Cutting BSPT threads with a die

| Bezzer | 01/05/2015 12:29:53 |

| 203 forum posts 16 photos | I want to replicate two radiator bypass hose connectors on a Suzuki Kettle I'm restoring in 303 stainless. They're 1/4" and 3/8" BSPT threads and I've never had to do taper threads before. Do I just turn the bar parallel to the major thread diameters or should I be using the top slide to taper them up to the major diameter before using the die?. I have looked it up and know the sizes but I can't find any reference as to which is the best way to do things. The taper is 1 in 16 which would mean an angle of 1.5 ish degrees so would have to be a good guesstimate if I did it that way. Edited By Mick Berrisford on 01/05/2015 12:31:46 |

| Brian Wood | 01/05/2015 13:43:47 |

| 2742 forum posts 39 photos | Hello Mick, I have not cut tapered threads before, but I believe the male part of the thread, the tapered section in other words, is cut at right angles to the taper face, as would be the case with any other thread cut on a component.. That means you will need to follow the taper with the threading tool and doing that mechanically means using a taper turning attechment, having first machined the taper using the attachment. I don't see how such a tapered thread can be cut with a die, parallel threads yes, but not taper. Sorry I can't give you more information than that. Brian |

| Tony Pratt 1 | 01/05/2015 13:46:29 |

| 2319 forum posts 13 photos | Brian is correct, you really need a taper turning attachment. Tony |

| Gordon W | 01/05/2015 14:06:59 |

| 2011 forum posts | I've never tried to cut a taper thread either. The mating female thread will be a straight thread ( usually) . Easiest is just use a parallel male thread and sealer or washer. |

| S.D.L. | 01/05/2015 14:09:15 |

| 236 forum posts 37 photos |

Posted by Mick Berrisford on 01/05/2015 12:29:53: I want to replicate two radiator bypass hose connectors on a Suzuki Kettle I'm restoring in 303 stainless. They're 1/4" and 3/8" BSPT threads and I've never had to do taper threads before. Do I just turn the bar parallel to the major thread diameters or should I be using the top slide to taper them up to the major diameter before using the die?. I have looked it up and know the sizes but I can't find any reference as to which is the best way to do things. The taper is 1 in 16 which would mean an angle of 1.5 ish degrees so would have to be a good guesstimate if I did it that way.

Edited By Mick Berrisford on 01/05/2015 12:31:46 Do as you suggest turn taper first then cut with BSPT die. Steve |

| Jeff Dayman | 01/05/2015 14:14:28 |

| 2356 forum posts 47 photos | I've always cut tapered pipe threads with a die, whether with a die in the lathe under power or out by hand. Pipefitters cut threads on millions of pipe ends around the world every day , and I've yet to see one do a cut taper thread in an engine lathe. Powered pipe threaders with dies, yes, engine lathes, no. JD |

| Russ B | 01/05/2015 14:49:05 |

| 635 forum posts 34 photos | I don't see any problem die cutting a taper, I guess the only tricky bit is ensuring the taper die is not driven to deep or the threads will bottom out before they seal. From my engineering handbook, the gauge plane and diameter at that plane that your aiming for are (for external threads) for the 1/4" for the 3/8"

Edited By Russ B on 01/05/2015 14:53:58 Edited By Russ B on 01/05/2015 14:57:07 |

| JasonB | 01/05/2015 15:08:28 |

25215 forum posts 3105 photos 1 articles | With the big hefty pipe threaders there is no need to put a taper on the pipe but if its a small split die then even 3/8BSP parallel needs quite a bit of elbow grease so cutting a small taper for BSPT will just make the job a bit especially on stainless. Also worth remembering that the pipe threading kit tends to have a guide to keep the die head true which you won't get on a split die so again a bit of a taper will help things along. This is what I sometimes use on the models especially exhaust pipes on the hit & miss ones, this is 3/8BSPT

Edited By JasonB on 01/05/2015 15:12:23 |

| fizzy | 01/05/2015 16:26:01 |

1860 forum posts 121 photos | are the male and female threads tapered? Or is it always one or the other?

|

| JasonB | 01/05/2015 16:39:17 |

25215 forum posts 3105 photos 1 articles | Usually parallel internal and tapered external. |

| Jon Gibbs | 01/05/2015 16:59:10 |

| 750 forum posts | I'd have thought you could single point thread it between centres fairly easily with the tailstock set over? Jon |

| Brian Wood | 01/05/2015 18:22:53 |

| 2742 forum posts 39 photos | Hello Jon, The thread will then no longer be at right angles to the face of the material, it might not matter a lot but it will also distort the thread pitch angle as well Brian |

| Jon Gibbs | 01/05/2015 19:36:37 |

| 750 forum posts | Brian, Can you not set the tool perpendicular to the axis of the taper rather than the surface of the taper? I'd have thought that would result in the thread being cut right or an I missing something? Jon |

| Hopper | 02/05/2015 01:06:10 |

7881 forum posts 397 photos | Usual way when threading pipe is to run the die straight on to the pipe. No taper put on pipe first. The size you are working on, the amount of taper is not going to be much. An old pipefitters' dodge is if you have trouble getting the die started on the cut, put a small hacksaw nick on the very end of the pipe to let the first teeth of the die get some "bite". That is usually only needed on larger pipe, 2" etc. But if you are using stainless, you know how uncooperative a material it can be, so it might help. Edited By Hopper on 02/05/2015 01:07:13 |

| Brian Wood | 02/05/2015 09:43:14 |

| 2742 forum posts 39 photos | Hello again Jon, Setting the tool perpendicular to the tapered face as you suggest doesn't overcome the basic problem of the geometry of tool travel down the axis of the lathe across an angled surface. Draw a sketch on paper to see what I mean Brian |

| Nigel McBurney 1 | 02/05/2015 11:41:13 |

1101 forum posts 3 photos | looking at some Machinerys publications, the flanks of tapered pipe threads are normal to the pipe axis not the taper with exception of gas fittings. Any way if you are making a couple of fittings for a radiator thread the form in relation to the pipe or the machined taper does not matter in practice, Use the die so that the tapered lead of the cutting teeth help produce a taper,then when getting close to size, and the thread is still tight in the mating hole,tighten up the die and only cut halfway down the thread so the first part fits and the rest is tight,and use loctite pipe thread sealer or boss white and hemp or ptfe tape. When I make steam fittings for full size I do use a taper turning attachment its just knowing when to adjust the thread by fiddling and when to do it correctly. |

| MalcB | 02/05/2015 14:38:27 |

| 257 forum posts 35 photos |

British Standard Pipe Threads used for pressure tight applications should ideally be taper thread to taper thread. You can use a parallel female to a taper male thread, but this is only usually where soft materials are in use that are known to have some give. It is recommended that you should never use a parallel male to a taper female. Using parallel to taper to seal means you are relying on forcing some/excessive distortion into the material of mating surfaces to gain the sealing effect or using adhesives/sealants to assist or both. It's literally like forcing a tapered bore bush onto a a parallel shaft to effect a good seal. For high pressure applications you should go for taper to taper as the sealing area if cut correctly is far greater.

|

| Jon Gibbs | 02/05/2015 15:32:46 |

| 750 forum posts | Posted by Brian Wood on 02/05/2015 09:43:14:

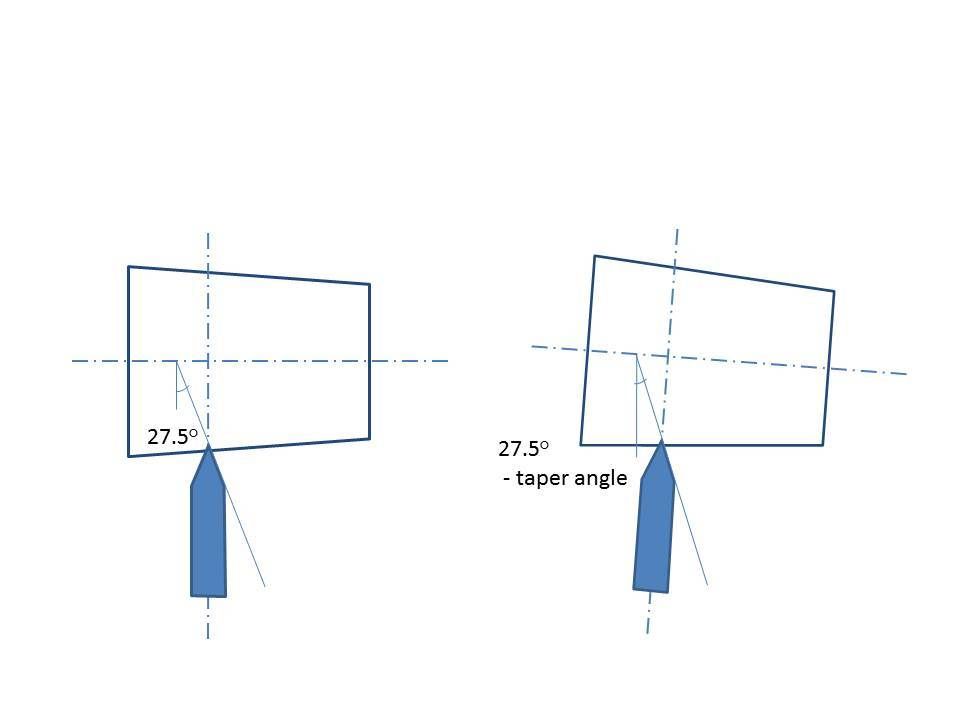

Hello again Jon, Setting the tool perpendicular to the tapered face as you suggest doesn't overcome the basic problem of the geometry of tool travel down the axis of the lathe across an angled surface. Draw a sketch on paper to see what I mean Brian Hi Brian, My point was to set the threading tool perpendicular to the taper axis and obviously change the setting on the the top-slide as well. I realize that cutting perpendicular to the taper face is wrong.

I think that the left hand picture would be as cut with a taper attachment and the second is with tailstock set-over (the whole lot is rotated so that the front face of the taper is parallel with the lathe bed) but I think that they may end up being practically identical. Having said that though I admit that the pitch length really would need to be made lightly longer in the second by a factor of sec(taper angle). Jon Edited By Jon Gibbs on 02/05/2015 15:37:04 Edited By Jon Gibbs on 02/05/2015 15:42:07 |

| Brian Oldford | 11/05/2015 21:59:48 |

686 forum posts 18 photos | May I add what little I know to this discussion. Washout plugs on full size loco boilers have a tapered 11TPI thread. The threads on the plugs are lathe cut using a taper turning attachment and with the tool set as shown on the LH diagram by Jon Gibbs. |

| Baldric | 12/05/2015 08:04:50 |

| 195 forum posts 32 photos | Posted by Brian Oldford on 11/05/2015 21:59:48:

May I add what little I know to this discussion. Washout plugs on full size loco boilers have a tapered 11TPI thread. The threads on the plugs are lathe cut using a taper turning attachment and with the tool set as shown on the LH diagram by Jon Gibbs. Brian, What you have said is slightly wrong, some plugs have the thread cut with the tool at 90 degrees to the centre line, others at 90 degrees to the taper, you do have to make sure you get the correct type, and depending on where they came from may not be 11tpi. See **LINK** for full details. Baldric |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in