Milling curves

Question on what kit I need

| Roy Garden | 20/03/2019 23:49:43 |

23 forum posts 9 photos | Complete newbie, Have searched for an answer, not found one. I'm guessing a dividing head table, but asking as I don't know. I'm using a Seig 2.7 mill. |

| duncan webster | 21/03/2019 00:09:45 |

| 5307 forum posts 83 photos | several suggestions

|

| Roy Garden | 21/03/2019 00:14:39 |

23 forum posts 9 photos | 1) I'm lazy and fairly inept, so that's a non starter. |

| John Reese | 21/03/2019 00:25:51 |

1071 forum posts | You didn't say in what plane you want the radius. |

| Roy Garden | 21/03/2019 00:29:46 |

23 forum posts 9 photos | around the x and y axis (is that horizontal plane?)

|

| duncan webster | 21/03/2019 00:33:57 |

| 5307 forum posts 83 photos | Posted by Roy Garden on 21/03/2019 00:14:39:

1) I'm lazy and fairly inept, so that's a non starter. as you only want a 1" radius a small one will do, but might be restrictive for future jobs. I have 4" and 6" and use the 4" most, but anything you can do on a 4" you can do on a 6". However I'm not sure how a 6" fits on your milling machine, others will advise. |

| Roy Garden | 21/03/2019 00:46:42 |

23 forum posts 9 photos | Which one tho?

|

| Hopper | 21/03/2019 03:31:35 |

7881 forum posts 397 photos | See this recent thread here for extensive discussion of a number of rotary tables, good, bad and toothless: LINK You probably would not go wrong with a 4" rotary table from ArcEurotrade. Edited By Hopper on 21/03/2019 03:33:58 |

| Paul Lousick | 21/03/2019 04:56:55 |

| 2276 forum posts 801 photos | If there is a hole at the centre of the radius, all you need is a pin in the hole and rotate the job in a vice. (see Youtube video). Paul Edited By Paul Lousick on 21/03/2019 04:59:42 |

| JasonB | 21/03/2019 07:02:12 |

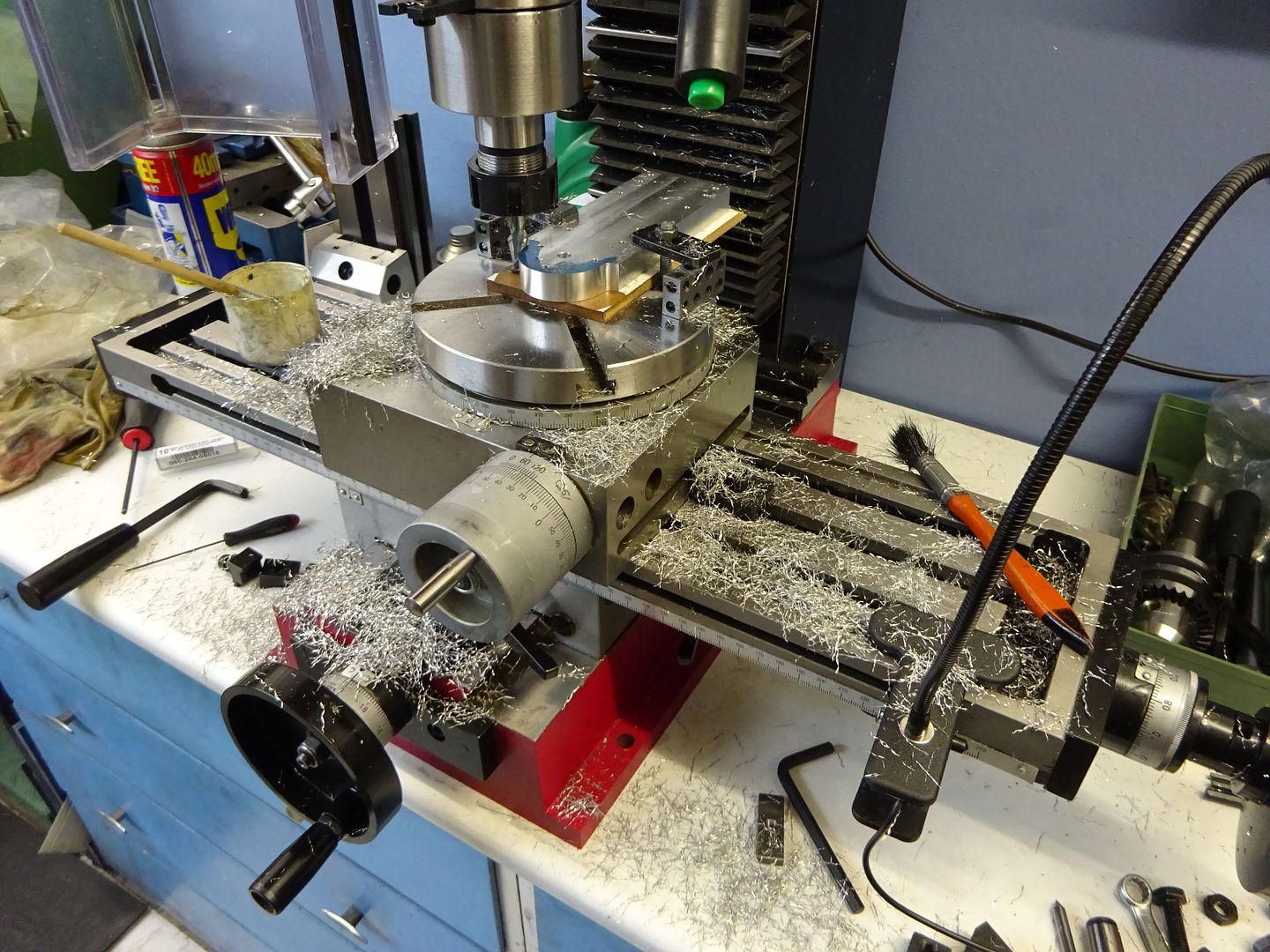

25215 forum posts 3105 photos 1 articles | Similar job on a SX2.7 with ARC 150mm table which gives you room for clamps

|

| Plasma | 21/03/2019 07:36:19 |

| 443 forum posts 1 photos | What is the material and how thick is it? If you're abilities are not enough to file a workpiece into a curve I wonder at how you would go about setting up to mill the workpiece. I'm not being rude but practical, as any apprentice will attest, you're expected to learn bench work first before being thrown near a 5 axis CNC machine. And a motorised table is kind of in that territory, you cant just bolt a lump.of metal to it, press a button and out pops the finished item. As with most things there is a hell of a lot more to do. And the idea that machining a piece would be simpler and quicker is false, sometimes setting up takes a lot more work than actually doing the job. Plus you can always apply Occams Razor, the principal that the simplest solution is usually the right one. For me, a one off curve would be easiest done on a vertical belt machine or abrasive disc. By the time you have done setting up your mill and rotary table I would have shaped the piece, had a cuppa, painted it and gone in for lunch.

|

| Brian G | 21/03/2019 08:15:35 |

| 912 forum posts 40 photos | Posted by Plasma on 21/03/2019 07:36:19:

What is the material and how thick is it? If you're abilities are not enough to file a workpiece into a curve I wonder at how you would go about setting up to mill the workpiece. ... Rather than buying a rotary table before you are certain which one you want (I made that mistake and haven't actually needed to use mine yet as for many jobs a file is quicker), you might be able to make filing it easier. After spending hundreds on machines, it was quite disheartening to realise that hand tools can be less work. Perhaps take off most of the metal with a couple of angled cuts, either on the mill or more easily with a hacksaw (where you don't have to do mulitple set-ups or worse still reset a rotating vice to straight) and then file it between a couple of steel buttons. If you can't harden them put layout fluid or Sharpie on them and try not to file it off. If there is a hole, bolt them through (which would let you use cheap ballraces as buttons) otherwise clamp them. Brian EDIT: If you do go down the motorised table route, take a look at Arduino Rotary Table for Dummies on HMEM. The whole project costs less (much less if you use an Arduino clone) than a set of division disks for a rotary table, and assembling the electronics was a fun introduction to Arduinos. I might even get around to fitting it to my rotary table one day should I need it... (EDIT2: If I can find it that is, I have a horrible feeling I nicked all the components for other projects, Arduinos are seriously addictive). Edited By Brian G on 21/03/2019 08:21:54 Edited By Brian G on 21/03/2019 08:24:20 |

| Speedy Builder5 | 21/03/2019 08:45:30 |

| 2878 forum posts 248 photos | For a low cost solution, if your vice sits on swivel base, you could hold the piece in the vice, offset from the centre of the vice by the required radius. Mill a flat over the end of the component. move the vice around a few degrees and make another pass. You could do that for 180 degrees of rotation of the vice. Now turn the component upside down and repeat (if you can't achieve full depth on the first passes). |

| John Haine | 21/03/2019 09:02:43 |

| 5563 forum posts 322 photos | If there is going to be a central hole in the end of the material...

|

| Michael Gilligan | 21/03/2019 10:19:13 |

23121 forum posts 1360 photos | Posted by Brian G on 21/03/2019 08:15:35:

EDIT: If you do go down the motorised table route, take a look at Arduino Rotary Table for Dummies on HMEM. The whole project costs less (much less if you use an Arduino clone) than a set of division disks for a rotary table, and assembling the electronics was a fun introduction to Arduinos. . Thanks for posting that excellent link, Brian ... It's sure to be useful sometime MichaelG. [the proud owner of one of Tony Jeffree's original DivisionMaster units]

|

| Howard Lewis | 21/03/2019 12:11:36 |

| 7227 forum posts 21 photos | Cannot see that a motorised Table would be much help, when you want to cut gears, other than to save time, when indexing. (But you would possibly spend more time programming it! ) FWIW, I use a HV6 Rotary Table, with Division Plates, to cut gears. So far, seemingly, with success. Do check that the Table has the Ratio claimed (Elsewhere, on the here we read of 48:1 tables with 47T gears! ) There have been instances of the chart supplied with the Table and Division Plates, containing errors, so if in ANY doubt, do the calculations and check!i When you are milling your radius; a) make sure that the work is clamped securely b) Do NOT "climb" mill. The work must approach the cutter blades, head on, (from the opposite direction). Without backlash correction, climb milling is likely to pull the work into the cutter with possible ruin for both. Howard |

| SillyOldDuffer | 21/03/2019 12:46:00 |

| 10668 forum posts 2415 photos | Variation of advice already offered by others. Make a pillar that can be clamped into the mill's vice, tapped to allow a carrier and/or workpiece to be rotated against the side of a milling cutter. Take care - the thick washer in the photo was damaged by a grab. Beware of fingers - take it gently, don't climb mill or use large diameter cutters that might allow a small job to be pulled inside the helix. Not tried it myself, but a more elaborate version of the pillar fitted with length of hacksaw blade bent in a circle, can be used to index a gear-wheel. Nice thing about owning a mill and a lathe is you can make things to make things. I often make jigs or fixtures to hold or support work during awkward cutting operations. For example, this aluminium block was made to put a filleted half-flat on a long brass pin.

Dave |

| John Reese | 21/03/2019 16:50:50 |

1071 forum posts | A lot of the import DROs will allow cutting a radius by providing a series of x and y coordinates for points on the circle. I suppose one could use the bolt circle function on most DROs if a huge number of holes were specified. Of course, it would be necessary to compensate for tool radius. Here is a link to a way to do it that does not require any special equipment: https://www.youtube.com/watch?v=hTj6LC6agrg That method may not work for longer parts. |

| AdrianR | 21/03/2019 17:38:48 |

| 613 forum posts 39 photos | If you want a useful tool too, you could make a face plate balancing spindle. Then use it with a long leaver as a rotary table. Two tools for the price of one. |

| Roy Garden | 21/03/2019 23:38:16 |

23 forum posts 9 photos | Gents, I'm profoundly grateful for the advice, thank you all. The "nail it to the table, and spin it round" advice kind of covers most of the equipment I currently have. Probably 4 hours time playing with the mill today, I think the finish looks good (it's what I wanted to see) Edited By Roy Garden on 21/03/2019 23:42:20 Edited to remove oil rig language. Edited By JasonB on 22/03/2019 10:03:55 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in