Tail alignment and gear handle play

| Hopper | 30/06/2015 01:24:26 |

7881 forum posts 397 photos | Posted by Nitai Levi on 29/06/2015 16:57:53:

So after some very careful scraping and lapping... I got it down to about 0.11mm high. This will take a while so I'll continue and see how it goes. Thanks again Yes, 'tis the nature of scraping to take a while! But I think, like Neil says, you are much better to spend some time scraping down the tailstock than disturbing the headstock alignment. Have fun! |

| Hopper | 30/06/2015 01:31:55 |

7881 forum posts 397 photos | Posted by Michael Gilligan on 29/06/2015 13:36:51:

Posted by Neil Wyatt on 29/06/2015 11:48:03:

P.S. the great pragmatist, LBSC, knew many of his readers wouldn't have a micrometer so suggested turning the test bar until you felt the same drag on a calliper pulled over each end, slightly tight. . Neil, No disrespect to LBSC ... I wouldn't dare, around here ... but that's not exactly a novel approach: it's how callipers were meant to be used. MichaelG. My old man always used calipers. I guess that is the way they used to do it in the old days. Each piece was made to fit its mating part rather than to an exact size, clearances done by "feel" and so forth. "Feel" was considered an essential part of being a good tradesman. Something that has been lost in the CNC age. |

| Eugene | 30/06/2015 09:19:26 |

| 131 forum posts 12 photos | "When Whitworth was working on The Standard Inch, he devised his "millionth machine" to compare different standard bars.

It 's accuracy depended on the feel of a scraped disc passing between the scraped surfaces of the sample bar and that of a facing piece. Whitworth claimed a skilled operator could indeed detect a difference of one millionth of an inch between "standards". Link to the free E-book description **LINK** Eug Edited By Eugene Molloy on 30/06/2015 09:24:57 |

| Bowber | 30/06/2015 09:50:51 |

| 169 forum posts 24 photos | Posted by Hopper on 30/06/2015 01:31:55:

My old man always used calipers. I guess that is the way they used to do it in the old days. Each piece was made to fit its mating part rather than to an exact size, clearances done by "feel" and so forth. "Feel" was considered an essential part of being a good tradesman. Something that has been lost in the CNC age. Yes but there's nothing like being able to get 2 parts for the same vehicle and they both fit. Steve |

| Michael Gilligan | 30/06/2015 10:28:17 |

23121 forum posts 1360 photos | Posted by Eugene Molloy on 30/06/2015 09:19:26:

Link to the free E-book description **LINK** . Eurgene, Good to see someone else referencing Whitworth's work. Unfortunately; Google seems to have 'done the dirty' on this e-book .... An alternative provider is available. MichaelG. |

| Russell Eberhardt | 30/06/2015 10:39:08 |

2785 forum posts 87 photos | Posted by Hopper on 28/06/2015 08:17:48:

Once the lathe is bolted down, put a piece of, say, 25mm diameter bar by at least 180mm long in the lathe between centres. It must be between centres, not held in the chuck. Then by taking fine cuts along the length of the bar, you can measure it and determine if it is turning parallel within reasonable limits. If the test piece comes out parallel within limits (say, .001" or less) there is no need to adjust anything any further. Err.. I think you have that the wrong way round. You need to turn work held in the chuck to test for bed twist. Russell. |

| Hopper | 30/06/2015 13:04:31 |

7881 forum posts 397 photos | Posted by Russell Eberhardt on 30/06/2015 10:39:08:

Posted by Hopper on 28/06/2015 08:17:48:

Once the lathe is bolted down, put a piece of, say, 25mm diameter bar by at least 180mm long in the lathe between centres. It must be between centres, not held in the chuck. Then by taking fine cuts along the length of the bar, you can measure it and determine if it is turning parallel within reasonable limits. If the test piece comes out parallel within limits (say, .001" or less) there is no need to adjust anything any further. Err.. I think you have that the wrong way round. You need to turn work held in the chuck to test for bed twist. Russell. We are not checking for bed twist. We are checking for tailstock alignment. Bed twist is best checked with a precision level. Holding a long test piece in the chuck is mostly used to check for headstock mandrel alignment with the lathe axis. Turning a test piece between centres is often regarded as the best way to check for tailstock alignment. Unlike tests with dial indicators, it tests the lathe under working conditions with cutting forces applying pressure to the various parts. But as with most things, there is more than one way to skin a cat I am sure.

|

| Hopper | 30/06/2015 13:19:36 |

7881 forum posts 397 photos | Posted by Hopper on 30/06/2015 13:04:31:

Posted by Russell Eberhardt on 30/06/2015 10:39:08:

Posted by Hopper on 28/06/2015 08:17:48:

Once the lathe is bolted down, put a piece of, say, 25mm diameter bar by at least 180mm long in the lathe between centres. It must be between centres, not held in the chuck. Then by taking fine cuts along the length of the bar, you can measure it and determine if it is turning parallel within reasonable limits. If the test piece comes out parallel within limits (say, .001" or less) there is no need to adjust anything any further. Err.. I think you have that the wrong way round. You need to turn work held in the chuck to test for bed twist. Russell.

Hmm, no, I think I have it right way around. We are not checking for bed twist. We are checking for tailstock alignment. Bed twist is best checked with a precision level. Holding a long test piece in the chuck is mostly used to check for headstock mandrel alignment with the lathe axis. It can show bed twist too, but you don't know for sure that the error is not caused by headstock misalignment. Plus, long unsupported test bars in small lathes tend to flex and bend and chatter and carry on on the usupported far end so its hard to get an accurate cut and reading. Turning a test piece between centres is often regarded as the best way to check for tailstock alignment. Unlike tests with dial indicators, it tests the lathe under working conditions with cutting forces applying pressure to the various parts. But as with most things, there is more than one way to skin a cat I am sure.

Edited By Hopper on 30/06/2015 13:21:28 |

| Hopper | 30/06/2015 13:32:23 |

7881 forum posts 397 photos | Posted by Eugene Molloy on 30/06/2015 09:19:26:

"When Whitworth was working on The Standard Inch, he devised his "millionth machine" to compare different standard bars.

It 's accuracy depended on the feel of a scraped disc passing between the scraped surfaces of the sample bar and that of a facing piece. Whitworth claimed a skilled operator could indeed detect a difference of one millionth of an inch between "standards". Link to the free E-book description **LINK** Eug Edited By Eugene Molloy on 30/06/2015 09:24:57 That is a great book. Thanks for the link. Downloaded no problems. Funny, I was just thinking about Mr Whitworth creating order out of chaos this afternoon after watching "Mad Max Fury Road" with all its steampunk inspired machinery and mechanisms. Millionth of an inch by feel, that's pretty good eh. I reckon I can feel a half a thou in a big end bearing on a motorbike engine but have a ways to go yet to get to Mr Whitworth's standard. Feel was something the old time tradesmen prided themselves on. One little dodge on old fella taught me as an apprentice toolmaker was when feeling for tiny ridges or imperfections on the surface of a stamping die, particularly around radiuses, use the middle finger of your left hand (if you are right handed). It has less callous on it than the fingers of the right hand, or than the index finger of the left hand and so gives a more sensitive feel. One of those things I'm sure they don't teach in college today. |

| Neil Wyatt | 30/06/2015 18:01:18 |

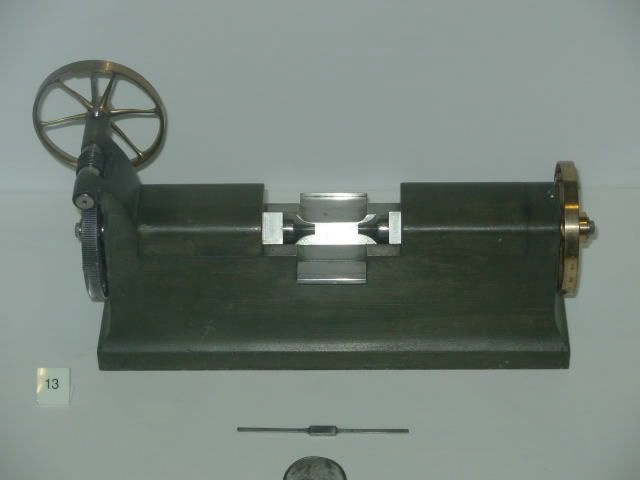

19226 forum posts 749 photos 86 articles | Just for completeness, these are the various arrangements for each of Dr Schlesinger's lathe tests. Click for a larger view. Neil |

| Michael Gilligan | 30/06/2015 20:31:59 |

23121 forum posts 1360 photos | Posted by Hopper on 30/06/2015 13:32:23:

Posted by Eugene Molloy on 30/06/2015 09:19:26:

Link to the free E-book description **LINK** That is a great book. Thanks for the link. Downloaded no problems . Hopper, That's rather curious !! If I go to Eugene's linked page, it inludes the statement 'No eBook available' ... maybe I'm seeing a special version of the page, especially for iOS users. MichaelG.

|

| john carruthers | 01/07/2015 08:09:47 |

617 forum posts 180 photos | this took me to a viewing page which I then downloaded; |

| Michael Gilligan | 01/07/2015 08:24:35 |

23121 forum posts 1360 photos | John, Yes, that's the alternative source that was provided in my previous thread [linked earlier]: What I found curious was that Hopper had managed to download via Eugene's link. MichaelG. |

| Hopper | 01/07/2015 08:52:41 |

7881 forum posts 397 photos | Posted by Michael Gilligan on 01/07/2015 08:24:35:

John, Yes, that's the alternative source that was provided in my previous thread [linked earlier]: What I found curious was that Hopper had managed to download via Eugene's link. MichaelG. My apologies. It was your link that I downloaded from. Got so absorbed in both Mr Whitworth's history and the Shelley issue on the linked thread I clean forgot where I was. |

| Michael Gilligan | 01/07/2015 09:11:26 |

23121 forum posts 1360 photos | Posted by Hopper on 01/07/2015 08:52:41:

My apologies. It was your link that I downloaded from. Got so absorbed in both Mr Whitworth's history and the Shelley issue on the linked thread I clean forgot where I was. . That's fine then; thanks for confirming. No need for apologies; I was just worried that I may have stumbled upon some odd Google-v-Apple behavior. MichaelG. |

| Ajohnw | 01/07/2015 11:41:57 |

| 3631 forum posts 160 photos | Posted by Neil Wyatt on 30/06/2015 18:01:18:

Just for completeness, these are the various arrangements for each of Dr Schlesinger's lathe tests. Click for a larger view. Neil Good to see that a between centre test bar is used. Easy to make pretty accurately even on a lathe that is a bit out. Turning can be substituted for the other test bar but would be best to sort out head stock bearings first. In fact it's safer to at least check that before doing anything else. Not come across the wire and weight before. Interesting one. Really the other one is to turn in several ways first as that can help interpret results. John - |

| Pete | 02/07/2015 23:50:47 |

| 128 forum posts | Finally!!!!!!!! Hopper has injected some proper technique and much needed logic into this thread. There's been a lot of other good information posted also. My apology's but I do think my post might get a bit long winded. I fully understand the OP's desire to adjust his lathe to get the best accuracy possible. I did the same with my little Emco compact 5 lathe, but I did so only after reading that Conolly book more than a few times until I understood as much of the techniques as possible. And most of what's on these hobby forum's is incorrect compared to what Conolly or Schlesinger have to say. I also got fooled for more than a few hours of wasted testing with a light weight dial test indicator bending a quite heavy mounting rod under the effects of gravity. That's all too easy to miss to be honest, and there's really no simple way to know for sure that gravity is or isn't affecting your results when swinging a DTI from the head stock. What I do now is turn a piece of scrap down to within .001"-.002" or the same in metric of either the tail stocks barrel's outside diameter, or the outside diameter of a morse taper blank arbour that fit's the tail stocks female morse taper. You then measure both of your plugs diameter and the tail stocks barrel or arbours parallel section.as accurately as you can with your very best micrometer. Then you use both the lathes carriage and the cross slide to run the finger of a .0001"s reading DTI across both diameters at both the head stock and tail stock. Simple addition or subtraction to account for any minor difference's in sizes for each diameter will then give you the exact numbers of your tail stocks position. I don't know of a simpler or better method that is any faster, more accurate, or easier to do that you can then be 100% positive your test numbers aren't being swayed by those gravity effects. But the tail stocks centerline height is just only one single check. Just as important you also need to use that DTI to check that your tail stocks barrel isn't pointing to the left or right, uphill or downhill, and if that barrel move's it's position between locked and unlocked, or extended and retracted. Some will say it's only a mini lathe so what's the point of all that? Well it's impossible to try to compensate or correct for any errors if you don't know if they do or don't exist, or even how much those errors might be. And unless your test numbers are 100% repeatable, then your methods will be highly suspect to the point of being useless. Machine tool alignment, and especially lathe alignment and and that mostly misunderstood "lathe leveling" is probably very close to the number 1 topic on almost any hobby machining forum out there today. And FAR TOO MANY will try and answer to the best of there ability what they think is correct. Yet the majority are basing those answers without taking the time to at least read what both Schlesinger and Conolly have to say, and who ARE those recognised authority's on the subject. Schlesinger's alignment and test procedures are available for free on the net. Possibly the Conolly book might be also. But almost all of us should be able to get a copy to read of the Machine Tool Reconditioning book through something called the "Inter Library Loan" system. I do own my copy, but it is almost $100 to buy it even today through Industrial Press. The book is boring to the extreme in large parts of it, but it will properly educate you so your answers in threads of this type are logical and well thought out reasoning. (Or at least I hope mine are) But in my opinion buying that book was the very best $100 I've ever spent on my shop and education about this so I finally did understand what the actual requirements really are. The subject is vastly more complicated than most understand I think. But those who haven't read it and then understand what's required are pretty obvious when they recommend (with the best of intention's) methods that are incorrect in these threads. Lapping slides etc. is or would be just one example, yes it will make things much smoother, but there's zero control over exactly where and how much material your removing. Very light lapping can probably work after your initial corrections have been done Trying to maintain or even correct the alignments on a lathe in all 3 dimension's at the same time can't possibly be done by what so many say you should be doing with just that slide lapping. In fact it's all too likely your actually making the accuracy far worse unless your extremely lucky.Scraping and using some very expensive and reliable test equipment, along with a whole lot of logic, knowledge and experience would be the correct and best method. You can of course make a machine a bit better fairly cheaply, and the more skill you have will make your results better. None of this is just my opinion either,those are just the simple facts if your willing to put some effort into researching exactly what is involved. We really should in my opinion be using these forums as a way to help educate ourselves. But they shouldn't be the only place your basing that all too important self education on. Yet today I see the problems of incorrect information on these forums as a large and growing problem. It should be exactly the opposite. Anyone ever wonder just how M.E.'s or the American term of HSM educated themselves before the internet was invented? My sincere apology's for the length of this post. Pete |

| Ajohnw | 03/07/2015 00:31:26 |

| 3631 forum posts 160 photos | The important aspect of a tailstock is the behaviour of a centre in it. Any test based on it's od assumes it's concentric which it may or may not be. Hence the need for a between centre test bar with varying projections of the tailstock quill. I may have mentioned lapping with a mix of CIF kitchen cream and oil. This will not correct errors only improve smoothness and for perfection needs a bit of thought to make sure that the added smoothness is applied evenly along what ever slide it is. John - |

| Pete | 03/07/2015 03:22:05 |

| 128 forum posts | Yes John I'd certainly agree that testing against the tail stocks OD would only be the first step. But if your metrology equipment is accurate enough? Then no lathe no matter how good or expensive they are including the worlds best that are available today including the temperature controlled spindle and bed machines that are designed for optical and/or laser equipment would be without fault. And yes you are 100% correct, the tail stocks OD is just a place to start. But I did have to shorten my post by over 2700 letters since the allowable limits on this forum don't like lengthly explanations of what are fairly complicated ideas that both Conolly and Schlesinger had. You do need to run multiple tests if possible on multiple areas just to start forming some ideas of where the problems might be.Then it will take some real thought and I think education before you can properly pinpoint where the those problems might be. To state the completely obvious, the cheaper your machine is, then the more knowledgeable you have to be to be able to wring the very best out of it. It's not impossible, but it does take a real desire to properly educate yourself. I've been learning about this for well over 30 years, and I never expect to ever know what I'd like to.

But..............to end up so that you are 100% positive of the exact issues and exactly where there located with any certainty can take a huge amount of time,testing, thought and energy. That's where your own personal understanding and education starts. I highly recommend NOT asking questions on forums like this first, but you should be doing your own research through Google, and then possibly start to ask some questions on these forums only after doing so. Pete |

| Michael Gilligan | 03/07/2015 06:52:47 |

23121 forum posts 1360 photos | ... .to end up so that you are 100% positive of the exact issues and exactly where there located with any certainty can take a huge amount of time,testing, thought and energy. That's where your own personal understanding and education starts. . Pete, Despite your obvious enthusiasm for the subject; I regret that you have lost some credibility/authority by your use of phrases like "100% positive". May I suggest that you continue your research by reading some of the excellent publications on the NPL website ? ... especially on the subject of Uncertainty of Measurement MichaelG. . P.S. ... You may need to register/log-in to get access to some of the material, but it's well worth doing so. Edited By Michael Gilligan on 03/07/2015 06:57:35 Edited By Michael Gilligan on 03/07/2015 07:04:59 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in