help identifying lathe

new aquisition

| James Tregaskis | 20/06/2021 17:52:01 |

28 forum posts | hi, I need help in identifying a lathe that I have obtained. I think it is built by Myford in the early 50's, but I am not sure. The only identifying mark is the label marked "Osborn Ltd. Newcastle upon Tyne". I am looking for a suitable 4 jaw and 3 jaw chucks also a suitable electric motor to drive it. Many thanks, |

| Lee Rogers | 20/06/2021 17:59:42 |

203 forum posts | Not sure that's a Myford. Have a look on the lathesuk website there is a big section on ML 1/2/3/and 4. That brass pulley is astonishing. You need to add a countershaft to your shopping list. |

| Peter Bell | 20/06/2021 19:13:27 |

| 399 forum posts 167 photos | Cannot help with the lathe but Henry Osborn sold tools and general engineering supplies from Percy Street in Newcastle-upon-Tyne when I knew them in the 60's. Very helpful people when I wanted some pulleys. Seem to remember them moving there from elseware but when I knew them looks like they were a shadow of there former selves.

|

| Roderick Jenkins | 20/06/2021 19:18:25 |

2376 forum posts 800 photos | Looks like a (modified) RandA/ Winfield **LINK** According to the RandA page these were sold my Myford in the 1930s. Winfield are always a good bet for identifying these small basic British lathes, they seem to have made a lot of models for badge engineering. Cheers, Rod |

| James Tregaskis | 20/06/2021 22:13:03 |

28 forum posts | Posted by Lee Rogers on 20/06/2021 17:59:42:

Not sure that's a Myford. Have a look on the lathesuk website there is a big section on ML 1/2/3/and 4. That brass pulley is astonishing. You need to add a countershaft to your shopping list. Lee thank you for that, I need to know more... countershaft, need to research.... all comments/links/examples please guys, I need help to get this machine back in action! |

| James Tregaskis | 20/06/2021 22:15:26 |

28 forum posts | Posted by Roderick Jenkins on 20/06/2021 19:18:25:

Looks like a (modified) RandA/ Winfield **LINK** According to the RandA page these were sold my Myford in the 1930s. Winfield are always a good bet for identifying these small basic British lathes, they seem to have made a lot of models for badge engineering. Cheers, Rod Dear Rod THANK YOU! Wow that's really good of you... I can dig deeper now. Still need some ideas/advice on powering it and sources to get backplate and chuck(s) -...... 3" yes? |

| Ady1 | 21/06/2021 08:03:25 |

6137 forum posts 893 photos | Hope its ok to put it up

The lump of brass that made the headstock pulleys would probably cost as much as the lathe on ebay nowadays Edited By Ady1 on 21/06/2021 08:04:59 |

| James Tregaskis | 21/06/2021 21:58:16 |

28 forum posts | Posted by Ady1 on 21/06/2021 08:03:25:

Hope its ok to put it up

The lump of brass that made the headstock pulleys would probably cost as much as the lathe on ebay nowadays Edited By Ady1 on 21/06/2021 08:04:59 Yeah, its fine! I am possibly going to fit a sewing machine motor to run it... thoughts anyone? Maybe not enough grunt but with pulley ratio, it might be OK? |

| not done it yet | 21/06/2021 22:06:47 |

| 7517 forum posts 20 photos | Wattage? If it is the typical domestic machine, no way. Likely enough to turn the lathe but not to cut. |

| James Tregaskis | 22/06/2021 06:48:10 |

28 forum posts | Posted by not done it yet on 21/06/2021 22:06:47:

Wattage? If it is the typical domestic machine, no way. Likely enough to turn the lathe but not to cut. OK, what spec motor should I aim for? |

| not done it yet | 22/06/2021 07:01:16 |

| 7517 forum posts 20 photos | I wouldn’t suggest any specific motor. Your sewing machine motor may be adequate, particularly if an industrial machine. Depends, really, on the Wattage, as I enquired above. |

| James Tregaskis | 22/06/2021 07:11:54 |

28 forum posts | Posted by not done it yet on 22/06/2021 07:01:16:

I wouldn’t suggest any specific motor. Your sewing machine motor may be adequate, particularly if an industrial machine. Depends, really, on the Wattage, as I enquired above. Yes, of course, thank you; I meant the specification, not any specific motor; i.e. power/wattage would suit?

Edited By James Tregaskis on 22/06/2021 07:12:20 Edited By James Tregaskis on 22/06/2021 07:30:22 Edited By James Tregaskis on 22/06/2021 07:30:48 Edited By James Tregaskis on 22/06/2021 07:32:43 |

| Ady1 | 22/06/2021 07:23:57 |

6137 forum posts 893 photos | If you're not hogging a lot of metal then a 0.25kw motor will run a well adjusted machine and cut fine swarf Other things to consider are duty cycle, will the motor run non-stop for 30-mins plus without blowing up? and RPM, your lathe will probably be about 500-700 max with solid bearings so a 4000RPM sewing motor will need to be restricted |

| James Tregaskis | 22/06/2021 07:31:11 |

28 forum posts | I have a pair of these motors, maybe I could use one of them. I have the O-drive controller and position sensor as well and a 24V PSU... maybe this would work? https://odriverobotics.com/shop/odrive-custom-motor-d5065 https://docs.google.com/spreadsheets/d/12vzz7XVEK6YNIOqH0jAz51F5VUpc-lJEs3mmkWP1H4Y/edit#gid=0 Edited By James Tregaskis on 22/06/2021 07:33:55 |

| Emgee | 22/06/2021 11:27:15 |

| 2610 forum posts 312 photos | Hi James If you have an industrial sewing machine motor of at least 250W output power it may be suitable for your lathe, the type I am thinking of were underslung from the machine and usually incorporated a manual brake at the NDE, some of these were 1/2HP and more. My first lathe was a Portass which was similar in design to yours, when bought it was fitted with a 1/3HP motor but I changed it to a 1/2HP because of the duty rating of the smaller motor, probably better if you are buying a motor to go for a 1/2HP in the first place. As said speed may also be something to consider, especially if you are not fitting a countershaft between motor and spindle. (a countershaft has pulleys to match the motor pulleys but the small pulley on the motor is belted to the large c/shaft pulley so giving a speed reduction, power to the lathe is taken from one of the other c/shaft pulleys to suit the spindle speed required) You could of course go the VFD route using a dual voltage (220/400) 3 phase motor, IMO a .37kW 4 pole would be suitable. The Vee belt showing looks very long, perhaps it was driven from an overhead shaft. Emgee

|

| Howard Lewis | 22/06/2021 12:58:05 |

| 7227 forum posts 21 photos | If from the 50s, would be a ML7, and it isn't. The ML7 was launched in 1947. Not a predecessor Myford such as the ML1,2,3 or 4. (The headstock and banjo are not like those, and the bed iooks to be too long. ). The photos don't show the bed form, whether flat or dovetaill, which will also help in identification.. For chucks, you need to measure the diameter and pitch of the thread on the Mandrel, and the register for the chuck.. A British lathe of that vintage is likely to have a Whitworth form threads, and have Imperial dimension.. It is likely, therefore that you will need to make up adaptors to convert your thread/register to one that is easily available. The 1.25 x 12 tpi of Myford would seem to be the most likely, IF the sizes allow. It may be worth sacrificing an inch or so of bed space to use such an adaptor. Here, you are in the Catch 22 situation of needing a chuck to hold the material while you do the machining. Sounds like you need to find your ,local Model Engineering Society and throw yourself on the mercy of someone to make the adaptor for you. Where are you located? Once you have an adaptor, you could leave in place so that subsequently Myford fitting chucks and faceplates, etc can be fitted. It would be worth spending some time checking your changewheels, to see what you have. Hopefully, a complete set, probably incrementing from something like 20T in 5T steps up to 65, 70 or even 80T You can calculate the DP of the gears by measuring OD and counting the teeth. It is possible that the Pressure Angle will be 14.5 on a machine of that age, rather than the 20 degrees favoured more recently. That would allow you to set up for power feeds or screwcutting, as and when you feel the need and have the confidence. Howard. |

| James Tregaskis | 22/06/2021 15:29:20 |

28 forum posts | Hi Howard, thanks for a very helpful reply… and I’m not at home so I can’t get hold of my callipers but it is 12 TPI 1 inch diameter so it’s probably Whitworth. Everything looks pretty straight and I have a good set of cogs I’ll go through them in due course. I’m already getting help from a kind person on this site I don’t want to ask too much of him. Hopefully I will get some kind soul to make me an adapter. It looks quite well cared for and I am now figuring Out how to best power it. I have an O-Drive board and skateboard motor; the controller which is pretty tough and is actually programmable to run the lathe. The kind of person who is helping me already has sourced me a chuck which will need an adapter. It is so nice here on this forum because everyone is helping newbies like me, please keep the comments coming I am devouring them! Cheers, james |

| SillyOldDuffer | 22/06/2021 18:55:35 |

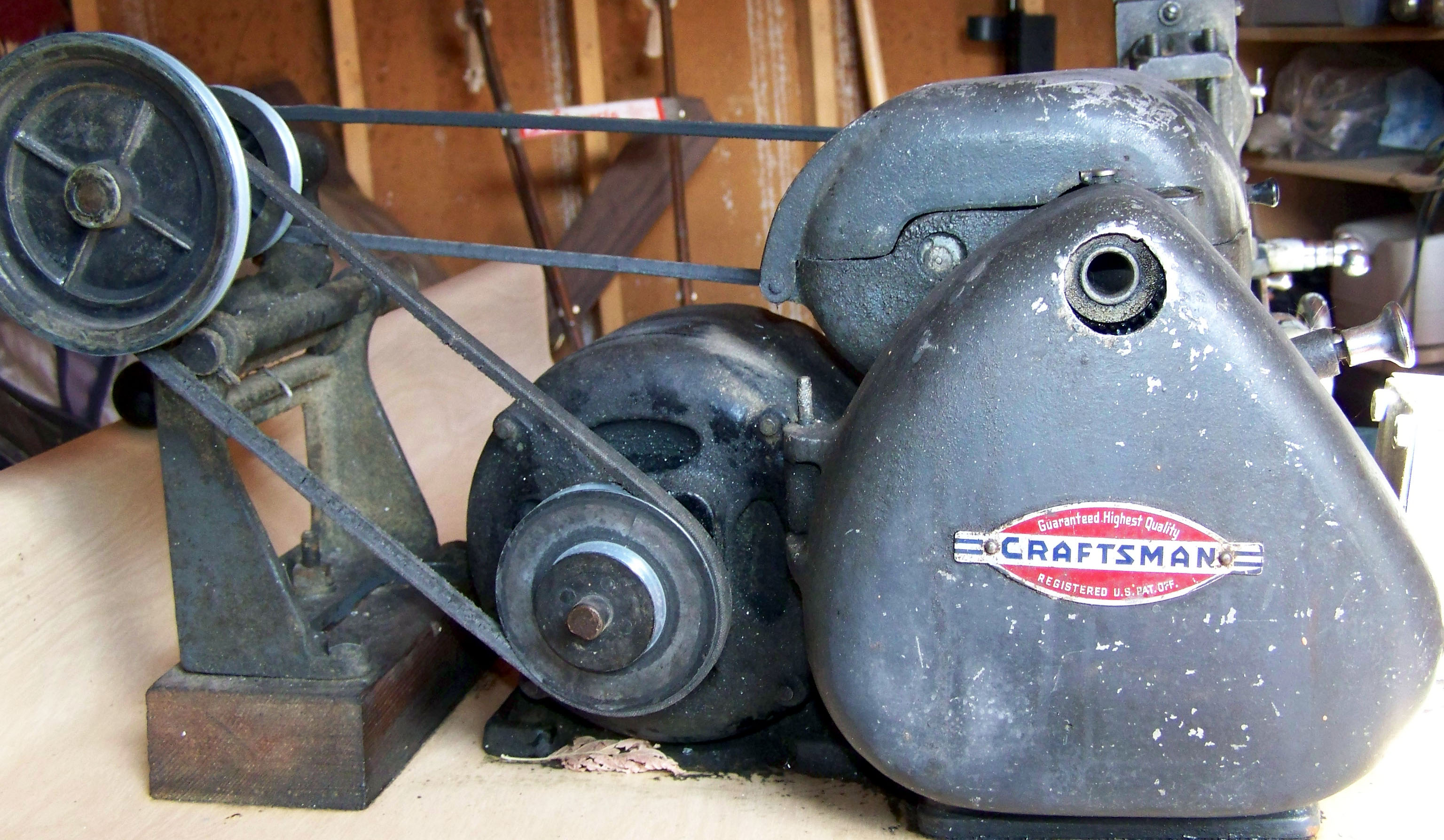

| 10668 forum posts 2415 photos | About 1/3HP - 1/2HP should be fine. Next step is to sort out the speeds, on a lathe with those plain bearings, I'd be thinking 1000rpm tops. Maybe 400rpm and 100rpm from the slower pulleys unless a variable speed motor is used. When the lathe was new, it was probably driven from a countershaft like this example from lathes.co.uk (recommended website!)

The motor would have been a fixed speed induction type, too fast for the lathe connected directly. So they're geared down by a belt to the countershaft (left of pic), which drives another three-way pulley, which your long belt would attach to, giving a choice of 3-speeds by moving the belt between pulley pairs. Your O-Drive motor isn't one I'd naturally think of using, but hey - you have one with controller and PSU. Flat out the motor is too fast and powerful for the lathe, so be very careful to keep it throttled well back. Being overkill, I think it would work well driving the lathe directly, assuming the power supply is man enough. (The motor is rated 1800W, max 8500rpm, from 32V @ 65A with 'extremely good forced air cooling'.) I'd set the motor up for direct drive and try cutting metal, keep an eye on the speed with a cheap ebay rpm meter. Check motor temperature frequently at first: it's allowed to get warm, but not hot! If it shows any signs of overheating, cool it with an electric fan. The spec says the motor delivers about 1/3 output with ordinary cooling, which should be 'good enough' for that size of lathe. Dave |

| James Tregaskis | 22/06/2021 19:59:14 |

28 forum posts | Posted by SillyOldDuffer on 22/06/2021 18:55:35:

About 1/3HP - 1/2HP should be fine. Next step is to sort out the speeds, on a lathe with those plain bearings, I'd be thinking 1000rpm tops. Maybe 400rpm and 100rpm from the slower pulleys unless a variable speed motor is used. When the lathe was new, it was probably driven from a countershaft like this example from lathes.co.uk (recommended website!)

The motor would have been a fixed speed induction type, too fast for the lathe connected directly. So they're geared down by a belt to the countershaft (left of pic), which drives another three-way pulley, which your long belt would attach to, giving a choice of 3-speeds by moving the belt between pulley pairs. Your O-Drive motor isn't one I'd naturally think of using, but hey - you have one with controller and PSU. Flat out the motor is too fast and powerful for the lathe, so be very careful to keep it throttled well back. Being overkill, I think it would work well driving the lathe directly, assuming the power supply is man enough. (The motor is rated 1800W, max 8500rpm, from 32V @ 65A with 'extremely good forced air cooling'.) I'd set the motor up for direct drive and try cutting metal, keep an eye on the speed with a cheap ebay rpm meter. Check motor temperature frequently at first: it's allowed to get warm, but not hot! If it shows any signs of overheating, cool it with an electric fan. The spec says the motor delivers about 1/3 output with ordinary cooling, which should be 'good enough' for that size of lathe. Dave ,Hi Dave, I will get a Nema 23 metal faceplate to hold the motor in place (not the 3D printed enclosure I have at present). I may need someone to machine me a brass V-belt pulley for the O-Drive shaft, I only have the ribbed kind at the moment. The O-Drive is really too 'good' for the lathe but I will opt for something more conventional longer term as I don't want to tie up the controller board for this application... The O-Drive and this brushless motor is very powerful and can do much more than this job, e.g. see this short video! https://www.youtube.com/watch?v=FUh36RUHzdU

|

| Nicholas Farr | 23/06/2021 09:41:44 |

3988 forum posts 1799 photos | Posted by James Tregaskis on 22/06/2021 15:29:20:

Hi Howard, thanks for a very helpful reply… and I’m not at home so I can’t get hold of my callipers but it is 12 TPI 1 inch diameter so it’s probably Whitworth. Everything looks pretty straight and I have a good set of cogs I’ll go through them in due course. I’m already getting help from a kind person on this site I don’t want to ask too much of him. Hopefully I will get some kind soul to make me an adapter. It looks quite well cared for and I am now figuring Out how to best power it. I have an O-Drive board and skateboard motor; the controller which is pretty tough and is actually programmable to run the lathe. The kind of person who is helping me already has sourced me a chuck which will need an adapter. It is so nice here on this forum because everyone is helping newbies like me, please keep the comments coming I am devouring them! Cheers, james Hi James, if the nose is 1 inch x 12TPI then it is probably 1 inch UNF, (not NF, which is 14TPI) which is what my father's old RandA lathe is and you may have to get a blank backplate or two and machine them to fit any chucks you want to use. My father's old RandA lathe worked happily enough with a 1 / 4 HP induction motor via a counter shaft similar to this RandA page 2 A 1 / 3 HP induction motor or something equivalent should be about the largest you would need though I would think. Regards Nick. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in