Member postings for Bill Kunz

Here is a list of all the postings Bill Kunz has made in our forums. Click on a thread name to jump to the thread.

| Thread: Easy power tailstock feed for your lathe |

| 09/05/2022 13:16:38 |

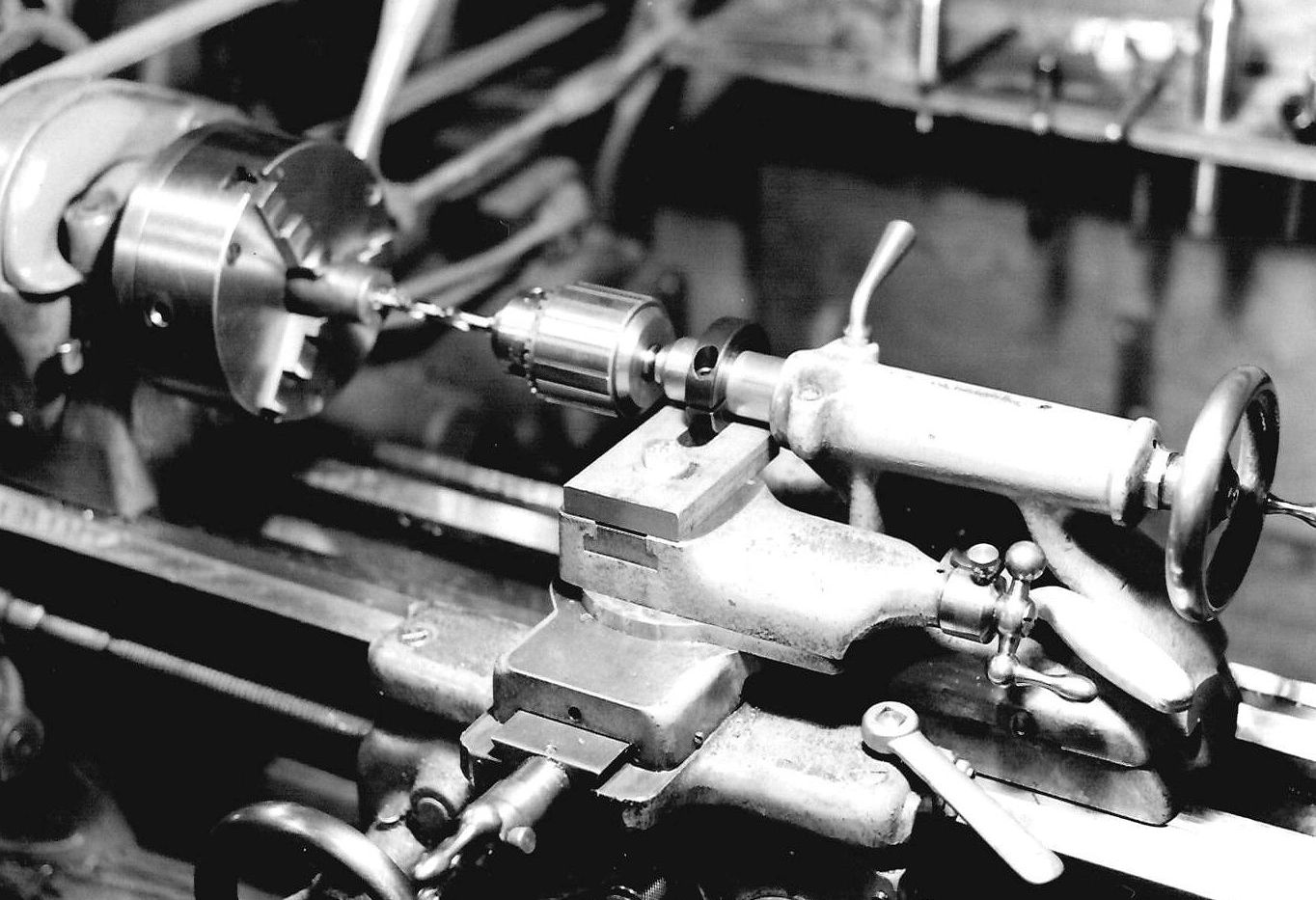

Posted by ega on 09/05/2022 10:47:43:

Nice to see vintage (black and white) photos of a vintage lathe! Here's another:

|

| 09/05/2022 02:14:27 |

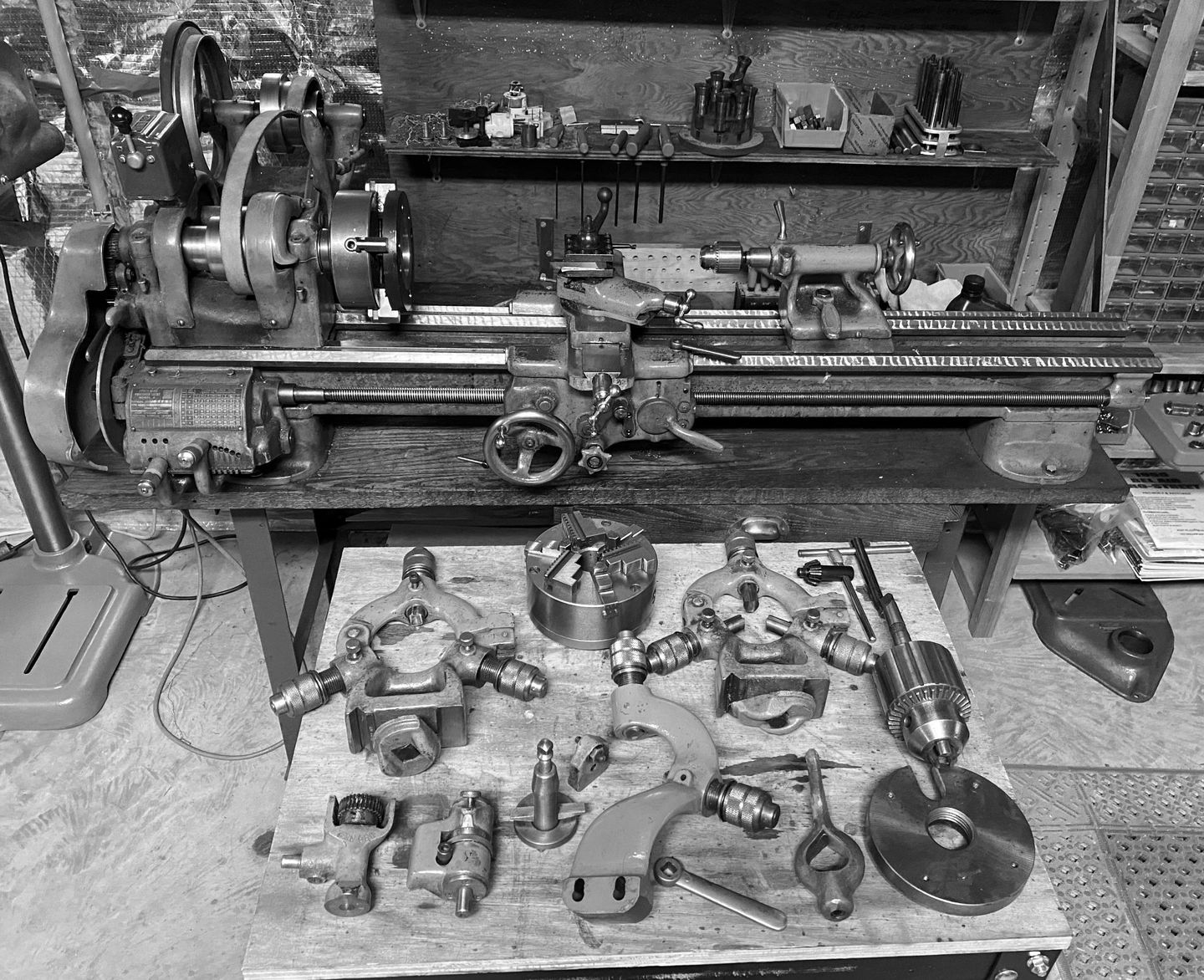

Many years ago I came up with a simple power feed arrangement for the tailstock on my 9" South Bend lathe when drilling, reaming, tapping, etc.

Edited By Bill Kunz on 09/05/2022 02:15:18 |

| Thread: Small (9cm x 9cm) home-made CNC plasma table |

| 08/05/2022 19:00:59 |

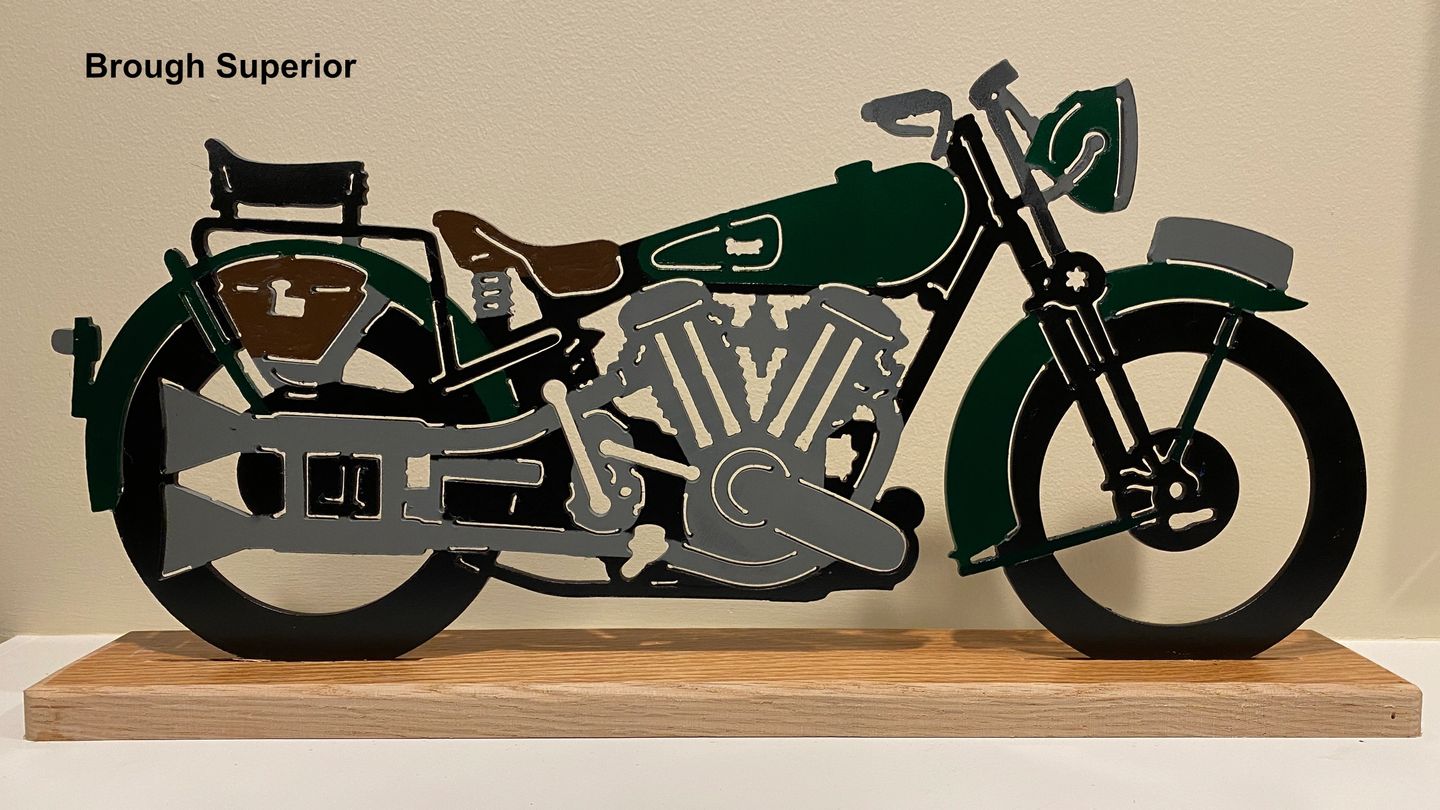

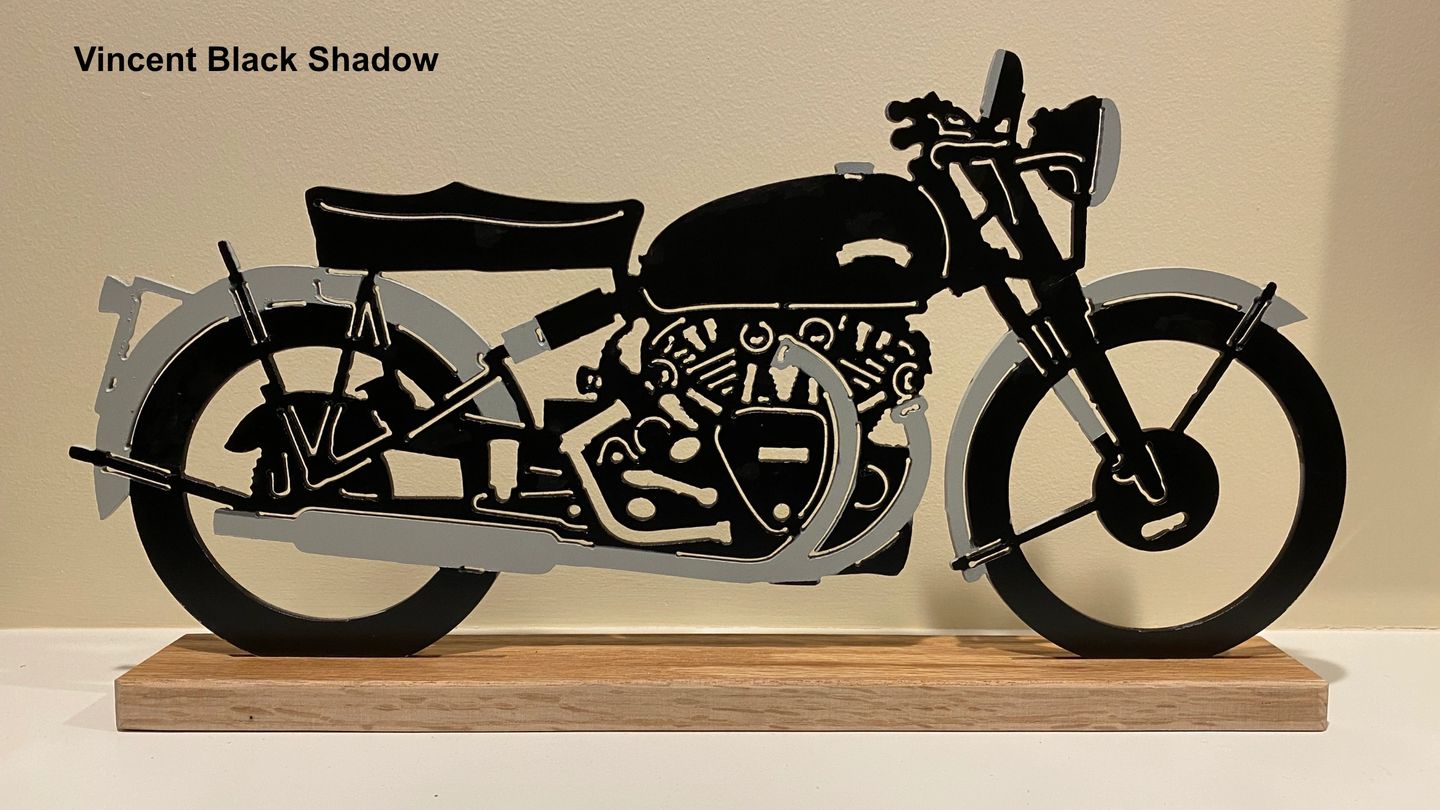

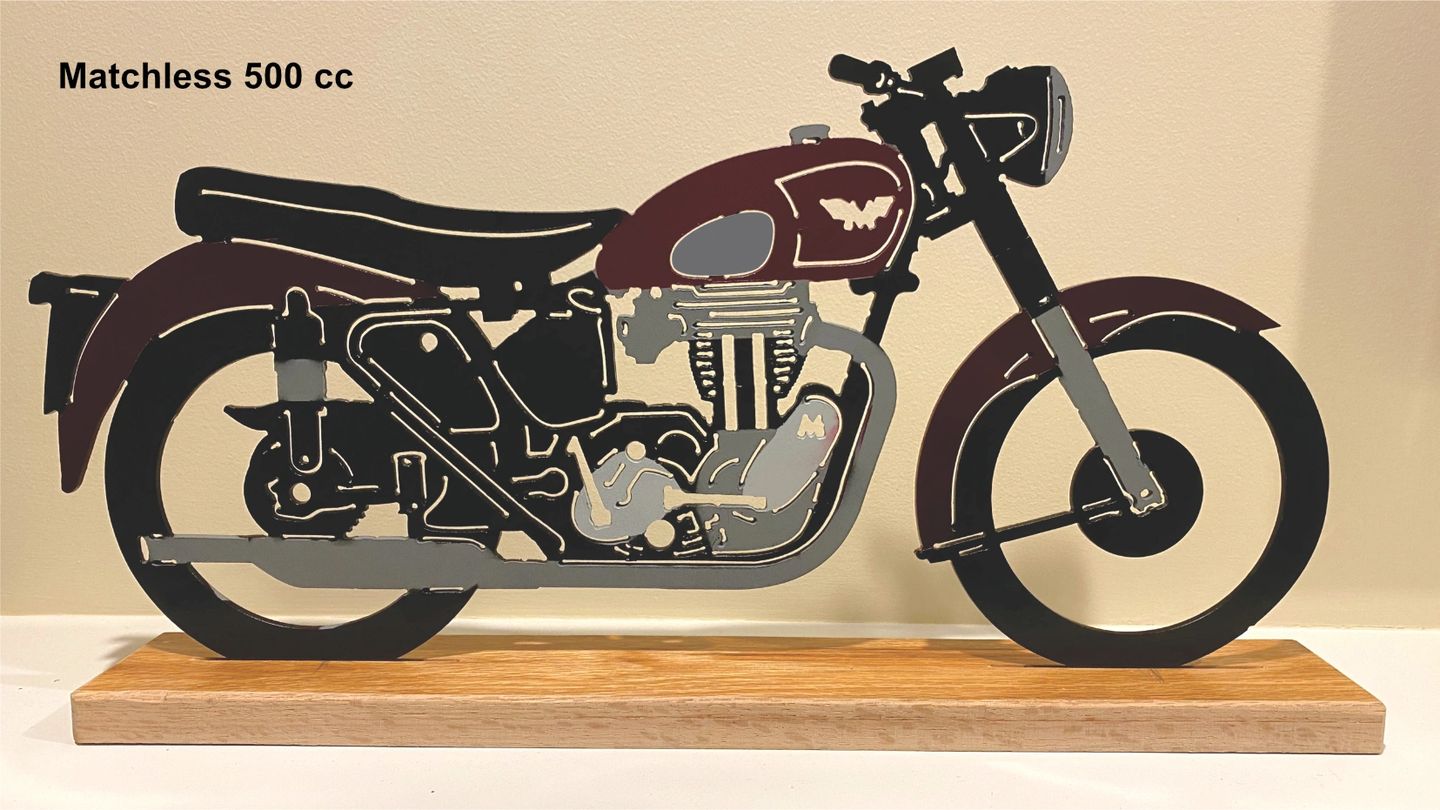

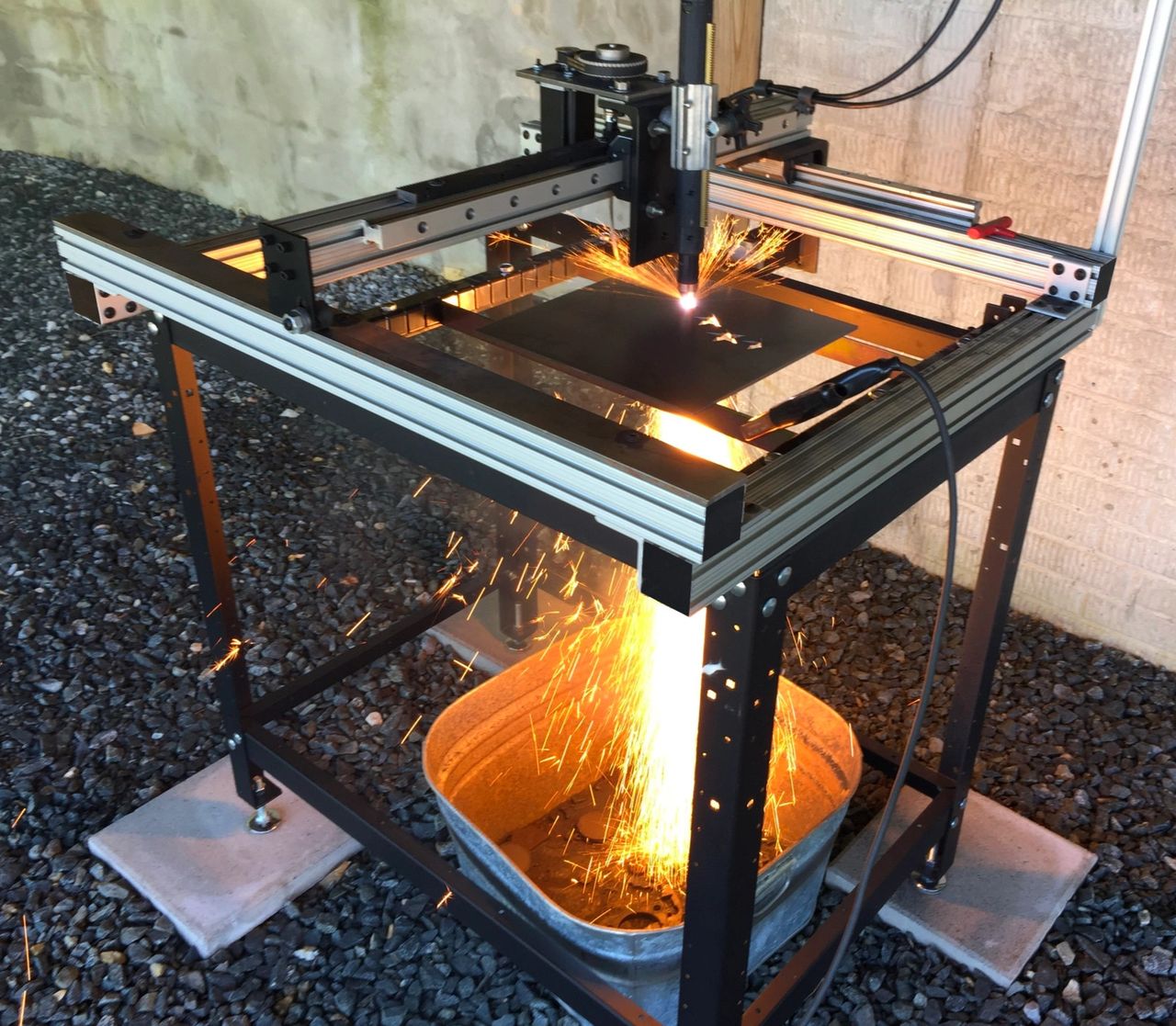

Some examples of pieces I've cut with the little machine:

|

| 08/05/2022 15:29:49 |

I built this small CNC plasma table, which is located just outside my basement door under my deck. I keep the unit protected by a fire pit cover when not in use. The stepper motors remain on the machine, and the cables can be connected in a couple of minutes. The air compressor, plasma cutter, and computer are inside the door. The electronics and software are from FlashcutCNC. This arrangement eliminates the problem of plasma dust and smoke, and possible fire hazards. More details about the physical table can be found at the link below. Some of the components, particularly the linear rails, are more readily available in the U.K. than in the U.S. Details about CNC plasma table build

Edited By Bill Kunz on 08/05/2022 15:32:47 Edited By Bill Kunz on 08/05/2022 15:34:24 |

| Thread: Pantograph Plasma Shape Cutting Machine |

| 08/05/2022 15:11:09 |

Posted by Ady1 on 31/03/2022 23:55:15:

Looks like a very capable setup Are you going to do a construction article? A pdf file containing construction plans can be found here: Pantograph machine plans |

| 30/03/2022 19:19:04 |

I fabricated this pantograph shape plasma cutting machine for duplicating steel brackets and other hardware. A variable speed magnetic knurled rotor moves around an overhead mounted template. The plasma torch tip, directly below, duplicates the shape in steel up to the thickness capacity of your plasma cutter. Shapes that would fit in a 16 inch circle, and straight lines up to 36" can be cut. Small holes can be drilled after parts are cut out.

|

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in