Alternative to PC based Cnc controllers

| Cyril Bonnett | 20/09/2016 11:59:33 |

| 250 forum posts 1 photos | This 'thread' shows one of the problems that we all have today, ask a question and the answers and others problems, ideas and experiences go on for days, nearly 9 in this case, JS's images of his shelves loaded with defunct or not used equipment looks much like a case of 'throwing' money at a problem which I seems is typically of today's society from government down to the garden shed. A big problem today when it comes to using computers is the amount of commercialisation that has crept into everything that involves them, even a simple search for information ends up with reams of useless advertising, advertising that is making someone somewhere money. Linux may be 'free' but the android operating system is based on it, so there is now big 'money' to be made from it. While forums do supply good advise, do help in many ways, sitting reading through them takes time and energy, time and energy that is better spent doing something more constructive! Modern day developers rely on modern day users, if their idea works they are quid's in, if it doesn't then like John and others you are out of pocket with shelves stacked high and the developer moves on to another 'idea'. Crowd funding is the ultimate 'makers' world, letting some else take the risk.

|

| MW | 20/09/2016 12:09:38 |

2052 forum posts 56 photos | Cyril, It sounds like quite a morbid diagnosis of society. In some ways you are showing your own modernity by highlighting how JS threw his money at the problem, years ago, people wouldn't have been so hung up on cost effectiveness, we have all followed the U.S down that garden path of "time is money". Michael W

Edited By Michael Walters on 20/09/2016 12:12:01 |

| John Stevenson | 20/09/2016 12:42:57 |

5068 forum posts 3 photos | It's not so much that time is money in my case although I have to agree, it's broken promises where a developer says buy this it will do all you want but then it doesn't and you are left without any support. When the Smooth Stepper came out threading was promised within a month, then Greg the developer went 'missing' for a whole year and the SS had an earth loop problem which he denied at first. Later the MKll can on the scene to cure this. But guess what, 4 years on and threading is a month away. |

| blowlamp | 20/09/2016 13:01:25 |

1885 forum posts 111 photos | It seems that PlanetCNC and UCCNC now support fully synchronised threading as well as rigid tapping.

Martin. |

| MW | 20/09/2016 13:27:46 |

2052 forum posts 56 photos | Posted by Cyril Bonnett on 20/09/2016 11:59:33:

A big problem today when it comes to using computers is the amount of commercialisation that has crept into everything that involves them, even a simple search for information ends up with reams of useless advertising, advertising that is making someone somewhere money. Linux may be 'free' but the android operating system is based on it, so there is now big 'money' to be made from it.

We shouldn't be so concerned that companies are making money using computers, that's their freedom to do so, theres plenty of "ordinary" people who use the internet without that purpose. I don't think it would be an exaggeration to say that the internet has become the biggest transformation of information availability since the radio or the printing press, and that can only be good for us, if nothing else. For much earlier civilization in Britain, the only places you could find out about anything were the pub or the church. I often find it quite ironic, that the elderly have the stereotype of being the most adverse to the internet/computers when, with their lack of mobility and all they are probably the biggest beneficeries of the technology. Michael W Edited By Michael Walters on 20/09/2016 13:35:01 |

| SillyOldDuffer | 20/09/2016 13:42:34 |

| 10668 forum posts 2415 photos | Posted by Cyril Bonnett on 20/09/2016 11:59:33:

This 'thread' shows one of the problems that we all have today, ask a question and the answers and others problems, ideas and experiences go on for days, nearly 9 in this case, ...The forum is all about creativity and I suppose that leads inevitably into discussion about what motivates us to do stuff. I do model engineering for fun and interest. Others are competitive, or practical, or collectors, and some are in it for the money. I suppose it's inevitable that creative people will want to fully explore a topic, that they won't always agree and that they will want to explore rabbit holes. On the whole I like to see a range of opinion even though it can be irritating to have to wade through guff to find an answer. I can quite see the rambling might spoil the forum for others. I'm doing it now... Sorry, Dave |

| Involute Curve | 20/09/2016 17:52:24 |

337 forum posts 107 photos | Posted by Neil Wyatt on 20/09/2016 10:36:58:

Posted by Involute Curve on 17/09/2016 03:34:47:

I'm having one of these on my to me! Xmas pressy list, it looks a no brainer, I need 4 axis mill to start with, this will replace Mach on the Hurco, but I might go for the lathe one as well, then look around for a lathe to convert. Has a group buy ever been done on this forum?!

Shaun Might be worth starting a discussion with JS.

Neil

I'm well up for this I have the cash sat here waiting for one of the more upmarket ones ie 990MDb or similar, when do you want the cash John I have a smooth stepper here in its original packaging, after all the hooha on the Mach forum I just gave up on the idea, I also have a PayPal receipt for a Mach 4 license that's never been activated for the same reason, I don't even bother with the Mach forums anymore its the same stuff over and over again. Now then after seeing the above systems its a no brainer for me, I went through the watching it do stuff ages ago, now I'm more interested in the quality of the parts and the speed I can get em made, I want to build and ride me bikes more that watch the miller do stuff. I will be looking for 4 axis mill, with MPG, VFD control, step dir for my Geko servo drivers, X,Y,Z, A axis has a Geko stepper driver and not used often, not too bothered about rigid tapping. Shaun |

| John Stevenson | 20/09/2016 21:02:15 |

5068 forum posts 3 photos | Posted by blowlamp on 20/09/2016 13:01:25:

It seems that PlanetCNC and UCCNC now support fully synchronised threading as well as rigid tapping.

Martin. .

Thank you for those links Martin, I wasn't aware that either could do threading on lathe. However having spent nearly an hour perusing both websites and down loading both hardware and software manuals for both I'm non plussed at what they can do. This is starting to get familiar ??

Planet CNC first. The board says it can take spindle encoder in but in the 35 page manual of which 7 pages are spent telling you how to wire all the different types of limits switch [ which aren't actually needed for the machine to run] but no explanation of how to wire the encoder in and not even is it just index pulse or multi line. I suspect it's index pulse only which is not a lot of good for accurate work

UCCNC next

Again hardly any information other than a video of threading with a felt tipped pan. The hardware manual is 21 pages long 19 of which tell you how to connect it up to the ethernet port, [ is it THAT hard ? and if it is WHY ? ] Then the last two pages tell you what the terminals are in flowing terms like output 1, 2,3 etc for Port 1, poert 2 is identical but no a clue where to connect to ?

So please excuse me if I don't throw 215 Euros for the UCCNC board and software plus breakout board and another 263 Euro for the Planet offering.

I don't think the shelf can stand any more white elephants.

Seriously lads it's this total lack of support that is killing this. They know if or how good it works but it's a closely guarded secret. |

| John Stevenson | 20/09/2016 21:27:47 |

5068 forum posts 3 photos | Reply to Sam and general to highlight what I mean but this is no detraction of the fact that LinuxCNC works, and works well, just the hoops you have to jump thru which mere mortals cannot achieve.

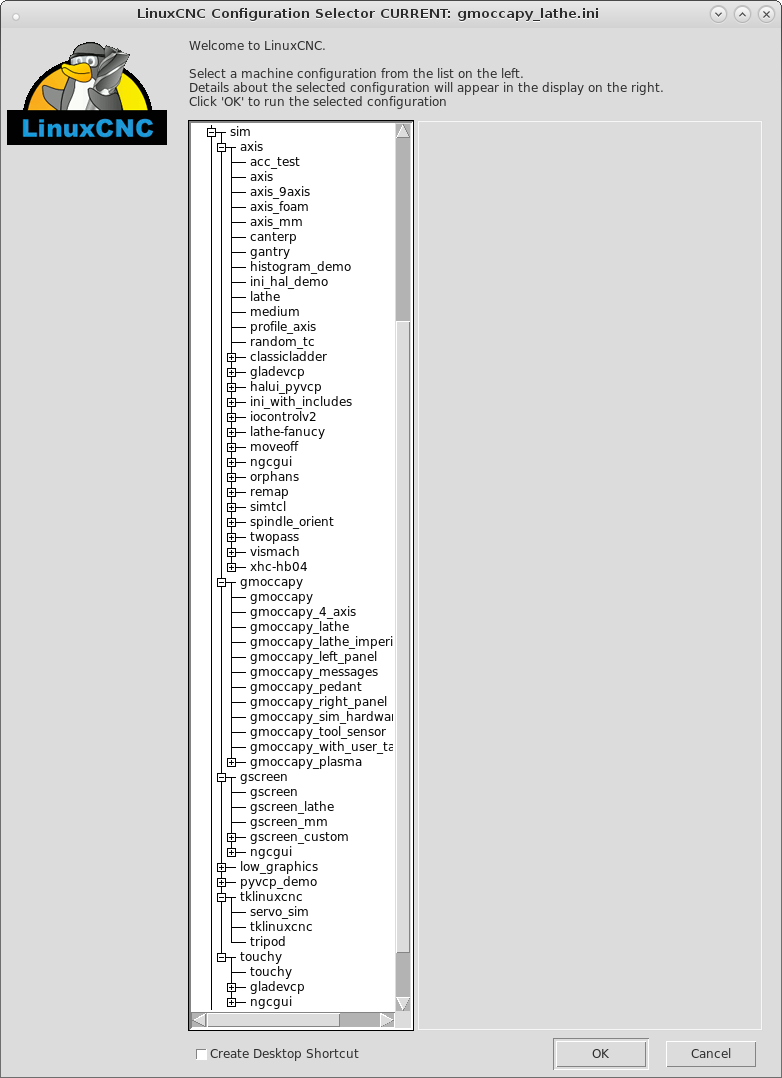

First of all because many haven't seen Linux out of the box this is it.

There are other screens but this screen called axis is the default. Any other screens are not just click and select you need to do work inside the program.

Now imagine you are a punter spending serious coin on a CNC conversion or machine and you are hesitant whether you can even use it and someone shows you this above.

Not one person I have shown it to has said "Yes I like that we'll go for it " I get remarks like where is the start and stop buttons. Even had a guy ask me where the readout is, I think he was expecting DRO type boxes. One guy was that amazed he said it looked like Etch-a-sketch on acid.

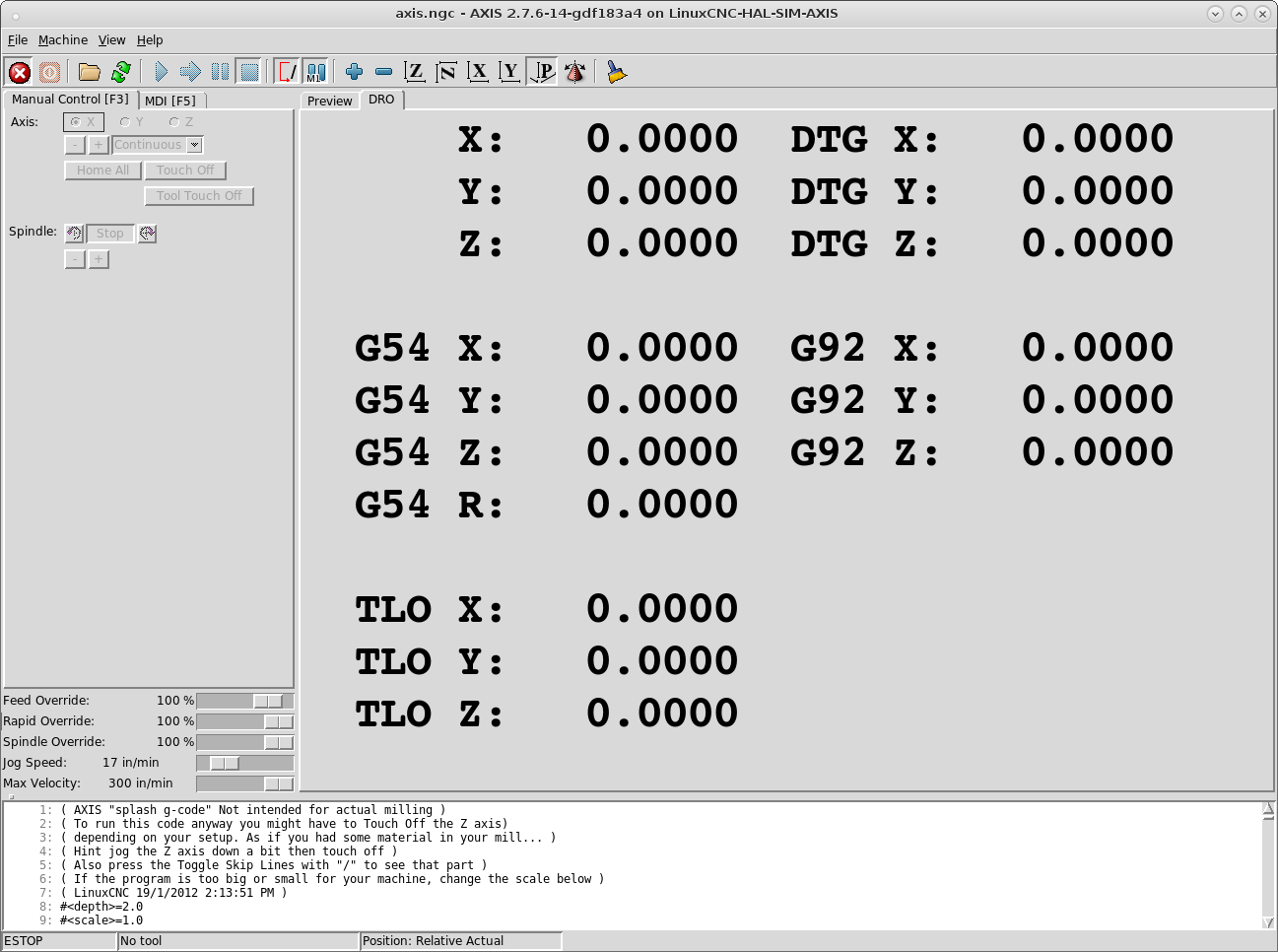

Now this is also a Linux screen.

I think it has been written to look a lot like Mach3 and as such it would have a good following for anyone making the change. However if you go on the Linux forum it's now into 5 pages and so far I don't think anyone has got it working which is a shame and remember the guys on there are dedicated and very clued up so doesn't give people like me much chance and more importantly how could I support this to a user who knew even less than me, if that's possible.

Now Tormach realising that they needed a lathe controller took Linux CNC, re- wrote the trajectory planner which had been broken for about 3 years and gave it back to the community, then wrote their own screens. This is the front screen.

Nicely laid out, menu bar across the middle for files, settings, tools and conversational for everyday jobs where you don't need to draw the part, things like pockets and profiles.

Which setup would you choose ? |

| Another JohnS | 20/09/2016 23:57:51 |

| 842 forum posts 56 photos | Posted by John Stevenson on 20/09/2016 21:27:47:

First of all because many haven't seen Linux out of the box this is it.

.... Even had a guy ask me where the readout is, I think he was expecting DRO type boxes. Hint: Click on the tab that says "DRO". You'll get a huge DRO replacing that backplot screen. Simple. BTW - I really like the Tormach screen, mainly for their take on conversational programming. (I'll not argue that the Axis screen is pretty, but really, who cares? It has everything there, and you can actually do a few neat things with it. It's like having an old lathe. Do you care if it is pristine, or do you care that it works reliably and accurately? Give me a solid machine over a shiny new one ANY DAY, but then, I use mine, I don't spend hours shining them) See you! The Colonial JohnS.

|

| sam sokolik | 21/09/2016 01:56:34 |

| 126 forum posts | I am the wrong person to comment on axis. It is the first gui I used when I started linuxcnc - and I still use it. I love it. I can add tabs and panels to customize it to my needs. there are a ton of example configs in linuxcnc. Here is a sample.

Here is axis with the DRO tap active

Here are some of the other gui - Gmoccopy (a bunch of views)

Gscreen is one of the build your own frameworks

You can easily add your own panels to existing gui

Touchy

Some older ones

sam |

| John Stevenson | 21/09/2016 08:28:22 |

5068 forum posts 3 photos | Posted by sam sokolik on 21/09/2016 01:56:34:

I am the wrong person to comment on axis. It is the first gui I used when I started linuxcnc - and I still use it. I love it. I can add tabs and panels to customize it to my needs. there are a ton of example configs in linuxcnc. Here is a sample.

sam

And this folks is the problem.

Whilst the developers are over the moon with the basic default screen NOTHING will move forward.

Now why if it's that good didn't Tormach use it ?

Because they knew their customer base wouldn't buy or use it - end of story. Yes other screens are available but they don't come setup like that out of the box and there are more people that want to use machines than play with computers..

The list is impressive Sam but I'll bet it's gone over most peoples heads on this forum |

| Neil Wyatt | 21/09/2016 17:46:03 |

19226 forum posts 749 photos 86 articles | Posted by sam sokolik on 21/09/2016 01:56:34:

I just love those meaningful names that make it so easy to select what you want/need Neil |

| Another JohnS | 21/09/2016 18:01:24 |

| 842 forum posts 56 photos | Posted by Neil Wyatt on 21/09/2016 17:46:03:

I just love those meaningful names that make it so easy to select what you want/need Neil, as editor of MEW, I know that you keep in mind that beginners to our hobby have difficulty with what to us old hats seems simple. I can remember getting tripped up over the "AF" symbol on drawings. Amongst other things. If *any* of this was really dead easy, there'd be no sense of accomplishment of learning and mastering a new skill so we'd probably not do it. (and, yes, what Sam posted and you replied to is simple, once you understand what's going on) John. |

| Paul Barrett | 21/09/2016 21:02:49 |

| 59 forum posts 16 photos | I am also interested in these controllers as an alternative to PC's and I think they will be the future. I am especially interested in one for the CNC laser i am building. I see there are several available and most lasers machines from China seem to use them. There is only one problem for me though and that is controlling the z axis for the lifting table. My machine is about 80% built and I am having trouble deciding how to raise the table. The table is 1200 x 600mm and is raised and lowered by screw jacks and guides at each corner. My original idea was to drive all screw jacks using one motor and a toothed belt but I have not seen one big enough in gt2, gt3, htd3 etc. It would need to be over 4 metres long. My current idea is to use 4 motors, one for each jack. I assume I would use 4 drivers with the 4 motors. So, can I connect 4 drivers to one output from the controller? If not then I assume these stand alone controllers will not work for me. I guess I would have to use a breakout board with at least 6 axis so I can slave 4 together and use a PC with some form of software. Anyone got any ideas please. |

| Frances IoM | 21/09/2016 21:53:01 |

| 1395 forum posts 30 photos | is it possible to use a slaved follower - use a stepper motor to move a reference away from table but measure this movement and servo control a large motor (maybe heavily geared) to move toothed belt to close the gap - I presume toothed belt arranged rather like these router lifters used in woodworking to precisely set height of tool - obviously any movement would be slow and rate controlled Large torque at slow speed with possibility of full software control might fit a large direct drive motor (discussed in an earlier thread maybe even off an old washing machine!) |

| Keith Long | 21/09/2016 22:32:42 |

| 883 forum posts 11 photos | Paul - have a look at the Brammer drive belts website - link - they do some belts as standard to pitch lengths in excess of 4 metres, but also do open end belting on the roll that can be joined by either spicing to make a continuous belt, or with a mechanical fastening if it can run in a back and forth motion without making a complete circuit. I was looking at similar material recently with a view to motorising a theatre stage curtain, and at the time the prices I was seeing were very reasonable. |

| Bazyle | 21/09/2016 22:58:34 |

6956 forum posts 229 photos | Wasn't Sam trying to point out the flexibility so that if someone wants a Tormach clone screen they can (copyright aside) make one, or get someone to interested in doing it. Of course too much choice can be a problem for some. |

| blowlamp | 21/09/2016 23:20:54 |

1885 forum posts 111 photos | Posted by John Stevenson on 20/09/2016 21:02:15:

Posted by blowlamp on 20/09/2016 13:01:25:

It seems that PlanetCNC and UCCNC now support fully synchronised threading as well as rigid tapping.

Martin. .

Thank you for those links Martin, I wasn't aware that either could do threading on lathe. However having spent nearly an hour perusing both websites and down loading both hardware and software manuals for both I'm non plussed at what they can do. This is starting to get familiar ??

Planet CNC first. The board says it can take spindle encoder in but in the 35 page manual of which 7 pages are spent telling you how to wire all the different types of limits switch [ which aren't actually needed for the machine to run] but no explanation of how to wire the encoder in and not even is it just index pulse or multi line. I suspect it's index pulse only which is not a lot of good for accurate work

UCCNC next

Again hardly any information other than a video of threading with a felt tipped pan. The hardware manual is 21 pages long 19 of which tell you how to connect it up to the ethernet port, [ is it THAT hard ? and if it is WHY ? ] Then the last two pages tell you what the terminals are in flowing terms like output 1, 2,3 etc for Port 1, poert 2 is identical but no a clue where to connect to ?

So please excuse me if I don't throw 215 Euros for the UCCNC board and software plus breakout board and another 263 Euro for the Planet offering.

I don't think the shelf can stand any more white elephants.

Seriously lads it's this total lack of support that is killing this. They know if or how good it works but it's a closely guarded secret.

John S and others that may be interested. The 27 page PlanetCNC USB hardware PDF manual is here. Page 7 has a good picture of the board showing the various connections quite clearly, page 11 illustrates the spindle index and encoder A & B terminals equally well. The 210 page software PDF manual is here. Looking thorough the G-Code list shows implementation of G33 & G76 threading support on pages 179 & 184 respectively. I've not looked deeply into the capabilities of the UNCCNC system but it appears to be roughly equal with that from PlanetCNC. While the other Chinese made self-contained units look really nice, they're still going to need wiring up and have a multitude of parameters set before they can be used. I think this part is going to be just as difficult for a inexperienced installer as something like the systems I've highlighted.

Martin. |

| Zebethyal | 22/09/2016 14:21:28 |

| 198 forum posts | @Paul, For a laser controller, one of the popular DSP options is the AWC807C - I bought mine last year from SanWeiHouse on AliExpress for $283.10 (about £190.00 at the time) with free shipping via DHL to the UK. It arrived in 7 days. It avoided customs attention because they stuck it in a battered second hand box and declared it at $10.00! I hasten to add that at no point did I even hint at any of this subterfuge to the seller - this was all their own doing. I bought the 'lite' version of the controller for use on my buildlog.net laser cutter, it has control for 4 axes and 2 lasers. The full version costs a bit more and has control for 6 axes and 4 lasers. My Table is only 560x410mm, so a bit smaller than yours, and uses a 1524mm 762tooth GT2-2 belt to drive 4 lengths of M6 studding via a 3.2:1 reduction from the Z axis stepper. It may also be possible for you to run 2 motors off the same driver using a reduction drive and a looped belt for each - I use a single StepStick driver for both Nema 17 motors on the Z axis of my 3D printer without issue. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in