Stuart 10V Big-End Bearing Lubrication?

| Dr_GMJN | 10/10/2020 18:41:47 |

1602 forum posts | Guys - as you all probably know, there’s no defined method of directly lubricating the big-end bearing on the Stuart 10V. I’m thinking of drilling a 1.5 mm hole from the curved base of the forked little end, all the way down to break through into the big end journal. I’d use a centre drill to form a v-shaped cup at the top. It’s not assembled yet, so would be a two minute job on the mill. My thoughts are that I could then easily fill the connecting rod with oil, and it would lubricate the crank pin during a run. Drawback is that any debris or wear particles from the crosshead/pin would also get directed straight down there. Worth it? Not worth it? Any thoughts welcome. Thanks. |

| JasonB | 10/10/2020 18:58:43 |

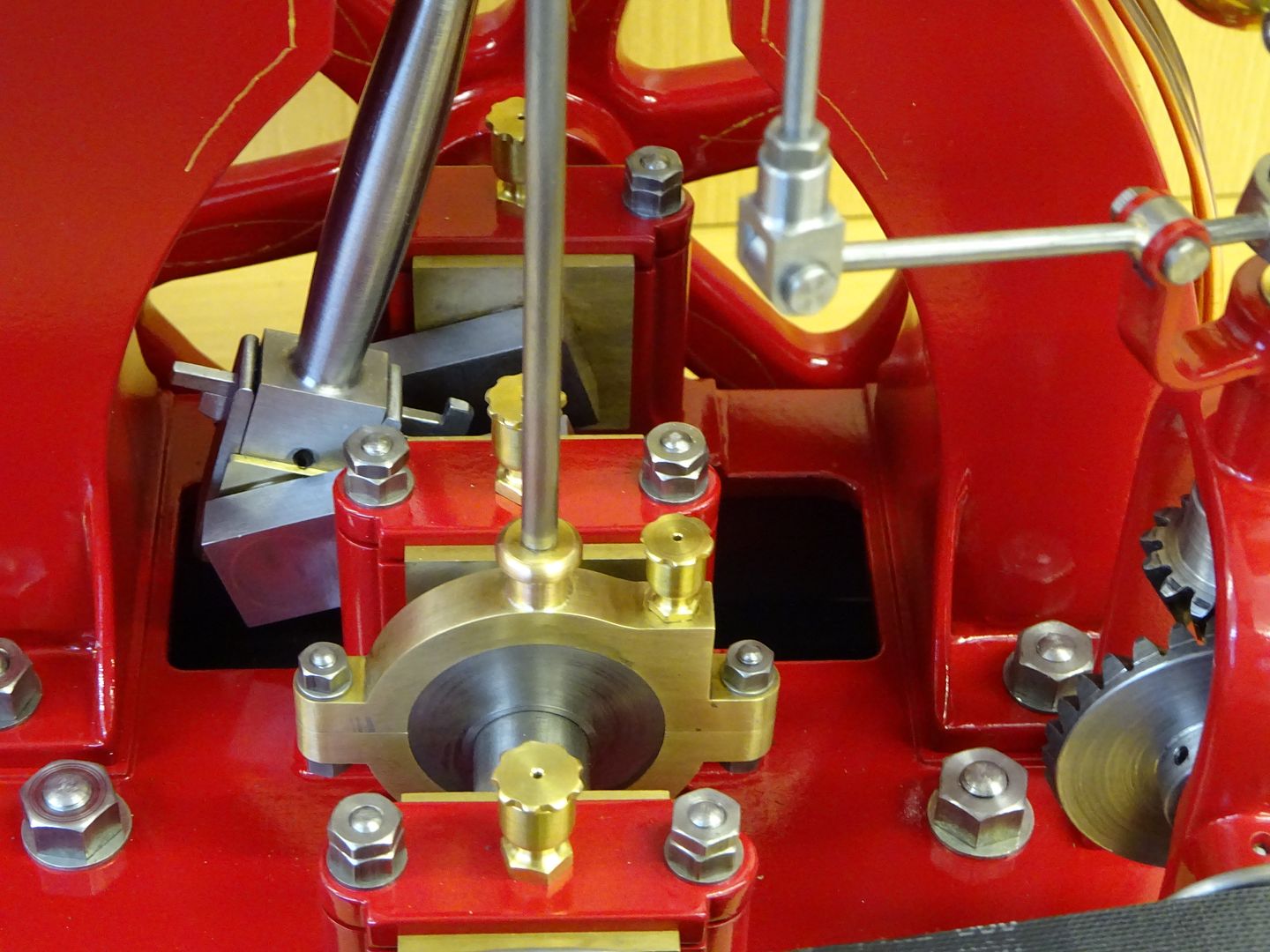

25215 forum posts 3105 photos 1 articles | Unless you are going to be doing extended runs probably not worth doing. However you could drill in from the side of the conrod at an angle which I have seen on full size and replicated here

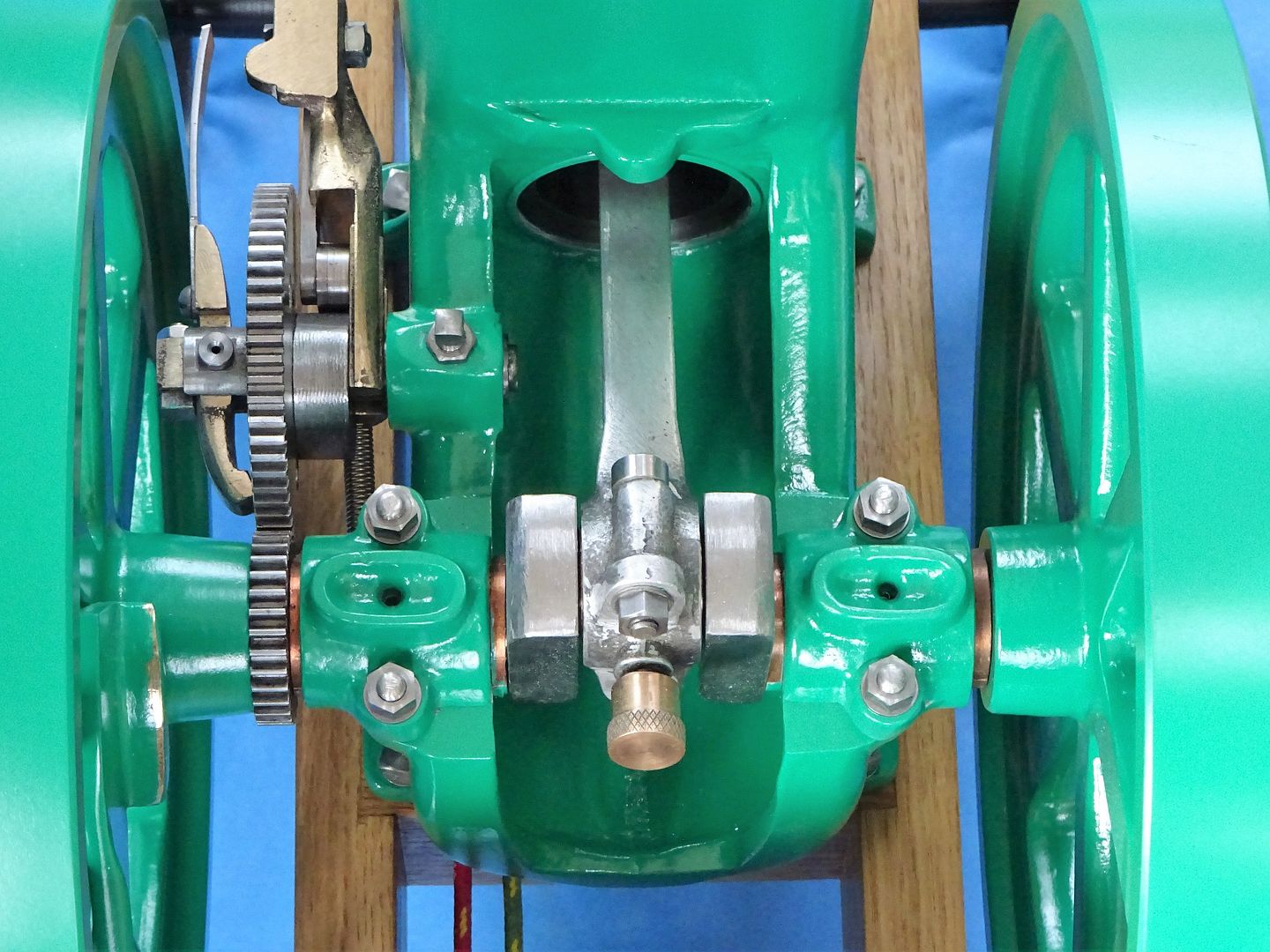

A similar arrangement but with an oil cup on this one of mine, you could simplify it by just turning a "funnel", bending the spout and poking it into a suitable oil hole.

A "Greaser" fitted to the bottom of the bearing cap would also work but a bit of a pain to get to. Greasers are a bit like an oil cup but they have a flatter base that is threaded externally for a "cup" that is filled with grease and then screwed on. You tighten the cap every so often and it squeezes out a bit more grease

|

| Dr_GMJN | 10/10/2020 22:25:39 |

1602 forum posts | Thanks Jason. It won’t be run for extended times, so I’ll leave it. It was just that the cheek bosses are a very close running fit against the crank webs, and it’s capillary action alone that will lubricate the big end bearing. Seems odd that the main bearings have provision for oiling, but not the more highly loaded pin. |

| mechman48 | 11/10/2020 13:45:54 |

2947 forum posts 468 photos | Hi, as you mentioned you won't be running it for any extended period so I wouldn't worry about it. My S10V is only for display, as my other models, so it rarely runs for any period longer than a couple of minutes to keep things free. When I give my models a run, on air, I generally put a few drops of lube oil in the crankshaft cups ( home made ) & drop a few drips down the cheeks of the big end & let capilliary action do the rest. George. |

| not done it yet | 11/10/2020 18:04:31 |

| 7517 forum posts 20 photos | One (full size) crank I have is lubricated from the end of the shaft. Drilled through the shaft and crank web, then cross drilled for the big end lube using a grease cap on the end of the crank. Simply occasionally grabbing the cap, to turn it a bit, was likely the usual modus operandi back in the day! |

| Dr_GMJN | 12/10/2020 13:06:00 |

1602 forum posts | Thanks guys. I'm going to leave it as-is. Firstly I don't want to risk damaging the connecting rod, and secondly, as suggested, there's no point since it'll only be run occasionally on air. It just seemed like a bit of an omission from a design point of view, and as a design engineer myself, it niggled me a bit. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in