Gear Cutting - Using Involute cutters outside range

| Durhambuilder | 29/11/2022 17:20:04 |

| 77 forum posts 5 photos | I’m really struggling to find a number 2 48DP gear cutter to cut a 72 tooth gear. I also need a number 3 to cut a 36 tooth and those appear to be easily available. What problems might my encounter using a number 3 to cut 72 teeth, it’s for a slow running hit and miss engine. |

| Pete Rimmer | 29/11/2022 17:47:07 |

| 1486 forum posts 105 photos | You shouldn't because it will likely bind at the proper centre distance. If you like I could hob either or both of those gears for you 48DP 20PA. |

| Brian Wood | 29/11/2022 17:47:13 |

| 2742 forum posts 39 photos | Hello Durhambuilder, It will have a little more shape to it rather than tending towards rack form as the # 2 but I don't think it will make a significant difference to running. To ease a slight mismatch with it's mating gear I suggest some gentle lapping of the two together with Timesaver Green if you have any before building them into the engine. You don't have any? Try toothpaste instead finishing with Brasso. Regards Brian |

| Clive Foster | 29/11/2022 17:47:40 |

| 3630 forum posts 128 photos | Theoretically you may have clearance issues. In practice slight adjustments to addendum, dedendum or spacing should give decent running. Albeit most likely with a touch of sliding contact rather than the pure rolling contact involute gears are designed to give. In a practical world I suspect that very few home workshop made gears are sufficiently accurate to run under pure rolling contact. Some sliding would seem inevitable. Cast iron change wheels on lathes certainly aren't super accurate and they work just fine for that job. So if your task is not seriously more demanding you should be fine. Its an over-simplification but the way I look at it smaller diameter gear wheels bend the basic line of the tooth slightly when compared to a larger one so the centre lines of the tooth would be slightly further apart if the profiles were identical. To compensate for that you need to cut a slightly narrower slot between the teeth if mating teeth are to contact where and how they should regardless of the gear diameter. In reality the profile of the tooth has to change too. Clive |

| Martin Connelly | 29/11/2022 17:50:36 |

2549 forum posts 235 photos | For a one off gear it would probably be cheaper to buy a gear, from HPC for example. It often only makes sense to buy a specific size and range cutter if you are going to make multiple gears for example lathe change gears to add extra pitches or TPI values to what is available. The old saying would seem to apply here, don't ruin the ship for a hap'th of tar. What will happen if you use a number 3 cutter instead of a number 2 cutter is that the teeth will be narrower than they should be and also have the wrong profile. The other option, if you want to go that way, is to make a rack cutter if you have already got a dividing table or spin indexer and a milling machine. I think this is the way Neil did things for some of his projects, but I may be mis-remembering who did this. An unhardened steel cutter will work for a one off or two off in brass and a 20° cutter can be ground from a piece of HSS Martin C The 20° cutter is to make the rack cutter. Edited By Martin Connelly on 29/11/2022 17:52:31 |

| Michael Gilligan | 29/11/2022 17:56:04 |

23121 forum posts 1360 photos | This is probably the handiest chart I have seen: **LINK** https://cdn.shopify.com/s/files/1/0424/4249/0019/files/Involute_Gear_Cutter_Chart_-_Evolvent_Design.pdf?v=1646765216 If you use a No.3 cutter for your 72 tooth gear, the teeth will be too curvy … so if it causes problems, there is a little material to remove from each tooth [and there are obviously several ways to skin that cat] MichaelG. |

| JasonB | 29/11/2022 18:20:21 |

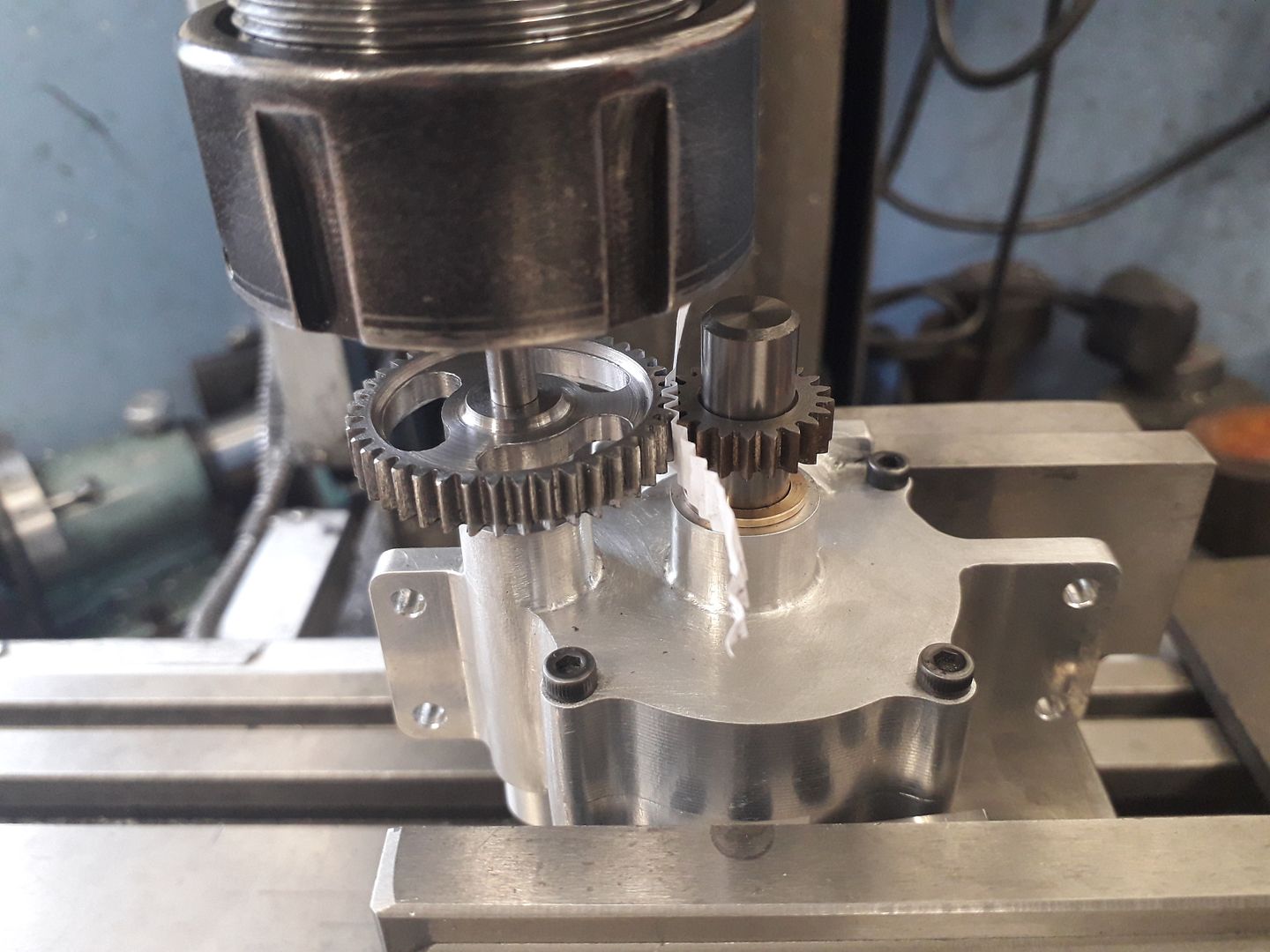

25215 forum posts 3105 photos 1 articles | As the main function of the gear is just to get the 2:1 ratio you could probably get away with using the No3 and just tweak the PCD. Don't know which Hit and Miss you are making but a lot of designs mount the cam gear stud on an eccentric so you can easily adjust the mesh. If not just use a depthing method to place the cam gear a suitable distance from the crank gear, I tend to do that anyway. Typical depthing with a dummy crankshaft supporting the smaller gear and the cam gear held in the mill which is rotated by hand to get a nice mesh and then note the handwheel position or zero the DRO so the cam stud hole can be drilled in that position.

That's quite a lot of fine teeth for a little gear, you could look at the availability of 32DP cutters and go with 48T/24T, might even get away with 24DP 36/18T. Or with a slight adjustment to PCD go for MOD 0.8 with the 48/24T count. Edited By JasonB on 29/11/2022 18:28:35 |

| Dalboy | 29/11/2022 18:41:20 |

1009 forum posts 305 photos | I got my No2 48 tooth from Home and workshop on e bay in September and the No 3 from RDG. Are you building the Farm Boy by any chance Edited By Dalboy on 29/11/2022 18:42:47 |

| Simon Williams 3 | 29/11/2022 18:44:54 |

| 728 forum posts 90 photos | Dunno if it helps, but I happen to have a 48DP no 2 cutter, but for 14-1/2 PA. If it is any use to you and you would like to borrow it send me a PM. Question for the group - is it asking for trouble to run a gear cut for 20PA against one for 14-1/2 in this application? I note the OP doesn't say which PA the pair gear is, but it becomes 20 deg as the discussion progresses. You're welcome to try it and see if it looks right.

|

| Durhambuilder | 29/11/2022 19:14:23 |

| 77 forum posts 5 photos | Oh my word, what a great set of responses, Thank You all. To answer some questions albeit in no particular order: The engine is the Jerry Howell Farm Boy, so far it’s looks as if it will be a great little engine. Some builders have used 76/38 tooth mod 0.5 which appear to work, another builder was caught out using 32DP due to the larger overall diameter of the bigger gear catching other parts of the valve gear. I wonder if there would be a similar issue with MOD 0.8? HPC do the gears in steel, ideally I need the smaller one in steel and the larger one in brass. The tooth cutting depth for 48DP is about 45thou so the teeth are really quite small, I don’t know how critical the tooth profile is given the limitations of a home workshop in these small sizes. I like Jason’s idea for meshing gears, given the limited demonstration use my engine will get I’m tempted to give it a go with just the No 3 cutter. The softer brass gear may just ‘wear in’. Simon that’s a really kind offer to loan a cutter, I’ll give it some thought and drop you a PM later. Once again Thanks All. |

| not done it yet | 29/11/2022 20:26:14 |

| 7517 forum posts 20 photos | As a point of fact, I believe the No.3 cutter is only the true size for a 35(?) tooth gear and the no.2 cutter is true for 55(?) teeth. There are, after all, only 8 cutters for a wide range of tooth counts. If unavailable, cutting gears a few teeth outside the designated cutter may make little difference to the pair, if slow and lightly loaded. I expect that these different cutters are good enough compromise - but would certainly not be used for high-speed, heavily-loaded gears used in commercial gearboxes (such as mass production automotive). Your gears may be a little more noisy, but should last quite a while on a model. Make the 72 in a less wear resistant material than the 36 and obtain the correct cutter as and when it becomes available (if ever necessary)? |

| Pete Rimmer | 29/11/2022 23:13:02 |

| 1486 forum posts 105 photos | You cannot go 'down' out of a cutter's tooth count range without risking interference. This is because as NDIY says each cutter is (should be) the correct shape for the lowest tooth count in its range and it cuts an excess of metal at the top of the tooth as you go 'up' through the cutter's normal range of teeth. The higher the tooth count the lesser the effect which is why the lower tooth count cutters cover a much smaller range of tooth counts. Going out of the tooth count range 'downwards' will cause the cutter to not remove enough metal at the top of the teeth and so they will eventually (depending on how much clearance you are using normally) bind in the meshing gear. Your no3 cutter is the correct form for 35 teeth but has a range of 19 teeth where the departure from form is considered acceptable (35T-54T). You want to go a further 18T outside of that range. The good news is that your gears won't bind but they may rattle and the tooth form will be very pointy at the top compared to how it should be. The only way you're going to know if this is acceptable to you is if you try. |

| JasonB | 30/11/2022 07:11:02 |

25215 forum posts 3105 photos 1 articles | I usually find the clanking of the governor weights (depending on type) and the cam going in and out of contact with the cam follower make far more mechanical noise than the gears If there were issues with a 32DP gear's larger diameter fouling something then 0.8MOD is likely to be the same. You could still go down the metric route and use 0.5MOD which would be closest to 48DP using 76/38T which would have a fractionally smaller OD and need the gears moving about 0.075mm closer together. Edited By JasonB on 30/11/2022 07:52:45 |

| Dalboy | 30/11/2022 08:30:11 |

1009 forum posts 305 photos | Well worth watching this as I believe he uses different cutters than what is stated on the plans

|

| Michael Gilligan | 30/11/2022 08:52:33 |

23121 forum posts 1360 photos | Posted by Dalboy on 30/11/2022 08:30:11:

Well worth watching this as I believe he uses different cutters than what is stated on the plans

. I’ve just watched his ‘intro’ and am well-impressed by his modest presentation Will get some coffee and watch the rest … Thanks for the link MichaelG. |

| Hopper | 30/11/2022 09:03:17 |

7881 forum posts 397 photos | You can buy metric module gear cutters so stupidly cheap, it is not worth mucking about with DP anymore. If 0.5 module would suit your needs, you can buy two cutters for under 15 quid, with virtually free postage. |

| Michael Gilligan | 30/11/2022 09:48:15 |

23121 forum posts 1360 photos | Posted by Michael Gilligan on 30/11/2022 08:52:33: […[ Will get some coffee and watch the rest …

. Job done and he got a very acceptable result. My only concern being that [purely from the sound of it] … I suspect his cutter was eccentric, and pretty-much acting as a single-tooth. MichaelG.

|

| SillyOldDuffer | 30/11/2022 10:46:42 |

| 10668 forum posts 2415 photos | Posted by Simon Williams 3 on 29/11/2022 18:44:54:

... Question for the group - is it asking for trouble to run a gear cut for 20PA against one for 14-1/2 in this application? I note the OP doesn't say which PA the pair gear is, but it becomes 20 deg as the discussion progresses. ...It is asking for trouble, but whether it matters or not depends on how efficient and reliable the gear chain needs to be. For many purposes, gears can be crudely made - 'good enough' provided they mesh reasonably and don't wear badly in short order. Models tend to be run infrequently and be lightly loaded, in which case the builder can get away with any reasonable mesh. The same approach is completely unacceptable if gears are expected to transmit significant power efficiently and reliably for any length of time. A mismatched gear installed in tens of thousands of car gear boxes would soon cause obvious trouble. The mismatched gear teeth would wear rapidly, showering metal filings into the bearings, get hot, and clunk, slap and whine. So a judgment call: mismatching is always a bodge, but it may not matter. Might possible to tabulate the relative good, bad, and ugly fits between different gear DP and Modules, but my gut feel is it's too complicated. For example, correctly matched involute gears have the useful property of working even if their centres aren't located spot on. I think the degree of interference between incorrectly matched gears varies with the distance between centres, so the same pair might jamb or run depending on the centre distance, which could be tweaked by a bodger to make them work. Bodging is the Art of adapting stuff to work within a range of circumstances in a way that's reasonably acceptable. Only the bodger can decide if it's 'good enough'. Manufacturing tends to avoid bodging like the plague; apart from one-offs and prototypes it's cheaper to match stuff correctly in the first place. Dave |

| Andrew Johnston | 30/11/2022 11:31:31 |

7061 forum posts 719 photos | Posted by Michael Gilligan on 30/11/2022 09:48:15:

…I suspect his cutter was eccentric, and pretty-much acting as a single-tooth. In my experience that is a consequence of using cheap cutters. Plus a less than rigid setup. Andrew |

| DC31k | 30/11/2022 12:37:11 |

| 1186 forum posts 11 photos | Posted by Michael Gilligan on 30/11/2022 09:48:15:

... I suspect his cutter was eccentric, and pretty-much acting as a single-tooth. Following on from the observation above about cheap cutters, does anyone know or has measured where the source of error lies in them? Are all teeth ground non-concentric with the centre bore of the cutter or is there a tooth-to-tooth variation? If his cutter were to be held in a four jaw or griptru chuck, it could be dialled in to overcome the first of these problems. I wonder what the milling machine equivalent of a four jaw chuck could look like. If the problem is the second option, is there any solution other than to buy better cutters? |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in