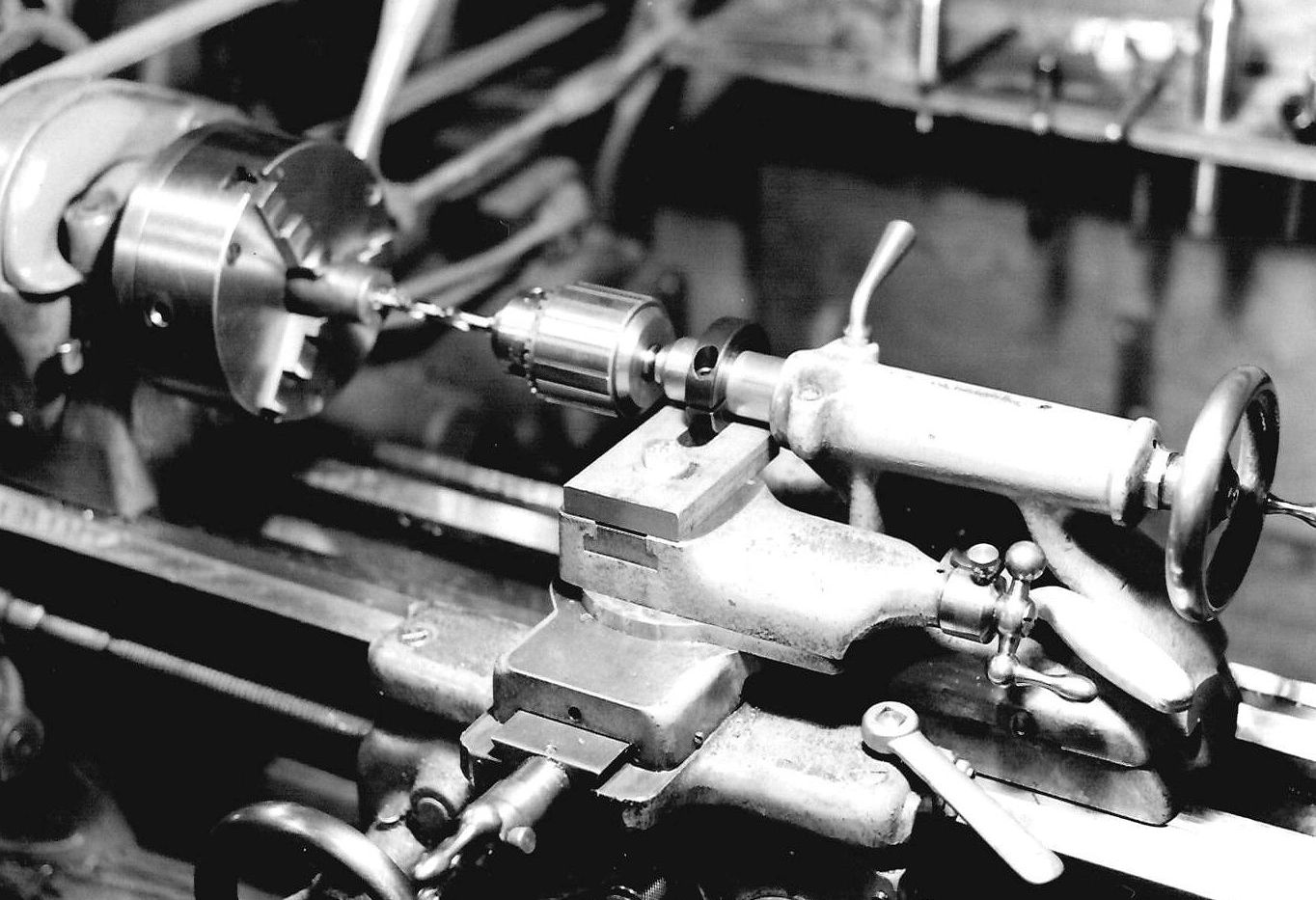

Easy power tailstock feed for your lathe

| Bill Kunz | 09/05/2022 02:14:27 |

| 6 forum posts | Many years ago I came up with a simple power feed arrangement for the tailstock on my 9" South Bend lathe when drilling, reaming, tapping, etc.

Edited By Bill Kunz on 09/05/2022 02:15:18 |

| Nicholas Farr | 09/05/2022 06:24:31 |

3988 forum posts 1799 photos | Hi Bill, that's a novel idea. Regards Nick. |

| Thor 🇳🇴 | 09/05/2022 06:45:30 |

1766 forum posts 46 photos | Thst is a neat way to get powered tailstock feed, I saw it here some time ago, but haven't had time to make one yet. Thor |

| Clive Brown 1 | 09/05/2022 09:01:30 |

| 1050 forum posts 56 photos | Posted by Bill Kunz on 09/05/2022 02:14:27:

Many years ago I came up with a simple power feed arrangement for the tailstock on my 9" South Bend lathe when drilling, reaming, tapping, etc.. I'd question the desirability of a powered feed for tapping, especially in a fairly small lathe. |

| Hopper | 09/05/2022 09:18:18 |

7881 forum posts 397 photos | I think I'd be using spiral flute taps if driving them in under power. But could be handy for drilling, as long as drill bits are well sharpened and don't clog the flutes. I have used power feed drill presses plenty of times and they work well. I suppose you could do the same thing by putting a bit of square bar in the toolpost and putting it up behind the chuck body itself. The taper should be enough to pull the unloaded tailstock along with it. Might have to try that sometime. Specially with the lever tailstock in place, the quill would just follow the chuck along without strain. I might even have a go at making a Y shaped attachment that goes straight in the toolpost and engages with the back of the chuck, so quick and easy installation and removal and no collar on the quill taking up valuable travel. I wonder what sort of feed rate one uses for power drilling compared with turning? Setting up the change gears for other than standard fine feed of about 2 thou per rev would be not worth the faff on my Myfrod. I like the concept though. Edited By Hopper on 09/05/2022 09:30:15 |

| Nigel Graham 2 | 09/05/2022 09:31:15 |

| 3293 forum posts 112 photos | Neat idea! I think I'd rather use a tapping-head for that, though - there is incidentally an old way to use a tap of appropriate pitch, in a suitable tool-post holder, as an internal chaser for much larger diameters than the tap itself. Using a large drill, it may better if the driving bar is one that extends back and pulls the tailstock body as a whole, rather than risking unloading the taper as could happen if the drill snatches. That may be a greater risk on screw-fed tailstocks, than with a lever feed. |

| John Hinkley | 09/05/2022 09:31:26 |

1545 forum posts 484 photos | You could prevent any potential wobble from an over-loose tailstock by mounting a chuck on a sliding shaft held in the tailstock taper, much like a tailsock-mounted die holder. Or, less easily, Do it like Stefan. John

|

| Tim Stevens | 09/05/2022 10:15:01 |

1779 forum posts 1 photos | Also useful for boring, using a boring head held in the tailstock. Cheers, Tim |

| ega | 09/05/2022 10:47:43 |

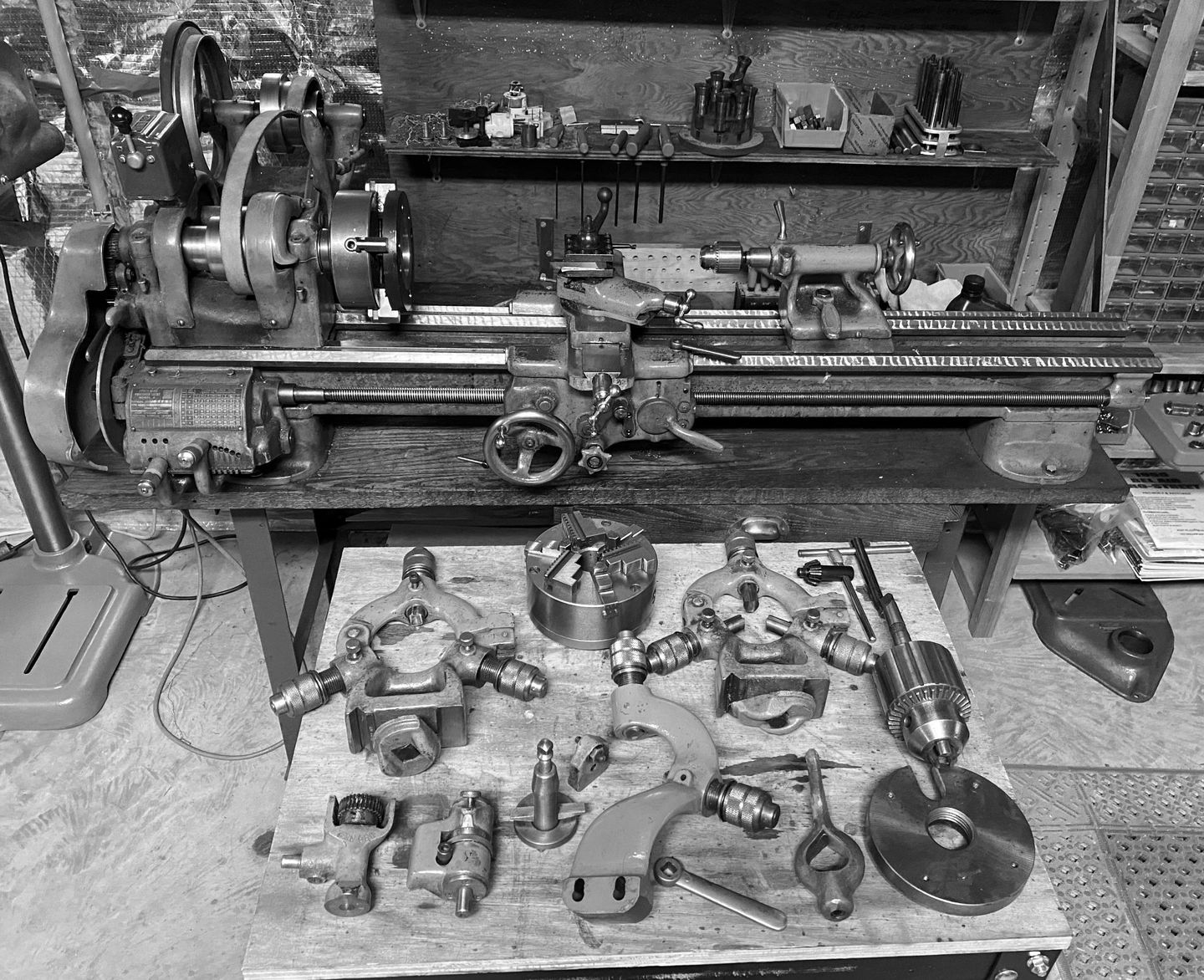

| 2805 forum posts 219 photos | Nice to see vintage (black and white) photos of a vintage lathe! |

| Bill Kunz | 09/05/2022 13:16:38 |

| 6 forum posts | Posted by ega on 09/05/2022 10:47:43:

Nice to see vintage (black and white) photos of a vintage lathe! Here's another:

|

| bernard towers | 09/05/2022 17:50:37 |

| 1221 forum posts 161 photos | There has been one in the past fitted to a Myford with a bracket fitted to the lower front portion of the tailstock and a connecting piece fitted to a t slot on the crosslide, was always going to make one but its still on the list! |

| Mike Poole | 09/05/2022 20:48:56 |

3676 forum posts 82 photos | I watched this video a couple of days ago by Stefan Gotteswinter describing his use of a toolpost mounted drill chuck and how it is very practical for speed of working.Toolpost Drilling Mike |

| Peter Spink | 09/05/2022 23:44:47 |

126 forum posts 48 photos | Posted by Nigel Graham 2 on 09/05/2022 09:31:15:

Neat idea! I think I'd rather use a tapping-head for that, though - Assuming a lever feed, is it possible to use a tapping head in the tailstock? |

| David-Clark 1 | 10/05/2022 07:45:31 |

271 forum posts 5 photos | Watching |

| old mart | 10/05/2022 15:18:42 |

| 4655 forum posts 304 photos | When we were working on the museum's Smart & Brown model A apron there was no way to use the lathe to produce the bushes and spindles needed. I did the exact opposite, using the tailstock to push the saddle using an extra piece of metal bar in the four way toolpost. I backed off the tool and manually returned the saddle to the start position after each cut. |

| Nigel Graham 2 | 16/06/2022 00:50:08 |

| 3293 forum posts 112 photos | Have just watched Stefan Gotteswinter's video - thank you for the link, Mike. Very interesting ideas, not just in the drilling, either. I had pondered the feasibility of a chuck-holder held and driven by the saddle but located directly by the bed, obviating having to align it every time. Using the saddle to pull the tailstock along sort of does that, but you've still the problem of a long overhang, especially with short drills, for the drill even to reach the work. I must admit a 6-jaw chuck is new to me. I might vaguely have heard of them but never seen one in the metal, so to speak. He says a centre-drill is wrong for spotting. Well, I won't argue with that, as it's often said by model-engineers rather nearer the Gold Medal than I'll ever be; but this does seem a recent development, and I don't recall seeing an explanation why they are fine for their named use but not for starting a drill. Regarding his counter-sinking the hole before tapping, assuming sensible metal depth I usually counter-drill to nominal full diameter to just below the surface, one to two thread turns worth. I still lightly chamfer the edge. 0.2mm drills..... I worry about whopping great 2 whole-millimetres.... (Like last night, in the bench-drill, making split-pin holes across 1/4" dia steel.)

|

| Hopper | 16/06/2022 01:06:23 |

7881 forum posts 397 photos | Posted by Nigel Graham 2 on 16/06/2022 00:50:08:

Have just watched Stefan Gotteswinter's video - thank you for the link, Mike. ...He says a centre-drill is wrong for spotting. Well, I won't argue with that, as it's often said by model-engineers rather nearer the Gold Medal than I'll ever be; but this does seem a recent development, and I don't recall seeing an explanation why they are fine for their named use but not for starting a drill. It seems to be a recent thing developed with CNC to eliminate the breaking off of the tip of centre drills when quickly starting a drilled hole. Traditionally we were always taught to start a drilled hole in the lathe with a centre drill. Probably because that is what we had in those days, and we were (supposedly) skilled enough to avoid breaking the delicate tip off a centre drill. So you can start a drilled hole with a centre drill if you want but with short spotting drills readily available today it is quicker, easier and safer to use a spotting drill and save the careful centre drilling for those occasions when you want to use a tailstock centre in the hole afterwards. It saves wear on your centre drills too. At home, I sort of have five bob each way and use a centre drill with about a 7/16" shank and 3/16" tip and just use the very end of the tip to put a small divot in the job to start the next drill, in effect using the large centre drill as a spotting drill. Again, because that is what I have. I bought some cheap spotting drills but they have one full turn of flute on them and seem to flex too much and run off centre. Must get some of the proper ones with about a quarter of a turn of flute and much more rigid. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in