Die head and chasers... got a bunch, no idea! swap for knowledge?

| JP Santos | 05/03/2023 13:00:57 | ||||||||||||||||||||||||||||

| 49 forum posts 9 photos | Hi all. here's me reaching out again for a little help. Edited By JP Santos on 05/03/2023 13:01:30 | ||||||||||||||||||||||||||||

| DC31k | 05/03/2023 14:58:06 | ||||||||||||||||||||||||||||

| 1186 forum posts 11 photos | They are Coventry dieheads. There is a manufacturer's publication, imaginatively titled "The book of the Coventry Diehead". Free pdf copies are available online. Study it well. | ||||||||||||||||||||||||||||

| Andrew Johnston | 05/03/2023 15:47:19 | ||||||||||||||||||||||||||||

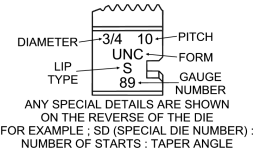

7061 forum posts 719 photos | This picture should give you some guidance as to the size of the dies for a given size of head: There are four dies per set, labelled 1 to 4. Not only do the thread type and die type have to match for all dies in a set there is also an arbitrary number on the dies which needs to be same for all dies in a set. The arbitrary number is related to the numbers on a tapered rule used when sharpening the dies, 51 in this case: Andrew | ||||||||||||||||||||||||||||

| noel shelley | 05/03/2023 17:20:41 | ||||||||||||||||||||||||||||

| 2308 forum posts 33 photos | The book of the coventry die head comes in many editions, running to ed 27 I think. How they work is clever and interesting. DO NOT try to sharpen them unless you have the special jigs ! depending on size they can need considerable torque to operate. Good luck Noel. | ||||||||||||||||||||||||||||

| JP Santos | 05/03/2023 17:30:02 | ||||||||||||||||||||||||||||

| 49 forum posts 9 photos | Hi Andrew, Thanks for those photos, it helps!

Edited By JP Santos on 05/03/2023 17:45:04 | ||||||||||||||||||||||||||||

| Martin Kyte | 05/03/2023 17:44:06 | ||||||||||||||||||||||||||||

3445 forum posts 62 photos | What a shame you didn’t pick up the Whitworth chasers. If you decide to sell one of the heads sit would make it so much more saleable. regards Martin | ||||||||||||||||||||||||||||

| JP Santos | 05/03/2023 17:48:35 | ||||||||||||||||||||||||||||

| 49 forum posts 9 photos | Posted by Martin Kyte on 05/03/2023 17:44:06:

What a shame you didn’t pick up the Whitworth chasers. If you decide to sell one of the heads sit would make it so much more saleable. regards Martin

Are they desirable? I can go back Monday evening for another look, i'm sure they'll still be there. | ||||||||||||||||||||||||||||

| jimmy b | 05/03/2023 19:02:47 | ||||||||||||||||||||||||||||

857 forum posts 45 photos | The die heads are worth good money, especially with complete (4) dies. All the ones I have sold have gone overseas.

Jim | ||||||||||||||||||||||||||||

| Speedy Builder5 | 05/03/2023 19:10:21 | ||||||||||||||||||||||||||||

| 2878 forum posts 248 photos | Odd chaser dies can be used on their own with a suitable holder as chasers. They can easily be sharpened at home and provide excellent formed threads on their own (without the die box). Bob | ||||||||||||||||||||||||||||

| Martin Kyte | 05/03/2023 20:58:22 | ||||||||||||||||||||||||||||

3445 forum posts 62 photos | Posted by JP Santos on 05/03/2023 17:48:35:

Posted by Martin Kyte on 05/03/2023 17:44:06:

What a shame you didn’t pick up the Whitworth chasers. If you decide to sell one of the heads sit would make it so much more saleable. regards Martin

Are they desirable? I can go back Monday evening for another look, i'm sure they'll still be there. I suppose I am making the assumption you are in the UK. Larger scale traction engine builders I believe tend to use Whitworth form. UNF UNC not so much. Andrew Johnston is more knowledgeable than me re die heads. Anyway if the dies are up for grabs for free it gives people choice. regards Martin | ||||||||||||||||||||||||||||

| Andrew Johnston | 05/03/2023 21:25:24 | ||||||||||||||||||||||||||||

7061 forum posts 719 photos | If the Whitworth dies are for free I'd definitely acquire them. Assuming they are in sets they have a value in the Uk. Andrew | ||||||||||||||||||||||||||||

| D.A.Godley | 05/03/2023 22:30:48 | ||||||||||||||||||||||||||||

| 143 forum posts 41 photos | Have a look at Wiseman Threading Tools Ltd . Redditch . You will find all details of available parts and combined with the handbook mentioned in a post above , I am sure clear up any question you may have , as they have in the past for me ! .

| ||||||||||||||||||||||||||||

| Hopper | 05/03/2023 23:40:26 | ||||||||||||||||||||||||||||

7881 forum posts 397 photos | If you can clamp one chaser in your lathe's toolpost, it makes a nice screwcutting tool. | ||||||||||||||||||||||||||||

| Nigel Graham 2 | 05/03/2023 23:42:11 | ||||||||||||||||||||||||||||

| 3293 forum posts 112 photos | The special jig for sharpening these dies also needs a special grinder: a tool-&-cutter grinder or (I think) a surface-grinder. | ||||||||||||||||||||||||||||

| Clive Foster | 06/03/2023 09:25:55 | ||||||||||||||||||||||||||||

| 3630 forum posts 128 photos | I'm unconvinced as to the general suitability of MT taper for mounting a Coventry Die Head. By their very nature there is significant lengthways pulling force on the head as it cuts the thread which will tend to pull it out of the MT socket. When using one with an MT taper in a tailstock the tailstock has to be fed hard enough to keep it properly seated in the taper but not so hard as to interfere with the thread profile. When reaching the end of the thread the taper seating grip has to be sufficient to resist the spring forces as the head pulls forward to trigger the opening process. If the taper grip is inadequate the head will go round with the job rather than continue cutting the thread. A bit fraught methinks. If the tapers are less than perfect it would seem that the only safe way is to eschew the self opening feature and use it like a simple fixed tailstock die carrier keeping continuous feed force applied and stopping the lathe when you get to the end of the thread. The head can then be opened manually. Perfectly practical unless the tapers are distressed almost to the point of being unusable but it does loose most of the benefits. Frankly an ordinary sliding die holder is may then be easier, although they too will spin if the tapers are poor. My die head has a parallel shank so I made a simple holder to mount it in a Dickson QC tool holder by welding a split tube to a solid bar. I feed up to a bed stop using the saddle hand wheel whereupon the thread pulls the head forward to trigger the disengagement. The disengagement pull forward distance is significant. Power feed by setting up the appropriate pitch and driving as per screw cutting works well but the half nuts need to be dropped promptly and final feed to the stop done by hand. I trimmed the bar to match the tube radius on the lathe with it mounted in the toolpost to ensure all was aligned. Did the same to finish the bore. The portion behind the die head shank is bored little larger so I can easily set it on centre using a short cylinder gauge mounted in the tailstock taper. It lives permanently in that toolholder, carefully selected as being the grottiest one which I didn't mind loosing from general stock. Clive

| ||||||||||||||||||||||||||||

| Andrew Johnston | 06/03/2023 09:35:20 | ||||||||||||||||||||||||||||

7061 forum posts 719 photos | Posted by Nigel Graham 2 on 05/03/2023 23:42:11:

...or (I think) a surface-grinder. A basic surface grinder is all that is needed. The required angles and placement of the dies is taken care of by fixtures: Andrew | ||||||||||||||||||||||||||||

| JohnF | 06/03/2023 13:17:05 | ||||||||||||||||||||||||||||

1243 forum posts 202 photos | Posted by Clive foster I'm unconvinced as to the general suitability of MT taper for mounting a Coventry Die Head. By their very nature there is significant lengthways pulling force on the head as it cuts the thread which will tend to pull it out of the MT socket. There is no problem with using die heads with a morse taper, I have cut probably thousands of threads mainly with 1/2" or 1/4" units and never a problem. Those with a parallel spigot are generally use on capstan lathes, the one I have and use is a 1/2" unit and to facilitate its use on my lathes made a No2 Morse taper holder with a 1" hole for the die box -- never a problem. John | ||||||||||||||||||||||||||||

| Clive Foster | 06/03/2023 13:55:15 | ||||||||||||||||||||||||||||

| 3630 forum posts 128 photos | John I'm impressed that a Morse Taper works so well at holding a die head. Like most folk using older machines I've had too many issues with drills pulling out of, presumably, less than perfect tapers to be totally confident in their holding power against pull out forces. Not quite the same but even after recutting the socket the MT 3 on my big Pollard drill isn't totally reliable when holding Pollard tapping heads. Which admittedly are quite large and quite heavy. Lifting the drill down-feed handle to engage auto reverse occasionally drops the taper either immediately or part way back. Hence my skepticism as to whether the mutual grip of an old shank in an old socket will suffice. My first encounters with a brand new shank in brand new taper were somewhat educational. The difference between old, albeit still adequately functional when used with care, and new being profound. Clive | ||||||||||||||||||||||||||||

| David Davies 8 | 06/03/2023 18:02:08 | ||||||||||||||||||||||||||||

202 forum posts 1 photos | If you want to see one in action have a look at Mr Crispin's channel on Youtube. He does not use the MT in the tailstock barrel but has made a sleeve to clamp the diehead and tailstock barrel together thus eliminating the risk of the DH pulling out of the tailstock socket. HTH Dave | ||||||||||||||||||||||||||||

| Nigel Graham 2 | 06/03/2023 18:36:27 | ||||||||||||||||||||||||||||

| 3293 forum posts 112 photos | My die-head came with a similar sleeve, made for the tailstock of a heftier lathe than my Harrison L5; but that would be the best approach on a reasonably large machine. I'd suggest a clamp rather than grub-screw fitting so you don't risk indenting the tailstock barrel. For a small lathe I think a tool-post fitting (as Clive Foster's) or saddle mounting may be better. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in