Jason's Firefly .46 Build

| Allan Roberts 1 | 10/08/2012 21:06:46 |

| 2 forum posts | Hi jason I have jt finished my Firefly and it started first go. I will run it in and let you know what RPM I can get out of it on a 10/6 prop. Regards Allan |

| JasonB | 13/08/2012 18:32:43 |

25215 forum posts 3105 photos 1 articles | Well I bought one of these from e-bay and fired up the engine yesterday, still with the 10x7 prop. Result was 7,100rpm which I was quite happy with considering teh fuel and its still a new engine Jason

PS Ramon if you are looking in, there is a diesel version on you tube that is basically the same engine with a contra piston and screw so come on lets see a Firefly 0.92 |

| Allan Roberts 1 | 19/08/2012 06:43:55 |

| 2 forum posts | Hi Jason I have my Firefly running now with a home made muffler and it is running at 9,500 after about 30 minutes. Tried to attach some picture with no luck. Regards

|

| JasonB | 27/09/2012 14:30:32 |

25215 forum posts 3105 photos 1 articles | Well I just saw a note on Model Engine News that 60 sets of materials have been sold for this engine, yet only a hand full of builders have put their heads above parapet and I've only seen pictures of one other being built in Singapore. So how about a thread with your builds in it? Jason

PS David can you confirm if Alan is giving any talks and if so what days? |

| David Clark 1 | 27/09/2012 14:55:48 |

3357 forum posts 112 photos 10 articles | Alex is giving talks and will be on the SMEE stand. Don't know who alan is. regards David

|

| David Clark 1 | 27/09/2012 14:58:13 |

3357 forum posts 112 photos 10 articles | Hi There I have forwarded 20 requests for the Firefly material pack. John is running out of material so it will be a while before any more packs will be available depending on demand. regards David |

| Wolfie | 13/10/2012 13:04:32 |

502 forum posts | Excellent tutorial. Cheers |

| Nick Prescott 1 | 22/10/2012 20:43:40 |

2 forum posts 1 photos | Jason, hope you don't mind, but I've printed your advice and pictures off as a sort of 'how to do it' to help me making this, my first engine (my workshop and computer are a long way apart!) Your clear pictures and helpful explanation have inspired me to make a start and I have flycut the body and bored the crankcase front and back - doesn't sound a lot to someone with lots of experience, but it's all a new learning curve for me and your notes have given me the confidence to make a start. Many thanks for taking the time to record your efforts and experiences for those of us with little or no experience. Just hope I don't make too many mistakes I can't dig myself out of - if it runs that would be a bonus too!! Thanks again, Nick |

| JasonB | 23/10/2012 07:23:50 |

25215 forum posts 3105 photos 1 articles | Good to know it was of use, just ask if you have any queries. J |

| mechman48 | 05/02/2013 21:25:55 |

2947 forum posts 468 photos | Jason Fantastic build. As an aside can you, or other members, tell / clarify how you set out a thread as you have, with paragraphs & pics interspersed with decriptions in between. I am assuming that you are writing text then inserting photo from album via the camera icon in the reply box, I'll give it a try with this post & see if it pans out. Rear toolpost project fitted & given a trial run. |

| mechman48 | 05/02/2013 21:35:01 |

2947 forum posts 468 photos |

Well, Well! seems as though I have answered my own question, seems the old grey matter hasn't given up the logical process just yet then Cheers George |

| geoff walker 1 | 26/08/2016 07:50:23 |

| 521 forum posts 217 photos | Hi All This engine looks interesting and a superb set of photos and build details from Jason, well done sir! I notice that the cylinder head with it's integral cooling fins sits on top of the the cylinder liner. Hope this is not a dumb question but does that still provide efficient cooling for the engine? I've seen engines where the head and fins are separate, the fins are lower down and wrapped around the upper half of the liner which to me would seem to give more efficient cooling of the engine. Is this just for larger engines generating more power and heat? Just curious guys that's all, I quite like this engine, bought the 2012 rcm and e with the free plan so am very tempted to have a go and make one. I'll give it a lot more thought and research before I do!!! cheers geoff

|

| JasonB | 26/08/2016 08:13:06 |

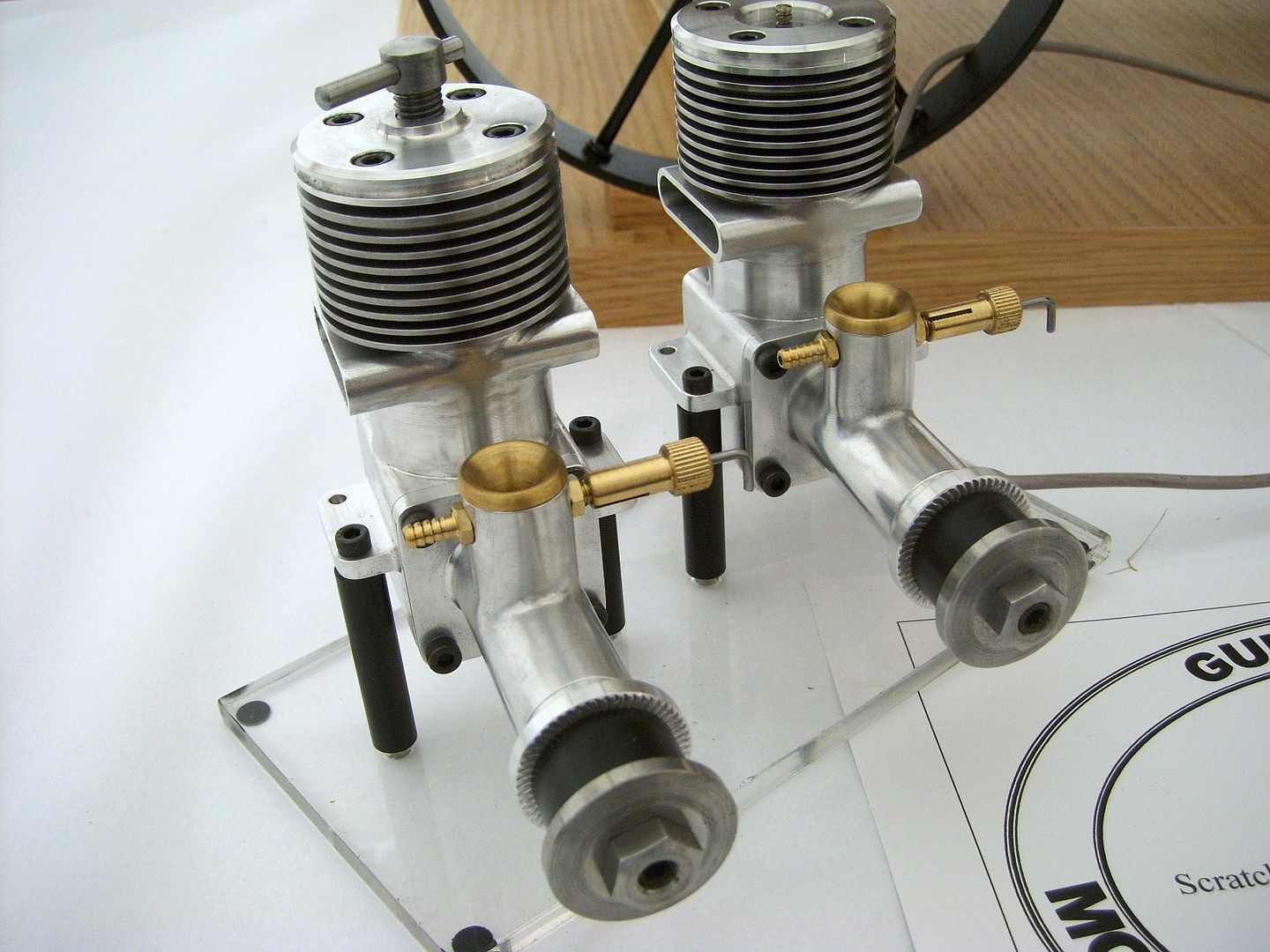

25215 forum posts 3105 photos 1 articles | Geoff, the cooling fins were just a bit of "tarting up" on my part. Alex's original design just had a solid top to the head and fewer but thicker fins around the perimeter and that seems to work OK actually flying in his planes. It is said that most of the heat is generated at the top of the cylinder and head area so the fins are usually concentrated in this area but it does vary quite a bit from one design to another. Take these 5cc ones of mine where there are more fins around the cylinder and none on the top of the head.

Also worth bearing in mind that a lot of the cast crankcase engines will have more in the way of fins than those cut from solid as its easier to produce them and that the modern ABC engines will be reving a lot higher than these engines with the resultant amount of heat generated needing to be dissipated. Engines destined for use in cars and helicopters will have considerably more cooling fins than ones for planes as they tend to be out of the airflow. There are also drawings of the individual parts on Alex's site shoule you need them. Hope you do go ahead and make one and always here if you have any queries

Edited By JasonB on 26/08/2016 08:17:52 |

| geoff walker 1 | 26/08/2016 14:29:05 |

| 521 forum posts 217 photos | Jason, thank you for your reply, informative and appreciated. I do intend to make a firefly and will make a start with some of the peripheral parts like the carb and needle valve body for which I currently have materials. In the meantime I can research materials for the "big bits". I recently made a carb for a Jones .605 and although untested it turned out quite well. The Jones was a considered build but I decided against it as I felt I needed a stepping stone. The firefly may well be that stone. The drawings are no longer available FREE online, now £17.50 from my hobbystore. The links on aw's site draw a blank. I got my copies through a back copy of RCM and E march 2012. If I may one more question for now. From your experience of making and running a firefly could you say that a marine option is feasible? e.g. marine flywheel and water cooled head. I intend to make an aero version first but a marine option would be of interest. I have a small 3ft. r/c launch currently electric powered, so maybe next year? cheers geoff |

| JasonB | 26/08/2016 14:54:18 |

25215 forum posts 3105 photos 1 articles | Thats a pity about the drawings no longer being online. I should think a marine one would be possible, let me have a think and I'll see what I can come up with.

J |

| Kerryn Offord | 28/08/2016 20:53:22 |

| 2 forum posts | Jason (or anyone else who might know), I really appreciated your "tutorial" on how to make an engine. I am a writer in Eric Flint's 1632 Universe (see Eric Flint's "1632", and my "1636:The Chronicles of Dr. Gribbleflotz), and for a story I am working on I need some information on how long it might take for a skilled worker to make, from scratch, a model aircraft engine using a well equipped workshop. A ball park man-hours estimate is all I need.

Thank you for your time Kerryn Offord

|

| JasonB | 29/08/2016 08:16:48 |

25215 forum posts 3105 photos 1 articles | Kerryn, I don't really keep a record of the time I spend on an engine and can often be working on more than one project at a time. The best I can do is take a look at the dates the photos were taken and then base an estimate on say 10-12 hrs in the workshop each week. So say I spent 75% of teh time on that engine On th Firefly I first cut metal on 13/6 and the engine was finished 27/7 so say 6wks = 45-55hrs The pair of 5cc engines just above were built at the same time, starting 25/3 and finished 30/5 so about 9wks = 70-80hrs but 35-45hrs would not be the time for one of them as you save setup time doing more than one. If the engine were being built with a cast crankcase as many are then you could knock 8-10hrs off the Firefly time and something like 25hrs off the pair of 5cc engines. The firefly was also my first glow engine so could make it quicker now and I would say I have an average workshop and certainly not as well equiped as some peoples. J |

| Kerryn Offord | 29/08/2016 08:32:02 |

| 2 forum posts | Jason, thank you very much for the prompt reply. The information you have given is more than enough for my purposes. Kerryn |

| geoff walker 1 | 11/09/2016 21:09:24 |

| 521 forum posts 217 photos | Hi All Does anyone know or tried to calculate the compression ratio for this engine? I understand the basics V1 over V2 , V1 the volume of the cylinder above the piston at bdc and V2 the volume above tdc. I would assume that for both V1 and V2 the volume of the bowl shape in the head will be included in the calculation. If that is so I get the ratio to approx 9 to 1 which seems about right for a glow plug engine from what I have read. My impression is that the bowl shape needs to be machined accurately to the sizes given to ensure a reasonably good ratio for the engine. My engine is coming on well, the crankcase is now almost complete geoff w |

| geoff walker 1 | 09/10/2016 19:24:14 |

| 521 forum posts 217 photos | Hi All Firefly is coming on slowly but surely! Some questions if I may for Jason or anyone who can help. I have never done any cylindrical lapping, this project will be the first time. I assume that the lap used and described by Jason in this thread has one slit which is cut right through and all the other slits just deep enough to take a charge of lapping compound. Would that be right? I was looking at turning the shaft to no.1 morse taper size as I have a morse no. 1 taper reamer I could use for the expanding barrel, turning the O.D. of the barrel about 0.2 under 21mm. How does that sound? Finally what is the lapping powder 320, 600 and a 1000 and where can I get it, preferably in fairly small quantities? Thanks for any help you may geoff |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in