Mary Baseplate

| Wolfie | 02/10/2012 18:13:29 |

502 forum posts | Hi all, I've started to build the beam engine 'Mary' from scratch. Now the baseplate is around 9" long and three wide and half an inch thick but a lot of the underside is hollow. Surely I don't buy a huge chuck of steel and then reduce a lot of it to swarf? Are there any other ways of doing this? |

| JasonB | 02/10/2012 18:20:20 |

25215 forum posts 3105 photos 1 articles | Make it from Ali is one option as its a bit quicker to machine and you can leave the inside solid and still be able to pick the engine up. Or just make from steel plate and don't worry about hollowing it out. It can also be fabricated with a 3/16 or 1/4" to and 4 strips to form the side, either screw together and fill the holes or weld if you can weld. This one is 6"x4" x3" and welded, hollow inside You could also use a steel top and a hard plastic such as Corian to build up the thickness I did my big Benson that way I'm going to be doing one soon that is 16" x 6" x 1.5" if you can hang on I'll post some photos. I did have a large bit of structural steel put away for this but since getting some photos of the original engine will now go for a 1/4" steel top with 1.5x0.5 aluminium for the downstand. J Edited By JasonB on 02/10/2012 18:23:22 Edited By JasonB on 02/10/2012 18:26:37 |

| Stewart Hart | 02/10/2012 18:31:37 |

674 forum posts 357 photos | Hi Wolfie My first engine was a Mary built from a cast kit, the base as suplied is an ally casting, do as Jason suggested and make it from a bit of ally plate (about 12mm thick) there is always plenty of off cuts for sale on ebay it will set you back about £15, or you could try your luck down at your local metal recycling emporium. Stew |

| Jeff Dayman | 02/10/2012 19:15:36 |

| 2356 forum posts 47 photos | Another suggestion - 1. find a short scrap piece of steel rectangular tubing to form the vertical body 2. weld/braze/solder on a plate a bit bigger than the tube for the base 3. weld/braze/solder on a plate for the top 4. weld/braze/solder on washers or nuts for the 4 base bosses 5. add filler or JB weld if desired to give a "draft angle" effect for the sides JD PS another one yet - heat up some scrap aluminum in a soup can over an air-blown charcoal fire and sand cast the shape. You need a wood pattern and sand mould for that though.

|

| JasonB | 02/10/2012 19:27:07 |

25215 forum posts 3105 photos 1 articles | Having just had a look at the Mary drawings on Reeves site I would say making the base from two layers of material will be the best bet. Cut the lower one to size and use a bull nose or home ground cutter to profile the 4 sides, drill say 6mm where the six bolting down holes go and JB weld in some short lengths of rod. The top layer can just be a smaller square edged plate fixed on top.

|

| neville rigg 1 | 02/10/2012 19:33:42 |

| 24 forum posts | Hi Wolfie, I have a Mary half finished, this is from castings, the base is an ali casting, bought them about 25 years ago second hand, I think I paid about 15 quid, good luck wih the build, I also have the original build series by Tubal cain in Popular mechanics. Neville |

| Stub Mandrel | 02/10/2012 19:57:34 |

4318 forum posts 291 photos 1 articles | Good Luck with Mary Wolfie, I have been working on the beam engine Lady Stephanie for about eight years... Neil |

| JasonB | 02/10/2012 20:09:10 |

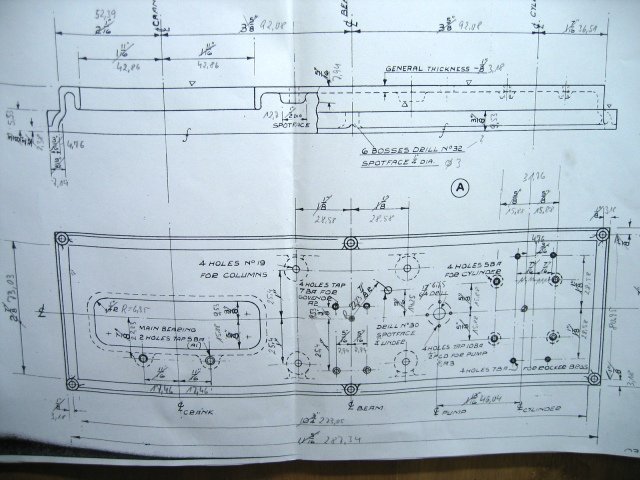

25215 forum posts 3105 photos 1 articles | Just so we all know what Wolfie is making, here is a drawing of the baseplate found on the web

|

| JasonB | 03/10/2012 16:14:02 |

25215 forum posts 3105 photos 1 articles | Had a suitable bit in the router this afternoon so ran this off from some scrap MDF to show what I was saying about making from two plates. Edited By JasonB on 03/10/2012 16:39:10 |

| peter ravenscroft | 03/10/2012 16:31:25 |

| 100 forum posts 3 photos | try using hardwood with metal plate inserts as long asit is well protected it will be ok regards peter |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in