Tangential lathe tool holder

............not another one!

| steamdave | 25/07/2013 16:40:01 |

| 526 forum posts 45 photos | For a Myford 7 series lathe, I found I had to crank the toolbit end down 1/4" + to be able to get the cutting edge at centre height, using a qctp.

Dave |

| Keith Long | 25/07/2013 16:47:24 |

| 883 forum posts 11 photos | Kenneth Just a thought - don't know if it would work on your lathe - but if you made the tool shank circular in cross-section and then gripped the tool in a split holder, like a boring bar, you could do away with the side ways slope on the slot for the bit and just cut the for and aft slope. Might make machining a bit easier as you wouldn't be milling on a compound angle, also it would allow you to experiment with the side ways angle for the best cutting performance just by rotaating the whole tool in the split holder. I could certainly go that route on my machines because I can use large tools in the standard toolpost - 1inch hich slot. Keith |

| Rik Shaw | 25/07/2013 17:36:53 |

1494 forum posts 403 photos | Kenneth - I sawed the blank for the original from a length of 1.5" x 0.5" bar. The 0.5" thickness was not reduced in any way unlike your drawing which shows one side machined at an angle. I chain drilled the basic elongated "L" shape and then hack sawed the shape out. If you look at my second post on this thread have a gander at the third photo. This clearly shows that the shank is machined as a parallelogram. It is the 12 degree angles incorporated in this parallelogram that cants the tool over to give the tool bit its sideways 12 degree attack angle unlike your drawing. Aside from that, your 20mm should be 23mm and your 30mm should be 38mm. The latter dimension is particularly critical given the clamp dimensions which I have detailed. And nit picking here, your drawing shows the clamp screw holes to far away from the tool bit slot. These need to be as near to the slot as possible without breaking through to allow the clamp to bite on the tool bit as near to the longitudinal centre line of the tool bit as is possible. Hope this helps. Rik |

| Rik Shaw | 26/07/2013 16:35:54 |

1494 forum posts 403 photos | Keith - There are no compound angles to machine on my version. --- Rik |

| SverreE | 05/01/2014 09:52:22 |

| 22 forum posts 14 photos | I just finished my version of tangential toolholder for my homemade QCTP: And here it is on the QCTP: And it woorks beautifully! Sverre |

| Rik Shaw | 05/01/2014 10:59:21 |

1494 forum posts 403 photos | Well done Sverre. Hope you will not mind me pointing out that I think you will find some limitations with your tool due to the very prominent tool bit fixing screw head. From the photo it looks as though the head will foul the first shoulder it comes up against - well before the tool point gets there This is a problem that is quite difficult to overcome in this design which is why I approached it from a different direction in my version earlier on in the thread. Rik |

| SverreE | 05/01/2014 15:07:15 |

| 22 forum posts 14 photos | Hello Rik; Yes - I know! I just wanted to get a quick way of trying out a tangential toolholder. The big screw holds the toolbit firmly, but limits the diameter for facing to about 20 mm. I'll have to finish the holder for grinding the toolbit, thought I would make a jig for grinding it on my new Worksharp 3000 (mostly for sharpening woodworking tools), but will give a very nice sharp edge. Sverre |

| Vic | 13/08/2014 20:09:32 |

| 3453 forum posts 23 photos | This is mine.

|

| _Paul_ | 14/08/2014 01:52:27 |

543 forum posts 31 photos | Very nice tool Vic what's it made from or is the grey colour some kind of heat treatment? |

| Michael Gilligan | 14/08/2014 08:20:46 |

23121 forum posts 1360 photos | Posted by _Paul_ on 14/08/2014 01:52:27:

Very nice tool Vic what's it made from or is the grey colour some kind of heat treatment? . Paul, I may be wrong, but I suspect it's made from "Ones and Zeroes" ... Whether I'm right or wrong; it's a lovely job, Vic. MichaelG. |

| Oompa Lumpa | 14/08/2014 09:06:49 |

| 888 forum posts 36 photos | Posted by Michael Gilligan on 14/08/2014 08:20:46:

Posted by _Paul_ on 14/08/2014 01:52:27:

Very nice tool Vic what's it made from or is the grey colour some kind of heat treatment? . Paul, I may be wrong, but I suspect it's made from "Ones and Zeroes" ... Whether I'm right or wrong; it's a lovely job, Vic. MichaelG. The only Ones and Zeros I know is binary. How would you make a toolholder from binary? I realise you could computer generate an image so are you suggesting the toiolholder is vaporware? graham. |

| Michael Gilligan | 14/08/2014 09:17:25 |

23121 forum posts 1360 photos | Graham, Yes, I'm suggesting it is a lovely piece of image rendering. MichaelG. |

| Les Jones 1 | 14/08/2014 09:32:38 |

| 2292 forum posts 159 photos | And thought Michael meant CNC by his "Ones and Zeroes" comment. Les. |

| IanT | 14/08/2014 10:04:47 |

| 2147 forum posts 222 photos | Or it's been sandblasted perhaps? IanT |

| Vic | 14/08/2014 10:32:51 |

| 3453 forum posts 23 photos | No, it's the real deal, I made it from some unknown steel but you're right, it's been sandblasted. Here's another pic of it with some other stuff I made.

|

| Vic | 14/08/2014 10:35:11 |

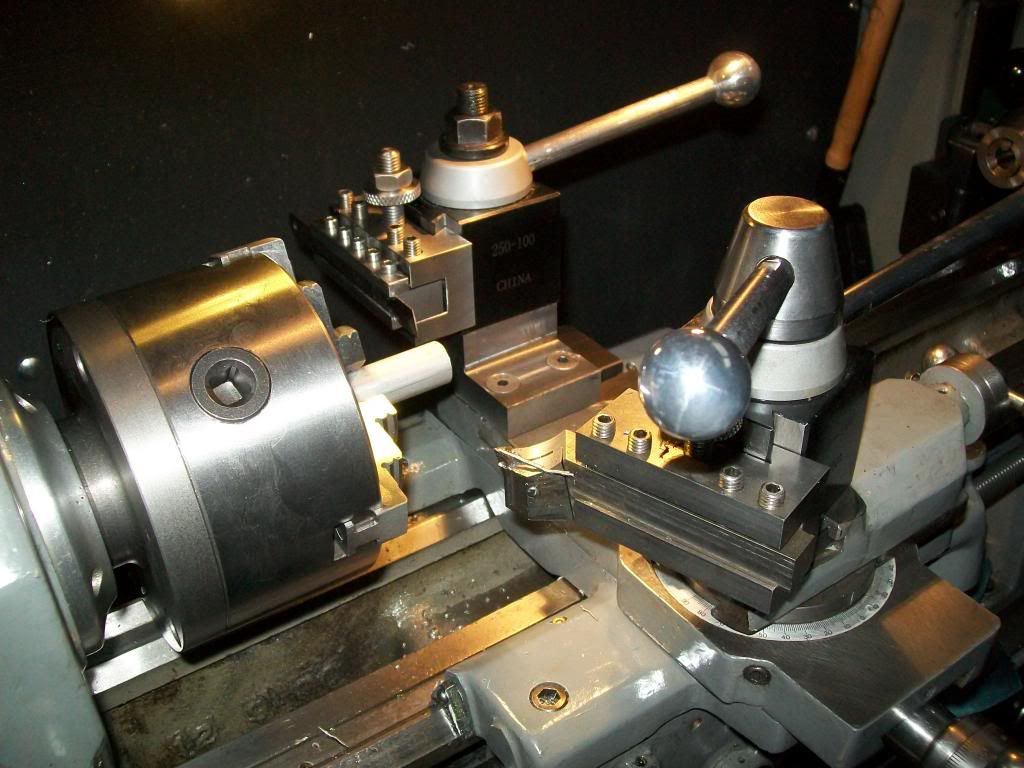

| 3453 forum posts 23 photos | In use on my Lathe (height setting).

|

| NJH | 14/08/2014 11:03:53 |

2314 forum posts 139 photos | Michael et all Oh ye of little faith!

Nice work Vic Norman

|

| Vic | 14/08/2014 12:59:22 |

| 3453 forum posts 23 photos | Thanks Norman! Couple more pics, how it started out:

Clamp setup.

|

| Michael Gilligan | 14/08/2014 13:30:53 |

23121 forum posts 1360 photos | Posted by Michael Gilligan on 14/08/2014 08:20:46 I may be wrong, but I suspect it's made from "Ones and Zeroes" ... Whether I'm right or wrong; it's a lovely job, Vic. MichaelG. . I did cover my options But I am VERY impressed !!! MichaelG. |

| _Paul_ | 14/08/2014 13:36:50 |

543 forum posts 31 photos | Its so nicely sculpted its almost a work of art my friend mine is nowhere near as nice:

Your Knurling tool is nice too mine is a similar design:

Paul |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in