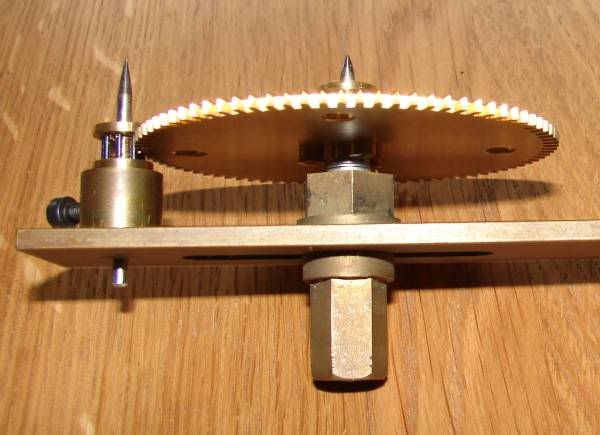

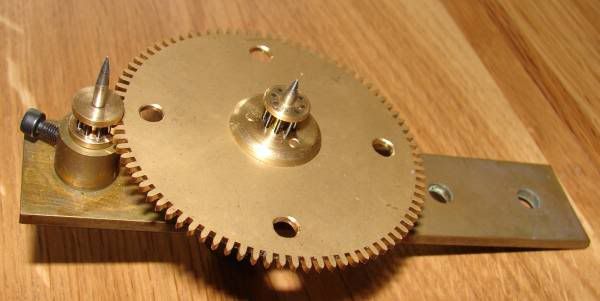

Gear Depthing Tool

| Mogens Kilde | 04/04/2011 21:40:23 |

| 60 forum posts 25 photos | Hi All

After making my dividing head, I have now made a depting tool

Next job will be making a wheel and a pinion to test my tools

Regards

Mogens

|

| Geoff Theasby | 05/04/2011 15:23:17 |

| 615 forum posts 21 photos | Now then, this raises a question which has been bothering me for a while. Why do clockmakers use a depthing tool? Most model engineering is so precise, the more accurate the better, and yet it seems that clockmakers have to hand-fit every spindle and shaft by reference to how well the gears fit together. Can't you make the holes in the right place, make the wheels and pinions to the drawings, and have it all fit together nicely as intended? Regards Geoff |

| RJW | 05/04/2011 21:22:36 |

| 343 forum posts 36 photos | Sorry folks, there seems to be a word limit or something, as my reply won't appear in full, Will try again later. John Edited By RJW on 05/04/2011 21:28:47 |

| Tony Jeffree | 06/04/2011 09:48:44 |

569 forum posts 20 photos | Posted by Geoff Theasby on 05/04/2011 15:23:17: Now then, this raises a question which has been bothering me for a while. Why do clockmakers use a depthing tool? Most model engineering is so precise, the more accurate the better, and yet it seems that clockmakers have to hand-fit every spindle and shaft by reference to how well the gears fit together. Can't you make the holes in the right place, make the wheels and pinions to the drawings, and have it all fit together nicely as intended? Regards Geoff Geoff - In clockmaking, the objective is to get a good "running fit" between each wheel/pinion pair. In an ideal world, yes you could predict the appropriate centre-to-centre distance to achieve that for a given pair; however, in a world where you are making your own wheels and pinions and the PCD of the resultant object may not necessarily be precisely what it should, you need to use a depthing tool in order to figure out precisely what C-T-C distance you need for the components that you have in hand. There's a saying in clockmaking - "if it rattles, it will run" - what you are aiming for isn't the perfect backlash-free fit, because in all probablility, the resultant friction will be way too high and the clock won't run. So a clockmaker will err on the side of a loose fit, which will help reduce the gearing friction. Bear in mind that the drive train of a clock involves a massive gearing up; the cord that suspends the driving weight in my long-case clock is wrapped around a barrel 16 times to give 8 days of running, so 1 turn of the barrel represents 12 hours of running, so the escape wheel (which carries the seconds hand) rotates 720 times for each rotation of the barrel. Introduce any unnecessary friction into that system and the clock won't run. And of course, given that the drive train is always being driven in one direction, any backlash in the train that may result from your "rattling" fit is of no concern whatever. Regards, Tony |

| Geoff Theasby | 06/04/2011 12:10:40 |

| 615 forum posts 21 photos | Thank you, Tony. That helped a great deal. Regards Geoff |

| Richard Parsons | 07/04/2011 17:36:31 |

645 forum posts 33 photos | One of the reasons why clockmakers use depthing tools is the type of gear wheels used. Firstly whilst Involutes are sometimes more often Epicycloids and Hypocycloids are preferred. Secondly the clock gear wheels are very often much thinner than an engineer would use. In my English Regulator in the ‘going train’ they vary from 1/16” (1.6mm) to 3/16” (appx 4mm) wide. These wheels drive/are driven by pinions or in my case lantern wheels. A lantern wheel is two disks joined by round bars. In my case these bars also rotate in their brass disks and are held in place by hardened steel disks which acts as end stones Making my regulator I was very careful to drill, ream and burnish the bearing holes as well as turning and burnish the pivots to the correct engineering running fits. I built the darned thing up and it would not run. I got the odd ‘tick’ out of it and once a ‘tock’. I spent 4 weeks checking everything again and again and found nothing. I dumped the thing in a box where it stayed for about 6 months. I mentioned the problem to a clock maker i knew. He said ‘your fits’ are not right. I pulled out my pocket note book and showed him. He muttered ‘God these are MUCH too tight. I broached the bearing holes with tapered broaches and burnishers. I ‘topped’ the wheels skimming up to 0.007” (0.18mm) off them. I rebuilt the clock. To my surprise (and horror) the blooming thing ran. That was 12 years ago. It is still running and I hope that when it is loose enough I will be able to fit the double pulley loop on to the drive weight and make it a 14 day clock.

Now i will use a deapthing tool! Edited By Richard Parsons on 07/04/2011 17:39:33 |

| Mogens Kilde | 07/04/2011 18:32:09 |

| 60 forum posts 25 photos | Hello All

Thank you for the kind words.

I'm also very happy about the latest replys, for a moment I thought that my work on this tool was a waist of time, but now I'm more comfort again.

Mogens

|

| Stephen Benson | 18/05/2011 10:36:39 |

203 forum posts 69 photos | I wanted to reply to this thread but I can not add pictures, I can add pictures if I create a new thread but not to an existing thread what am I doing wrong I am using Chrome |

| YouraT | 18/05/2011 14:47:44 |

| 83 forum posts 22 photos | Hi Mogens. Nice depthing tool - is it to your own design, or another? How did you ensure the parallelism required ? Cheers, Youra. |

| Mogens Kilde | 18/05/2011 15:26:40 |

| 60 forum posts 25 photos |

Hi

I made a special fixture for my mini mill

Mogens

Edited By Mogens Kilde on 18/05/2011 15:27:29 Edited By Mogens Kilde on 18/05/2011 15:28:04 |

| Stephen Benson | 18/05/2011 16:41:14 |

203 forum posts 69 photos |

I did not want to upset anyone as

you have beautiful depthing tool which would be great for clock repair as well as clockmaking however I did not want somebody thinking they need to buy or make a traditional

depthing tool like yours to make a clock from scratch. I prefer lantern pinions on my clocks

as I believe they offer lower friction but there are many that hold the reverse

view so the only work in progress clock I have at the moment has

lantern pinions. I

have added enough views so that anyone could make one there several designs of

this tool mine is based on a John Wilding design modified so it can be mounted

in a vice.

Sussed the insert picture problem I had to scroll up to find the insert picture popup

Edited By Stephen Benson on 18/05/2011 16:47:12 |

| YouraT | 18/05/2011 16:59:32 |

| 83 forum posts 22 photos | I made a very similar tool when I constructed my first (and, it has to be said, thus far only) clock - also a Wilding design - the Egg Timer. Lantern pinions also. http://picasaweb.google.com/youra.turceninoff/WildingEggTimerConstruction Your vice mounting modification is a good idea - I may need to copy...  I still like the idea of making a depthing tool to the 'old pattern' as it were - but a fabricated version rather than one based on a casting seems the way to go. Edited By YouraT on 18/05/2011 17:02:41 Edited By YouraT on 18/05/2011 17:02:59 |

| NJH | 18/05/2011 19:14:49 |

2314 forum posts 139 photos | Hi Guys Here is my variation on John Wildings theme! I have added a "fine adjuster" as I found that tightening the moveable arbour sometimes changes the adjuustment and the need for three hands is reduced! Edited By NJH on 18/05/2011 19:16:15 Edited By NJH on 18/05/2011 19:17:38 Edited By NJH on 18/05/2011 19:18:04 |

| roy entwistle | 10/02/2017 19:40:44 |

| 1716 forum posts | Remember that in a clock the wheels are driving the pinions which is not how an engineer would design it but thats the way things are. Also remember that a lot of country clocks were made by the village blacksmith who by tradition wouldn't measure anything. Things were made to fit each other. Roy |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in