crankcase construction

| Perko7 | 13/09/2020 05:04:55 |

| 452 forum posts 35 photos | OK, dumb question time |

| JasonB | 13/09/2020 07:14:11 |

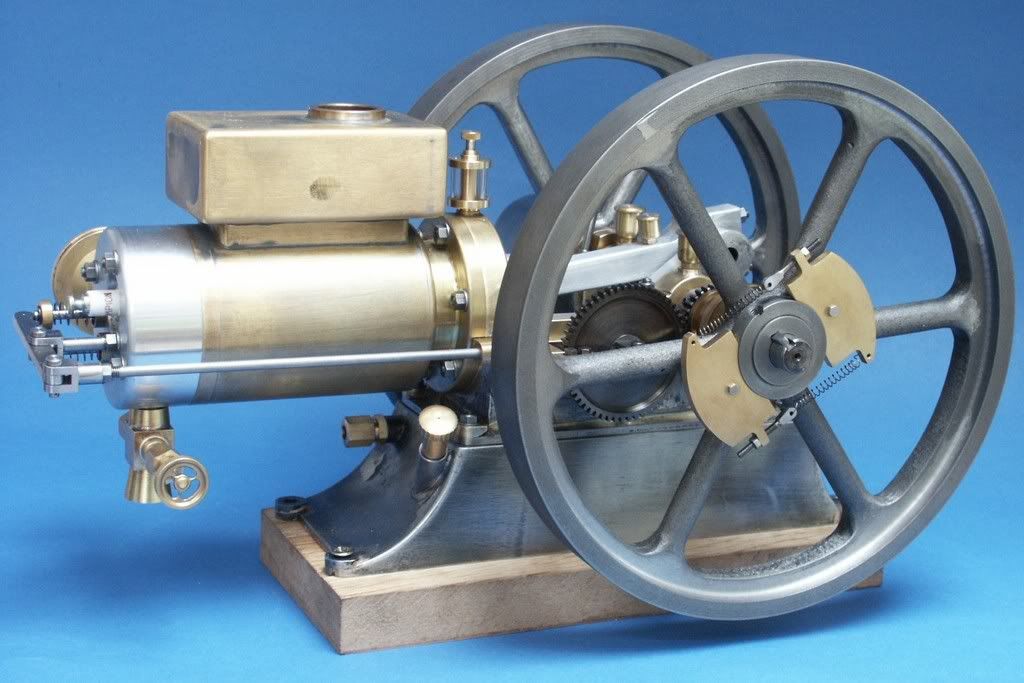

25215 forum posts 3105 photos 1 articles | Engineers Emporium sell the castings but if you want to make from scratch the DX engine is quite simple to fabricate being a very "boxey" shape and could be done a number of ways. You could silver solder the cross pieces into a open box with it's divisions and then screw side plates on which would make for easier fabrication and assembly. Or weld up sub assemblies and then silver solder together etc In both cases but particularly the later I would fabricate a slightly oversize "casting" and then finish machine any faces and bore for a cast iron cylinder liner. This is mostly welded with a few bits like the bearing pockets silver soldered on

This one the steel base and open crank area were brazed with carbon arc and the cylinder jacket and hopper silver soldered

Edited By JasonB on 13/09/2020 07:49:56 |

| clogs | 13/09/2020 07:25:20 |

| 630 forum posts 12 photos | slightly dif but on the same subject..... I often looked thru the door of Crossley's Diesels in Manchester..... huge engines and all crankcases were fabricated from plate.....

then I worked at a company that odered something similar to the above but a complicated hollow sphere about 5m in diameter from cast steel....walls about 50-60mm thick..they were poured in Norway..... |

| Brian H | 13/09/2020 10:14:47 |

2312 forum posts 112 photos | The crankcases at Crossey Bros would almost certainly be for the 'Pielstick' engines. These were made at the Sandiacre works of Crossley Premier and moved to Manchester when the Sandiacre works were closed. The fabricated design meant that the same components could be used for a range of engines " built by the mile and cut off by the yard". Brian Edited By Brian H on 13/09/2020 10:16:48 |

| Perko7 | 13/09/2020 13:13:00 |

| 452 forum posts 35 photos | Thanks for those responses, nice work Jason. I'm reasonably handy with a stick welder but don't have the gear for silver soldering larger objects. Thinking that fabricating with tabs and slots for accurate location, tack weld in position, then full weld, stress relieve, then machine working surfaces should provide a stable platform for further work. Have a friend who does wrought iron work, he has a suitable hearth to heat up largish bits like a completed crankcase to relieve welding stresses, but not for silver soldering. Early days, probably won't be until next year that any metal is fabricated, but wanted to get an idea that it would be feasible. Will now start designing the bits. |

| Howard Lewis | 13/09/2020 14:31:05 |

| 7227 forum posts 21 photos | The original Paxman Valenta engines that powered the HSTs had fabricated crankcases. Eventually, the locos were re powered as the engines wore out. It was not unusual for prototype engines to be fabricated, If the principle looked to be viable, patterns would be made for subsequent prototype castings. The Perkins Heritage group have several prototypes with fabricated cylinder blocks. Howard |

| Neil A | 13/09/2020 22:47:54 |

| 160 forum posts | The tab and slot location system is very similar to the Steven's Patent for producing fabricated diesels engine crankcases introduced into Britain at the Olympia Exhibition of 1931. Here the firing loads are carried through the vertical plates from the cylinder head to the main bearings without loading any welds. Some of the submarine engines of that period were constructed in this way. Fabricated crankcases are also easier to repair if one should suffer a mishap, more than can be said for an iron casting. The only drawback to fabrication is that it requires more work to get it to the machining stage, with a casting, once you have a pattern, it is a fairly quick process to make more castings. Probably not much in it for a one off project. The MOD used to favour fabricated steel crankcases for shock loading purposes in their ships, but I think that may no longer be the case as modern resilient mounts can now attenuate some of the load. The original Paxman Ventura and Valenta engines were fabricated mostly from pre-machined steel plate, although the more complex shaped drive end gear housing was a steel casting, as were the main bearing plates. Later HST train engines were however, SG Iron castings. Nothing wrong with a fabrication, just think, they don't cast submarines! Neil |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in