Servo Motors

Trying to find out how much I don't know

| richardandtracy | 06/06/2017 15:06:48 |

943 forum posts 10 photos | Sorry to launch into really basic questions, but when you are utterly ignorant on a subject it's best to start small and work up from there. I know 'Servo Motors' are a special type, but don't know anything else. I understand they are controllable, but that's as far as I do know. So, can I ask a few basic questions that will at least enable me to go forward to search for more detailed info elsewhere (if need be)

Hope that this isn't too basic, but I really am trying to find the limits of my ignorance so I can find the info as I need it. If you could point me to an idiots guide to servo motors, I'd appreciate it. I have read the Wikipedia article on them, but left with more questions and less knowledge than when I started. Regards, Richard

Edited By richardandtracy on 06/06/2017 15:08:43 |

| Michael Gilligan | 06/06/2017 15:16:51 |

23121 forum posts 1360 photos | Richard, I still share much of your ignorance of the matter; but I did find these pages useful: **LINK** https://www.electrical4u.com/servo-motor-servo-mechanism-theory-and-working-principle/ To be honest: I abandoned the project when I found how complex and expensive the driver would be [for a particular 3 phase ServoMotor] I shall follow this thread with interest. MichaelG.

|

| richardandtracy | 06/06/2017 15:40:06 |

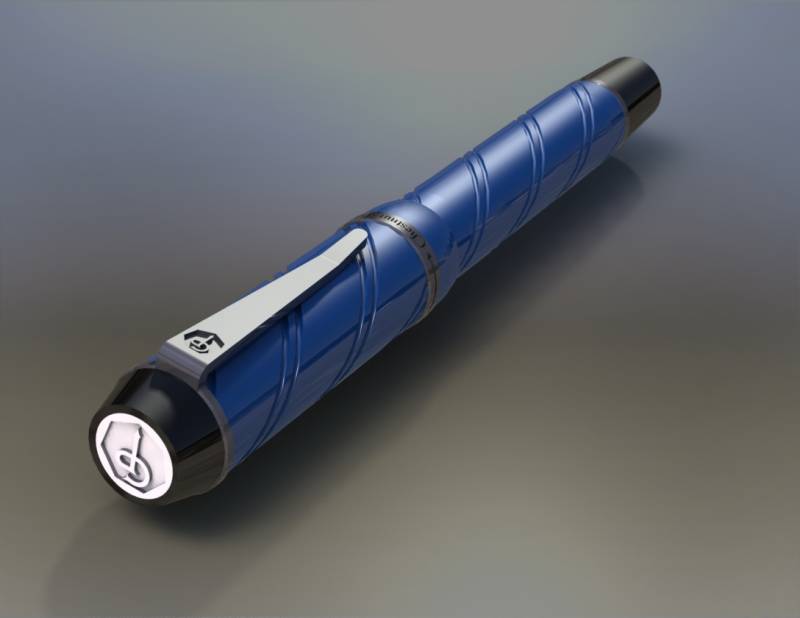

943 forum posts 10 photos | The purpose of my question is to enable me to gather enough info to determine if what I think I want to do will be possible. I intend to convert a Clarke 430 to CNC, and want to do engraving on the outside of the cylindrical objects (fountain pens) as well as the usual cnc lathe stuff. What I don't know is whether I am going to be able to use a single servo motor on the spindle for this, or whether I'll need to keep the 1 phase motor for the turning, and then detach that and use a separate stepper motor on the spindle when I wish to do the engraving. This is the sort of thing I want to engrave on the outside:

Regards, Richard.

|

| richardandtracy | 06/06/2017 15:49:20 |

943 forum posts 10 photos | Thanks Michael, those articles were useful. So it is possible to get servomotors to rotate through more than 360 degrees. One question answered. Thanks. Now I'll have to look up armature & field control motors. Regards, Richard |

| Involute Curve | 06/06/2017 16:48:38 |

337 forum posts 107 photos | Some VFD's have encider input but I think you are looking for more control than that, The link below may give you some good pointers Shaun and this http://www.practicalmachinist.com/vb/cnc-machining/servo-vs-vfd-spindle-control-249639/ Edited By Involute Curve on 06/06/2017 16:53:11 |

| Frances IoM | 06/06/2017 17:10:29 |

| 1395 forum posts 30 photos | can't you use a mill - simple (limited) control of Z axis (head) to change engraving depth and cnc on X + Y axes but mount your cylinders + a 2nd drive cylinder of same dimension between centres along the Y-axis - fix a band around the drive cylinder with ends attached to 2 fixed points - as you move X axis linearly the cylinder to be engraver will rotate - you can design the engraving as though on a XY plane but will engrave on the cylinder same trick as used to cut gears on a shaper |

| Bikepete | 06/06/2017 17:15:48 |

| 250 forum posts 34 photos | Oh go on then, I'll have a go. 1 Are they like stepper motors and need a separate controller? Yes, almost always. There are some with the controller built into a housing on the motor, but it's pretty rare. Just to be clearer, the box of tricks which connects directly to the servo motor is called the 'servo drive/driver' or 'servo controller'. But just like with a stepper motor driver, you typically need e.g. a computer or separate motion controller to tell the servo driver what to do, usually by sending it step/direction signals. 2 Can they do single steps? Yes, if the controller is set up to use 'step and direction' inputs. Typically there are loads of other control modes as well, e.g. a simple voltage input to control speed. 3 Can they be set to run at a certain speed without external control? Generally, yes - you can usually program the driver box to do that. 4 Do they all have positional encoders built in? As far as I know, yes (i.e. there is an encoder built in, on the motor shaft). The resolution of the encoder varies of course, and there are many different types. They are only rarely interchangeable between makers or even between model ranges by the same maker, so it's best to buy motor and driver box as a set (also making sure you get all of the necessary cables). 5 Are they all powered by DC power supplies? Not at all - you can find some DC powered ones but generally servo systems relevant for CNC are powered by AC i.e. mains, connected into the driver box. Bigger ones need three phase in. Some also need a separate 24V input for their control circuits. Typically you'd install drivers etc in a control cabinet with appropriate circuit protectors, contactors, PSUs etc. The manual for the servo driver will specify what's needed. Note that when talking servo motors, AC vs DC usually refers to the TYPE of motor, not the electrical input to the driver box. AC typically means "brushless three phase" and DC usually (but not always, confusingly) means "has brushes". The brushless AC type has pretty much taken over now. 6 Is there a type that is best for a particular type of job? Bit of an open question but for hobby CNC axis drives most people seem to use AC servo systems at about 200-400W nominal power. There are many online calculators to help you size servos correctly, and also bear in mind that most will put out up to about three times their nominal rated torque for short periods. 7 Can single step motors be run at higher speed (eg 1200 rpm)? I'm not sure what you mean by a 'single step motor' but in general servos can usually go to a few thousand RPM. If you are using a 'step and direction' input to drive the servo, and its encoder gives many steps per rev, you will need something capable of putting out the steps very fast to get high RPM. Most servo drivers have an option for 'electronic gearing' which effectively lets you set it up as if the encoder was lower resolution than it actually is, so a slow stream of steps (from e.g. a parallel port) can still rotate it at decent RPM. 8 As I know nothing, can you think of something basic that I haven't asked about ? If you can, I'm certainly ignorant of it and would like to change that situation. Well, the main advantages over steppers are:

Main disavantages

For most purposes steppers are fine. If you want to drive something a bit bigger or faster, then servos are probably the way to go. The price is falling for servos, though - see e.g. here for some from a reputable China seller... brand name ones tend to be a lot more. There are also UK suppliers who can advise and offer backup e.g. Zapp. I intend to convert a Clarke 430 to CNC, and want to do engraving on the outside of the cylindrical objects (fountain pens) as well as the usual cnc lathe stuff. What I don't know is whether I am going to be able to use a single servo motor on the spindle for this, or whether I'll need to keep the 1 phase motor for the turning, and then detach that and use a separate stepper motor on the spindle when I wish to do the engraving. This is the sort of thing I want to engrave on the outside: Yes, you can drive the spindle with a servo motor no problem - it's a 'deluxe' solution used on many CNC lathes and will also be handy for threading. You'll want to connect it to the spindle with a toothed belt, though, so there's no slip, and use a fairly hefty servo motor. The alternative you suggest of just using a stepper to position the spindle when it's needed as a rotary axis (for engraving) would end up a lot cheaper, though, and I can't see any reason it wouldn't work fine. Edited By Bikepete on 06/06/2017 17:23:44 |

| Tim Stevens | 06/06/2017 18:38:16 |

1779 forum posts 1 photos | In general terms a servo is a device which amplifies effort. A typical example is a power steering system, which increases the load applied to the wheels in proportion to the (smaller) effort you apply to the steering wheel. It would therefore be helpful for me (and others I'm sure) to have some further detail about the specific servo motor application being discussed here. Thanks, Tim |

| Martin Connelly | 06/06/2017 18:50:41 |

2549 forum posts 235 photos | There is a lot of useful information on the CNCcookbook Web site. Martin C |

| John Rudd | 06/06/2017 19:24:31 |

| 1479 forum posts 1 photos | Servo motors are not necessarily the same as steppers..... The servo's I use in my model planes use standard brushed motors driven through a H bridge based controller, neither do they need a computer per se to drive them. They are driven by ppm signal decoded by the receiver, from the signal sent from the transmitter. Feed back within the servo is by means of a potentiometer driven via a geartrain driven by the motor. So not all servomotors are the same..... |

| richardandtracy | 06/06/2017 20:28:20 |

943 forum posts 10 photos | Thank you all for your help. I have a feeling I now have a start in finding out what I need to know now. My particular thanks to Bikepete. Zapp Automation are on my list of people to talk to, I suspect I'll have to do it face to face if I can - so mustn't give warning of my arrival as they'll run screaming for the hills. At least I now know where to start my research and will be less ignorant when I get to talking to them. Many thanks, Richard. |

| John Haine | 06/06/2017 20:45:15 |

| 5563 forum posts 322 photos |

If you already have a CNC mill or router then it would probably be easier to just add a z axis to it driven by a stepper motor, imho. Even going the lathe route, I think it would be fine and cheaper to drive the spindle from a large stepper size 34 or bigger, via toothed belt reduction. I don't think for engraving pens as you show you need to run the spindle very fast. If you want to do threading then use Mach 3 or LinuxCNC with conventional drive to the spindle, adding an encoder so the driver software knows where the spindle is. Trying to drive the spindle with a servo or stepper fast enough to do conventional threading sounds just too hard to me. I've converted my Super 7 to CNC under Mach 3 and it threads fine at least for small pitches.

|

| richardandtracy | 07/06/2017 08:44:15 |

943 forum posts 10 photos | John, I have a 4 axis CNC router & Mach 3, The machine is not stiff enough by far, but it can do the engraving. The main pen bit needs me to use the manual lathe. I have discovered over the years of doing it, repetitions of pen shapes bore me intensely. I enjoy the pens, not the twiddling of the handles after making the first one of a particular design. That's why I want a cnc machine, as it's more accurate, quicker & less tedious. Now, my workshop is also a PC killer. In 3 years, I'm on number 3 for controlling the cnc. I can envisage a time in the near future when I won't be able to get a replacement XP machine for Mach 3 when my last one dies. Need a decent control method, and everything I have ever seen about Linux makes me avoid LinuxCNC like the plague - I want something that works, not a new OS that'll take me 3 years to learn, and then another year or two to realise that the programs are not working due to some techie using deliberately obscure geek language in place of English in the instructions (I've played with GIMP - a Linux program ported to Windoze - and the smartarse geek stupidities within the program enrage me, I am not going to subject myself to an OS developed by the same type of people, ever). So, I am looking at the Chinese alternatives to the Fanuc controllers. I think I now know which one I'm going for. So, if I'm going for a fully fledged cnc lathe, then the next logical extension is to see if I can get it to do the engraving, as all you need to control when engraving a pen is the X,Z and C axes. The axes are already there on a lathe, and the lathe will be vastly stiffer than the router. Also, being stiffer, I may be able to get the engraving speeds to exceed 50mm/minute. Once I have got the cnc bit sussed, maybe I can stray away from cylindrical & conical shapes on the pens, going for arcs & other forms. An aim for the future, that. Regards, Richard.

|

| John Stevenson | 07/06/2017 08:56:55 |

5068 forum posts 3 photos | Yes it can be done but be prepared to spend 3 times more than you can afford |

| richardandtracy | 07/06/2017 09:57:45 |

943 forum posts 10 photos | Posted by Frances IoM on 06/06/2017 17:10:29:

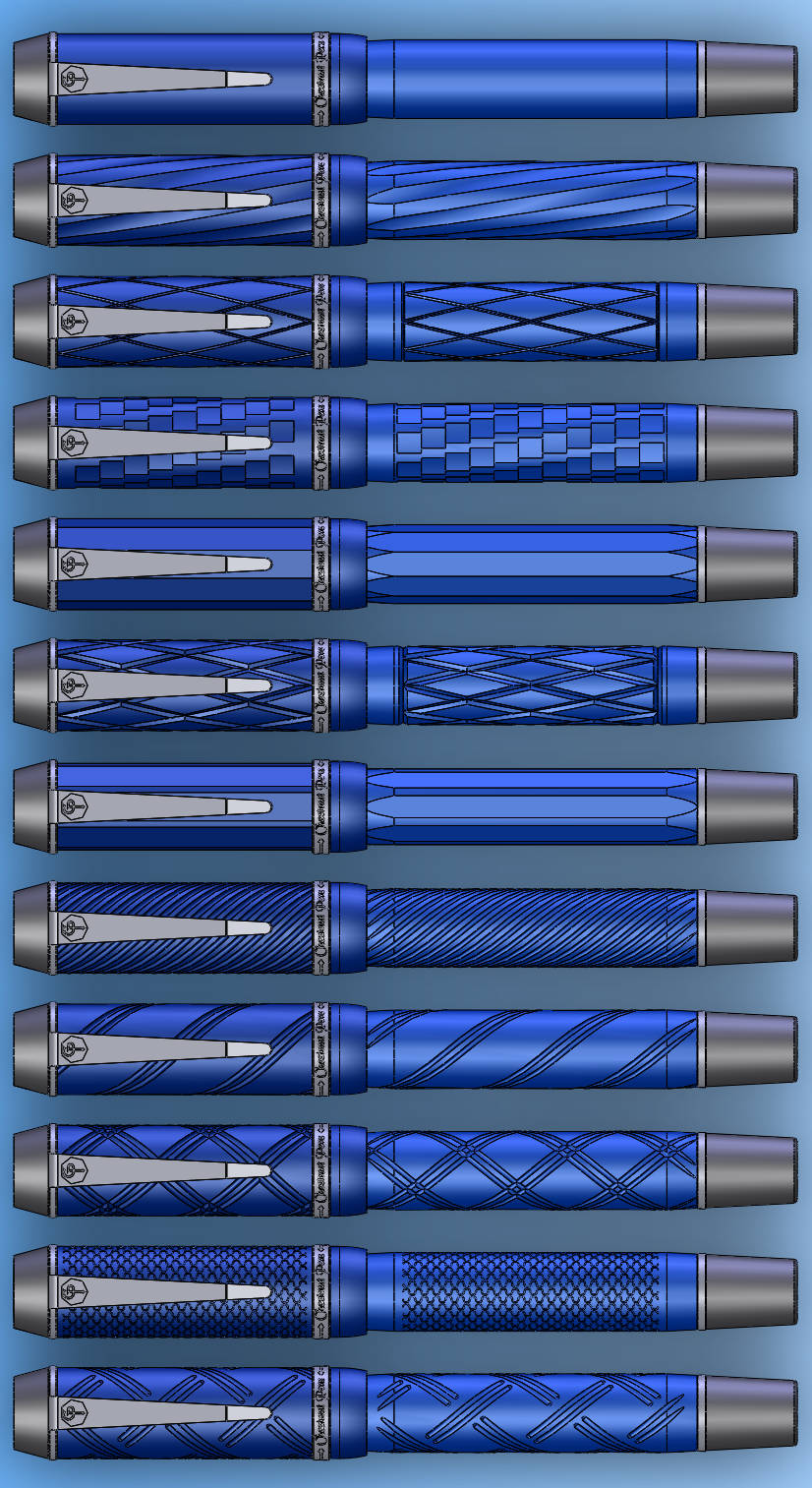

can't you use a mill - simple (limited) control of Z axis (head) to change engraving depth and cnc on X + Y axes but mount your cylinders + a 2nd drive cylinder of same dimension between centres along the Y-axis - fix a band around the drive cylinder with ends attached to 2 fixed points - as you move X axis linearly the cylinder to be engraver will rotate - you can design the engraving as though on a XY plane but will engrave on the cylinder same trick as used to cut gears on a shaper Frances, I don't just want to do one pattern, the ones below took me just a few days to come up with & model. Where there are spirals, LH & RH versions can be offered too.

In fact the cnc toolpath program for most of these is stunningly simple, but they are not easy to do with conventional machining. Regards, Richard |

| John Haine | 07/06/2017 10:17:09 |

| 5563 forum posts 322 photos | Richard, understood. I'm fortunate to have a CNC mill, a little Novamill, which is very rigid. I also have a motorised dividing head which I could use on it if and when I need a 4th axis. The problem with using a servo to drive your lathe spindle is that, if it's essentially a servo motor driving the spindle direct, maybe through a smallish reduction, you will be relying on the servo dynamics to provide the rigidity around the rotational axis. If the work gets deflected by the cutting force, the servo won't correct it unless it can be detected, so the encoder will need to have very high resolution to enable it to detect the movement. I'm not saying this is impossible but it feels very hard to do to me. By contrast, if you drove the spindle through a worm drive for example, just like spindle dividing, the rotational stiffness will come through the worm action, essentially friction when you try to turn a worm drive backwards. Once you have a worm drive, you don't need nearly so much torque from the motor so a stepper becomes feasible as long as you don't want to turn too fast. So this indicates to me that an optimum approach would be a CNC lathe, using one of the stand-alone controllers discussed here in another thread, used in standard turn mode for profiling and threading the pen bodies. Then to do the engraving you disconnect the main motor, engage the worm/stepper drive, and use the system in (effectively) "mill" mode with a fixed Y position (Y=0), moving the cutter (now an engraving spindle) in the X and Z directions and rotating the workpiece around the A axis using the "spindle" drive. On another note, why is your workshop a "PC killer"? When I first CNC'd my Myford I was given an old PC by a mate that turned out to be duff, so I actually bought a used Dell Optiplex PC with XP from a dealer. That was 8 years ago and it's sat on a shelf under a bench ever since without complaint, driving the lathe and now the mill as well. What has gone wrong with yours? (Mind you having said this it'll probably pack up next time I try to use it!) The benefit of staying with the PC is that I can easily envisage running Mach3 with two profiles for the same "machine", one mill and one lathe, to cover the two applications, but I'm not sure if it's so easy to do the same with one of these standalone controllers (but probably just because I'm not familiar with them). |

| Michael Gilligan | 07/06/2017 10:34:57 |

23121 forum posts 1360 photos | Richard, Forgive me if I have missed something here: [... I'm sure that others will jump-in to correct me if I have.] It would appear simpler to just use a Stepper Motor [of appropriate performance] to drive the lathe spindle. MichaelG. |

| richardandtracy | 07/06/2017 10:55:36 |

943 forum posts 10 photos | PC Killer: Uninsulated steel sheet roof, converted 35ft x 15ft commercial kennels that was open on one long side, and two open doorways at either end. I have put in a plank garden gate in each doorway, and on the open side I made a window wall structure 35ft x 4ft using pallet tops, and sheeted with 150 micron clear PVC roll. This window wall approximates to water tight in anything other than the worst storms, but is far from draft proof. No heating at any time. The condensation in winter can be extreme and it rains regularly inside the building from condensation, and dewfall occurs within the building regularly. Due to the pole-barn style construction it's not practical to insulate. This environment is dreadful for PC's, and not much fun for machine tools either. We have a brick built Victorian stable/hay loft which I have been in the process of dry lining for 3 years (other things have interfered Regards, Richard.

|

| richardandtracy | 07/06/2017 11:06:21 |

943 forum posts 10 photos | Michael, So far as I understand it, stepper motors tend not to be up to the oomph of a 550W lathe motor to drive the spindle. If I'm wrong that would add a nice alternative to my ideas. I have done calculations on my normal steel cutting depth & feed rate and found that the machining usually is less than 45W absorbed, and with the expected drive train efficiency the lathe is probably absorbing 50W. Acceleration up to cutting speed could well be a momentary 300-400W. I have not heard of lathe spindles being driven by stepper motors, but my knowledge is far from encyclopaedic. Just been looking at the dreaded e-bay, and found one NEMA 34 motor, 7.2A @80VAC = 576Watts. Hmm. Regards, Richard.

|

| John Haine | 07/06/2017 12:12:01 |

| 5563 forum posts 322 photos | Now I understand why your PCs don't last long... Not sure a dedicated controller would be much better! How about getting a suitable environmental enclosure? I have seen an article on using a stepper to drive the lathe spindle for threading (was it Tony Jeffree on a Taig lathe?), but I think it's not optimum. Yes, you deal with the indexing problem as you always know where the spindle is, but you can do that with a simple encoder anyway. Two cases. One, you have let's say for the sake of argument a 1:1 drive from stepper to spindle. You want a lot better than 1 step resolution (1 step being 1.8 degrees), so lets say 16 microsteps per step (giving you about 0.1 degree resolution), for engraving. But the torsional rigidity to cutting forces comes solely from the torque vs. displacement curve of the stepper, over which you have little control. And whilst the resolution may be 0.1 degree the accuracy won't be as microstepping isn't that good unless you get a special stepper. So this sounds like it might work for turning but not engraving. The other case: use the stepper to drive the spindle through a worm drive such as 60:1 like a dividing head. Now the torsional rigidity comes from the worm and is much better, but as I know from my digital DH, if you want to drive it continuously at any sort of speed the step frequency gets VERY high, the motor shrieks, and if running continuously I think the worm would get very hot! So this arrangement is great for engraving where spindle rotation will be slow but not for conventional turning, In my view it's best to separate the functions, use a stepper + worm for engraving but keeping a conventional motor with spindle encoding for turning and threading. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

and intend to use for the CNC lathe, & move the router there when done. But I doubt that'll be this year - we've just bought another 26 sheets of 8x4ft plasterboard which may be enough it and I am very slow at plasterboarding. This building was roofless when we got it, but now has a slate pitch roof with 2" of insulation underneath & will have a dpc fitted by the time the plasterboard goes up. One of the delays has been caused by the foundation failure of the building next to it, and the time we spent replacing it using all the same bricks. So, the kids have a nice 11ft x 13ft play-room to ignore...

and intend to use for the CNC lathe, & move the router there when done. But I doubt that'll be this year - we've just bought another 26 sheets of 8x4ft plasterboard which may be enough it and I am very slow at plasterboarding. This building was roofless when we got it, but now has a slate pitch roof with 2" of insulation underneath & will have a dpc fitted by the time the plasterboard goes up. One of the delays has been caused by the foundation failure of the building next to it, and the time we spent replacing it using all the same bricks. So, the kids have a nice 11ft x 13ft play-room to ignore...

Register

Register Log-in

Log-in