sept 1991 issue of MEW carries on page 42 a design by Allan Mackintosh for a two wheel "Quick" knurling tool, however It is not quite as straight forward as JohnS's single wheel design pictured earlier in this thread. Clive

|

| Roger Head | 20/11/2015 23:36:29 |

| 209 forum posts 7 photos | Thanks for that Clive. Unfortunately I didn't get into this hobby until 2003, so I only have MEW from #79 onward. I'm in Perth, Western Australia, so my options for accessing a copy are somewhat limited. Besides being Aug/Sept 1991, is there an associated issue # ? It may help in an internet search. Thanks, Roger

|

| Muzzer | 21/11/2015 00:00:42 |

2904 forum posts 448 photos | JS - presumably in your second photo, the work comes in from the right, keeping the knurl against the holder? Neat concept that I haven't seen before. Presumably the adjustment of the 2 grub screws is very critical / sensitive to getting the knurls nicely parallel to the axis? Murray |

| Clive Foster | 21/11/2015 00:28:54 |

| 3630 forum posts 128 photos | The three wheel "nutcracker" type knurling tool puts much less stress on the machine than the conventional type as the crushing force is applied by squeezing the handles. Not quite on topic as mine is a commercial one but a contructional article by R.V.Howis for an essentially identical device with minor simplifications to assist home shop manufacture was published in Model Engineer 29 th January 1999. If I hadn't already got mine I'd have made it having used one at work and found it good. Mine came for free out of a tool dealers scrap bin. Spotted when buying a big Pollard drill. Works well on most materials although I imagine some of the harder steels might cause problems. Technique is pretty simple but there is a slight knack to picking up a proper diamond knurl due to there being two wheels of the same hand. Basically don't be shy. Get everything moving with the wheels lightly in contact then squeeze fast and hard. Apply a little tilt force, but don't actually tilt it, if you see what I mean, to run from side to side when the knurl is longer than the width of the wheels. Keep running and squeezing until a nce clean knurl of the right depth is needed. I've never bothered with the calculate theoretical depth nonsense. Clive. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Very limited files types only.

Very limited files types only.

Register

Register Log-in

Log-in