Polishing Castings

| Matt Stevens 1 | 30/10/2018 18:04:38 |

105 forum posts 17 photos | Now that I have started to make bigger parts - i.e. a 7" flywheel, I am finding that using various grit papers to polish becomes a magnitude harder! I would like to get the flywheel to a mirror finish but I am finding using 600-grit is really just polishing the edges and not particularly removing the machine marks. Does anyone have any hints and tips? For example - what about using a buffing wheel and polish sticks using a grinder? |

| JasonB | 30/10/2018 18:22:06 |

25215 forum posts 3105 photos 1 articles | If you still have machine marks when using 600 grit you have not worked through the grits correctly. First obviously aim for the best finish you can get off teh tool then say start with 120g to remove all tool marks, then 180g to get rid of the marks from the 120 and you should be able to get a bright finish with 320g. If you want to go further then do so but make sure one grit has removed the previous grits marks or you will just be polishing scratches. personally I stop at 150g which gives a nice sheen rather than an unscale mirror finish

Edited By JasonB on 30/10/2018 18:32:54 |

| Matt Stevens 1 | 30/10/2018 18:26:35 |

105 forum posts 17 photos | Ok....maybe you are right and I need to start with a more coarse grit. ..... I just wondered if there was another technique that was perhaps more effective (hence the comment about a polishing wheel on a dremel or bench grinder) |

| Zan | 30/10/2018 18:27:26 |

| 356 forum posts 25 photos | You need to work down the grades of abrasive, when all the lines are from the current one, it’s time to go onto the next. With f lat material this is easy as the idea is to use each grade at right angles to the previous one, making it very clear when the marks from the previous one have been fully erased. Do not buff! This will seriously round the corners and remove detail, unless you are using it for a final light polish. It’s difficult to keep it even a Drexel would be even worse, too small and easy to form depressions, tiny, but so obvious when a high finis is wantedAlways use abrasive on some form of backing, hands are rounded, and just holding it will round the work. Sticks, files etc can be used. If your flywheel is cast iron, a mirror finish is difficult due to the natural micro holes (or pits) found where the free graphite in the iron was previously located. Good luck mirror polished work in my opinion always looks so poor, it’s completly non standard some people seem to polish everything, although it does have its place with brasswork, but not machined components Edited By Zan on 30/10/2018 18:29:14 Edited By Zan on 30/10/2018 18:33:35 |

| Richard S2 | 30/10/2018 19:16:09 |

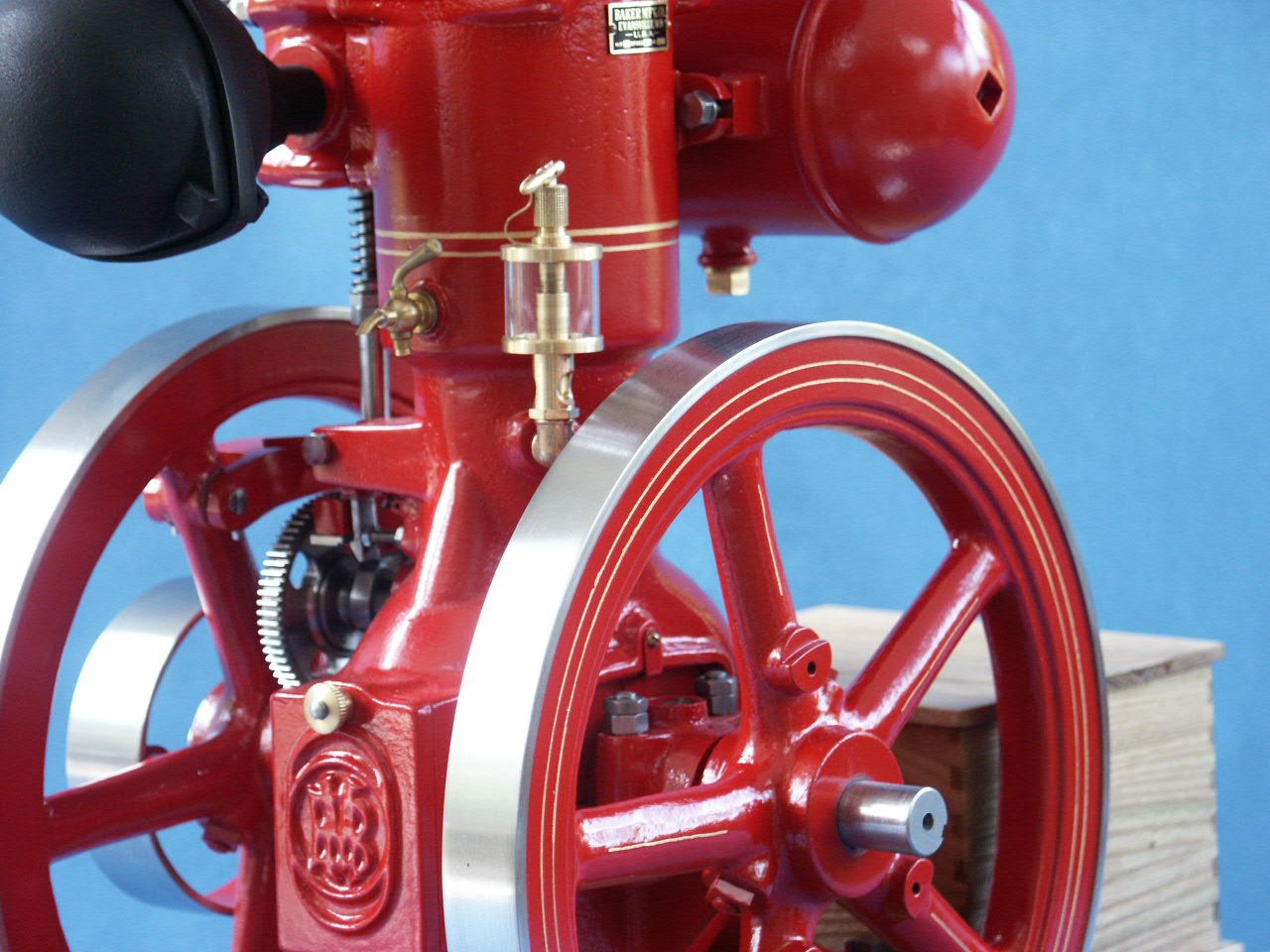

237 forum posts 135 photos | Whatever the casting base metal is, the process is more or less the same. Depends whether it is a machined surface, or the rough casting that is to be polished. Machined/ part finished surface is finished as mentioned above. Finish is a personal choice and can be for practical reasons. The finish on my TE Flywheel (cast iron) here- .......is achieved with the process described above by Jason B (35 years ago). The high finish is to resist any corrosion due to my very slow progress on the project and proof that a good finish is more resistant. There are some before and after examples in my album of rough to polished castings in bronze as well. Patience is also a requisite, so keep at it and good luck.

Edited By Richard S2 on 30/10/2018 19:16:34 |

| Mark Elen 1 | 30/10/2018 19:55:06 |

| 142 forum posts 356 photos | I made up a couple of sticks as described here: **LINK** Really easy to make up and they last for ages. Cheers Mark |

| Dalboy | 30/10/2018 20:05:24 |

1009 forum posts 305 photos | Like any hobby that uses a sandpaper/emery paper to smooth a surface the important thing is to start with a grit that will remove (in your case machine marks), then when you have removed those go to the next grit of paper in the range. Do not skip a grit and remove the marks of the previous grit each time this will make it easier to get the required finish that is needed |

| Philip Rowe | 31/10/2018 12:27:58 |

| 248 forum posts 33 photos | Posted by Mark Elen 1 on 30/10/2018 19:55:06:

I made up a couple of sticks as described here: **LINK** Really easy to make up and they last for ages. Cheers Mark I'm ashamed to admit I've always bought mine (being lazy) but having watched that video I will definitely make my own from now on. One thing though, do the multi layers formed by wrapping the emery tend to make a cushioned surface as opposed to a single layer glued to the wood? Clearly the ability to tear off worn parts must be a great advantage. Phil |

| Nigel McBurney 1 | 31/10/2018 17:40:21 |

1101 forum posts 3 photos | The original engine flywheel would not have been polished, just machined ,most small engines were painted on the rim, Collectors and model makers do like to see cleaned up flywheel rims though scaling down to a 1/4 a reasonable slightly grained finish is all that is required,polishing to a chrome like finish is wrong.I was trained to use use emery paper wrapped around a 6 inch file which had been ground flat and all the teeth removed, known in our works as a "papering file" as we never used emery cloth only emery paper which stays flat,emery cloth is stiffer and so does not lay flat on the file and tends to remove material from the centre and does not keep the work flat.Lubricate the emery with 3 in 1 oil or diluted hydraulic oil to keep it cutting and do not go too fast, be careful with the oil to much oil splashed all over the casting, as it can affect paint adhesion, when finishing optical benches and the beds of travelling microscopes, after painting and before assembly any marks on the grained machined cast iron surfaces would be cleaned up with a few strokes of dry emery wrapped around a very flat wooden block.I once heard that clockmakers polish everything,isntrument makers straight grain every thing.

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in