Controller for a 3 axis lathe

| richardandtracy | 12/05/2018 13:55:08 |

943 forum posts 10 photos | I am in the process of building a CNC lathe to make pens with. I want to be able to engrave the outside of the pen as well as make all the usual 2 axis lathe stuff. Now, my workshop is unheated and is a killer forPC's, so I want to avoid the usual Mach3 route and use a standalone controller. WinXP PC's are getting less & less reliable as time passes and becoming less available to act as replacements, and I hate the faff of setting up a new PC every 6 months. There are quite a few milling controllers on the market, some of which are both cheap and capable. The problem is that 3 axis lathe controllers seem to be like hens teeth, a bit rare and disappear when you start looking harder for them. A gent suggested I used a 4 axis milling controller instead. Used the x & y axes for the 2d bit of the lathe work, then remove the main drive belt and hook in a stepper motor onto the spindle for the thread cutting and engraving and then use X,Y and A. It sounds like it could work. Has anyone tried a system like this? And can anyone see any drawbacks that I may have missed? I can write programs to generate code that would make up for the lack of a G76 thread cutting canned cycle, if that's the only drawback. Regards Richard.

|

| Nick Hulme | 12/05/2018 21:10:04 |

| 750 forum posts 37 photos | Lathe is a different set of G Code to Mill so a stand alone milling controller will not support lathe. |

| John Haine | 12/05/2018 22:53:52 |

| 5563 forum posts 322 photos | Maybe you should think of it as a mill with an A axis where you don't use the X axis (very much)? Becomes a machining centre really. You compensate for the lack of lathe G code support through CAD/CAM. |

| richardandtracy | 12/05/2018 23:06:11 |

943 forum posts 10 photos | Nick, What bits of a lathe will it not support? As far as I can see, the following:

Is there more I have missed? The majority of a lathe's work can be simulated by 2 axis movement, which is well within the scope of a milling controller. There will be milling specific canned cycles that I'd have to avoid, but with thought it's not hard to imagine most lathe functions simulated as 2 axis mill functions. It should be relatively simple to work through a G1 command linking the spindle rotation axis (which I'll call 'A' I have never used a CNC lathe, and am not totally sure of the full operation of one, or which codes are most useful, but I have studied the list G an M codes for each, and made a basic assessment of the possible viability of the idea. I am looking for specific cases that I may need or have not considered. Sweeping statements and no specifics will not persuade me one way or the other. John, That was the sort of thing I was thinking of. Apart from being slightly crippled in its use, have I forgotten something obvious? I well know the thing hiding in plain sight is the bit you don't see.. Regards Richard.

Edited By richardandtracy on 12/05/2018 23:10:15 |

| Neil Lickfold | 12/05/2018 23:07:20 |

| 1025 forum posts 204 photos | I am looking at Centroid controllers for my next project. They seem to do one that allows the unit to be configured for a lathe. Not cheap, but looks to be a really robust system, the one on the converted Bridgeport that I saw was , and was a neat tidy conversion. They also have a cheaper option for DIY as well. |

| richardandtracy | 12/05/2018 23:18:30 |

943 forum posts 10 photos | There are several small controllers that may work. The TC55 at about £130 is an option for a milling controller with a small screen built in. The Adtech is pricey, and both Newkye and Tomatech produce 3 axis lathe controllers at prices greater than the lathe - starting a £680 or so. These latter controllers have 7 or 8 inch screens built in. Thus far I've seen no reason not to go for a milling controller, but my knowledge is less than complete. Regards Richard.

|

| John Haine | 13/05/2018 07:15:57 |

| 5563 forum posts 322 photos | I use both CNC lathe and mill. On the lathe I've used G00, G01, G02/03, G38 for probing (yes it does work in Mach turn), and threading using a wizard. |

| richardandtracy | 13/05/2018 20:36:26 |

943 forum posts 10 photos | Thanks John. Not using Mach turn, but will be trying to get the similar result through a different means. Regards Richard.

|

| John Haine | 13/05/2018 20:43:06 |

| 5563 forum posts 322 photos | Yes, understood, just to say that most things need only a small number of g codes to be supported on the lathe. I keep wondering about moving from Mach 3, but I have an increasing number of special hacks that I've now implemented that would need to be reimplemented that it gets more daunting. My workshop is warm and dry and so far the Dell computer I bought used in probably 2010 hasn't gone wrong, I should probably plan an upgrade of some sort pretty soon! Edited By John Haine on 13/05/2018 20:57:10 |

| richardandtracy | 13/05/2018 21:03:08 |

943 forum posts 10 photos | The first two PC's I used were Dell's. They failed fairly quickly, and I had a third that failed between me firing it up on arrival and needing to use it. Win some, loose some. The most expensive was £17. Regards Richard.

|

| Muzzer | 13/05/2018 22:33:44 |

2904 forum posts 448 photos | Most controllers come in milling and turning versions. My Newker (Chinese) controller is a 4 axis milling controller (990MDC), whereas Neil Blackmore (working with John Stevenson I believe) got the turning model (990TDC). There are quite a few differences that you might not appreciate until you miss them. I suspect that lathe-specific g codes won't be supported on the milling controllers for example. Similarly the Centroid Acorn has different versions of software for each. I don't see any benefit in trying to use a milling controller on a lathe. It's like turning on a mill - it can be done but requires a lot of buggerage. Given that they cost the same (or possibly less for a 2 axis lathe controller than a 3 or 4 axis milling controller), why not just get a lathe controller? Your call.... Murray |

| Michael Gilligan | 13/05/2018 23:36:43 |

23121 forum posts 1360 photos | Posted by Muzzer on 13/05/2018 22:33:44:

I don't see any benefit in trying to use a milling controller on a lathe. It's like turning on a mill - it can be done but requires a lot of buggerage. Given that they cost the same (or possibly less for a 2 axis lathe controller than a 3 or 4 axis milling controller), why not just get a lathe controller? . Maybe because of what Richard wrote in the opening paragraph of this thread ? MichaelG. |

| jason udall | 13/05/2018 23:56:11 |

| 2032 forum posts 41 photos | Here's my two pence X axis on mill is front to back up axis is left right Z is along the spindle Lathes map these the same but less "arbitrarily" X effects diameter through center line Z length of part to and from headstock Y axis is generally interpretated as tool height not generally used that way The C axis is also controlled for "pseudo"y axis where a plane x' -y' is wrapped around the part in a cylinder using C axis and z ...and X axis being z' or depth Now your control may or may not understand all that as must your CAM Software... A milling control without a turning mode won't be able to convert all those axis /coordinates for you..but I have in the past used Excel is post process milling engraving g codes to "around" a cylinder g codes.. As to your compound curves for pen handles...good luck.. Maybe consider ppnot a CNC lathe but an egg lathe...whole different hobby |

| richardandtracy | 14/05/2018 09:06:21 |

943 forum posts 10 photos | Jason, I have written a wrapper program to convert cambam milling output to go around an 'A' axis, such conversions are not a problem **LINK**. I have also got part way through a program that will use a reference profile to define the diameter of a piece of work so that non cyclindrical wrappings can be created. It's less easy than I had originally hoped - mostly because of the multiple ways a DXF file can define curves (splines, arcs etc). I do find the lathe axis designations less intuitive than the mill ones. I always feel X should be along the lathe bed, Y the cross slide and Z the missing vertical axis. I can understand why the lathe designations occurred - trying not to re-write all the hard won code from milling controllers when they were pressed into use as the early lathe controllers - I just think it's less intuitive than it could be. Murray, I am looking for 3 axis lathe, not 2. That is the current cause of my wallet related pain. There is a 2 axis lathe controller for a little more than the milling controller I pointed to earlier, this is it: **LINK** If they did a 3 axis version at a little more I'd have been in heaven. They do not. Which is why my wallet is protesting at the £400 price hike to add a rotary axis. OK. I admit it, I I do agree that it looks as if it's going to be a PITA to use a milling controller on the lathe. But I think it is going to be the same if I use a lathe controller too, mostly down to my decision to use the motor the Clarke 430 comes with and not use a servomotor to drive the spindle. A 750W servo motor looks like it's coming in at £2-300 - again a big part of the cost of the lathe. I would prefer not to rule this option out as a future upgrade, which using a milling controller would pretty much do. I am close to being convinced about not using a milling controller, doing the job closer to 'right' rather than quick. Regards, Richard.

|

| John Haine | 14/05/2018 09:27:55 |

| 5563 forum posts 322 photos | Think of a lathe as a mill laid down on its left hand side, then on its back. The designations then make sense, as does the odd fact that normal threading counts as clockwise spindle rotation, which it is looking from "above". Sadly that lathe controller doesn't support probing. Edited By John Haine on 14/05/2018 09:29:03 |

| jann west | 14/05/2018 09:43:35 |

| 106 forum posts | . Edited By jann west on 14/05/2018 09:47:42 |

| blowlamp | 14/05/2018 11:09:10 |

1885 forum posts 111 photos | I'm still very impressed with PlanetCNC TNG. It would surely do what you're after and could be configured in any way you like... Lathe, Miller, 3d Printer or some Hybrid machine setup. It also now runs on Windows, Linux and RaspberryPi. Synchronised threading is sorted in v2017.10.30 but is at the moment in the latest version being revised, along with some other g-codes. I've been getting some serious use out of this software and it's proving nice and stable too.

Martin. Edited By blowlamp on 14/05/2018 11:09:42 |

| richardandtracy | 14/05/2018 11:50:42 |

943 forum posts 10 photos | Martin, I came to the conclusion I want to go for a semi-industrial self contained unit with screen, keypad et al in the same unit rather than have a board where I plug a laptop in to find out what's going on. Furthermore, I was so 'impressed' with their fulsome and wholehearted response to your problem (last year, or a bit before?) with the encoder I rapidly ruled out the PlanetCNC controller from my list of options. Regards, Richard |

| blowlamp | 14/05/2018 15:07:18 |

1885 forum posts 111 photos | If your workshop is "a killer forPC's" then what makes you think "a semi-industrial" unit will fair any better? If it's still cold & damp in there won't you need to sort that out first? I don't tend to plug and unplug the laptop I use with my CNC lathe, I just switch it on, start the software and get machining. However, I could easily move the laptop & control to the house to keep it dry if I needed to - could you do the same with something semi-industrial? The problem with the encoder was resolved after PlanetCNC opened a personal support ticket and issued updated software. I've put that episode behind me now and am enjoying the the new features that are included in TNG. Do you even need the threading/encoder facility? Let us know when you find something.

Martin. |

| richardandtracy | 14/05/2018 15:53:18 |

943 forum posts 10 photos | Yes, I do need the threading. I want to make pens, and there are masses of odd threads I need to do: here is a list from the first set of pens I want to make:

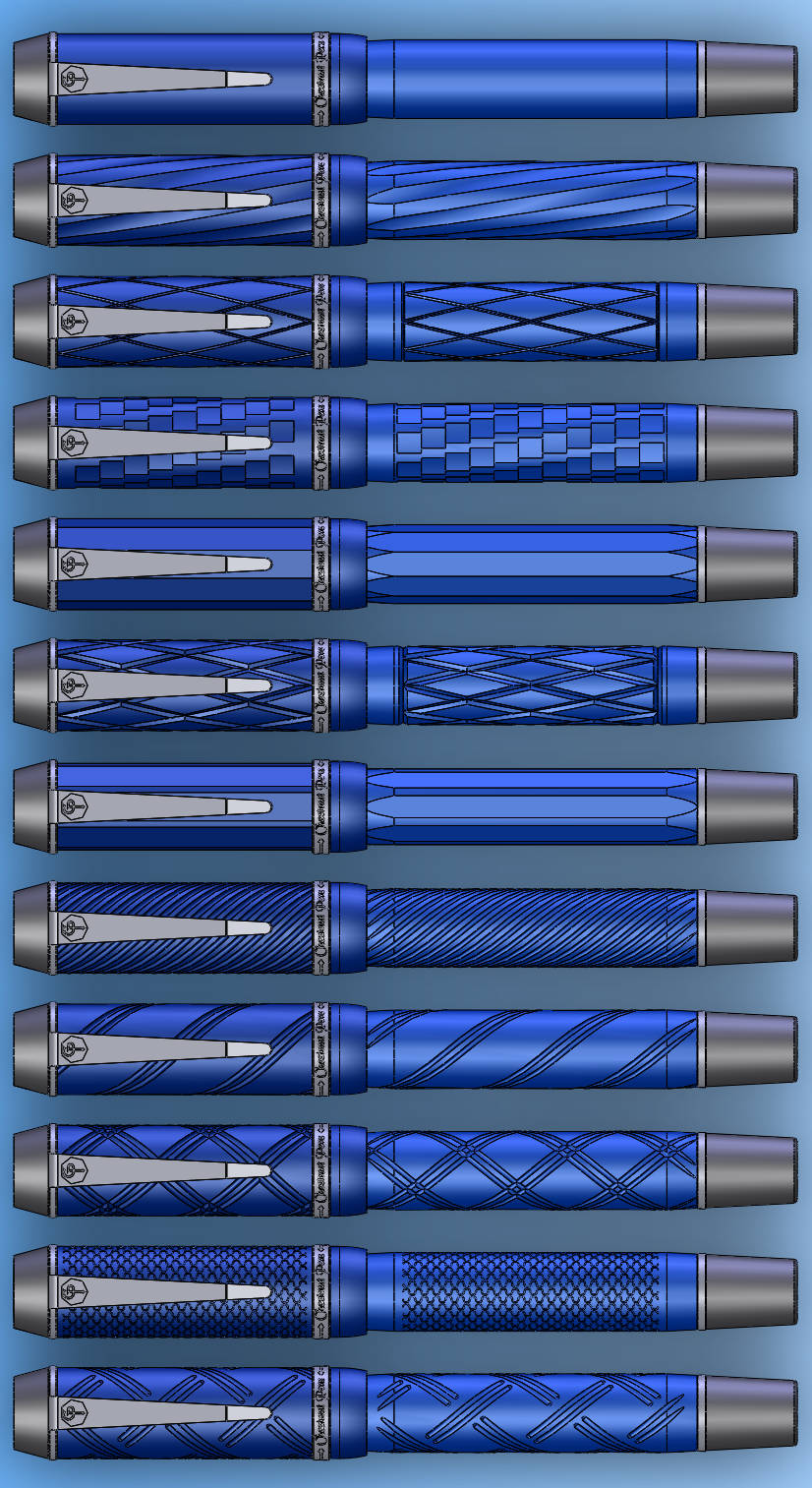

Depending on the levels of symmetry on the engraving on the outside of the pen, the Cap-Barrel thread may be 3 to 5 starts, but I am expecting the standard to be 4 starts. The form of the pens is as below:

All spirals will also have an opposite hand spiral variant. The pens will all be in Fountain Pen, Rollerball and Ballpoint versions. Having finally ruled out the milling controller option, I am looking at the Newkye/SZGH 990TDb/TDc **LINK** and the Tomatech TAC-1003T **LINK**. There doesn't seem to be anything between them on controller capability. Unfortunately the Adtech range does not have a 3 Axis lathe controller in the range. Regards, Richard.

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

and the lathe bed axis (usually called 'Z'

and the lathe bed axis (usually called 'Z'

Register

Register Log-in

Log-in