Member postings for Nick_G

Here is a list of all the postings Nick_G has made in our forums. Click on a thread name to jump to the thread.

| Thread: Info For Jason |

| 17/09/2014 20:26:27 |

Posted by JasonB on 17/09/2014 20:04:56:

bargain basement

It certainly seems as if it was and by a very considerable amount on what the general retailers are selling them for. It was pure luck on my part as I was not searching for a chuck. It just came up as 'suggested' presumably from previous searches I had done. I think the seller had bought some bankrupt stock from somewhere and just wanted to turn their money over with a small profit as quickly as possible as their previous sales were not tool or engineering related. As a separate note Jason I have just been doing some turning with mine and noticed that the jaws carry the same serial number as the body.

Nick |

| 17/09/2014 19:16:19 |

. Presumably this will ease any fears of 'too good to be true' we may have had until your delivery man arrives. Youtube clickity linkity thingy :- https://www.youtube.com/watch?v=djI7akwo7Ww&feature=youtu.be

Nick Edited By Nick_G on 17/09/2014 19:17:34 |

| Thread: Installing a new lathe |

| 16/09/2014 08:14:17 |

Posted by Phil Whitley on 15/09/2014 21:36:35:

I would still check the floor for damp Robin. When I did my place the walls seemed far wetter than the floor, but when I took up the tiles, put in a dpm and concrete, the walls dried out. It was damp from the floor condensing on the walls, which were colder. Get some air moving through before you commit to any work, it might dry out by itself, unless you have leaky rainwater drains, as we discussed before. Phil

I agree. There are thousands of properties with damp cellars that never were so before previous owners and botch-it-men sealed up air bricks and general ventilation. Air movement is one of the best things for curing many damp problems. Even a small extract fan tricking over can work wonders in many situations.

Nick |

| Thread: d13 camlock pins |

| 11/09/2014 23:48:37 |

. Thread on these is 10 x 1 so perhaps of no value to you. :- **LINK** But you may be able to cut the threads off, tap and stud them to your required thread.

Nick Edited By Nick_G on 11/09/2014 23:51:36 |

| Thread: When does a beginner cease to be a beginner? |

| 10/09/2014 15:52:33 |

. “When I was a boy of 14, my father was so ignorant I could hardly stand to have the old man around. But when I got to be 21, I was astonished at how much the old man had learned in seven years.” Mark Twain

Nick |

| Thread: Workshop Electrics |

| 09/09/2014 23:08:06 |

Posted by Bazyle on 09/09/2014 21:20:24:

Anyone know if it is it ok to put 3 phase and 1 phase in the same run when it is that big?

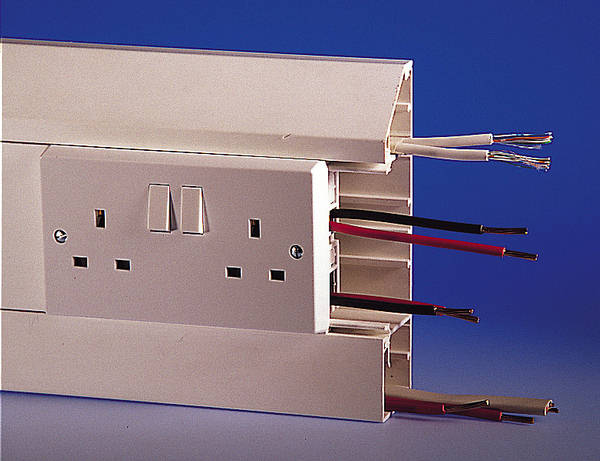

Yes that's fine providing the insulation value of both is high enough. Which it will be unless you start running door bell and telephone / data cables in the same compartment. If you wish to be uber posh in your workshop and attach sockets directly to the wiring runs as you hint at, do a search for 'Dado trunking'. They even do versions with several segmented compartments. Nice stuff but not the cheapest option. It would however make alterations and additions at a later stage a piece of cake.! Nick e.g. The lid just clips on and off and you can add outlet boxes where and when you need them. The above image is just a sample type. There are many different forms, sizes and profiles available.

Edited By Nick_G on 09/09/2014 23:17:20 |

| Thread: 'War Department' (arrow) Marking |

| 03/09/2014 10:30:51 |

. Some very interesting and informative replies here. How about people posting a few pics of their broad arrow / WD marked items they have.

Nick |

| Thread: Myford secondhand machine prices |

| 03/09/2014 10:27:24 |

Posted by CotswoldsPhil on 03/09/2014 09:50:21:

What's happening to Myford prices? Regards CotswoldsPhil

They are being governed by what people are willing to pay. - It's as simple as that.!

Nick |

| Thread: Computer backup |

| 02/09/2014 15:13:29 |

. Hi John. I have used Syncback for many years without problems. As a photographer I have a vast number of quite large files to back up to several places regularly. It can be configured in many ways and is free. Here you go :- **LINK**

Nick |

| Thread: polishing spindle taper threads |

| 02/09/2014 11:39:23 |

Posted by Douglas Johnston on 02/09/2014 09:15:16:

and the use of descriptive language when things went wrong at the end. Doug

That was quite tame for him.!

Nick |

| Thread: 'War Department' (arrow) Marking |

| 31/08/2014 21:43:54 |

. Yesterday I was given some goodies when visiting a friends workshop. One of the items was a small surface table that had been in storage for years. It is actually brand new and still had the manufacturers grease and protective paper on it. - It looks 'yukky' in the picture as I have doused it with parafin to help remove the grease. Under the crud it's perfect.

Upon turning it upon it's side there are markings visible. One states 1970 and I am presuming that this was the year of manufacture. One of the other markings is the 'War Department' arrow logo. When did the government stop using this once iconic arrow marking and generally was the tooling that carried it any good.?

Cheers, Nick |

| Thread: What did you do today? (2014) |

| 31/08/2014 14:37:34 |

Posted by Raymond Sanderson 2 on 31/08/2014 08:35:57:

no pressure from the hot water a small squirt was all I got. Checked other taps silch nothing although cold water was ok.

Is it a combination boiler.? Has the pressure in it dropped.? If it is a 'combi' boiler there will be a pressure guage on it. This should show a pressure of about between 1 - 2 bar. If this has dropped the boiler will auto shut off. There is normally a 'filling loop' close to the boiler if this is the case. Repressurise by opening the filling loop valve until the pressure rises again. (don't forget to turn off when pressure has increased) It may of course be something totally different that is at fault. - But this is a common one.!

Nick |

| Thread: My Friends 'Jobbing' Workshop (video) |

| 30/08/2014 16:00:08 |

. I was at an old friend of mines workshop this morning. So I shot a bit of video of it (on iphone so poor quality) as I thought it 'might' be of some interest to some of the sites members to have a nosey. Edited By Nick_G on 30/08/2014 16:00:34 |

| Thread: Warco 290V comments n feedback |

| 27/08/2014 22:57:32 |

Posted by mechman48 on 27/08/2014 21:12:23:

I could say that about the 280 as well or are these two different beasts? George

I 'think' the 290 is basically a larger spindle bore 280.

Nick |

| Thread: No.9 Back 'Home' !! |

| 22/08/2014 09:54:30 |

. Is there any product available that will fill holes in cast iron and then enable them to be drilled and re tapped. Or will it always have a tendency to re follow the original hole.

Cheers, Nick |

| 21/08/2014 08:32:41 |

Posted by Bandersnatch on 21/08/2014 01:26:02:

Posted by Nick_G on 20/08/2014 23:21:29:

So what is the best plan for this do you think.?

Put it in a box and send it to me with your compliments. Pre-paid of course.

Pahhhh.! You are not even offering a packet of Hob Nobs in trade.

Nick |

| 20/08/2014 23:21:29 |

. Going back nearly 20 years I had just started to set up a home workshop (Deja vu) To cut a long story short the relationship I was in went south in a right royal fashion and I left leaving behind the machines (which I had only owned for a couple of months The other week my son mentioned to me a steam engine I had also left (TBH I had forgotten all about) Memory cogs start turning in my head and I recalled starting a Stuart No.9. So I asked him to bring it. The photos show what I have :-

Obvious first missing is the drawing.! I seem to have made a right dogs danglers all those years ago of the PCD on the cylinder ends. Although the covers fit they do so in only one position of rotation. The main bearings don't look right somehow and one of the caps is AWOL. There may be others missing. I know spare castings are available from Stuart's for this engine still, but I have mixed thoughts about 're-attacking' the project as in the last 20 years I have become more fussy about standards of finish etc. And I think I will be always looking at faults. So what is the best plan for this do you think.? Also I am basically a 'newbie' once again to model engineering.

Cheers, Nick

|

| Thread: Damaged Sieg C0 lathe...what to do ? |

| 20/08/2014 15:56:03 |

Posted by Ketan Swali on 20/08/2014 15:36:28:

sitting on a 'throne' in China

Golly.! The toilets in China have Wi-Fi. ???

Nick |

| 20/08/2014 14:14:26 |

Posted by John McNamara on 20/08/2014 14:04:24:

That will put paid to the December story. Regards

Unless they get palmed off with the 1st reject.

Nick |

| 20/08/2014 11:19:56 |

Posted by Brian John on 20/08/2014 11:11:51:

They will not accept another return.

Who are 'they' ???? ................. "Name and shame" !!!!!!!!!!!

Nick |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in