Access to drawings for G.H Thomas design sheetmeatal rollers

| rodger kallu | 17/07/2016 03:10:12 |

| 4 forum posts | Hi, I am looking to make some sheetmetal rollers. I have seen several designs including one described over two recent MEW issues. However a recent article in issue 241 entitled "Exhaust cones" shows a photo and reference to an early geared type by G.H.Thomas. Can someone please tell me what issue (if any) of MEW plans for this type is shown in. I particularly like the under rollers are adjustable as I am hoping that I can get quite wide range of diameters rolled from them. I have drawn a scale drawing of 40mm dia rollers out on paper and from what i can see will get quite quite small diameters from a top adjusting roller type. I would like to be able to roll up to 400mm rings if possible |

| Neil Wyatt | 17/07/2016 09:32:04 |

19226 forum posts 749 photos 86 articles |

Neil EOE! <EDIT> see below Edited By Neil Wyatt on 17/07/2016 14:20:45 |

| Robbo | 17/07/2016 09:33:01 |

| 1504 forum posts 142 photos | The G H Thomas bending rolls are probably those he described in Model Engineer issues 3546/3547, vol142, Oct 1976. Also in GHT's book "The Model Engineers Workshop Manual" Long before MEW was thought of! (1st issue MEW Summer 1990) Send me a PM if you have difficulty finding them |

| Mike Crossfield | 17/07/2016 09:33:16 |

| 286 forum posts 36 photos |

Full details and much more besides are in GHTs book "The Model Engineers Workshop Manual". If you don't have this I can't recommend it highly enough. |

| rodger kallu | 17/07/2016 11:15:27 |

| 4 forum posts | Hi, thanks for those 3 replies. I have since googled the GHT Model Engineers Workshop and the cost is a bit steep for me (I have quite a few of the workshop series already). What I would really like is a way to access and pay for the model engineers series 3456 and 3457 only , preferably online without having to pay for an annual subscription. Is this possible plse? |

| Ajohnw | 17/07/2016 11:24:35 |

| 3631 forum posts 160 photos | If you watch Myfordboys video on making a furnace you will see a much simpler design. I understand this also appeared in Model Engineer. He uses it in a couple of video's. The rolls are linked by cranks. I am an admirer of GHT but not so sure in the area of his particular design of rolls. Why - because I have seen the usual type used in tin smith work areas. They don't seem to have any problems with them. Myfordboys is a simplified version of these that gets round the need for gears. It appears to work well. John - Edited By Ajohnw on 17/07/2016 11:25:40 |

| AndyP | 17/07/2016 11:46:14 |

| 189 forum posts 30 photos | Rodger, Model Engineers Workshop Manual although its name might suggest it is part of the workshop series is infinitely more than that. I was new to this game 10 years ago and bought lots of books and I can honestly say the best money I spent was on this book and Tubal Cain's Model Engineer's Handbook. I have a set of the rolls although I didn't make them and they are really nice to use, the major advantage being that they curve the stock right to the end whereas pyramid rolls always leave a straight section I am told. Andy |

| Ajohnw | 17/07/2016 12:31:07 |

| 3631 forum posts 160 photos | You might like to watch this video and note the comments Andy which from memory uses GHT's principle - from memory cause at the moment I can't get at the book. The books size and content up's the price. It's compact as he wanted to roll very thick steel with it. There is a little bit of info on making it in another of his videos. I'm not sure which edition of Model Engineering that his other design appeared in but some might find the video's of him using them of interest if they are using pyramid rolls. John - |

| Ajohnw | 17/07/2016 12:48:19 |

| 3631 forum posts 160 photos | If some one does want to make the GHT design there is probably enough info for many here This video shows the alternative being pushed to the limit but doesn't show the work being reversed from time to time. It handles thinner wider stuff easily. John - |

| Neil Wyatt | 17/07/2016 14:20:10 |

19226 forum posts 749 photos 86 articles | Just checked the index and it is definitely says 3546 and 3547 NOT 3456 and 3457 I did say EOE.... Neil |

| Neil Wyatt | 17/07/2016 14:24:01 |

19226 forum posts 749 photos 86 articles | Posted by rodger kallu on 17/07/2016 11:15:27:

Hi, thanks for those 3 replies. I have since googled the GHT Model Engineers Workshop and the cost is a bit steep for me (I have quite a few of the workshop series already). What I would really like is a way to access and pay for the model engineers series 3456 and 3457 only , preferably online without having to pay for an annual subscription. Is this possible plse? Afraid as they are 40 years old they are long out of print and issues from the 20th century are not in the archive. As they feature in a current publication it's not really fair for me to put the articles on here as a PDF, but you should be able to get the back issues (or the volume with them in) with a bit of internet searching. Neil |

| Ajohnw | 17/07/2016 15:17:20 |

| 3631 forum posts 160 photos |

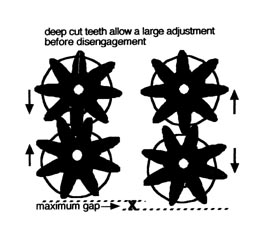

I suspect some wouldn't need plans. The cranks at each end are 90 degrees apart as per a loco. Some how I'd guess readers didn't take it seriously however for most of the sort of things people do with them it does work and can from the video's cope pretty well with them for much much simpler manufacture than even pyramid rolls. There are 2 designs here It's a good job that the mistake is noted in the comments. It need another gear between the 2 shown. Or There is also another design that GHT and the above has copied after a fashion. 2 rollers have meshing gears. They are used to feed stock against another roller. The gear teeth have an odd shape so that they can cope with variations in metal thickness as the gap between the rollers is used to grip the metal. The teeth are similar to clock style cycloid teeth with plenty of clearance, similar to the ones that used to be used on mangles. Some may remember their gran using one of those to pre dry the washing. Also called a wringer. I'm pretty sure there was an article in ME on this type of tooth form. The gears do need to rotate in op... directions with this arrangement and it's more suitable for materials that are easier to bend due to the strength of the gear teeth. Probably ok for steel up to maybe a 1/16" or so thick if suitably sized. John - |

| Keith Long | 17/07/2016 15:36:56 |

| 883 forum posts 11 photos | Rodger PM sent - check you forum "Inbox" Keith |

| Clive Hartland | 17/07/2016 15:48:11 |

2929 forum posts 41 photos | Is there any reason you could not use gears from a lathe? Perhaps size and thickness may be a problem? Clive PS. I could not make one in my lathe if I wanted to. ML10. |

| Maurice | 17/07/2016 16:35:52 |

| 469 forum posts 50 photos | I believe that the kit for bending rolls offered by Hemingway Kits is base on Gerge Thomas's design. I remember asking a member of their staff about it at an exhibition. If so, they will sell you the plans on their own, and, if you decide to buy the kit, they refund the cost of the drawings. Maurice |

| Ajohnw | 17/07/2016 16:56:43 |

| 3631 forum posts 160 photos | I suspect the design for the GHT will be found on the web if general metal rollers is googled. The style of gear teeth I mentioned may have been lost to posterity unless they are in Machinery's. This shows the idea roughly. In this case as used on a printing press.

The teeth were generally pretty thick and I believe sometimes removed from mangles when they were being thrown away. There used to be lots of them about. I'm pretty sure I have seen a roller made using chains and sprockets as well. That will have been a pyramid type as the rollers will both role in the same direction.

John - |

| Neil Wyatt | 17/07/2016 17:47:33 |

19226 forum posts 749 photos 86 articles | Will Dogget's design was published in MEW 236/237 which are available as back issues. Bear in mind that the systee he muses on in part 1 was abandoned and he used a better system detailed in part 2. Neil |

| rodger kallu | 22/07/2016 08:13:06 |

| 4 forum posts | Thanks again for all the posts, particulalrly those with links. From this I can see the George Thomas capacities are too light for what I want. have found other design

Thanks

Rodger K |

| JasonB | 22/07/2016 08:24:12 |

25215 forum posts 3105 photos 1 articles | Roger it is possible to increase the size of the GHT design and at the same time shorten the length of the rolls which will make them capable of rolling things like traction engine wheel rims. If you follow Johns link to MEM forum the rollers by Andrew are not far from this approach. You also have some unread private messages, go to the green bar at the top of the page and click "inbox" which will be flashing, there may be more help & info in those messages. Edited By JasonB on 22/07/2016 08:26:52 |

| Hopper | 22/07/2016 13:06:32 |

7881 forum posts 397 photos | Posted by rodger kallu on 17/07/2016 11:15:27:

Hi, thanks for those 3 replies. I have since googled the GHT Model Engineers Workshop and the cost is a bit steep for me (I have quite a few of the workshop series already). At 27 quid from Tee Publishing it is not a cheap book, but it is great value for money. One of THE definitive books of the golden era of model engineering and great reading. And a different thing altogether from the Workshop Practice series, as good as they are in their own right. Edited By Hopper on 22/07/2016 13:07:01 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Maybe you could pdf the Myfordboy one Neil. It was published circa 21 years ago in model engineer.

Maybe you could pdf the Myfordboy one Neil. It was published circa 21 years ago in model engineer.

Register

Register Log-in

Log-in