Locktite

| Garry Coles | 24/08/2020 09:43:58 |

121 forum posts 100 photos | Good morning all. I'm going to be fabricating the crankshaft for my 2in D & NY traction engine and was wondering which loctite to use. I've got 290 and 603 on the shelf, but is there a better one for this job. Also if you say to use another number what sort of fit should the parts be for that number. Thanks Garry |

| Michael Gilligan | 24/08/2020 09:52:12 |

23121 forum posts 1360 photos | My first choice would probably be Loctite 638 Copious information on this and other Loctite versions is available on the Henkel website. MichaelG. |

| Garry Coles | 24/08/2020 10:00:48 |

121 forum posts 100 photos | Thanks for that, That's the number I was thinking about using, I just wanted confirmation. |

| bernard towers | 24/08/2020 10:10:46 |

| 1221 forum posts 161 photos | If you make your crankshaft a built up version even if you use loctite I would definitely pin it as well which would help if the loctite was ever to breakdown over time. I machined mine from solid and it’s not too difficult the worst bit is the hacksawing ( no bandsaw) Edited By bernard towers on 24/08/2020 10:11:40 Edited By bernard towers on 24/08/2020 10:12:09 |

| JasonB | 24/08/2020 10:18:00 |

25215 forum posts 3105 photos 1 articles | Although I do loctite some of my smaller crankshafts (with 648) I would never be happy with that method on an engine of that size. Either cut from solid if a casting is not available or silversolder and pin as a lesser option. You don't need to do much sawing if you stitch drill out the waste.

Edited By JasonB on 24/08/2020 10:18:52 |

| derek hall 1 | 24/08/2020 11:49:38 |

| 322 forum posts | Hi Jason, How do you deal with the locked in stress after chain drilling out the crankshaft out of a piece of mild steel? There are solutions such as use black hot rolled steel or normalise it, but just wondered if you have had issues in this area and if so what do you do to overcome it? I suppose a lot depends on the thickness of material and the size of the cut outs... Regards Derek |

| Howard Lewis | 24/08/2020 11:55:44 |

| 7227 forum posts 21 photos | My guess would be that any distortions from locked in stresses in rolled bar would be out and accommodated by the time that all the turning has been done. Hopefully, the distortions will be less than the depth of metal that you remove to reach finished size. Anyone who has had experience of this, like to comment? Howard |

| JasonB | 24/08/2020 12:10:58 |

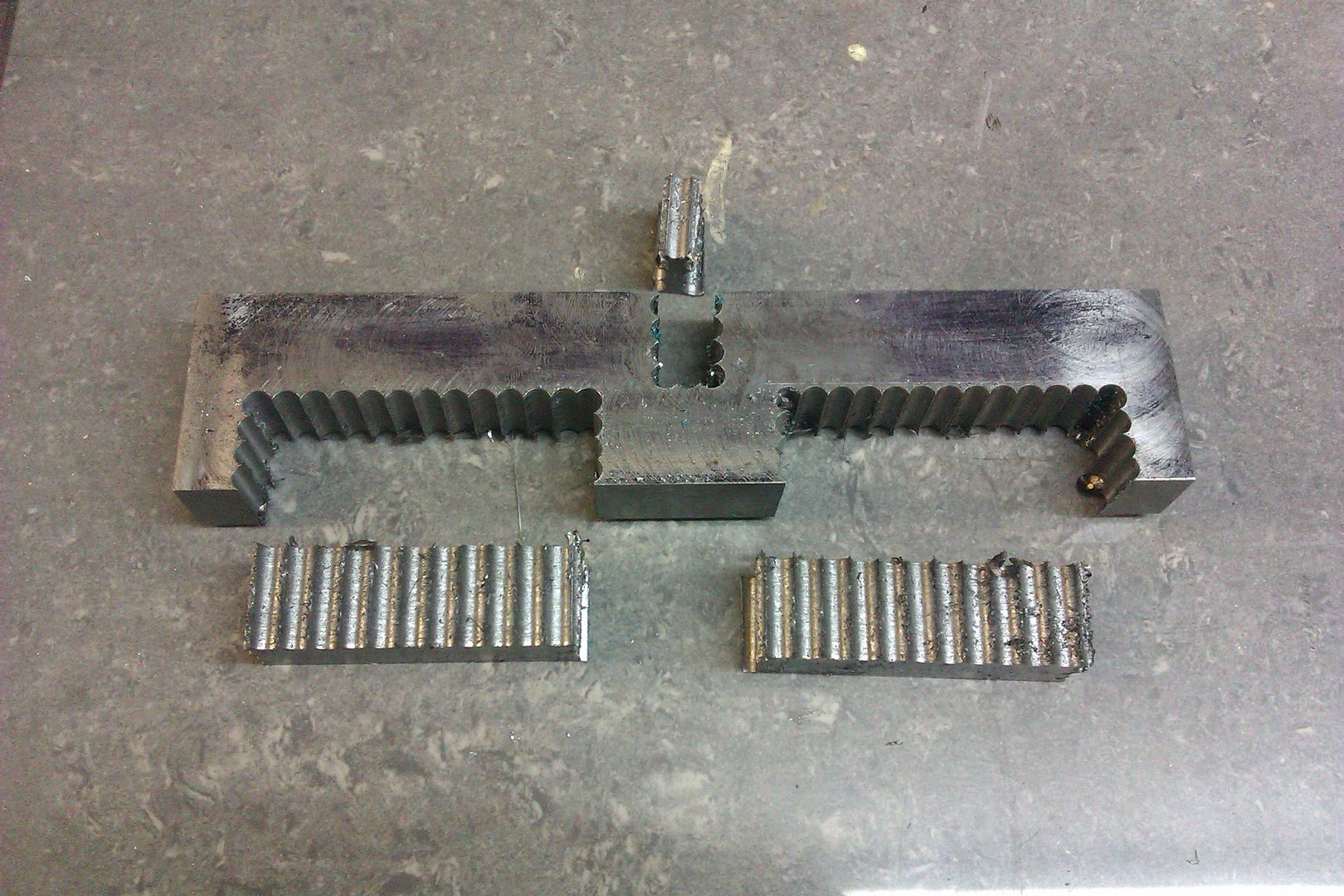

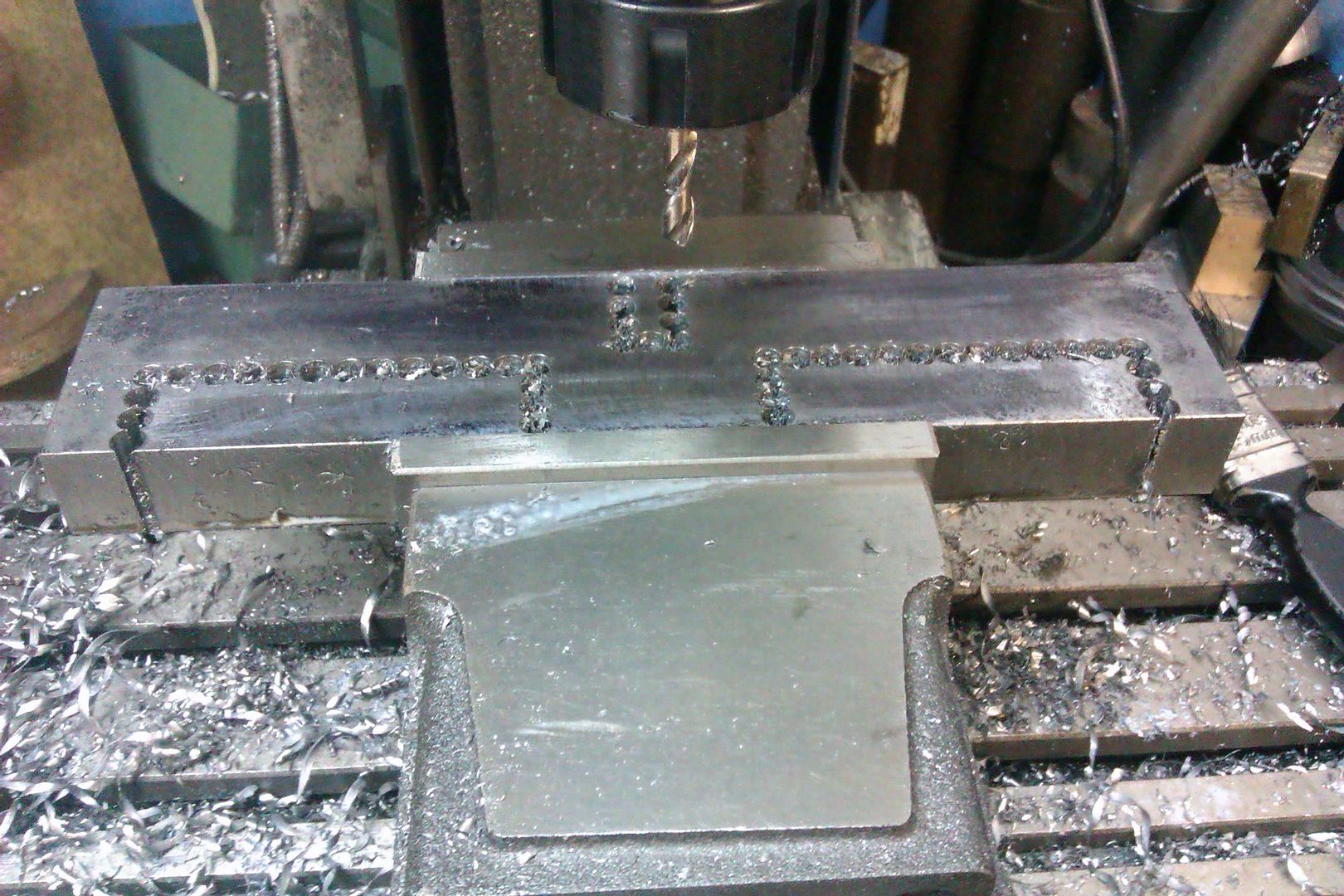

25215 forum posts 3105 photos 1 articles | Ideally avoid using bright bar and if you have to use it then leave plenty of material so that when it moves you can still get the part out of what is left. That one was cut from some unknown steel flame cut from 2" thick material that was cleaned up first.

On that one I could actually see the two ends curling away from me as I drilled the series of holes, the two ends had probably moved a 1/32" to 1mm by the time they were all drilled.

Ideally start with black ( hot rolled) bar which does not seem to move much, this was 50 x 25 stock that was pickled to remove the mill scale first.

In all cases I like to leave them for a couple of weeks after the stitch drilling to settle before roughing out and will then leave for another week or so before finish machining, this is the one above and some of the remaining length of bar.

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in