non-circular boring.. Literally - it is boring!

| sam sokolik | 31/03/2020 04:10:11 |

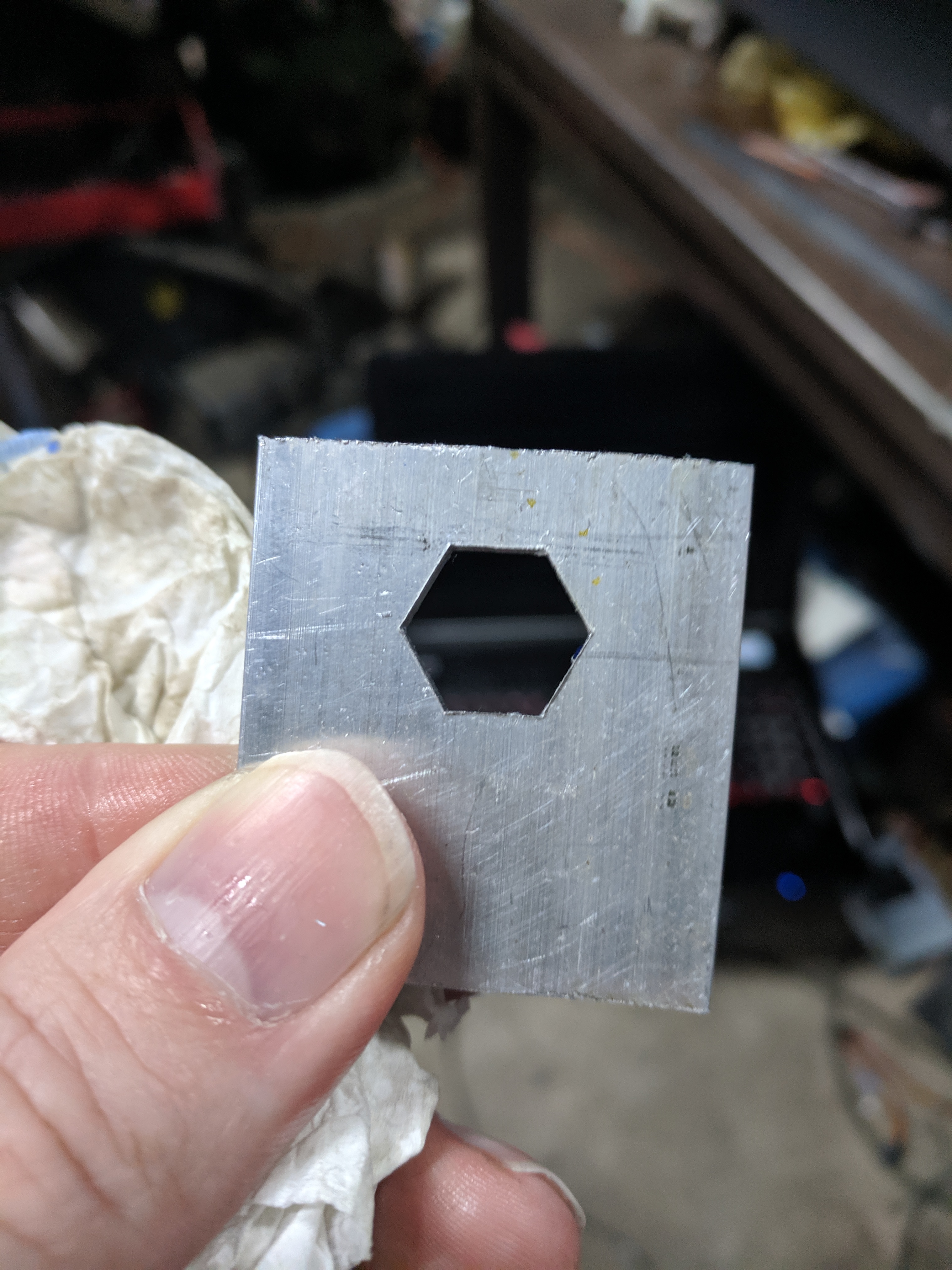

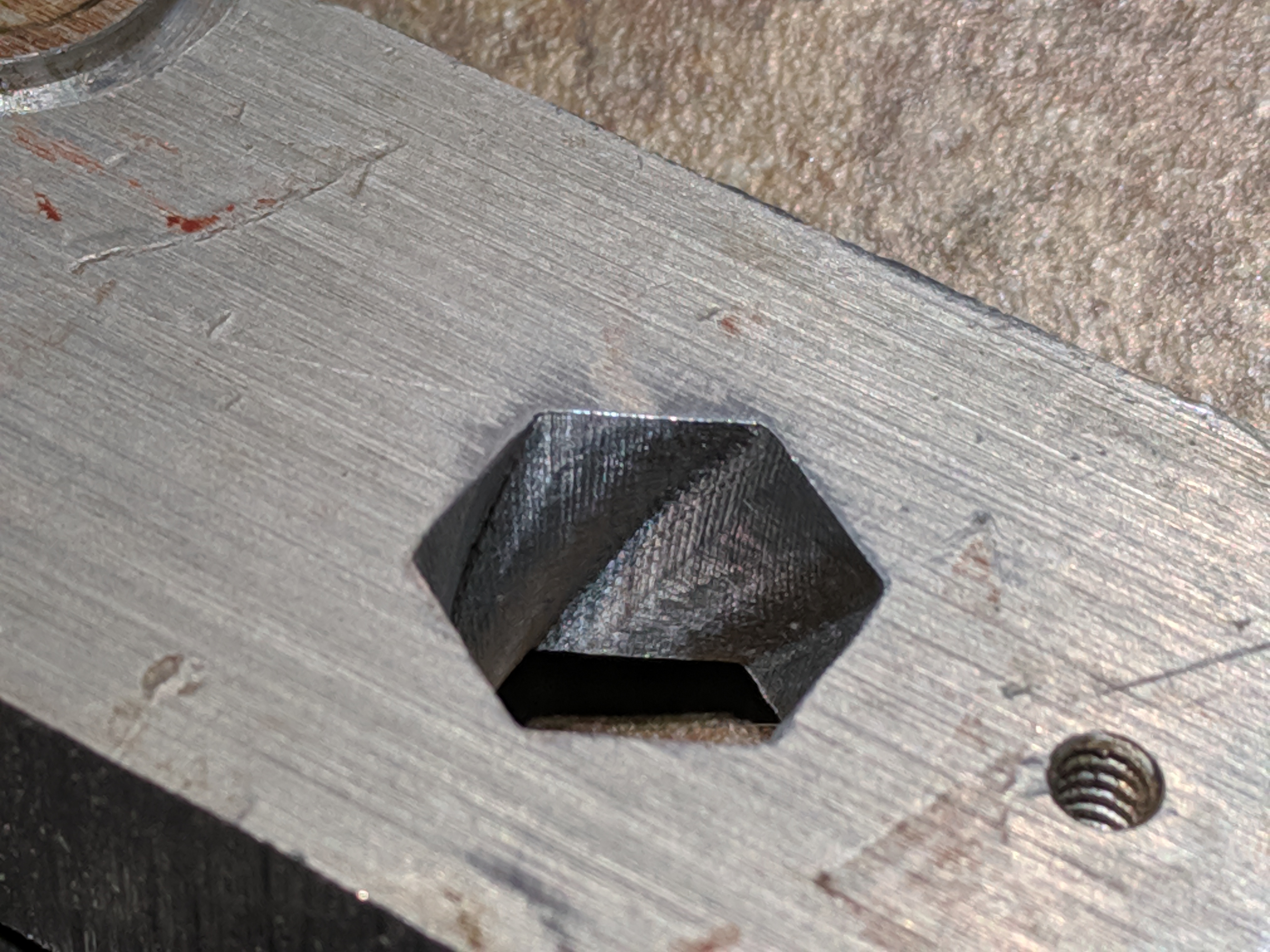

| 126 forum posts | I decided to see if I could create a polygon shaped hole with a little math and a cnc..

Edited By sam sokolik on 31/03/2020 04:16:05 |

| Thor 🇳🇴 | 31/03/2020 06:09:27 |

1766 forum posts 46 photos | Impressive Sam, now you should be able to make your own socket head cap screws. Thor |

| Martin Connelly | 31/03/2020 09:41:57 |

2549 forum posts 235 photos | Looks useful. I expect the maths is similar to what is used for single point turning of polygons on CNC lathes with the added complication of a rotating tool. Martin C |

| Brian H | 31/03/2020 12:43:13 |

2312 forum posts 112 photos | That's excellent Sam, thanks for sharing. I'm just beginning to find out about CNC and it's fascinating what can be achieved. Brian |

| sam sokolik | 31/03/2020 14:01:20 |

| 126 forum posts | I expanded on the work Andy did... |

| sam sokolik | 31/03/2020 14:18:49 |

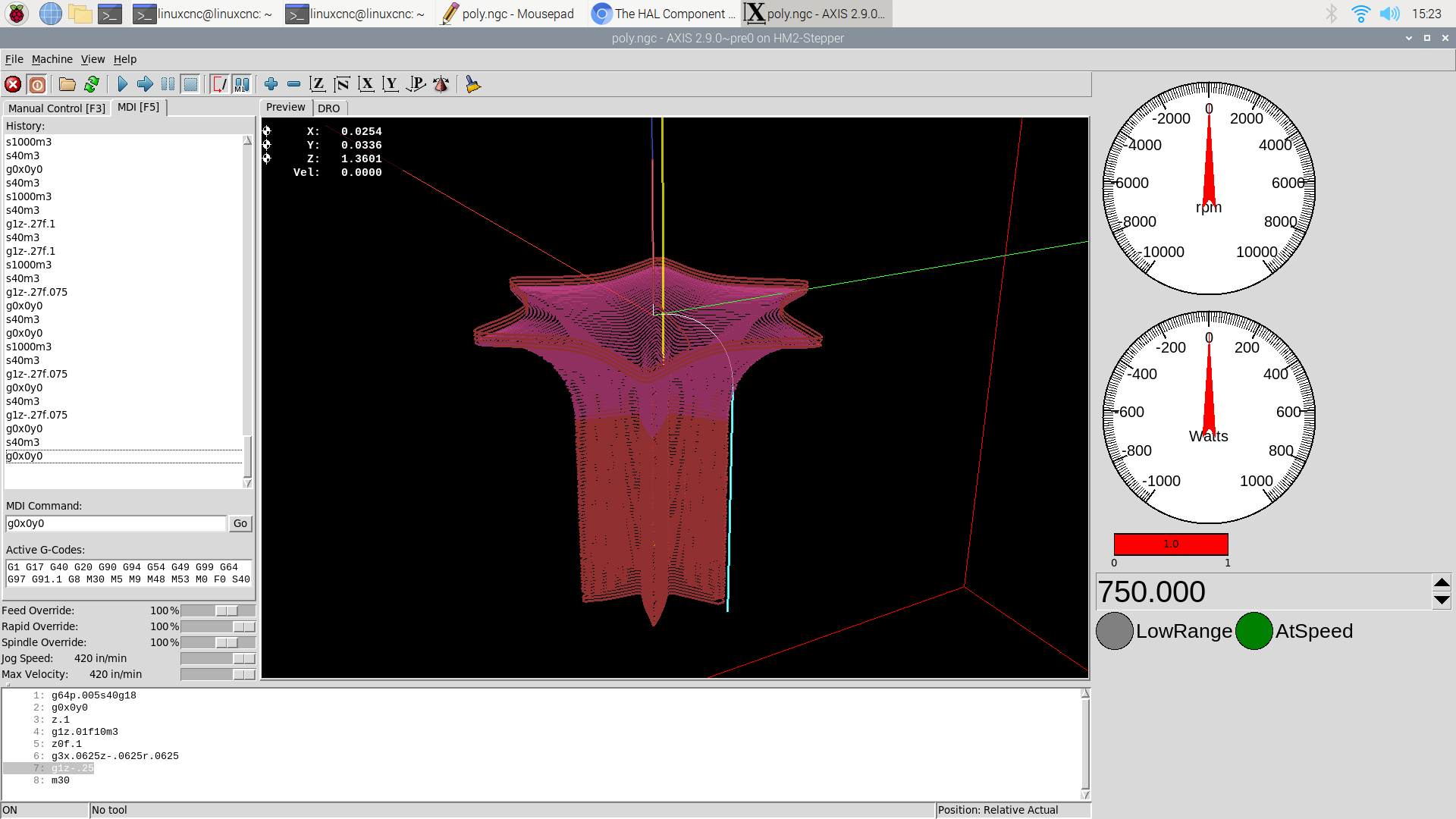

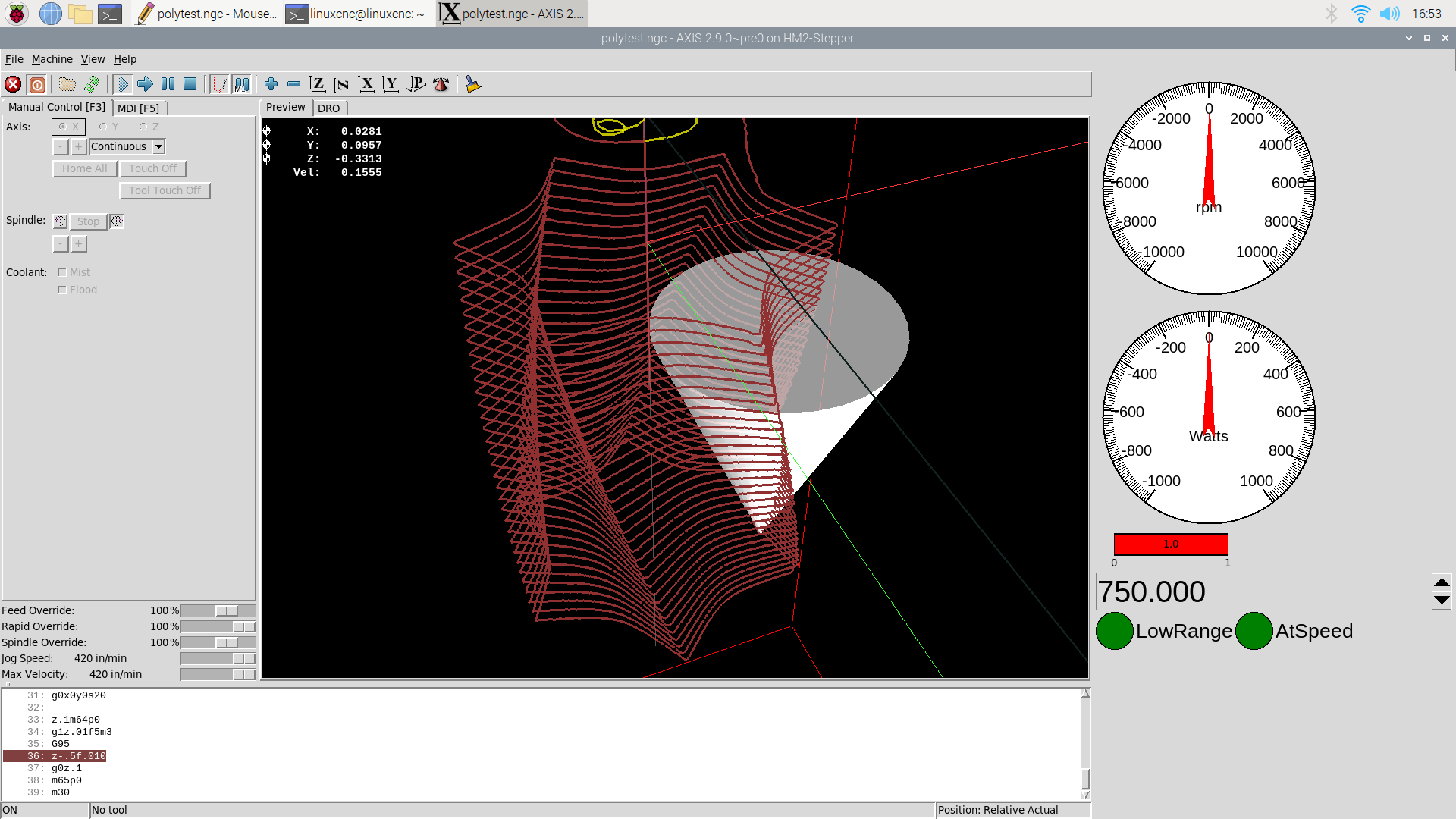

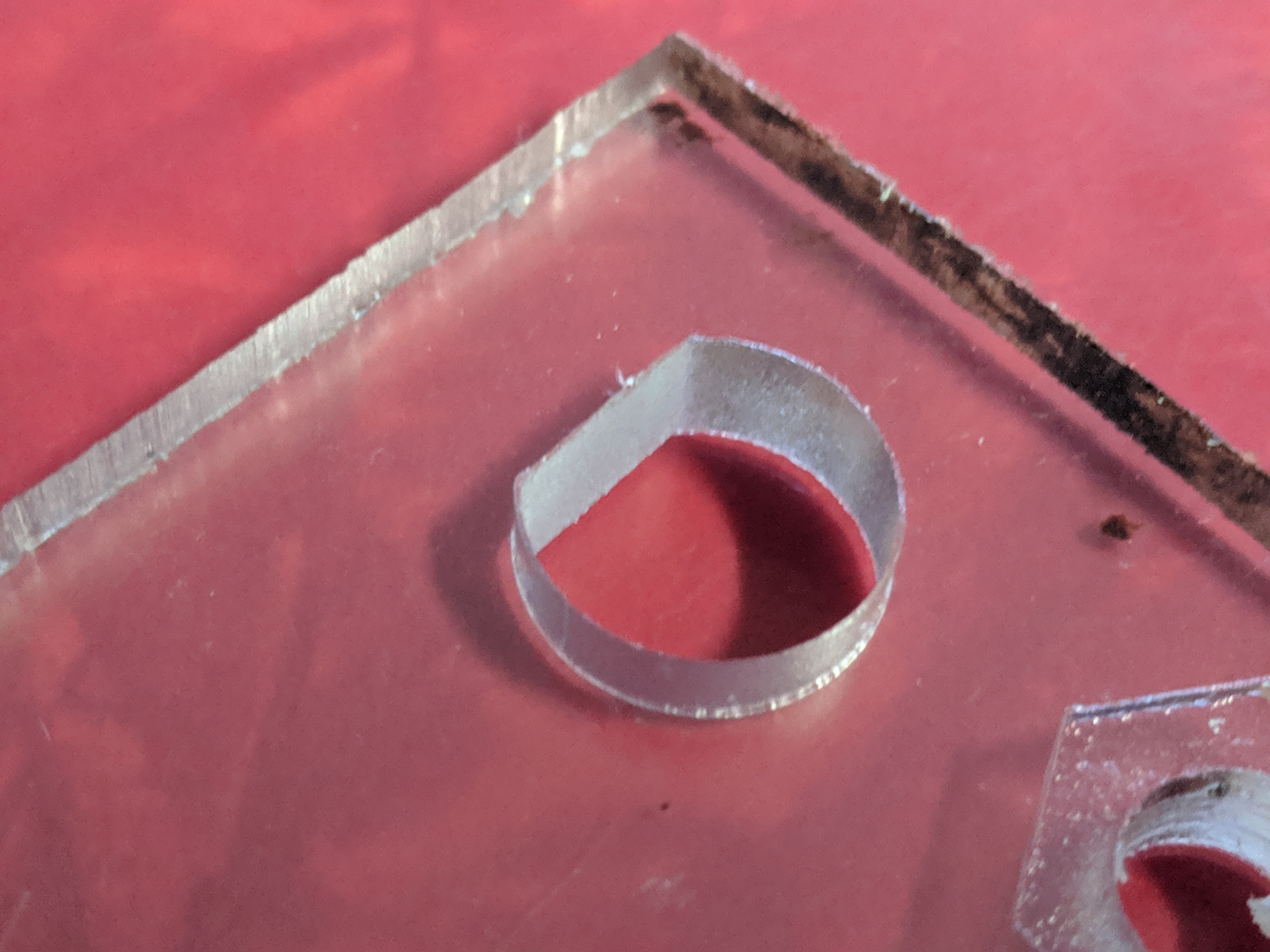

| 126 forum posts | I also am working on the functionality of slaving the x axis to the radius of the polygon... SO you can do things like create a profile for the polygon to follow. So this is a radius into a taper..

|

| blowlamp | 31/03/2020 15:54:31 |

1885 forum posts 111 photos | That's interesting stuff you're doing, Sam. Could you post some gcode here please, so I can try it with my PlanetCNC control, which is designed to be LinuxCNC compatible? I'll get Alan at cncyourmyford to have a look too as I'm sure he'll be interested.

Martin. |

| sam sokolik | 31/03/2020 17:12:10 |

| 126 forum posts | This is a simple hal component that takes the spindle posltion from the encoder and calculates where the x/y axis need to be to keep the tool tip perpendicular to the polygon. (well - to the inscribed circle.) This is done in the real-time layer of linuxcnc. So 1000 times a second it reads the spindle postion and calculates the polygon shape. I use currently the digital/analog i/o functionality in gcode to communicate with the component. I think it could be converted to remap to make it more user friendly. I don't have the gcode here at the moment but I think this is the latest hal component.

|

| sam sokolik | 01/04/2020 05:14:09 |

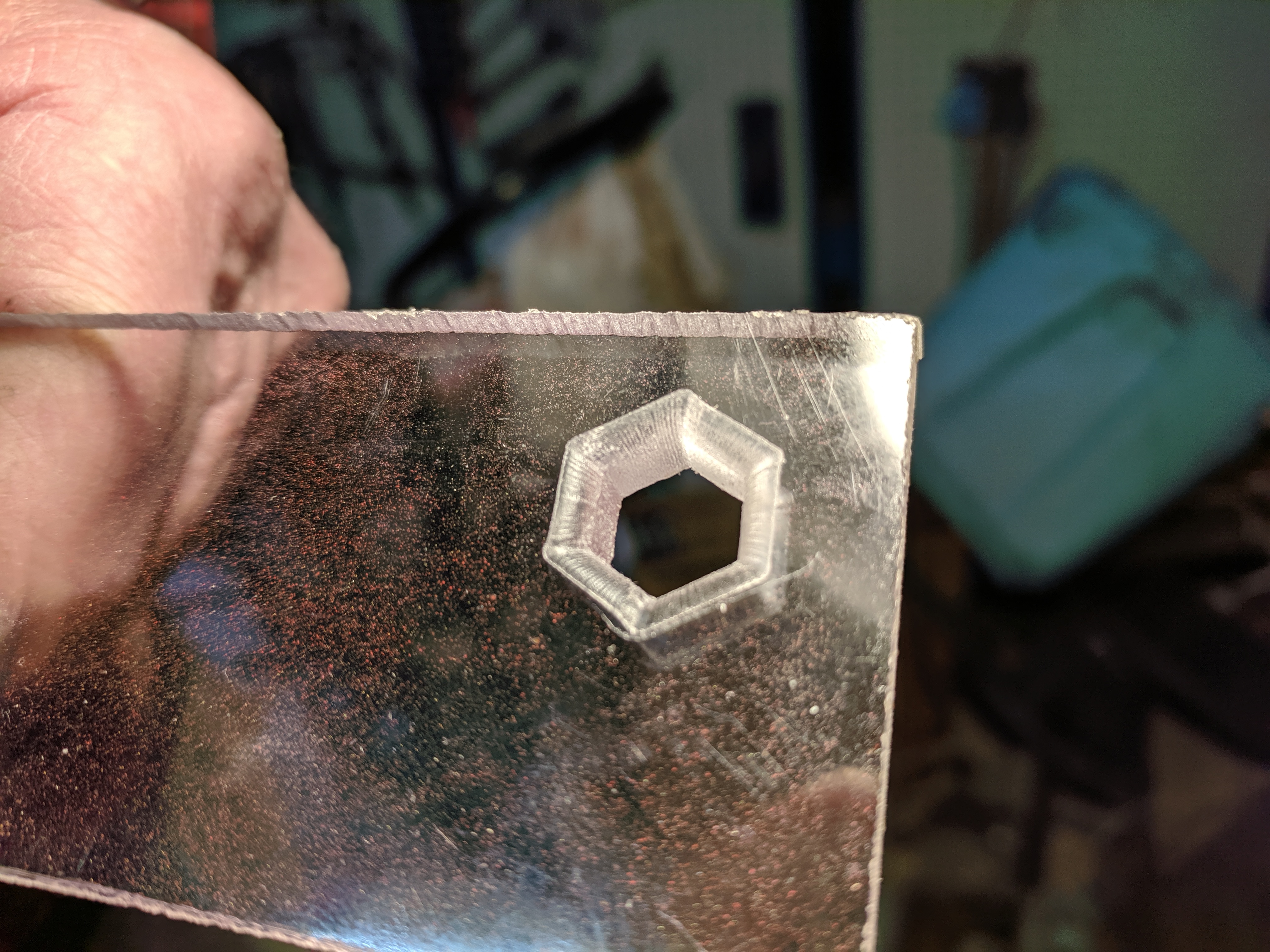

| 126 forum posts | A hex bolt head isn't exactly a standard.. but..

|

| Michael Gilligan | 01/04/2020 07:53:19 |

23121 forum posts 1360 photos | Nice !! MichaelG. |

| sam sokolik | 02/04/2020 01:11:05 |

| 126 forum posts | Hmm...

|

| sam sokolik | 04/04/2020 01:18:53 |

| 126 forum posts | Broach this!

|

| Michael Gilligan | 04/04/2020 07:22:01 |

23121 forum posts 1360 photos | Comment rev.1 Very Very Nice !! MichaelG. |

| sam sokolik | 10/04/2020 16:55:17 |

| 126 forum posts | Ok - I need to get a higher resolution encoder.. Then The surface finish will be better and I will be able to go slightly faster.... (I might have to bake in backlash comp too.... (x axis has a bit of backlash))

|

| sam sokolik | 13/04/2020 15:07:58 |

| 126 forum posts | Phase 2 - Better spindle encoder.. |

| sam sokolik | 22/04/2020 05:08:13 |

| 126 forum posts | |

| sam sokolik | 24/04/2020 05:19:44 |

| 126 forum posts |

|

| sam sokolik | 26/04/2020 22:10:53 |

| 126 forum posts | Encoder seems to work better...

|

| Michael Gilligan | 26/04/2020 23:08:42 |

23121 forum posts 1360 photos | Comment rev.2 Even nicerer still ... I’m clean out of superlatives now MichaelG. |

| sam sokolik | 29/04/2020 15:43:20 |

| 126 forum posts | I think I get a D for effort...

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

(the vertical lines are the encoder resolution...)

(the vertical lines are the encoder resolution...)

Register

Register Log-in

Log-in