Reverse thread cutting

| martin perman | 21/12/2018 12:20:33 |

2095 forum posts 75 photos | Gentlemen, Having read the post regarding the Mini lathe repair there was mention of "reverse thread cutting" can anybody, Jason Martin P Edited By martin perman on 21/12/2018 12:21:20 |

| pgk pgk | 21/12/2018 12:44:35 |

| 2661 forum posts 294 photos | This vid as a demo of cutting an internal thread away from chuck.. same sort of process for external- reverse the lathe and cut from the back or with an inverted tool from the front. https://www.youtube.com/watch?v=k1DHKjMtdQw |

| not done it yet | 21/12/2018 12:49:41 |

| 7517 forum posts 20 photos | He means starting where you would normally stop the carriage. Nothing more difficult than that to imagine.... Cutting the thread with the lead screw running in the opposite direction. Try it. Your only fear then will be running into the tailstock - if you bother to use it to support the workpiece. |

| martin perman | 21/12/2018 13:07:12 |

2095 forum posts 75 photos | Posted by not done it yet on 21/12/2018 12:49:41:

He means starting where you would normally stop the carriage. Nothing more difficult than that to imagine.... Cutting the thread with the lead screw running in the opposite direction. Try it. Your only fear then will be running into the tailstock - if you bother to use it to support the workpiece. So do I assume the chuck runs backward and the tool is upside down or is the tool mounted on the other side of the work piece. Not so easy to imagine. Martin P |

| JasonB | 21/12/2018 13:15:12 |

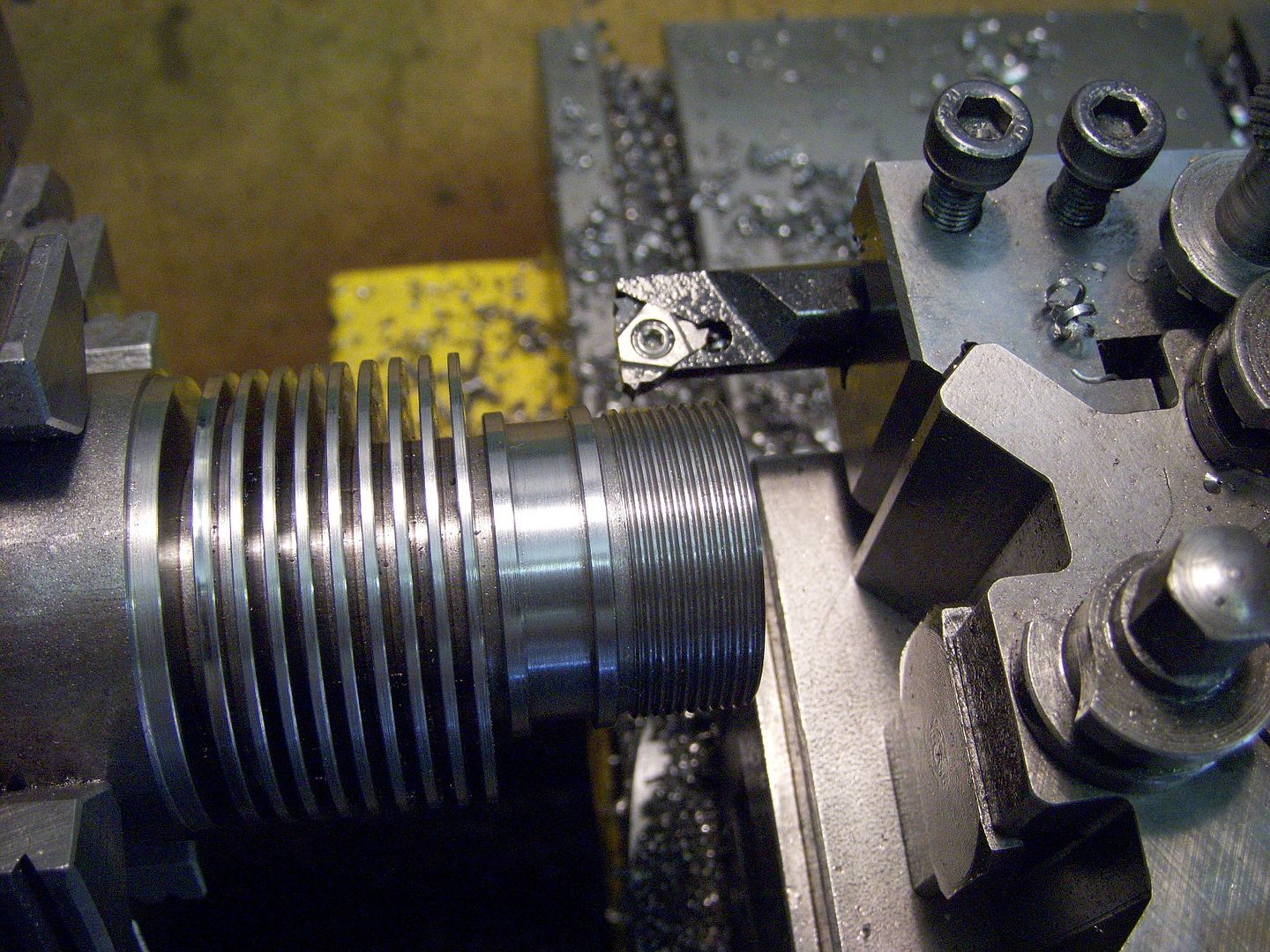

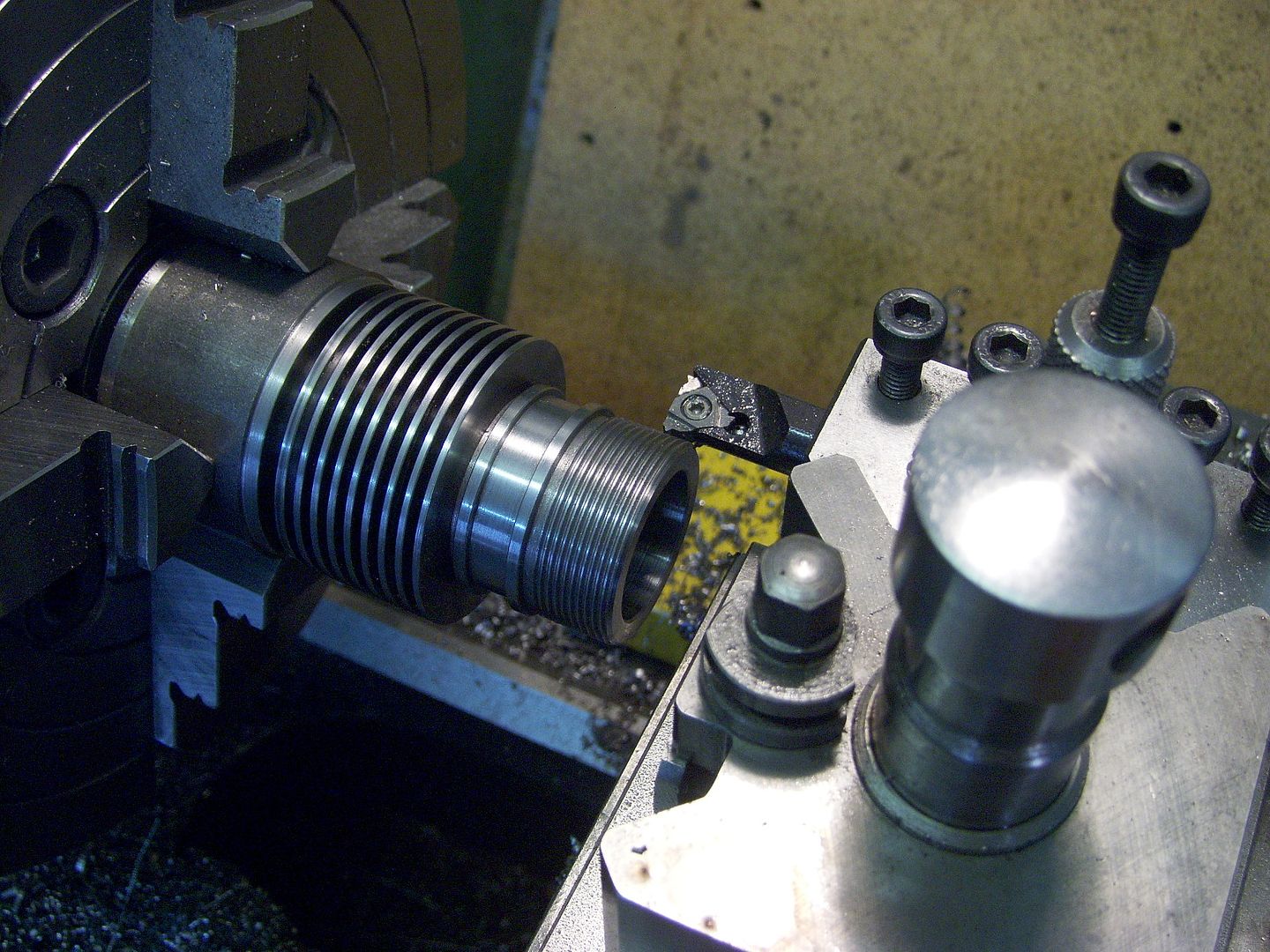

25215 forum posts 3105 photos 1 articles | You set everything up as per cutting conventionally but just mount the tool at the rear of the work (right way up) and run the machine backwards. It can be done with a conventional HSS bit or if you use insert tooling and don't need ctr support then the internal threading tool makes it easy to reach around the back without having to move the topslide rearwards. Cut the run out (in) groove as you would so that you can put the cut on and simply switch the lathe on with nuts engaged or engage the nut once upto speed if using the dial. For internal you either need a cack handed bar to cut at the back or mount it upside down cutting at the front. Here is one I prepared earlier.

You set the leadscrew up for a standard right hand thread don't reverse it for left hand cutting. Basically by running in reverse you are following the same helix by unscrewing the thread rather than screwing it on. Edited By JasonB on 21/12/2018 13:17:55 |

| Bazyle | 21/12/2018 13:55:54 |

6956 forum posts 229 photos | If your lathe can't run backwards or you are worried about the chuck coming loose you really should fit a simple electrical stop switch to the motor that is pushed by the carriage. If you have a lathe that has interlocks like for a chuck guard then check it uses low voltage and wire a plain micro switch into that circuit. If you only have a mains on off control get a sealed switch. google 'limit switch' The Boxford had this as a standard accessory to protect the school lathes from careless children. |

| martin perman | 21/12/2018 14:20:57 |

2095 forum posts 75 photos | Posted by Bazyle on 21/12/2018 13:55:54:

If your lathe can't run backwards or you are worried about the chuck coming loose you really should fit a simple electrical stop switch to the motor that is pushed by the carriage. If you have a lathe that has interlocks like for a chuck guard then check it uses low voltage and wire a plain micro switch into that circuit. If you only have a mains on off control get a sealed switch. google 'limit switch' The Boxford had this as a standard accessory to protect the school lathes from careless children. Thank you Jason, a picture speaks etc, Bazle, my lathe can run in reverse and the chuck bolts to the spindle back plate, this would make thread cutting less panicky as I dont have split nuts and no thread dial. Martin P |

| not done it yet | 21/12/2018 14:39:15 |

| 7517 forum posts 20 photos | Deleted

Edited By not done it yet on 21/12/2018 14:43:00 |

| Speedy Builder5 | 21/12/2018 14:52:25 |

| 2878 forum posts 248 photos | What ideas do the team have to lock the chuck onto the spindle nose when cutting in reverse or rear tool post parting off. Typically on a Boxford with screw on chuck. |

| Neil Wyatt | 21/12/2018 15:07:56 |

19226 forum posts 749 photos 86 articles | Posted by Bazyle on 21/12/2018 13:55:54:

If your lathe can't run backwards or you are worried about the chuck coming loose you really should fit a simple electrical stop switch to the motor that is pushed by the carriage. If you have a lathe that has interlocks like for a chuck guard then check it uses low voltage and wire a plain micro switch into that circuit. If you only have a mains on off control get a sealed switch. google 'limit switch' The Boxford had this as a standard accessory to protect the school lathes from careless children. That is already planned as the Neil |

| Ron Laden | 21/12/2018 15:33:52 |

2320 forum posts 452 photos | Posted by martin perman on 21/12/2018 14:20:57:

Posted by Bazyle on 21/12/2018 13:55:54:

If your lathe can't run backwards or you are worried about the chuck coming loose you really should fit a simple electrical stop switch to the motor that is pushed by the carriage. If you have a lathe that has interlocks like for a chuck guard then check it uses low voltage and wire a plain micro switch into that circuit. If you only have a mains on off control get a sealed switch. google 'limit switch' The Boxford had this as a standard accessory to protect the school lathes from careless children. Thank you Jason, a picture speaks etc, Bazle, my lathe can run in reverse and the chuck bolts to the spindle back plate, this would make thread cutting less panicky as I dont have split nuts and no thread dial. Martin P Which lathe do you have Martin |

| Andrew Johnston | 21/12/2018 15:44:09 |

7061 forum posts 719 photos | It should be noted that external and internal full form threading inserts do not necessarily produce the same form. Of course only a dedicated follower of over-complication would know about that sort of thing. Andrew |

| martin perman | 21/12/2018 16:24:34 |

2095 forum posts 75 photos | Posted by Ron Laden on 21/12/2018 15:33:52:

Posted by martin perman on 21/12/2018 14:20:57:

Posted by Bazyle on 21/12/2018 13:55:54:

If your lathe can't run backwards or you are worried about the chuck coming loose you really should fit a simple electrical stop switch to the motor that is pushed by the carriage. If you have a lathe that has interlocks like for a chuck guard then check it uses low voltage and wire a plain micro switch into that circuit. If you only have a mains on off control get a sealed switch. google 'limit switch' The Boxford had this as a standard accessory to protect the school lathes from careless children. Thank you Jason, a picture speaks etc, Bazle, my lathe can run in reverse and the chuck bolts to the spindle back plate, this would make thread cutting less panicky as I dont have split nuts and no thread dial. Martin P Which lathe do you have Martin

I have a Clarke CL500M which does nicely for me, Martin P |

| JasonB | 21/12/2018 17:07:10 |

25215 forum posts 3105 photos 1 articles | Posted by Andrew Johnston on 21/12/2018 15:44:09:

It should be noted that external and internal full form threading inserts do not necessarily produce the same form. Of course only a dedicated follower of over-complication would know about that sort of thing. Andrew Andrew, if you happen to know any people like that you may want to let them know that if you put a full form external LEFT hand insert into a RIGHT hand internal holder you can use it at the back of the machine and get the correct profile, though I expect they know that already |

| Howard Lewis | 22/12/2018 14:02:40 |

| 7227 forum posts 21 photos | Some of the later Eastern lathes (examples are:Warco BH600, BH900, Chester craftsman, Engineers ToolRoom BL12 - 24. And probably others) with screw on chucks have dogs which hook behind the flange on the mandrel, do that the machine can be run in reverse without fear of the chuck unscrewing. Possibly, it may be possible to devise something similar for lathes without this feature. Maybe even a small grubscrew and brass pad to bear on the thread, if space allows? At times, I used to run my ML7 in reverse, having made sure that the chuck was firmly in place (not so firmly that it could not be removed without undue force) . But slowly, and without taking big cuts! Howard |

| Jon | 22/12/2018 14:58:39 |

| 1001 forum posts 49 photos | I used to have serious trouble unscrewing my old ML7 chucks, always needed spindle locking down and a hard sharp smack on spanner or gripped bar in the jaws. |

| Andrew Johnston | 22/12/2018 15:07:50 |

7061 forum posts 719 photos | Posted by JasonB on 21/12/2018 17:07:10:

Andrew, if you happen to know any people like that................ Nope, don't personally know anyone like that. Surely a LH insert may not have the correct clearances? Not that I've got any LH inserts as thus far I've never needed to cut a LH thread. Think I'll stick to the conventional method of screwcutting. Andrew |

| fishy-steve | 22/12/2018 15:59:20 |

| 122 forum posts 30 photos | Posted by Speedy Builder5 on 21/12/2018 14:52:25:

What ideas do the team have to lock the chuck onto the spindle nose when cutting in reverse or rear tool post parting off. Typically on a Boxford with screw on chuck. Hi Bob, As far as parting off with a rear mounted tool post, just invert the tool and run in the conventional manner. I do it that way on my Boxford. Steve. |

| Speedy Builder5 | 22/12/2018 16:51:48 |

| 2878 forum posts 248 photos | hi Steve, yes, but you are "lifting"the saddle off the bed. On the Boxford, there is a rear saddle clamp, and a front saddle/ bed lock, but its a fiddle trying to tighten the rear cap screws when they are inverted and out of sight. |

| fishy-steve | 22/12/2018 17:30:42 |

| 122 forum posts 30 photos | Posted by Speedy Builder5 on 22/12/2018 16:51:48:

hi Steve, yes, but you are "lifting"the saddle off the bed. On the Boxford, there is a rear saddle clamp, and a front saddle/ bed lock, but its a fiddle trying to tighten the rear cap screws when they are inverted and out of sight. Hi Bob, I never have to tighten the rear saddle clap screws when parting off with HSS.. I purchased a parting tool from JB cutting tools at the midlands show this year. My Boxford can easily part off in the conventional manner when using it. I have yet to try it in the rear tool post. I think this would probably be the best set up though. Steve. Edited By fishy-steve on 22/12/2018 17:31:31 Edited By fishy-steve on 22/12/2018 17:31:48 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in