Filing finish on castings.

To file further than the flash?

| James Hall 3 | 14/01/2022 22:38:13 |

| 92 forum posts 12 photos | Just removed parts of my first model from castings - a Stuart H10 - from its bubble wrap. Advice and experience would be much appreciated. |

| Paul Lousick | 15/01/2022 01:00:03 |

| 2276 forum posts 801 photos | It depends on what type of surface finish that you are after. Rough casting or Smooth painted. Sand blasting with a big grit size will roughen smooth areas to look like a casting. Use a Dremel type grinder with different shaped wheels to get into complex places. Fill cavities with a suitable filler. (I use JB Weld or a 2 pack filler that contains fibreglass strands). Spray on putty is good as an undercoat if you want to smooth a rough surface for painting. (Available in pressure cans and easy to sand) |

| Thor 🇳🇴 | 15/01/2022 06:36:30 |

1766 forum posts 46 photos | Hi James, I have just accepted that the areas of the casting that has been filed or sanded down may have a different appearance. Spray on putty works well for me so if you want a smooth surface follow Paul's advice. Good luck with your 10H. Check Harold Hall's website about machining the Stuart 10. Thor Edited By Thor 🇳🇴 on 15/01/2022 06:39:26 |

| JasonB | 15/01/2022 07:08:08 |

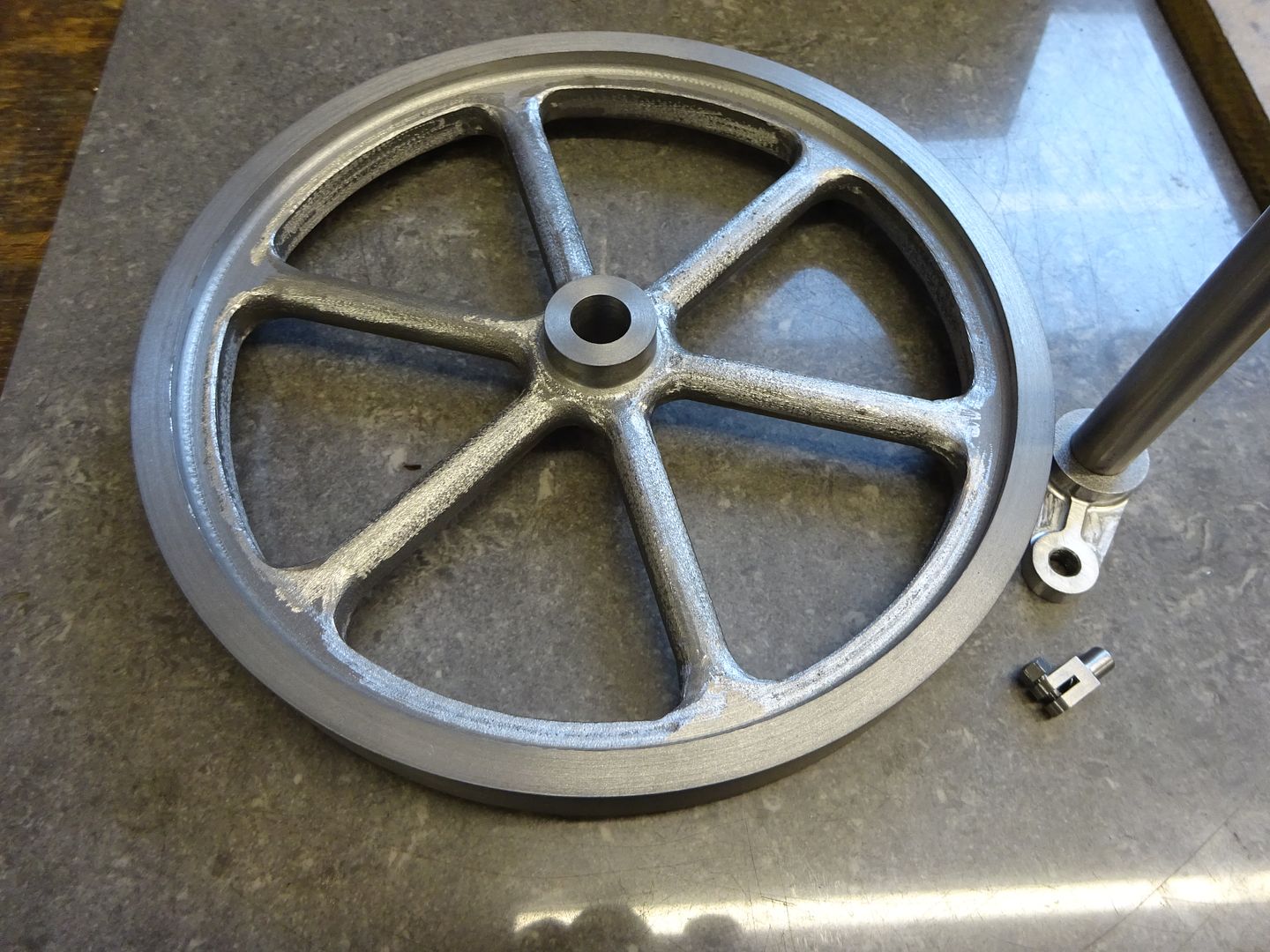

25215 forum posts 3105 photos 1 articles | I'll usually run a Dremel with orange teardrop shaped stone in it lightly over the surface to remove and high spots which is usually enough to get a paint finish that still looks like it was a casting as there will be some slight surface irregularities. You can do more if you want a mirror smooth painted look. Scale also comes into it as a casting from a half scale traction engine will tend to need less prep than a 1/12th scale model to get the same size original cast finish to look right as the same sand is used for both castings I did a Stuart 7" flywheel last weekend this shows it before. A good casting with little flash and well lined up halves, flash was filed off before machining, dremel after as I wanted to also blend in the turned surfaces that will be painted with the cast ones. And after That will most likely get a coat of high build primer, rub down and then final prime and colour. This thread goes into a bit more detail of how I finish castings and a few of their "features"

Edited By JasonB on 15/01/2022 07:19:47 |

| noel shelley | 15/01/2022 08:39:17 |

| 2308 forum posts 33 photos | Hi James, High build primer or spray putty are available in aerosol cans from most car spares shops. Fettling castings is a fine line between just enough and not to much. If the 2 halfs of the pattern were lined up spot on then there may not be much to do, or you may have to try and blend 2 poorly lined up pattern halves, the smaller the part the more difficult it will be. It all depends on what you want - show case model or just a working model ? Best wishes and Good luck. Noel |

| Circlip | 15/01/2022 11:21:31 |

| 1723 forum posts | Full size textile machinery, "Exhibition finish" cost far more than "standard finish", same paint but surface prep different. Customer decided how much they would be prepared to pay. Regards Ian. |

| Ian Johnson 1 | 15/01/2022 11:29:38 |

| 381 forum posts 102 photos | Real sized engines have sand castings which are usually painted to give a very smooth finish, so on a scale model the castings should be very finely finished and painted. It is difficult if not impossible to scale casting sand, so there is no reason why scale models need to show any gritty sandy surface. If sand was scaled up, each grain would be half an inch diameter or so. Ramble over! IanJ |

| Bazyle | 15/01/2022 14:12:09 |

6956 forum posts 229 photos | We sometimes talk about the scaling effect on the gaugeone3Dcircle (3Dpriting forum on groups.io). If you look at an N gauge wagon you can see the planks delineated along the bottom but in full size they were not even chamfered and fitted flush to avoid trapping coal dust etc. But people expect to see the planks so they are modelled with effectively 1 inch chamfers or it doesn't look 'right'. The brain-eye interface does odd things. |

| James Hall 3 | 20/01/2022 18:50:55 |

| 92 forum posts 12 photos | Thanks to everyone for your advice. I had initially been mainly worried about the contrast on the same surface between smoothed areas as a result of removing flash and the rough sand finish elsewhere. It now seems that more work is really needed to smooth off/fill the rest of the castings if a good-looking model is required. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in