Mill recommendations

| Puddleglum | 19/05/2023 21:44:21 |

| 23 forum posts | What would be your recommendations for a milling machine? Haven't got the space for the big free-standing type of machine Edited By Puddleglum on 19/05/2023 21:56:04 |

| Thor 🇳🇴 | 20/05/2023 07:18:14 |

1766 forum posts 46 photos | I have a Mini Mill, it doesn't take up much space. A larger and heavier bench milling machine means you can handle larger work and take heavier cuts. Get a milling machine as large and heavy as you can find space for. Have a look at Arc or Warco to get info on various machines. I upgraded from the Mini Mill to a larger machine. Thor |

| Clive Foster | 20/05/2023 08:24:34 |

| 3630 forum posts 128 photos | Puddleglum It all depends what you want to do. Fundamentally you need enough room for the jobs planned, long enough travels to work on them and enough set up flexibility to get at all the faces. Not forgetting affordability and the need to accommodate the beast. For first time buyers the big trap is forgetting that pretty much everything goes inside the workspace so things like vices and other work holding significantly reduce the space for the job. Long tools like larger drills can be a particular problem on smaller machines. A set of stub drills can be real handy here. Who needs a 6" long drill when your biggest job is only 1" thick! Smaller hobby mills have to be made at a price the ordinary guy can afford which inevitably puts limits on performance. The art is to pick one whose serious limits are outside what you want to do. Lighter cuts, smaller tools and more passes are a given for small machines tho'. For example tilting heads man for a more flexible machine but tend to reduce rigidity. The need to reset after working at an angle often dissuades folk from exploiting that feature. For small jobs tilting the workpiece is generally not that difficult anyway. So why pay for what you won't use. Another example is the popular round column drill-mills that put a lot of workspace into an affordable and relatively compact package. Major issue is that it's hard to keep the head in dead nuts alignment if moving the head up up and down so, all too often, the useful vertical envelope is limited to the quill travel. Back to the coping with long drills and short cutter problem. When choosing it's easy to concentrate on what the potential object of your affections can do. Which may cause you to overlook something it can't do that will end up being important. How do I know! Before finally putting money down its a useful exercise to compare your choice against a Bridgeport which can, probably, handle anything Home Workshop Guy can lift by listing out what the Bridgeport can do but your choice can't. Hopefully there will be nothing of significance on the can't do list beyond sheer size but if there is at least you have been warned and can look into work arounds. Generally folk have figured out work arounds for the limitations of all the smaller hobby machines. A bit of internet searching will find the answers so its just down to whether the work around is something you can handle. Clive Edited By Clive Foster on 20/05/2023 08:25:19 |

| Puddleglum | 20/05/2023 09:18:43 |

| 23 forum posts | Thanks both - really helpful. |

| DiogenesII | 20/05/2023 09:58:55 |

| 859 forum posts 268 photos | As Clive mentioned, if you have a particular field of interest or projects in mind that you can share, it would probably draw out some more specific recommendations. There's range of subtleties between what's good for automotive repairs or traction engines and what's good for building model aero engines or clocks. Also (if it's not indelicate) do you have a (vague) budget in mind? |

| SillyOldDuffer | 20/05/2023 10:01:02 |

| 10668 forum posts 2415 photos | How much space do you have? And what do you want to do with it? General rule with machine tools is bigger is better unless specialising in small work. It's because big machines can usually do small work, albeit uncomfortably, but small ones can't do big. Anyway, assuming you're after a mill that will sit on a bench, there are various options. One of the many attractions of clockmaking is that the equipment doesn't take much space, and is clean and quiet enough to be done indoors: box-room, or under the stairs etc, Same applies to small-stuff hobbies like jewellery, model-railways, and makers adding modest metalwork to 3D printed items. The Sherline Mill is popular for this scale of work:

Or, bit bigger, a Far Eastern micro-mill, this example is sold by ArcEuro, an SX1LP, weight 50kg:

The micro-mill is first in a series of similar machines, each bigger and more capable. From Warco, the WM12 (weight 54kg), WM14(60kg), WM16(113kg), and WM18 (220kg) Of these, I think the biggest I would put on a bench is the WM14. A WM18 is much too big. Although the WM12 and SX1LP are similar, there are reasons for preferring one over the other. For instance, the SX does high RPM with a less powerful motor. This may be exactly what's wanted on a small milling machine. Small cutters work best at high-rpm, so with a 2mm diameter drill in the chuck, an SX should do better than a WM12. However, if the mill routinely tackles larger work (still small), I'd expect the WM12 to win, because it's more powerful motor can also manage the lower rpm needed. With a 6mm drill in the chuck, the WM12 has the advantage. Both machines will do the job, but they're not identical. Proxxon sell a micromill too:

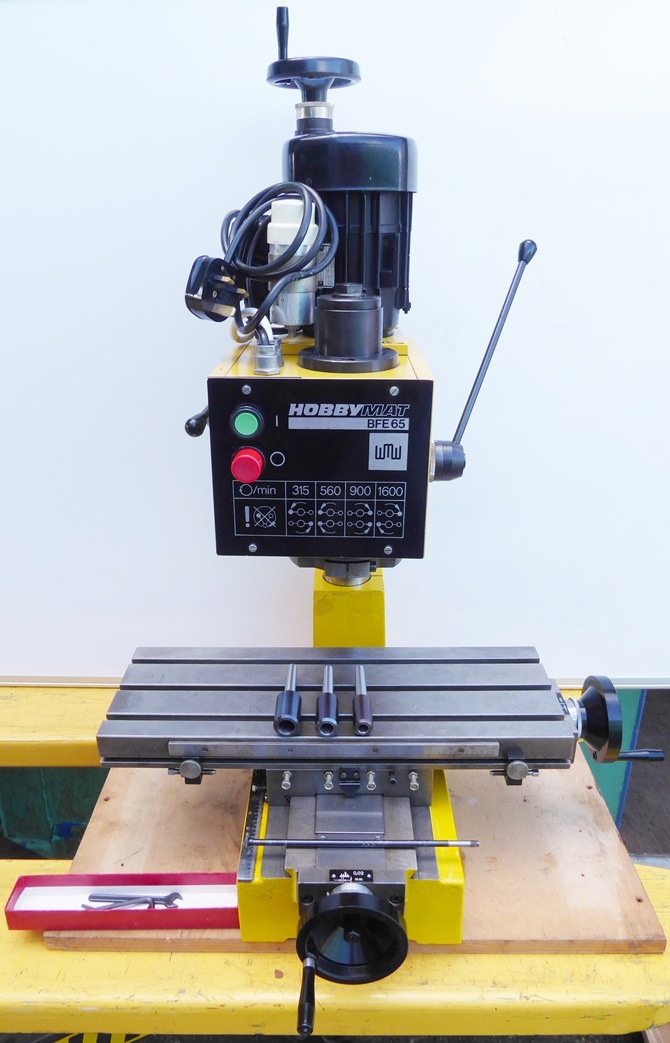

There are second-hand possibilities too, but with these condition is everything. This example is a Hobbymat:

Ought to say affordable small milling machines get mixed reviews. I suspect the problem is they have to be operated carefully within their limitations. They're not powerful or rigid, so anything remotely heavy handed will cause trouble ranging from low accuracy, to cooked electronics and burnt out motors via stripped gears! Patient delicate cutting rather than showers of red-hot swarf! Can you say more about what the mill is for? Clocks and motor-bikes are very different. Dave |

| Dave Halford | 20/05/2023 10:21:41 |

| 2536 forum posts 24 photos | Wayne, If you have a grand spare the Arc Seig mill bundle will start you off. Anything cheaper is a toy and will disappoint. Less spendy are the secondhand belt drive round column type mentioned by Clive that look similar to the current Warco Major WM50. They were made in 3 sizes back in the day when Warco sold all three, they called them Economy (1/2hp), Minor (1hp) and Major (2hp). The Major was and still is enormous for a bench mill needing 1sqM of space and has been sold under various names. This is an Axminster version The Minor is probably the best size, your problem will be fetching it yourself and making sure it has all the handwheels intact. |

| Puddleglum | 20/05/2023 11:59:01 |

| 23 forum posts | Again, thanks all. |

| mgnbuk | 20/05/2023 12:25:53 |

| 1394 forum posts 103 photos | Space available - something like the footprint of a washing machine, Be aware that milling machine needs more space around it to function - uinlike a lathe the area needed is larger than the basic footprint of the machine as the table is moved throughout its working envelope. You will only get a small machine "working space" in the 600mm or so width of a typical washing machine. Nigel B. |

| Puddleglum | 20/05/2023 12:31:38 |

| 23 forum posts | Be aware that milling machine needs more space around it to function Yep - noted, ta. |

| Peter Cook 6 | 20/05/2023 12:54:29 |

| 462 forum posts 113 photos | When choosing, don't forget you will also need to buy tooling and "other stuff". That quickly gets expensive. I would agree with most of what has been said above. I bought an SX1LP from ARC a couple of years ago, and am not at all disappointed, but then most of the work I do is clock scale in brass and aluminium and the SX1LP is ideal for that. Occasionally when milling something a bit bigger in steel it can feel frustrating having to take small cuts. But the next job ( e.g. putting an 0.75mm hole in the edge of an hour pipe) it's high speed and delicacy of feel is a saving grace. |

| JasonB | 20/05/2023 13:28:17 |

25215 forum posts 3105 photos 1 articles | Posted by Puddleglum on 20/05/2023 12:31:38:

Be aware that milling machine needs more space around it to function Yep - noted, ta. So was your 600mm washing machine space taking movement of the table into account/ If so you will be very limited as even something like an SX1LP and SX2PG need a minimum of 850mm, 900 is more comfortable. |

| Puddleglum | 20/05/2023 14:18:39 |

| 23 forum posts | Table clearance in addition - if on bench can move out over space at end and where have bench top available for doing other stuff

|

| Puddleglum | 20/05/2023 14:25:20 |

| 23 forum posts | Is the Clarke CMD300 more equivalent to Sieg SXP1 or SXP2? |

| not done it yet | 20/05/2023 19:57:15 |

| 7517 forum posts 20 photos | Posted by Puddleglum on 19/05/2023 21:44:21:

What would be your recommendations for a milling machine? Haven't got the space for the big free-standing type of machine Edited By Puddleglum on 19/05/2023 21:56:04 Not nearly enough info in that simplistic post. New - or secondhand? I would compare the different types to see what fitted my needs before asking for recommendations on that limited range. Search for ‘bench-top’ machines? But, there again, one of my machines was bolted on a bench for some time, until I installed the original stand. There are quality differences, not just size difference to take into account. Unlimited funds will purchase a (hopefully) far better better machine than a cheap budget option. Is this going to be a ‘keeper’ or the start of a series of improvements in the foreseeable future?

|

| Dave Halford | 21/05/2023 10:50:08 |

| 2536 forum posts 24 photos | Posted by Puddleglum on 20/05/2023 14:25:20:

Is the Clarke CMD300 more equivalent to Sieg SXP1 or SXP2? Wayne, The answer lies in the specs tab for each machine. It is more SXP2 table wise. The Clarke is more expensive (you still need all the bits Arc bundle in) and I don't think the Clarke is a Seig and when Clarke cease to sell that model spares become unavailable. You need to be very careful when comparing the power in Watts. Some UK suppliers will list the output watts which is a mechanical figure, others will quote the input electrical power which will be a larger figure. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in