Chilled cast Iron - a small Rant

| Tony Martyr | 01/06/2020 16:59:06 |

226 forum posts 45 photos | The job of machining two small valve chamber covers should be a nice simple task - in fact the job was saved for a relaxing evening. Tony |

| JasonB | 01/06/2020 17:03:18 |

25215 forum posts 3105 photos 1 articles | Good luck drilling them! heat is probably your best option and being thin it should not bee too hard to get then red hot (850deg) |

| old Al | 01/06/2020 17:22:02 |

| 187 forum posts | send them back

|

| mechman48 | 02/06/2020 12:19:59 |

2947 forum posts 468 photos | I had a similar problem with my S10V having a chilled area on the OD of the standard. I managed to get around it by using a carbide tipped tool & a carbide insert face cutter. Chilled area around the OD... George. |

| Mark Gould 1 | 02/06/2020 12:43:52 |

| 231 forum posts 131 photos | I am a novice but was told that the best way around this is to take a heavy cut. Otherwise the tool skates on the chilled outside. Mark |

| JasonB | 02/06/2020 13:08:57 |

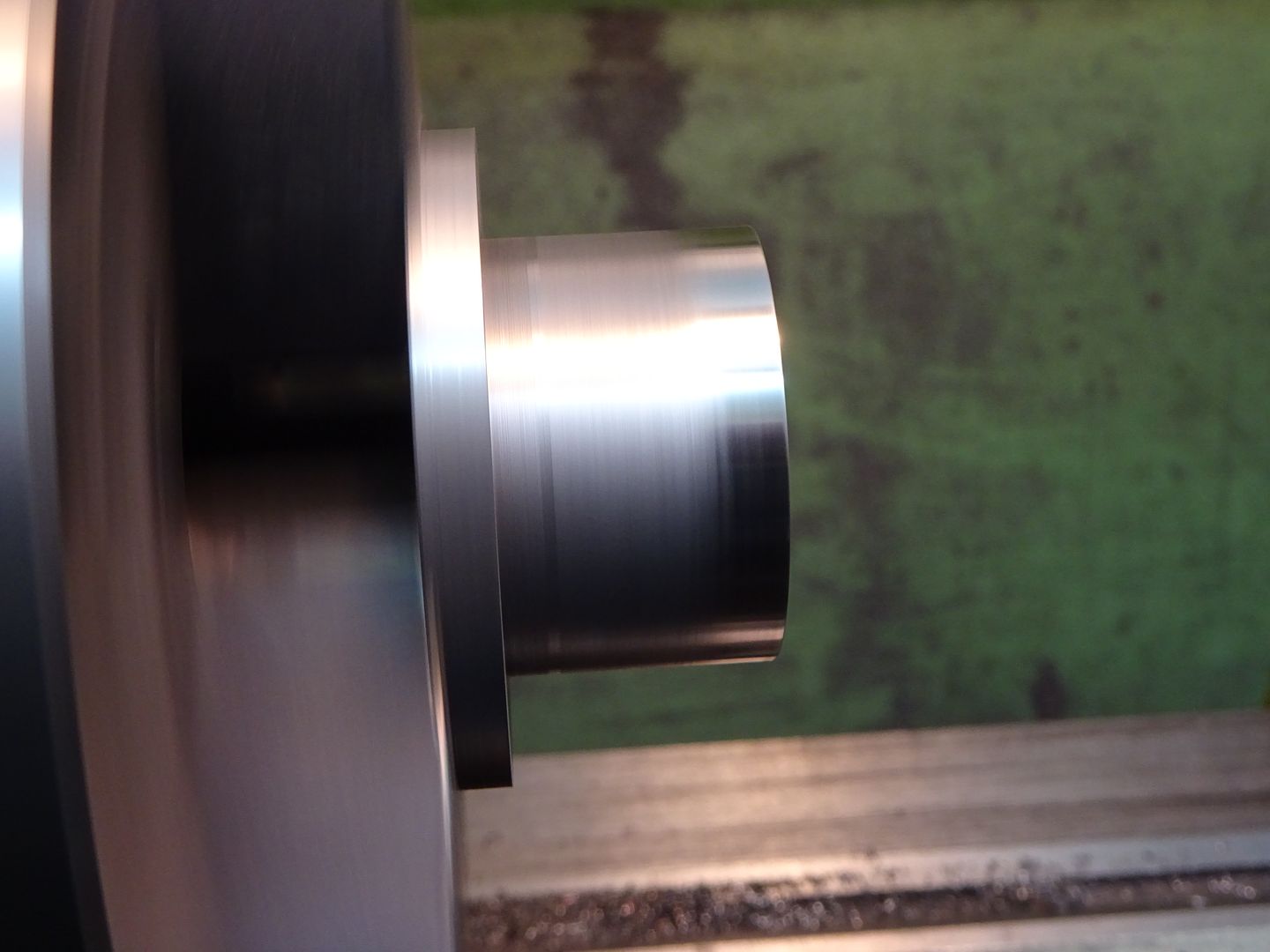

25215 forum posts 3105 photos 1 articles | A lot will depend on the depth of the chill which is not quite the same as a hard skin, In the photo above it is just limited to corners and thin edges in bad cases it can be quite deep or go all the way through. Then there is the problem that some castings only give you a very small machining allowance so no deep cuts possible You can see the shine from the chill on this part even though I have taken a total of 3mm depth of cut. Metal was coming off in long blue ribbons more like steel than iron.

|

| Baz | 02/06/2020 13:31:57 |

| 1033 forum posts 2 photos | Send them back, not fit for purpose. |

| Tony Martyr | 02/06/2020 15:19:50 |

226 forum posts 45 photos | I have consider the 'send them back' option and may do so but if the hole positions are clear of the chill (which is full depth on the edges) they will be usable. It is many years since learning about chemistry of cast iron, I seem to remember that I found it about as boring as the chemistry of boiler feed water in power stations

|

| Grindstone Cowboy | 02/06/2020 17:35:27 |

| 1160 forum posts 73 photos | Is heating to red heat and allowing to cool slowly a guaranteed fix for this problem? Thanks, Rob |

| Oily Rag | 02/06/2020 17:51:57 |

550 forum posts 190 photos | Time for a diamond milling insert cutter. I had a job a few years ago which were a high chromium alloy of cast iron (motorcycle disc brake rotors off a Norton Commando - the chromium was so they wouldn't rust!) The only way to machine them was with a diamond tipped tool. Knife through butter with those inserts!! I then used one as a fly cutter for some chilled white iron castings - again they cut beautifully!! |

| Maurice | 02/06/2020 18:07:10 |

| 469 forum posts 50 photos | I had this problem on some "Clarkson " castings many years ago. On advice, I put them in our coke stove, banked it up well with fuel, opened the damper to get everything nice and hot, then let it go out and cool overnight. No more hard spots in the castings! I realise that coke stoves are probably rare now, but heating and then slow cooling seems to be the answer. Maurice |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in