Micro Burner

Surely we could do better than this ...

| Neil Wyatt | 23/08/2017 18:39:57 |

19226 forum posts 749 photos 86 articles | Surely the holes are in the base of the needle not the needle itself. The rubber tube looks a bit over-long if relying on the bunsen jet. |

| Michael Gilligan | 23/08/2017 19:41:28 |

23121 forum posts 1360 photos | Posted by Neil Wyatt on 23/08/2017 18:39:57:

Surely the holes are in the base of the needle not the needle itself. . ... As per George's observation, this morning. The trouble is: This is the only reference I have found to the device, and the text far from explicit. ... I would have expected dimensions and pressures to be quite critical; but nothing is specefied I may find something tomorrow, and will report back if I do. MichaelG.

|

| JasonB | 23/08/2017 20:08:00 |

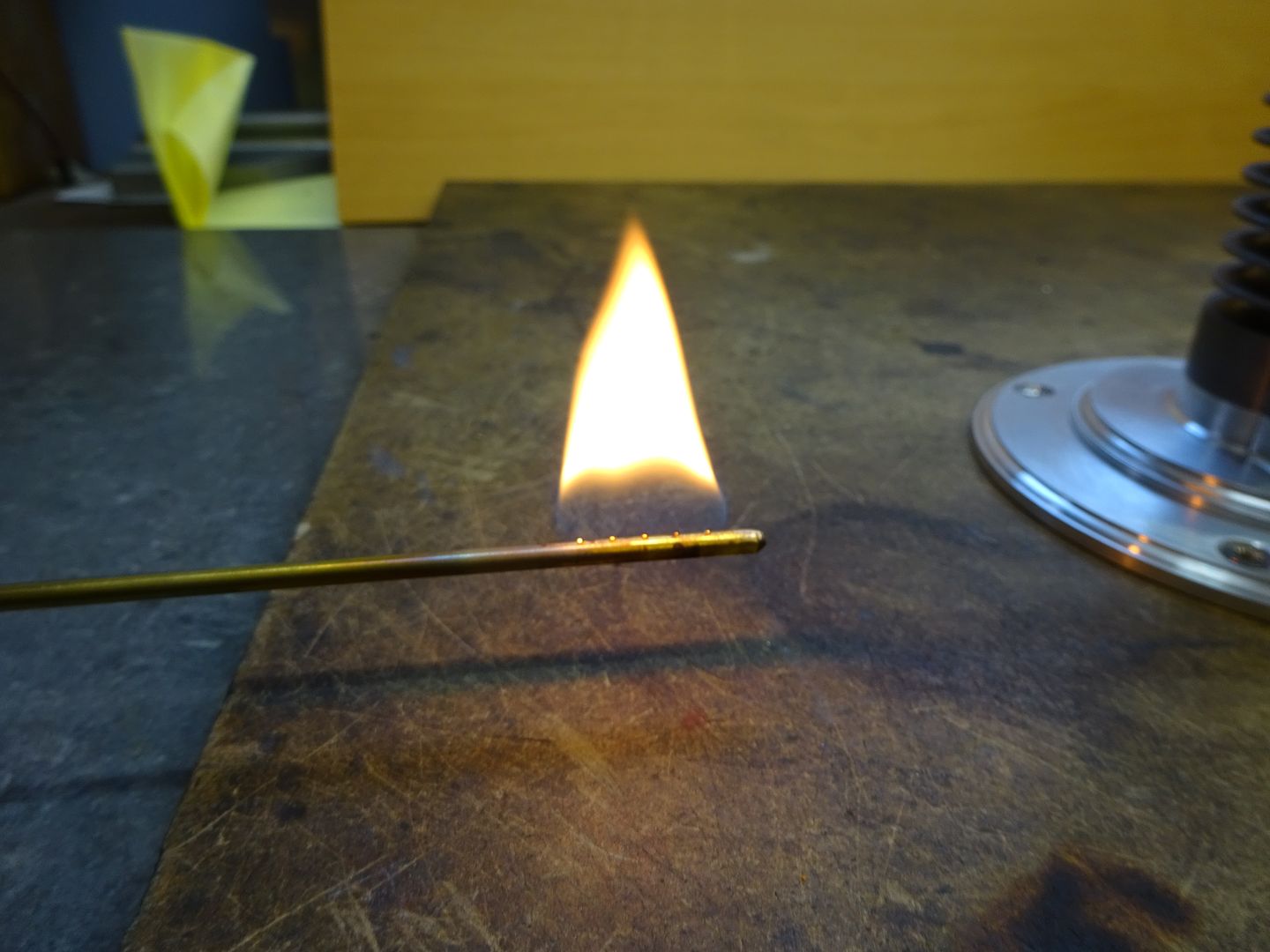

25215 forum posts 3105 photos 1 articles | I did have a play tonight while in the workshop. I blocked off 3 out of the 5 holes in the burner for my flame licker, held a bit of silicon tube over one and lit the other this gave a soft orange flame, by gently blowing down the tube I could get a blue flame but if too much puff it moved too far from the burner and then went out. Blocking the 3 middle holes and lighting the end one did not draw air in and the flame jumped across to the other end Burner is 1/8" brass tube with five 0.5mm holes. and gives this sort of flame off a camping gas bottle on a low setting.

Edited By JasonB on 23/08/2017 20:09:32 |

| Michael Gilligan | 23/08/2017 20:24:02 |

23121 forum posts 1360 photos | Thanks, Jason ... a very useful 'benchmark' MichaelG. |

| Ian Skeldon 2 | 23/08/2017 22:12:39 |

| 543 forum posts 54 photos | Hi, Jason what would happen if you drilled a small hole (0.75mm maybe?) nearer the gas supply end of the brass tube? Would that allow air to be drawn in, maybe crimp it slightly before the new hole to speed up the gas flow and reduce pressure? Ian |

| JasonB | 24/08/2017 07:26:11 |

25215 forum posts 3105 photos 1 articles | Short of making a new burner I don't really know. However when I was making that one I did put a hole 0.5mm hole about 4" along the pipe and it made no difference when open or covered. |

| Martin Whittle | 24/08/2017 14:01:47 |

| 102 forum posts 12 photos | As I basically stated in my posts yesterday, this will not work! A bunsen burner uses a small jet of fast-moving gas within a much larger tube, which sucks in air from an airhole which is then mixed with the gas. The tube is large and there is minimal back-pressure. A gas burner on a cooker, or a camping stove, works much the same way - except there is no tube as such, but the flame burns externally, not at the jet, after mixing with air., but without an actual 'tube' If you have a narrow constricting pipe after the 'air hole', the back-pressure is going to be substantial - the gas will leak out, and air will not come in (why on earth should it? - it needs negative relative pressure for that to happen, and we have positive pressure). So the solution is either:

Note one cannot expect designs etc to scale with size. Drop a mouse off a table and it will run away; drop an elephant off a table and it will probably be fatal. With this in mind, should the pressure at the jet be increased very substantially and the jet made even smaller within the tube: maybe not relevant, but the pressure inside a soap bubble is in inverse proportion to the bubble radius: small bubbles have high pressure!

|

| Michael Gilligan | 24/08/2017 16:20:23 |

23121 forum posts 1360 photos | Gentlemen, I now have another source of information ... and can confirm that there is, typically, no air inlet on the microburners. I'm on the 'bus at the moment, but will post this evening. MichaelG. |

| Neil Wyatt | 24/08/2017 18:42:46 |

19226 forum posts 749 photos 86 articles | Posted by Michael Gilligan on 24/08/2017 16:20:23:

Gentlemen, I now have another source of information ... and can confirm that there is, typically, no air inlet on the microburners. I'm on the 'bus at the moment, but will post this evening. MichaelG. I did wonder. Back in the days of Thomas Salter chemistry kits I used to 'work' soda glass on a spirit burner. Neil |

| Michael Gilligan | 24/08/2017 19:13:45 |

23121 forum posts 1360 photos | As promised ... extract from 'Micromanipulators and Micromanipulation' by Hamed El-Badry, 1963 . Micromanipulator tools are usually prepared by the experimenter who uses them and makes them in accordance with specifications considering his own special needs. It is therefore very important that the operator masters the techniques of preparing the tools he needs, especially because such tools have to be frequently replaced because of their delicacy.

Simple glass microtools may be prepared by hand with the use of a suitable microburner. Accurately reproducible fine micropipets and needles may be prepared mechanically by means of needle and pipet pullers. A great diversity of microtools of unusual shapes may be most precisely and conveniently prepared under microscopic control by means of microforges. These methods, together with the necessary apparatus, will be considered in turn. |

| Michael Gilligan | 24/08/2017 19:15:33 |

23121 forum posts 1360 photos | a) Hand Drawing.

Simple glass micropipets and microneedles may be drawn out by hand from a stock of glass capillaries or threads, usually of about 0.8 to 1 mm in outer diameter. This diameter is usually determined by the opening of the tool holder into which the microtool is to be inserted. The capillaries and threads may be drawn out from pieces of soft glass tubing and rod varying from about 4 to 8 mm in outer diameter (3 to 6 mm bore) in the flame of an ordinary Bunsen burner or of a Meker burner if hard glass is used. The large flame of the burner shown in Fig. 95, is also suitable for drawing capillaries from glass tubings. The capillaries produced are cut into the lengths required for preparing the microtools to be made.

Further operations for making pipet and needle points are carried out over a pinhead flame supplied by a suitable microburner such as those described below.

Microburners.

A simple and serviceable microburner is shown in Fig. 94. It can be easily constructed from a length of hard glass tubing of about 5 mm internal diameter. Over a narrow flame, one end of the tubing is drawn out into a capillary of approximately 0.5 to 1 mm bore. The capillary is then cut at a point approximately 7 to 10 mm from the original tubing. The tubing is bent at right angles at a point 4 to 5 cm from the drawn-out portion. The wide end of the original tubing is simply inserted into a large rubber stopper which has been bored diametrically to receive it. The stopper acts as a base for the microburner as shown in the figure. The wide end of the glass tubing is connected to the gas line by means of a soft rubber tubing. The gas supply can be regulated by means of a screw pinch-cock clamped on the rubber tubing so as to give a microflame as small as a pinhead. A similar glass microburner, but with an orifice in the form of a narrow elongated aperture, was used by CHAMBERS (54, 55) for preparing microdissection needles and micropipets. The tip of the burner was made by pinching one end of the glass tubing, softened by heat, with a pair of forceps so as to close it except for the narrowest possible aperture that would retain the flame. The burner was connected with an acetylene generator or, preferably, a small compression tank which could be recharged at a small cost. CHAMBERS recommends the use of acetylene rather than ordinary gas because, with acetylene, a narrow flame can be obtained without clogging. Ordinary gas may be improved, if necessary, by passing it through alcohol or benzene.

|

| Michael Gilligan | 24/08/2017 19:16:24 |

23121 forum posts 1360 photos | A simple metal microburner may be made from a hypodermic needle soldered to a short length of brass tube (228). A useful, commercially available (245) burner is shown in Fig. 95. The main burner yields a large flame suitable for drawing out glass tubing and rod into capillaries and threads. At a distance of about 3 cm from the main tube, the burner is equipped with a narrow pilot flame tube giving a microflame which can be regulated to the desired size. The pilot flame tube has a conical orifice for inserting a hollow needle similar to an injection needle. The microburner is supplied with two needle canulae of different internal diameter. An adjustable black screen attached to the main burner tube serves as a suitable background for observation while working over the microflame. Fig. 96 illustrates the use of this burner in preparing microtools. |

| Michael Gilligan | 24/08/2017 19:18:02 |

23121 forum posts 1360 photos |

. Thanks for your interest. MichaelG.

Edited By Michael Gilligan on 24/08/2017 19:19:39 |

| JasonB | 24/08/2017 19:22:17 |

25215 forum posts 3105 photos 1 articles | Looks like my thought that a soft flame would be enough to heat such a fine piece of glass was about right. Suppose its a bit like holding fuse wire over a candle which will make it red hot but the candle would not get a 4" nail red hot. Thanks for the extra pics. |

| Tim Stevens | 24/08/2017 21:35:49 |

1779 forum posts 1 photos | Two thoughts come to mind: 1. Is the burner intended for the 'ordinary' gas we are assuming? Or could it be intended to be used with an electrolytic gas-producer as used in the jewellery trade, a gas which includes most of the needed oxygen? (The trick to avoid H + O explosions relies - from memory - on passing the gasses through a volatile fuel mix on the way through the machine. This richens the mixture enough to avoid explosions). 2. Could it be that at very small sizes the 'ordinary' gas burns hot without needing the extra air ? The flame is so small, I guess, that the middle is very near to the outside (and the air) so extra air is not needed. Or perhaps not. Cheers, Tim |

| Michael Gilligan | 24/08/2017 23:28:15 |

23121 forum posts 1360 photos | Tim, I can only assume that the device referenced in my original post ran on ordinary 'coal gas', at low pressure, as per the common suply to laboratories at the time. [I may be wrong!] The note on the 'Chambers' version is more specific, [my note at 19:15:33 refers] [quote] ... CHAMBERS recommends the use of acetylene rather than ordinary gas because, with acetylene, a narrow flame can be obtained without clogging. Ordinary gas may be improved, if necessary, by passing it through alcohol or benzene. [/quote] In all probability, for the sake of convenience, I will try to get something working on propane ... I have 'Sievert 2000' cylinders to hand, and have written tonight to Bullfinch, asking if it is O.K. to remove the POL connector from one of their 'Tinyreg' regulators and replace it with a Sievert valve. [this would make a compact unit, with a wide range of controlled pressures available]. MichaelG. . Edited By Michael Gilligan on 24/08/2017 23:35:42 |

| Ian S C | 25/08/2017 03:32:07 |

7468 forum posts 230 photos | The acetylene in a lab would probably been made on site from a generator, and be at low pressure compared to cylinder gas as supplied fror welding. Over the years ME has published designs for building an acetylene generator, starting with two in vol 1 of 1898. Ian S C |

| Michael Gilligan | 25/08/2017 07:39:38 |

23121 forum posts 1360 photos | Thanks, Ian ... Would those be simple Calcium Carbide devices ? I was tempted [having once had a carbide Caving light]; but seeing the price of Calcium Carbide on ebay, decided to try using my Propane first. MichaelG. |

| John Ockleshaw 1 | 25/08/2017 08:10:27 |

56 forum posts 7 photos | Hello Michael, I direct the output of a air/acetlyene torch into the inlet of an aquarium air pump then couple the pumps discharge to a hand piece carrying a hypodermic needle, with plastic hose. By adjusting the air/acetylene torch's output you can get a stable flame on the hypodermic that will not burn off when you wave it around. If you like I will take a photograph of the set up. I use it for silver soldering chain links made from 0.005 " diameter bronze wire under a microscope, amoung other things. Regards, John |

| JasonB | 25/08/2017 08:20:56 |

25215 forum posts 3105 photos 1 articles | John what is the reason for going via an air pump as you would only be pumping the gas air mix from the torch at the rate you were putting it into the pump?, I would have thought you could just use a micro nozzle straight off the torch, they can be bought readily enough. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in