Stevenson Blocks...

... the M1 at Long Eaton?

| Michael Gilligan | 07/01/2016 15:45:23 |

23121 forum posts 1360 photos | Understood, John That said: What I may do, in my forthcoming idle-moments, is see if I can design a little adapter to take watchmaker-style split collets ... with a slimline substitute for the ER nut. I currently have 6mm, 8mm &10mm bodied collets available [plus, of course the 11mm BCA ones], so should be able to work something out. ... All I really want the 'Stevenson' blocks for is their concentricity. MichaelG. |

| Andrew Johnston | 07/01/2016 16:13:17 |

7061 forum posts 719 photos | Posted by John Alexander Stewart on 07/01/2016 15:36:37

John - if you *really* want to pi$$ her off, tell her that "Rocket Science is easy - one equation - E=mc2 The general relativity field equation: is possibly more apposite to rocket travel, if not rocket science. Andrew

|

| JasonB | 07/01/2016 16:25:26 |

25215 forum posts 3105 photos 1 articles | Michael could you not accurately bore a bit of square and hex stock to take a parallel shank ER20 Holder, could even size the block to clear the nut. Put a flat on teh parallel shank and use a grubscrew to retain it which will allow it to be taken out for other uses. Must admit that since I got theStevenson 5C spin indexer I use that to put squares and hexes on things as its quicker and more accurate than blocks. |

| jason udall | 07/01/2016 16:47:26 |

| 2032 forum posts 41 photos | While I hold with G R.. Newtons laws get the job done to first order |

| Chris Evans 6 | 07/01/2016 16:49:03 |

2156 forum posts | I use 5C blocks for the hex and square operations. I stay with 5C due to having a full set of collets off my old South Bend lathe. I may start to look into ER stuff soon now the price is right due to popularity. |

| Michael Gilligan | 07/01/2016 17:13:41 |

23121 forum posts 1360 photos | Posted by JasonB on 07/01/2016 16:25:26:

Michael could you not accurately bore a bit of square and hex stock to take a parallel shank ER20 Holder . Jason, I was rather hoping that 'Stevenson's accurately ground blocks' would be closer tolerance than 'a bit of square and hex stock'. MichaelG. |

| JasonB | 07/01/2016 17:17:04 |

25215 forum posts 3105 photos 1 articles | Nothing to stop you skimming the stock to a better size/finish/accuracy Another option is to hold the parallel shank ER20 in an ER32 block and buy just one suitable ER32 collet. Edited By JasonB on 07/01/2016 17:18:29 |

| Michael Gilligan | 07/01/2016 17:22:56 |

23121 forum posts 1360 photos | Posted by JasonB on 07/01/2016 17:17:04:

Nothing to stop you skimming the stock to a better size/finish/accuracy . Jason, I was rather hoping that 'Stevenson's accurately ground blocks' would be closer tolerance than that too !! Let's just forget it. MichaelG. |

| John Hinkley | 07/01/2016 20:39:18 |

1545 forum posts 484 photos | Is there any reason (apart from the obvious one of extra expense on materials) why they can't be made double-ended? That is to say, have an ER20 on one end paired with an ER25 on the other end. Likewise ER32/ER40. That way you would only need two blocks to cover quite a range. Of course, you wouldn't sell so many. I think I've found the reason! John |

| Michael Gilligan | 07/01/2016 21:39:38 |

23121 forum posts 1360 photos | Posted by John Hinkley on 07/01/2016 20:39:18:

Is there any reason ... < etc. > . It might be tricky to stand them vertically. MichaelG. |

| John Hinkley | 08/01/2016 15:23:37 |

1545 forum posts 484 photos | Not if it was clamped to an angle plate and cylindrical square combination, though I'm struggling to think of an operation that would need it to be mounted in such a way, that couldn't be acheived horizontally or with a rotary table. Doubtless someone will come up with several! John |

| John Stevenson | 08/01/2016 15:34:24 |

5068 forum posts 3 photos | Give over John, I have to think of the Royalties and me 4 quid.

Oh and the two quid that Steven at Ausee owes. |

| JasonB | 08/01/2016 16:53:14 |

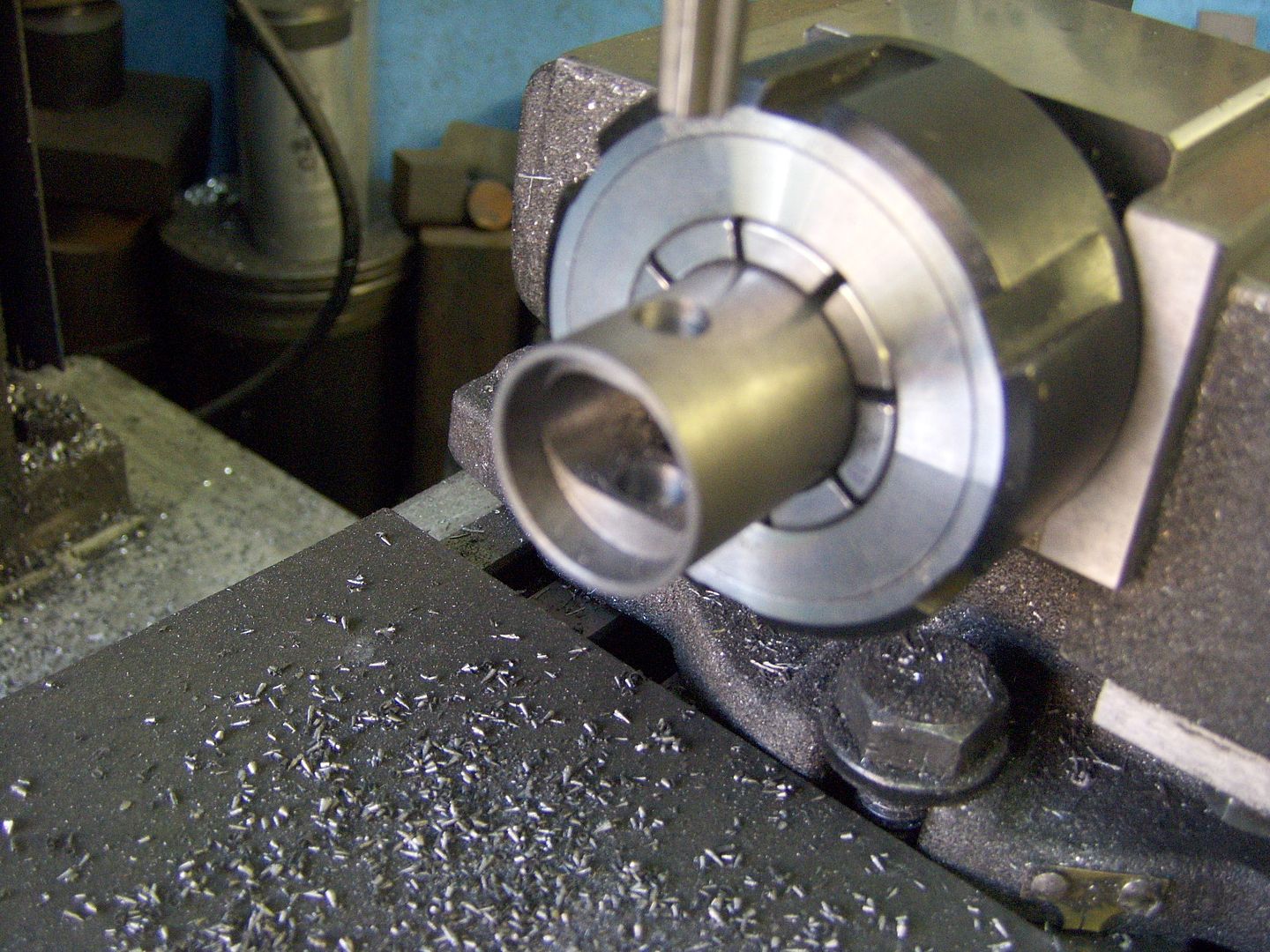

25215 forum posts 3105 photos 1 articles | Her you go John H Milling the slot in the underside of a piston and then laying teh block on it's side to drill & ream the Gudgeon pin at 90degrees. Yes it can be done in a rotary table but you need to remount and clock teh table and have a 3-jaw to fit the table. This way you only need to centre it once and the vice fixed jaw does not move so no need to ctr again. ER being smaller also allows you to get in closer with a small piston where the 3-jaw may get in teh way

Edited By JasonB on 08/01/2016 16:54:10 |

| Ian P | 08/01/2016 16:59:22 |

2747 forum posts 123 photos | Posted by JasonB on 07/01/2016 16:25:26:

Michael could you not accurately bore a bit of square and hex stock to take a parallel shank ER20 Holder, could even size the block to clear the nut. Put a flat on teh parallel shank and use a grubscrew to retain it which will allow it to be taken out for other uses. Must admit that since I got theStevenson 5C spin indexer I use that to put squares and hexes on things as its quicker and more accurate than blocks. Jason I'm curious as to why a spin indexer is more accurate than JS collet blocks? Having said that your piston is done by the block method. Ian P |

| JasonB | 08/01/2016 17:18:46 |

25215 forum posts 3105 photos 1 articles | Ian I tend to work small parts on the end of a bar so can often have 18" or so of bar sticking out the end of a block if say machining a square on the end. Each time the block is reset in the vice for the next face you have to ensure it is up tight against a vice stop and knocked down firm which is not easy with a long length of bar making the block unbalanced. With the indexer all I do is undo spindle lock, index to next position, lock spindle , cut and repeat. Its not that the blocks are inaccurate but that you have to spend time making sure you accurately reposition them. Piston can't be done in a Stevo indexer as they don't stand on end for the first op. One other thing is what do you do if you are holding say a 10mm dia part in your ER block and want to hold a 10mm cutter in your ER collet chuck to machine it? Not a problem if holding work in a 5C collet J Edited By JasonB on 08/01/2016 17:21:48 |

| Ian P | 08/01/2016 17:21:56 |

2747 forum posts 123 photos | Posted by JasonB on 08/01/2016 17:18:46:

Ian I tend to work small parts on the end of a bar so can often have 18" or so of bar sticking out the end of a block if say machining a square on the end. Each time the block is reset in the vice for the next face you have to ensure it is up tight against a vice stop and knocked down firm which is not easy with a long length of bar making the block unbalanced. With the indexer all I do is undo spindle lock, index to next position, lock spindle , cut and repeat. Its not that the blocks are inaccurate but that you have to spend time making sure you accurately reposition them. Piston can't be done in a Stevo indexer as they don't stand on end for the first op. J Fully understand all that, so it all makes sense now, thanks Ian P |

| JasonB | 08/01/2016 17:43:18 |

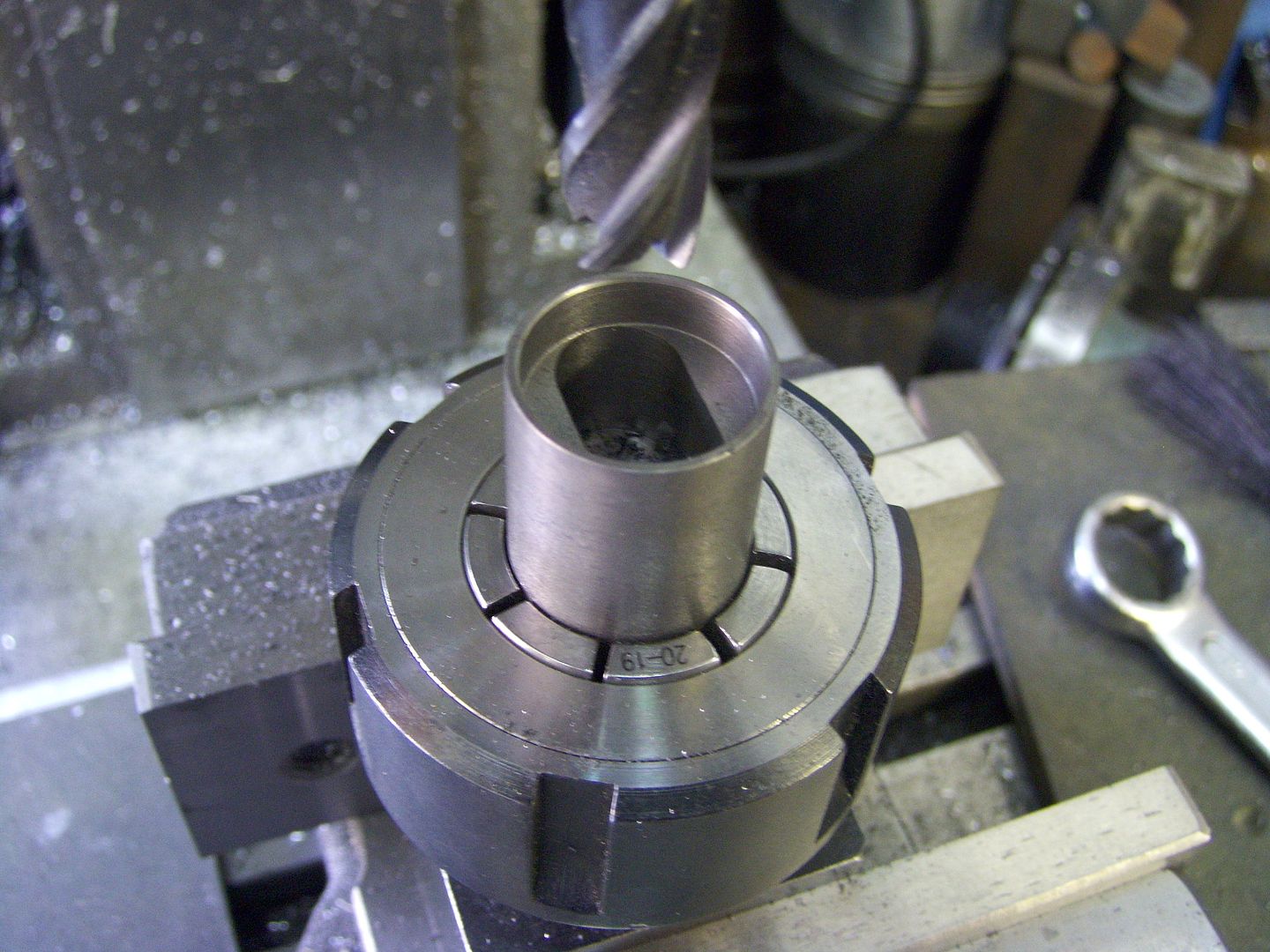

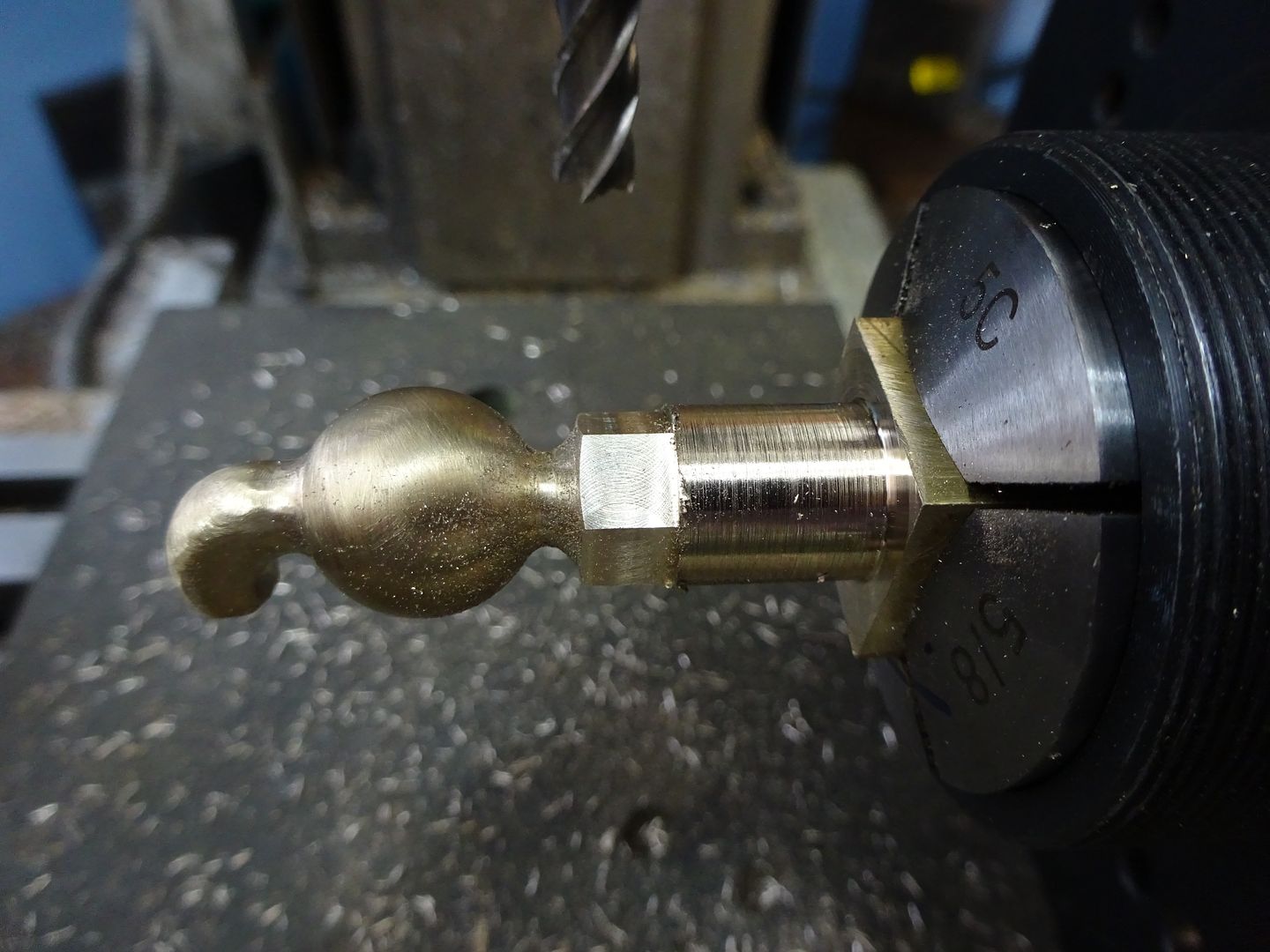

25215 forum posts 3105 photos 1 articles | One other thing that you can't do with an ER block that you can with an indexer

I'm not running the ER blocks down, its just that all tools have their uses and some suit a particular job more than others and I managed OK with the blocks before I got the indexer. Also just got a set of 5C blocks from Santa. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in