Extrusion Press

| Paul Boscott | 19/12/2009 17:46:10 |

99 forum posts 21 photos | I have started my latest model a 2 year project to make a working model of an extrusion press from photos and memory if any one would like to help me fill in the gaps please visit my website thank you for your time

All being well you should be able to see it working at the 2011 Model Engineering Exhibition.

Paul Boscott

|

| Paul Boscott | 28/12/2009 11:22:49 |

99 forum posts 21 photos | I have updated my web site http://www.boscott.co.uk/

added wanted page and new drawings

Paul Boscott |

| JasonB | 28/12/2009 13:32:28 |

25215 forum posts 3105 photos 1 articles | Paul, can I ask what sort of size this model will end up? All I can see in the spec for the full size is its weight and using the cube rule the model will weigh in at around 160kg assuming similar materials.

Looks like you will have a lot of milling to do if no one cumes up wiyh a source of UB, There are brass ones available but only upto 10mm.

Jason |

| Paul Boscott | 28/12/2009 14:51:07 |

99 forum posts 21 photos | Jason

Thank you for your interest The baseboard that I am currently looking at is 60 inches long by 28 inches wide (must go through a standard door) this includes a short section of cooling table to extrude on to. The actual press part of the model as in the website drawings is 38 inches by 15 inches but there is the billet furnace yet to add to the width. The intention is to fit it on to a wheeled box like structure with the computer controls and pump in the base and a hinged side that opens up to make a half size mock up of the real control desk. To include temperature, pressure indication and computer mimic screen as well as the fully manual set of command switches. Paul |

| Paul Boscott | 21/03/2010 08:11:46 |

99 forum posts 21 photos | Hello All

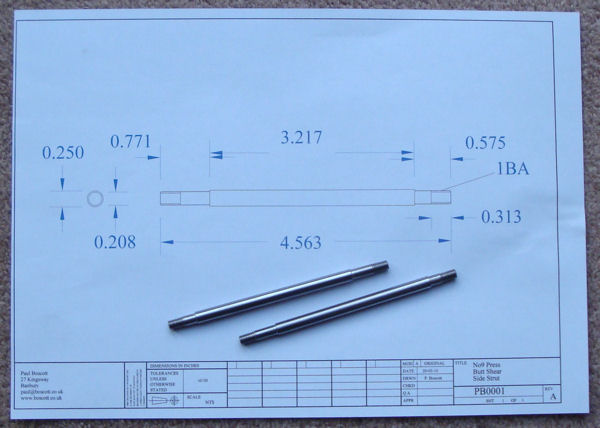

Project on schedule drawings 90% complete and first two parts made seehttp://www.boscott.co.uk/index.html

Paul

|

| Paul Boscott | 04/07/2010 18:40:19 |

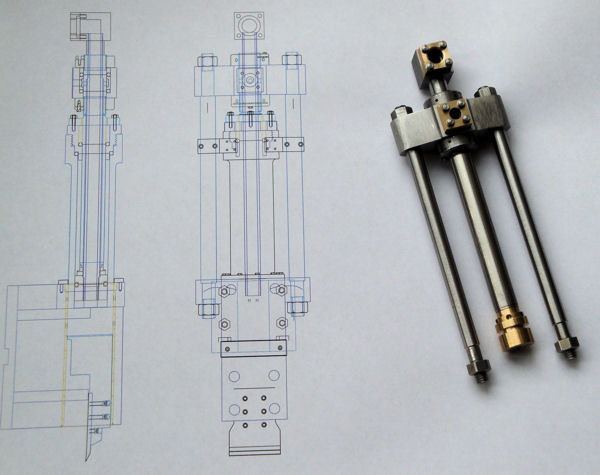

99 forum posts 21 photos | At last a weekend in the workshop see http://www.boscott.co.uk/modelphotos.html

Paul |

| Paul Boscott | 25/07/2010 20:31:48 |

99 forum posts 21 photos | Model finish How accurately should a model reflect the finish of the original? The quandary that I have is that the finish on the actual extrusion press that I am making as a 1/12 scale model is in some places where it did not matter is to say the least is rough some of the parts have been flame cut and the rough edges smoothed of with an angle grinder though the mating faces were surface ground. see http://www.boscott.co.uk/photos.html I have heard the fitters at the time refer to this as Russian tank manufacture (a reference to the system where the finish is only controlled by the actual engineering requirement to minimise workshop hours) My question to you as model engineers is should I reproduce the machine as it actually was or should I improve the look of the finish to a better standard? |

| Ian S C | 26/07/2010 06:12:59 |

7468 forum posts 230 photos | I think you should model it as per the full size machine, and explaned in any write up as you have done above. the finish is going to be reasonable at any rate, ie not too well finished hand filed, or groud up with the Dremel. Ian S C |

| JasonB | 26/07/2010 16:28:27 |

25215 forum posts 3105 photos 1 articles | I would also try to get the same finish, if the 1/35th tank boys can do it then at 1/12 it will be far more noticable. You may just get away with a hacksawn finish to represent the flame cut edges.

But you can bet when its finished someone will come along and say "he hasn't even filed the edges"

Jason Edited By JasonB on 26/07/2010 16:28:50 |

| Paul Boscott | 12/09/2010 21:53:30 |

99 forum posts 21 photos | Just to let you know that progress is being made check

I have tested it using compressed Air and it works correctly

|

| John Olsen | 13/09/2010 09:31:34 |

| 1294 forum posts 108 photos 1 articles | I hope you are keeping full drawings and will do a write up in the magazine later since it would be a nice change from all the locos... regards John |

| Paul Boscott | 14/09/2010 13:34:33 |

99 forum posts 21 photos | John

Thank you for your intrest I am making a drawing sheet for each part as I go. I have drawn up the compleat press assembled using AutoCad to ensure that the bits wil all fit togeather before I statred to machine any thing

Paul |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in