The Workshop Progress Thread 2020

| JasonB | 01/01/2020 06:54:49 |

25215 forum posts 3105 photos 1 articles | Report your modelling and workshop milestones in this thread. Anything else should go into the What did you do thread 2019 posts can be found in this thread

Edited By JasonB on 01/01/2020 06:56:16 |

| JasonB | 03/01/2020 13:31:28 |

25215 forum posts 3105 photos 1 articles | First post and the first completely finished engine of the year. Now that the paint has had a chance to dry I took a few photos and a bit of video. It will run slower than that but I did not want to risk it stalling in the video which is quite pleasing as I deviated from the usual layout and size of the ports which allows more air/steam to flow.

|

| Ron Laden | 04/01/2020 07:59:30 |

2320 forum posts 452 photos | Very nice Jason as always and a very sweet runner, the flywheel runs very true considering it is a soldered fabrication, very good. |

| JasonB | 04/01/2020 19:13:51 |

25215 forum posts 3105 photos 1 articles | Thanks Ron, there is a slight amount of run out on the inside of the rim a sit cooled off slightlu oval by about 0.5mm so I trued up the outside in the lathe and had also left the hub undersize so that wa sbored out at the same setting which got it good enough and better than any casting. I had intended to give the Root and Van Dervoort vertical another try over the holidays and with the Type-B and Preston's Oscillator running thought I may be a on a bit of a roll so spent most of today on the R&V. One of the issues was getting it to run strongly and for any length of time and I was having difficultly getting the timing right, as both the ignitor and exhaust valve are operated by the same rod it was impossible to get the ignitor to fire at TDC and the exhaust to open in the right position, if I set one then the other was well off. I decided to partly strip the engine and take the cam off for a closer look - not easy as the person who started the engine had pressed it onto an oversize shaft but I managed it in the end with a few levers and a hammer. Turned out that the cam profile which moves the pushrod was not that close to what was on the drawing and the integral eccentric that drives the fuel pump was 20thou oversize so I made a new one and things have improved quite a bit. Still needs a couple of breaths before it fires in the hit position and therefore not making as much speed as it should preventing it latching out into miss mode for long but a lot better than it was. Need to put another pin hole in the push rod so the crocodile clip that in compressing the spring more can be removed. It ran for another 3-4mins after I stopped the video and then I turned it off as things were getting a bit warm with no water in the engine. |

| Ron Laden | 04/01/2020 20:06:54 |

2320 forum posts 452 photos | Well 10 out of 10 for the improvements Jason it seems to be running strongly now and it kept running also. It does look good on the trolley/carriage better than sitting on the bench I think. Three engines running in just a few days, cant complain at that. |

| Ron Laden | 06/01/2020 09:14:24 |

2320 forum posts 452 photos | Jason, I know it says so in the Preston video but the flywheel rim is a piece cut from a 7 inch diameter steel tube am I understanding that correctly, if so it must have been quite a thick walled tube..? |

| JasonB | 06/01/2020 11:10:27 |

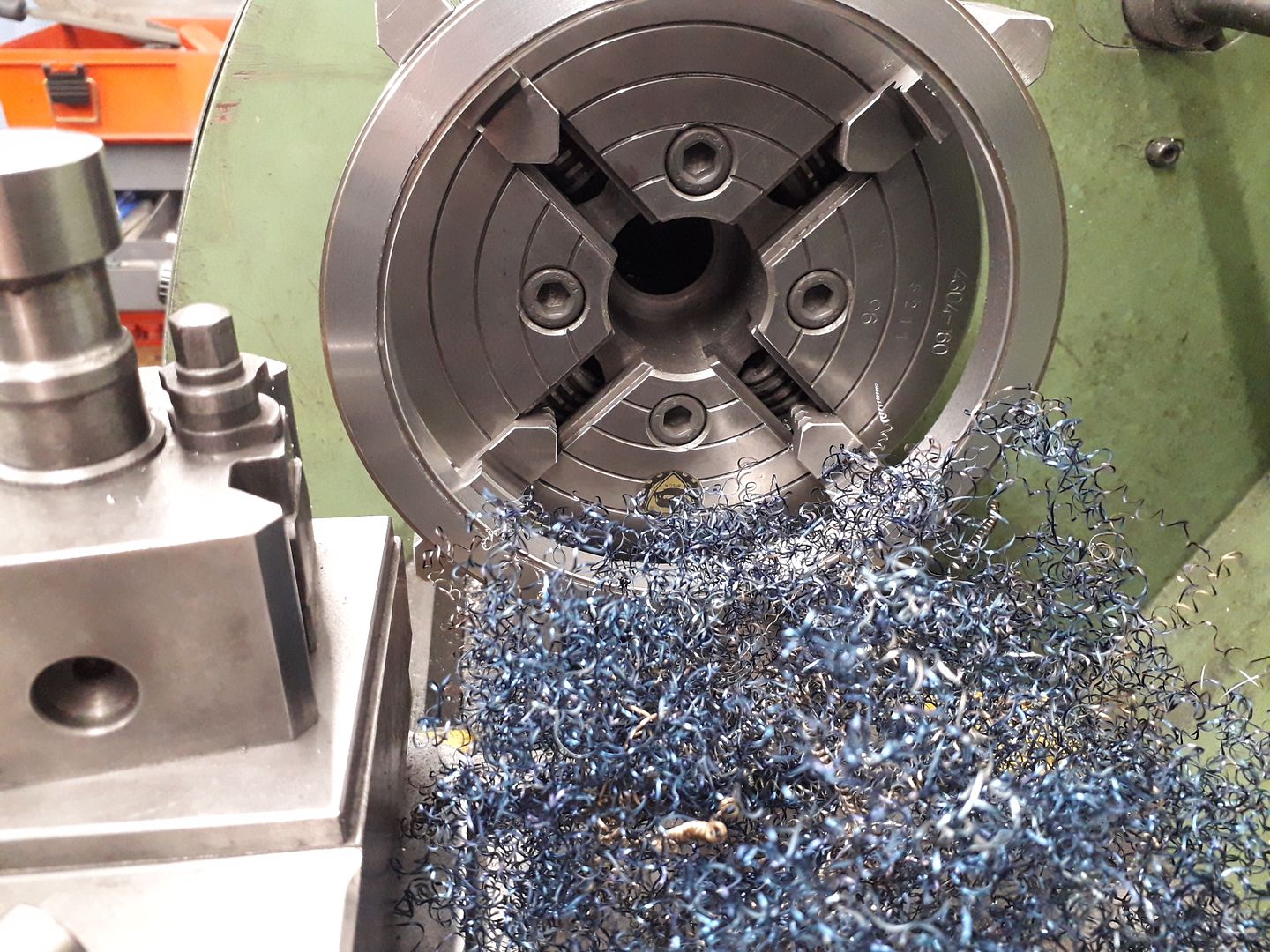

25215 forum posts 3105 photos 1 articles | Yes Ron, wall thickness was a bit over 3/4". I was given a couple of slices and the width of the slice was my limiting factor and I was able to get a 14mm diameter cross section to the rim.

Not the nicest metal to turn but it did the job.

|

| Limpet | 06/01/2020 12:22:28 |

| 136 forum posts 5 photos | Jason - I feel a bit of an idiot now, when you said the flywheel was tube I thought you meant a tube rolled in a circle not a slice of it and I was beginning to wonder how you got the weight up to act as a flywheel, all is now clear - Doh |

| Jim Nic | 07/01/2020 15:10:42 |

406 forum posts 235 photos | Progress over the holiday period on the Muncaster Double Acting Oscillator. Finished off the cylinder mounting arrangement but deviated from Muncaster's plan by incorporating a spring and a bronze ball to hold the cylinder port face to the air inlet block. Then made the cylinder covers and all was going well until I was given a chance to test my New Year's resolution not to yell bad words whenever anything went wrong. I broke a 10BA tap in the con rod stuffing gland. I managed to retain my cherubic demeanour and calmly considered how to avoid making a whole new cover. I had planned to use 3 studs so the solution was to leave the broken tap in situ and drill and tap another 3 holes in the cover and just turn the gland through 60 degrees. This time my taps survived. The now almost completed cylinder just needs banding to retain the planned wooden insulation but that can wait until the finishing phase. Jim |

| geoff walker 1 | 08/01/2020 18:26:13 |

| 521 forum posts 217 photos | Hi Jim, Keep the photos coming, looking forward to seeing the complete model I like your mod with the spring and ball, makes sense to me. 10 BA tap!!!!, I've never used one Jim, my smallest is 8. I'm just completing Part 2 of an article for this engine for a well known model engineering magazine. Part one is with the editor, early signs are that he will publish, we'll see, fingers crossed. ATB Geoff |

| geoff walker 1 | 08/01/2020 18:31:26 |

| 521 forum posts 217 photos |

Hi Jason, Just browsing back through the posts and spotted your complete engine I really like it, full of character Geoff |

| geoff walker 1 | 08/01/2020 18:41:50 |

| 521 forum posts 217 photos | cont.........and I've just seen the video, great. You see a lot of oscillators with short aggressive strokes but yours with it's long stroke, I personally find much more appealing. In particular when you have it running really slow. Geoff |

| Jim Nic | 09/01/2020 15:33:29 |

406 forum posts 235 photos | Hi Geoff Although I'm close to completing the major components I'd be very interested to read your build article to see where I went wrong (other than not feeeling when my 10BA tap had reached the bottom of the hole). A heads up when publication is imminent would be appreciated. Jim |

| geoff walker 1 | 09/01/2020 18:36:42 |

| 521 forum posts 217 photos | Hi Jim, "Went wrong"? I can't see anything wrong, you've just put your own slant on it, which is what most modellers would do. Yes I will let you know, need to get it finished this month, off to Australia for 6-7 weeks in early feb so need it over and done with soon Atb Geoff |

| JasonB | 12/01/2020 16:23:14 |

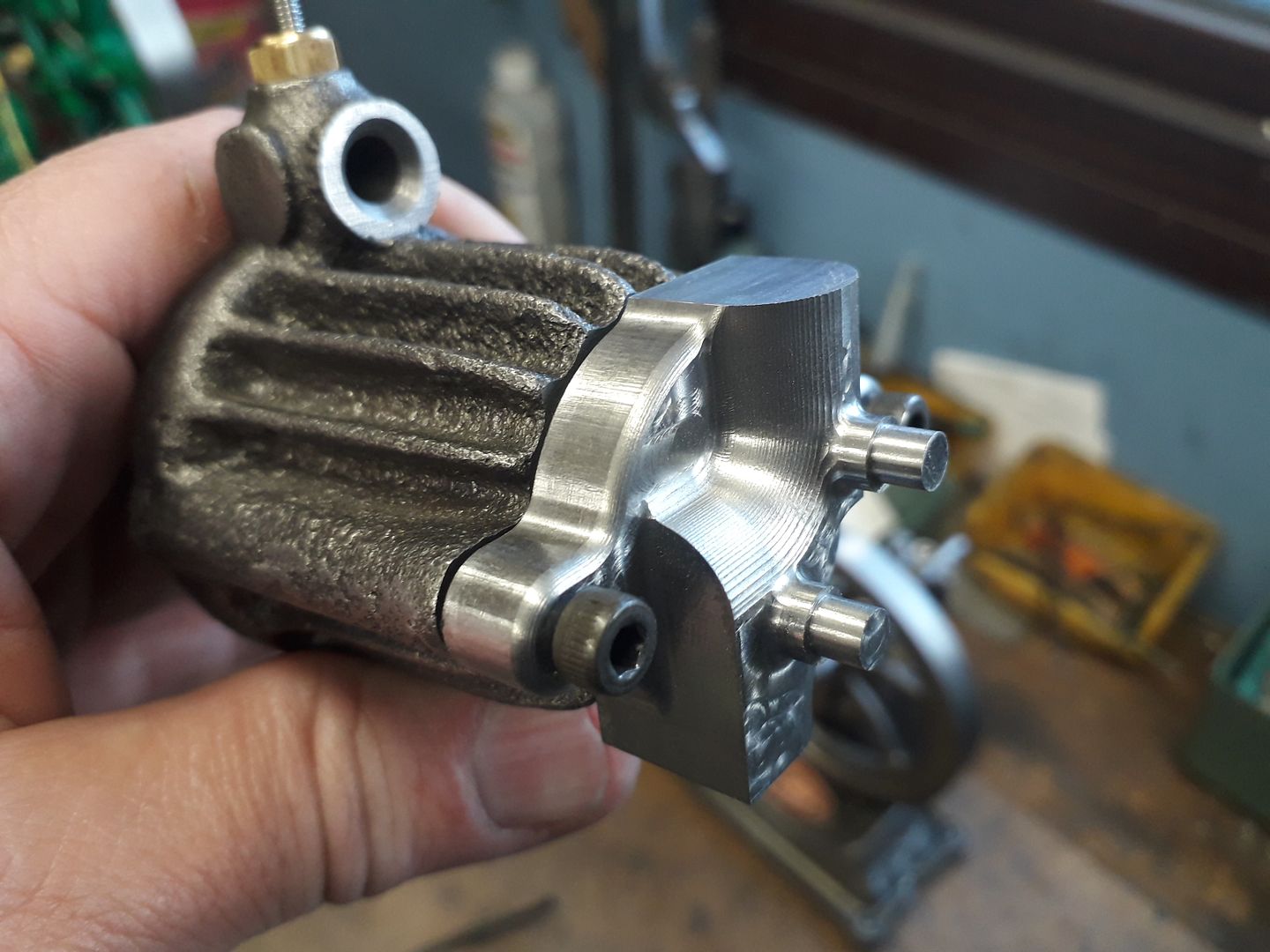

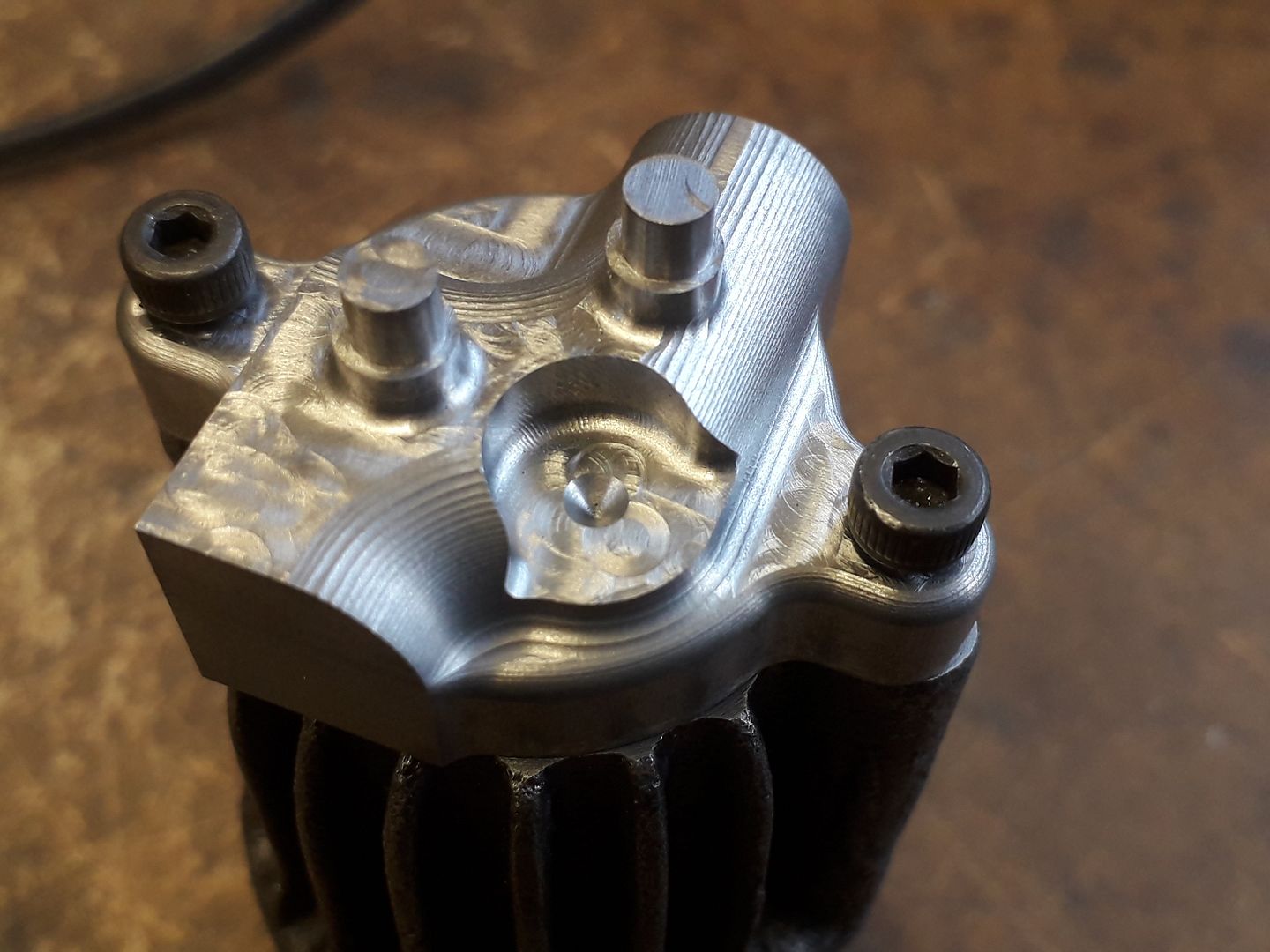

25215 forum posts 3105 photos 1 articles | Having spent quite a while on Frday evening and even more on Saturday flicking teh RMC type A flywheel round I came to the conclusion that it is not going to work on propane instead of the now unobtainable MAPP gas I drew out a new head for it last night so it can be built as a 4-stroke, did the CAM this morning and then after lunch got the Sieg KX3 to spit out the new head in just over an hour. Still needs some holes here and there but will do those on the lathe and manual mill and then give it a lick with the needle files to get rid of the contour lines..

|

| Mark Rand | 15/01/2020 02:47:41 |

| 1505 forum posts 56 photos | I spent the productive part of the day making two clean oblongs out of a piece of 15x150x500mm BMS, then cut a Myford sized T-slot in each. With a bit more work and some additional bits, the bandsaw will no longer have problems cutting small bits square and medium/small bits at an angle.

|

| Ron Laden | 15/01/2020 07:03:34 |

2320 forum posts 452 photos | Posted by JasonB on 12/01/2020 16:23:14:

Having spent quite a while on Frday evening and even more on Saturday flicking teh RMC type A flywheel round I came to the conclusion that it is not going to work on propane instead of the now unobtainable MAPP gas I drew out a new head for it last night so it can be built as a 4-stroke, did the CAM this morning and then after lunch got the Sieg KX3 to spit out the new head in just over an hour. Still needs some holes here and there but will do those on the lathe and manual mill and then give it a lick with the needle files to get rid of the contour lines..

The bonus of CNC Jason that would have been a lot of work on a manual. What is the make up of MAPP that makes it different to propane and why no longer available..? Edited By Ron Laden on 15/01/2020 07:04:59 |

| JasonB | 15/01/2020 07:50:56 |

25215 forum posts 3105 photos 1 articles | MAPP had more hydrogen in it which made it suitable for these type of non compression engines. Most of the full size old ones that are run now use a home mix that is about 85% hydrogen and 15% propane. Not sure why the one company that made it stopped. |

| Mark Rand | 15/01/2020 22:28:50 |

| 1505 forum posts 56 photos | Less hydrogen! Also a triple bond on one of the atoms, which decomposes exothermically, like acetylene does. Conversely, hydrogen as H2, rather than a part of larger molecules has an incredibly large flammable concentration range. Got to be useful for little engines! |

| Steviegtr | 15/01/2020 22:47:25 |

2668 forum posts 352 photos | I saw Mapp gas bottles for sale only last week. Cannot remember where but it was in Leeds. Probably old stock. |

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in