Lathe screwcutting

| Plasma | 10/03/2019 17:11:51 |

| 443 forum posts 1 photos | The weekend has been a thread free zone as I'm building a wind vane for the front of the house and both lathes have been turned over that job for a few days I will set up for conventional thread cutting and send in some images. I'm looking at using hss tooling rather than insert but will try both the see where I get. Is there a dedicated tool bit holder for threading tools in square section hss? |

| John Rudd | 10/03/2019 18:50:17 |

| 1479 forum posts 1 photos | Posted by Plasma on 10/03/2019 17:11:51:

I'm looking at using hss tooling rather than insert but will try both the see where I get. Is there a dedicated tool bit holder for threading tools in square section hss? HSS thread cutting tools are generally ground from a blank....Use your fishtail to grind the correct profile for 55-60 degrees Edited By John Rudd on 10/03/2019 18:51:17 |

| Hopper | 10/03/2019 22:51:17 |

7881 forum posts 397 photos | And no dedicated holder, just held in the conventional manner like a turning tool. |

| Plasma | 11/03/2019 06:46:48 |

| 443 forum posts 1 photos | Thanks Hopper, I use a multifix tool post and its tricky to put small tool bits in. Sparey shows a home made sprung threading tool bit holder which is supposed to do a sterling job due to the flex in the neck allowing for fine cuts by repeating passes with no infeed. I just wondered if anyone had seen a commercial equivalent. |

| JasonB | 11/03/2019 07:42:01 |

25215 forum posts 3105 photos 1 articles | The sprung cutters were available commercially but don't know of anyone selling them now. If you find it hard holding small bits then just mill a channel in some 16mm square stock and add some tapped holes for grub screws. You can then hold small square HSS blanks in that and put the 16mm block in your larger tool holder. One with a round hole will also be useful for tools ground from round material like old cutter shanks. |

| Hopper | 11/03/2019 08:00:38 |

7881 forum posts 397 photos | A Mulitfix should hold a length of 1/4" HSS tool bit ok. You need to put some packing pieces underneath it of course. It's best if the bit is long enough to have two clamping screws bearing on it. |

| Niels Abildgaard | 11/03/2019 08:14:50 |

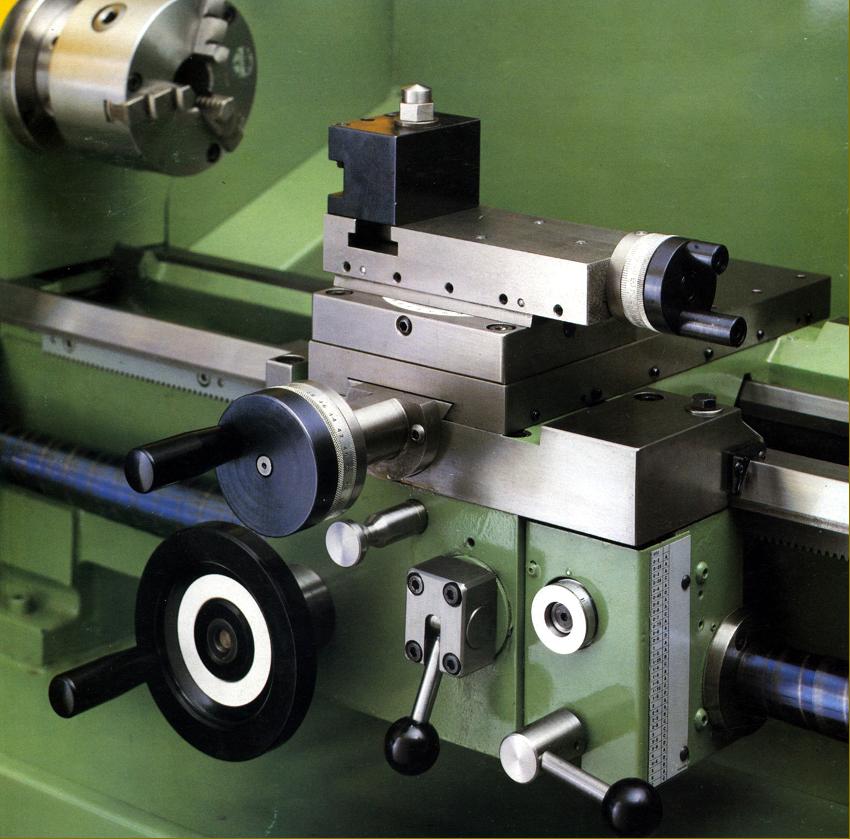

| 470 forum posts 177 photos | Posted by JasonB on 07/03/2019 16:17:13:

Edited By JasonB on 07/03/2019 16:51:55 Thats an awfull nice picture of a very well engineered slide system. Been there myself

Found this from Boxford

It does not show the Boxford locking screw/cone very well.Does someone have a picture of underside of compound slide base with integral cone please? Edited By Niels Abildgaard on 11/03/2019 08:20:32 Edited By Niels Abildgaard on 11/03/2019 08:21:14 Edited By Niels Abildgaard on 11/03/2019 08:22:37 |

| Rik Shaw | 11/03/2019 10:51:43 |

1494 forum posts 403 photos | Plasma - I have a lot of small section HSS and made this holder for it. It gets used a lot primarily because its less time consuming to form a tool in small stuff. To give an idea of size the HSS bit in place is 3/16" square Rik

|

| SillyOldDuffer | 11/03/2019 13:45:57 |

| 10668 forum posts 2415 photos | Posted by Plasma on 11/03/2019 06:46:48:

Sparey shows a home made sprung threading tool bit holder which is supposed to do a sterling job due to the flex in the neck allowing for fine cuts by repeating passes with no infeed. I just wondered if anyone had seen a commercial equivalent. Sparey has one fault - he wrote 70 years ago! Although most of his advice remains fresh, his books have a few obsolete ideas, and - of course - he doesn't cover technology that became available after his time, notably carbide inserts. Hand grinding a 60° or 55° pointy threading tool in HSS requires practice and not everyone is good at grinding. Give it a try, you can get started making external threads with quite a poor tool shape. The result may not be beautiful, or strong, or a tight fit, but they do work. Once you've made a few threads you can concentrate on improving them, most likely with better grinding and lathe technique. I don't think many people bother with spring holders, but they do pop up second-hand or you could make one. Personally I find it easier to use indexed thread inserts, these cut properly shaped thread profiles, and can be changed quickly without interrupting my workflow if the point gets damaged. Deciding between HSS and Carbide depends on your interests, goals and equipment. Some love HSS, others swear by inserts. As is the way with hobbies, I've maximised the cost by insisting on both... Dave |

| JasonB | 11/03/2019 20:45:31 |

25215 forum posts 3105 photos 1 articles | Niels, this video shows the cone arrangement and problems with it. |

| Niels Abildgaard | 11/03/2019 21:32:56 |

| 470 forum posts 177 photos | Posted by JasonB on 11/03/2019 20:45:31:

Niels, this video shows the cone arrangement and problems with it. Jason,Thank You for link. It is as I thougth but it is nice to see it clearly. Material looks cast Iron to me and I am using mild steel,and ca 18 mm thick I have a piece of 16MnCr5 ready. I do not use QCTP with tool overhang either so I will make one more for a friend. |

| Robin Graham | 11/03/2019 23:51:56 |

| 1089 forum posts 345 photos | Plasma, I asked a similar question a while ago - I was getting ragged threads with carbide inserts. The advice I had was to go faster and/or get better inserts. I'm not sure that I've got to the bottom of it yet, but my experience was that better inserts made a big difference, and going faster helped too. I should have been more systematic, but when you hit on something that works for what you're doing it's hard to backtrack. The 41x1.5 mm thread shewn in my earlier post was cut at 550 rpm with a 4.5mm relief. Buttock clenching territory I know, about 325 milliseconds (guess) to snap the half nuts open, but it can be done. And itb gave a smooth thread. Robin

Edited By Robin Graham on 12/03/2019 00:35:45 |

| Martin Connelly | 12/03/2019 09:30:30 |

2549 forum posts 235 photos | This is slightly off topic but is connected to the video and the issue with the tool post loosening. I had a problem with the cam action, i felt it was not locking the way it should so I made a new plunger. I made it long enough for the cam action to go just over the peak of the lobe and so make it lock in place. Martin C |

| Chris Trice | 12/03/2019 10:12:15 |

1376 forum posts 10 photos | I've had a similar experience with an identical QCTP clone as featured in the video. I machined a few thou off the inner surface of the sprung Tee piece where it fits into the tool holder slot so the cam shaft rotated a little further. It makes it pull the holder into the post harder and the extra friction makes the cam less likely to loosen. Having said that, it mostly languishes in a box because both it and the associated holders don't fit the two genuine Dickson posts I have very well and virtually all the rest of my tooling is held in genuine Dickson holders. Edited By Chris Trice on 12/03/2019 10:12:58 |

| Plasma | 12/03/2019 11:18:27 |

| 443 forum posts 1 photos | Hi again. I set up this morning to cut an M10 x 1.0 fine thread in brass. I set the change wheels, gear box and found the correct pick up point. Speed was 292 rpm and the tool is the insert type I mentioned in earlier posts. Top slide set parallel and infeed by cross slide. Half nuts engaged at correct pick up point, cross slide backed out, manual return to start point, infeed to 0 plus new cut , and so on and so forth. Worked perfectly and produced a thread which fits well in a tap cut nut. Look like back to basics is the way forward. Any thoughts on retracting tool holders? Relieved of Barnsley

|

| Phil Whitley | 12/03/2019 11:29:44 |

1533 forum posts 147 photos | Dear Relieved of Barnsley, just another point which I don't think has been covered above. Is there a shear pin in your gear train? My colchester has one and it needs to be in good condition and a good fit or the thread gearing will be slightly out of sync with the rotation, check in your manual. I had a problem with mine on the Colchester student. frustrated of Driffield (two week enforced holiday after coming off second in a scrap with an angle grinder and wire cup brush!) |

| Hopper | 12/03/2019 12:30:27 |

7881 forum posts 397 photos | Posted by Plasma on 12/03/2019 11:18:27:... ... Speed was 292 rpm and the tool is the insert type I mentioned in earlier posts. ... Good work! You should now have another practice go but knock the speed down to somewhere below 100 rpm to see if the insert still cuts ok. Much easier to screwcut up to a shoulder at low rpm if you can. 292 rpm is great on long jobs etc but could be sudden death at a shoulder if you are not quick off the mark every single time. No margin for error, or tripping over the cat. |

| Neil Wyatt | 12/03/2019 13:12:37 |

19226 forum posts 749 photos 86 articles | Not sure if anyone has mentioned this before, bu I note the problem was multi-start thread AND bad finish. If you are a few passes through a thread and lose position the next cut is going to go in very deep so bad finish as well as a multi-start is to be expected. Neil |

| Plasma | 12/03/2019 14:07:59 |

| 443 forum posts 1 photos | Hi Neil yes you're right. I took heart care with the pick up point this try and everything was fine. Also not setting at an angle seemed to help with the maintaining of infeed. The boxford has a pull out thread indicator to give different pick ups for different threads so that has to be carefully observed. That's why I'm asking about retracting tools holders, is it worth the outlay to make the process a bit more streamlined? Certainly you tube shows one being used to good effect. Cheers mick |

| Andrew Johnston | 12/03/2019 14:41:52 |

7061 forum posts 719 photos | Posted by Neil Wyatt on 12/03/2019 13:12:37:

Not sure if anyone has mentioned this before, bu I note the problem was multi-start thread AND bad finish. Yes they did, on page 1. Either nobody read it, or they didn't pick up on the underlying logic, as there was no response. Andrew |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in