filling cast iron blow holes

| Tony Martyr | 27/03/2018 09:17:23 |

226 forum posts 45 photos | I have a 12"x12" cast iron engine base that, in addition to a couple of chilled hard areas, has a series of small 'blow holes' on one flank. This do not create a problem to the structure but don't look nice so I want to fill them before prime and finish painting - but with what? The base is far enough away from the working parts not to suffer any great temperature gradient but it would be embarrassing if bits dropped out. Tony

|

| not done it yet | 27/03/2018 09:32:42 |

| 7517 forum posts 20 photos | Vehicles have had bodywork filled, after accidents or corrosion, for decafes. Doesn’t fall out when properly applied. A suitable key, for adhesion, is what is required. |

| fizzy | 27/03/2018 09:40:43 |

1860 forum posts 121 photos | Best stuff ive used is Plastic padding bodyfiller |

| Chris Evans 6 | 27/03/2018 10:04:32 |

2156 forum posts | I use JB weld, strong and a good shelf life. Can be machined/drilled/tapped when fully cured. |

| vintagengineer | 27/03/2018 10:14:06 |

469 forum posts 6 photos | Chemical Metal is the best solution. Countersink the holes both sides so the filler is wedged in. |

| John Paton 1 | 27/03/2018 10:14:48 |

327 forum posts 20 photos | I would go along with JB weld but have also successfully used Araldite loaded with with cast iron filings / linishing dust. Warm the resin to help keep it fluid during filling of smaller holes. Ideally use a carbide burr to clean and roughen the hole and clean with acetone and blow ou with compressed air (a bit like dental treatment!) and trim off any excess with a sharp knife or trimming tool when it is set but still 'green'. Final flat into surrounding area will require filing and wet and dry sanding once the resin is fully cured. This treatment also works well for filling 'oops' holes in pillar drill tables. I don't believe resin is strong enough to refix damaged items like snapped off mounting lugs, despite what the adverts say - happy to be proven wrong by others on this! |

| Emgee | 27/03/2018 10:55:39 |

| 2610 forum posts 312 photos | I'm with Vintagengineer for Chemical Metal from the Plastic Padding manufacturer, also follow John Paton method of cleaning before application. Emgee |

| IanT | 27/03/2018 11:03:37 |

| 2147 forum posts 222 photos | Tony, before you fill the blow holes - you might think about treating the casting for those hard spots. I've not done this with a casting as large as yours (12" x 12" ) but have done so with smaller (wheel etc) castings that seemed to have hard spots. Basically they've gone in a garden incinerator when I've had wood to burn (once it's well alight - with additional wood added for an hour or so afterwards) and have then been left buried in the hot ashes overnight. They then turned/machined well. I do this to some steel parts (to de-stress) them too... I can't think of any reason it wouldn't work for you. I've used JB Weld to fill blow holes but it does 'shrink' - so usually needs a top-up. If you can pop it in a low heat oven that helps it cure. I've also mixed cast iron 'dust' with Araldite, which works well for cosmetic purposes (filling small external blow holes) but JBW would be a better choice where heat is involved or you need to machine it... Regards, IanT Edited By IanT on 27/03/2018 11:04:05 |

| SillyOldDuffer | 27/03/2018 12:35:02 |

| 10668 forum posts 2415 photos | If you want to be authentic the old boys used Iron-Filings with a dash of Ammonium Chloride mixed to a stiff paste with a little water. Inside the blowhole the mix corrodes and expands whilst bonding to the casting. Three problems: I don't believe it works particularly well as a filler; it takes a long time to set, and it's not compatible with many paints. Dave |

| JasonB | 27/03/2018 12:44:47 |

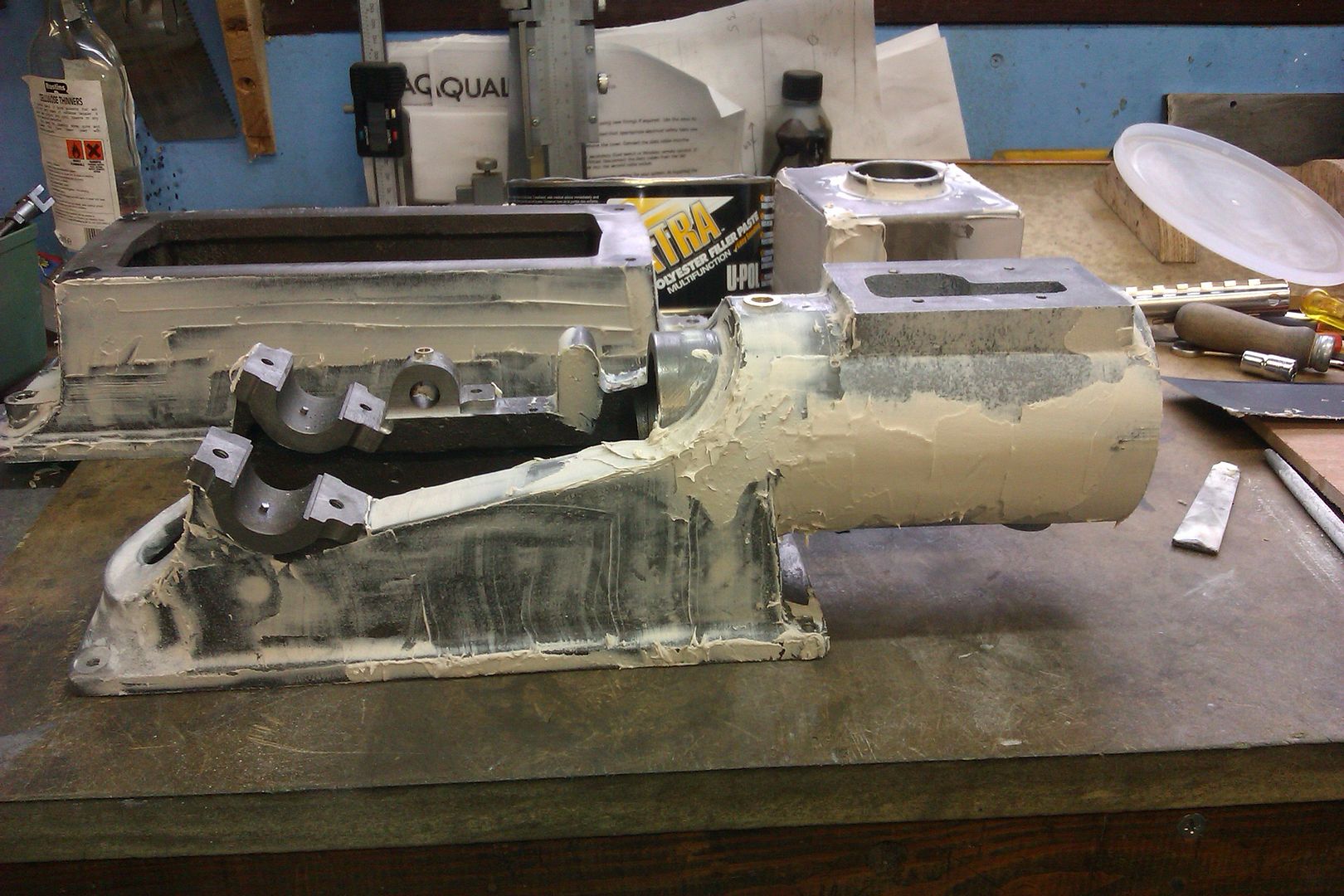

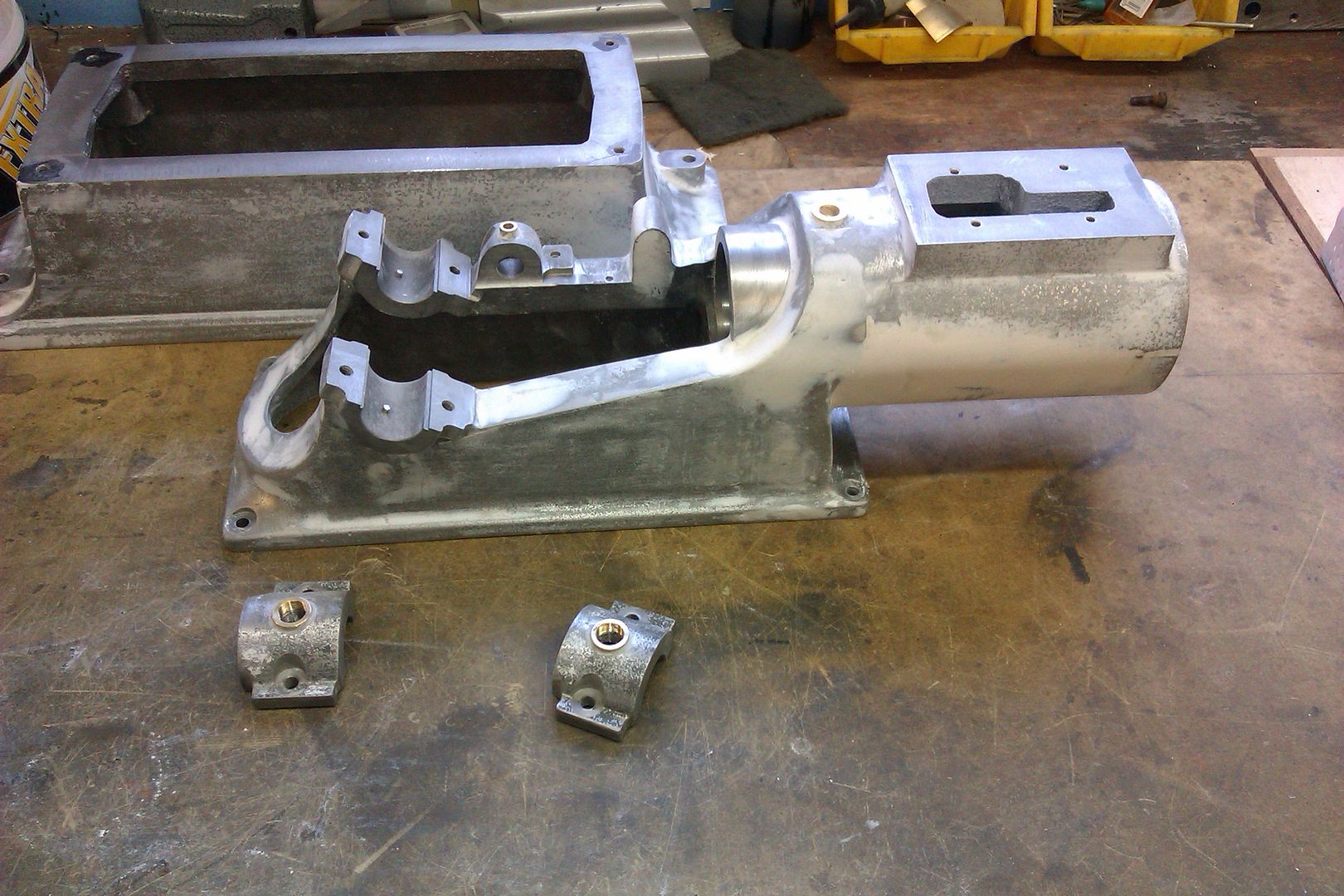

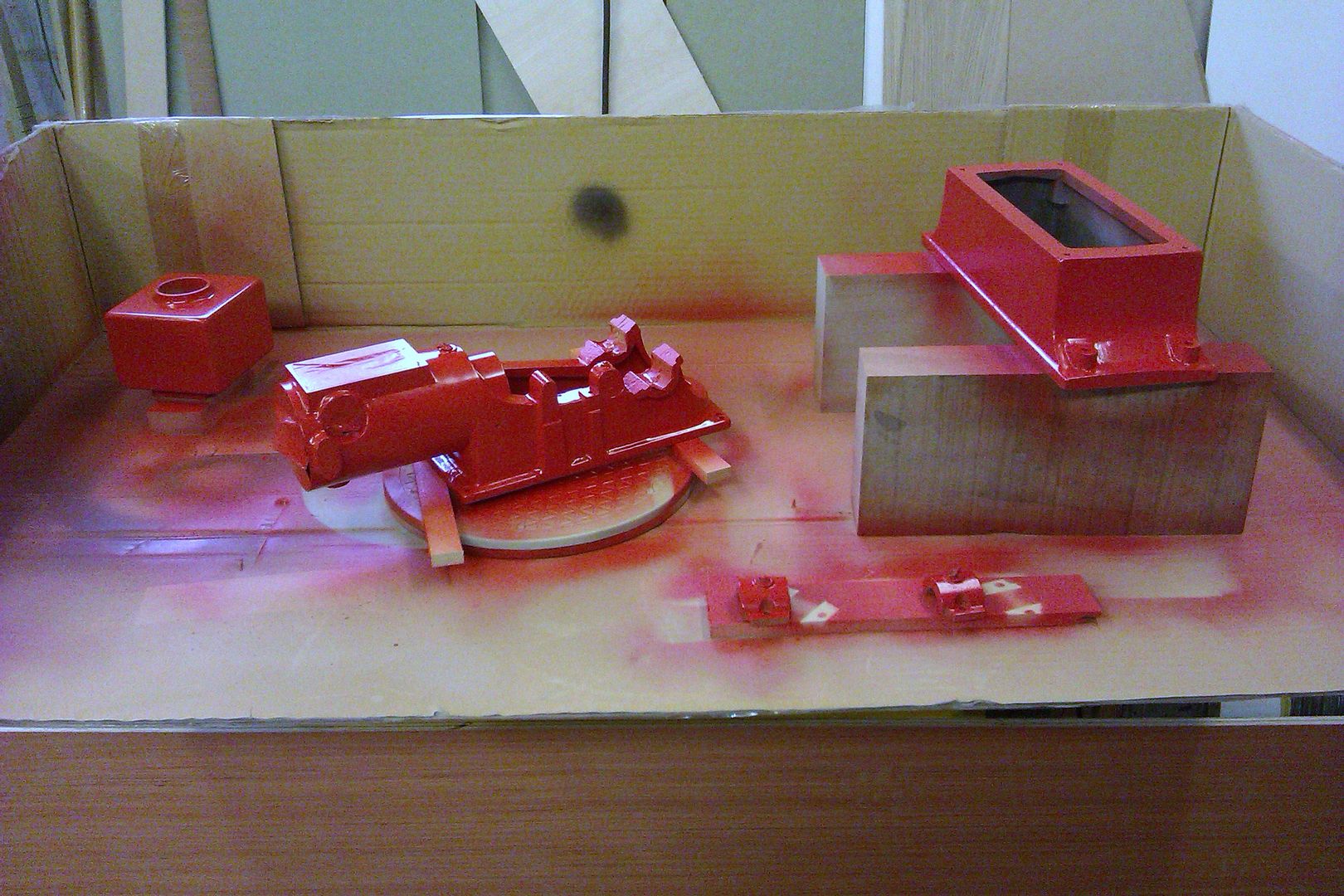

25215 forum posts 3105 photos 1 articles | As it is only cosmetic I wouldn't bother with JB Weld or Chemical metal as they are harder to rub down. Car body filler will be quite adequate for this. I tend to use U-POL but whatever your local car shop has will do. Once that has been applied and rubbed down very small imperfections are best dealt with using a high build filler primer, again I use U-POL "High5" and again rub that down when dry. This may also show up areas than are deeper so spot fill with your body filler or knifing putty. Finally pirime with teh required colour to suit your topcoat, denib and apply topcoat. Few pics of the process below. Over fettled casting and roughing in of mismatched parts

First application of filler

Rubbed down

Filler/primer

Colour after grey primer

This post shows a similar process on another engine but also includes the prep of the raw castings

|

| HOWARDT | 27/03/2018 13:27:23 |

| 1081 forum posts 39 photos | Production castings were always filled with a two part filler, very often the whole thing was filled to get a good finish. That was the difference in days now gone by between UK manufactured machine tools and East European imports. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in