2MT Turning Attachment

| Tom Gullan | 10/07/2016 21:18:39 |

| 89 forum posts 35 photos | Hello, I'm wonder if anyone can give me help regarding a 2MT Turning Attachment which is on sale on eBay from Myford Ltd priced £95.00. This particular tool is inserted into the tail stock, and the dead centre can be offset by 5mm. I would like to know just how successful this tool is. Regards Tom

|

| Michael Gilligan | 10/07/2016 21:49:54 |

23121 forum posts 1360 photos | Here is a previous thread about such devices, Tom The principle is well established [same effect as offsetting the tailstock [but without the bother of having to re-align it afterwards] MichaelG. |

| Bazyle | 10/07/2016 22:24:33 |

6956 forum posts 229 photos | You mean this? which got a bit cheaper but is still way overpriced for something you can make yourself then never use. Much much cheaper to get a boring head which can be used for other things, has greater resale value, has greater offset range etc

|

| Michael Gilligan | 10/07/2016 22:36:16 |

23121 forum posts 1360 photos | Posted by Bazyle on 10/07/2016 22:24:33:

. I would think he meant this ... [having specifically mentioned Myford Ltd.] But your general analysis seems sound. MichaelG. |

| Tom Gullan | 10/07/2016 23:16:40 |

| 89 forum posts 35 photos | Gentlemen, thank you very much for your input. Regards Tom Edited By Tom Gullan on 10/07/2016 23:17:15 |

| Michael Gilligan | 10/07/2016 23:18:39 |

23121 forum posts 1360 photos | ... Also available, at a different price, from the Myford store |

| bodge | 11/07/2016 02:37:12 |

| 186 forum posts 3 photos | Well i think the boring heads a good idea. Usually i do morse tapers using the top slide , set a number 2mt between centre`s , dti in the tool post adjust so dti on the mt centre line then traverse and adjust top slide angle till dti holds zero on full traverse, The top slide on the lathe is an ml7 type but its been re-worked and now has a longer slide, so can manage up to 3mt.............b wow 101 post think id best slow down !!

Edited By bodge on 11/07/2016 02:42:12 Edited By bodge on 11/07/2016 02:42:34 |

| bodge | 11/07/2016 02:45:49 |

| 186 forum posts 3 photos | Why has the above post got such a big empty bit, ? ive not had that happen before .....................b |

| bodge | 11/07/2016 02:49:26 |

| 186 forum posts 3 photos | Think i might have double click the edit tab , as i only did one edit.......oops........b see what happens now with edit.............b ............ Sorted.............b Edited By bodge on 11/07/2016 02:53:48 Edited By bodge on 11/07/2016 02:55:15 |

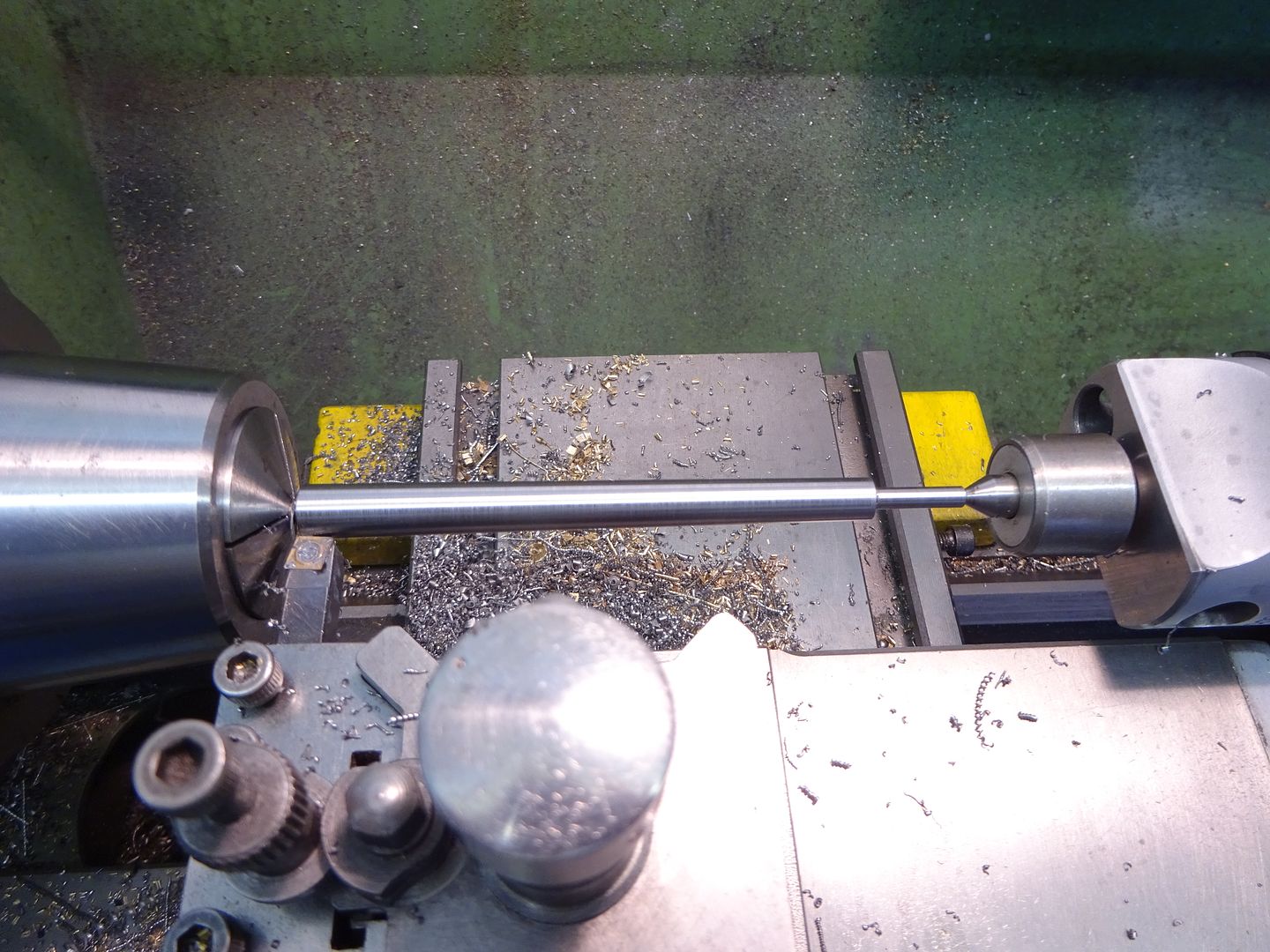

| JasonB | 11/07/2016 07:17:58 |

25215 forum posts 3105 photos 1 articles | In the past I have always set over the tailstock but on the latest engine I thought why risk upsetting things so tried the boring head method, made a sleeve so I could put a small Emco live ctr into the hole and had nice fine adjustment of the taper and over a larger range if needed than the Myford one offers. Hemmingway do a kit if you fancy making one though. The boring head also takes up less horizontal space than the Myford one so less problems of it clashing with your toolpost.

|

| Michael Gilligan | 11/07/2016 08:55:30 |

23121 forum posts 1360 photos | Posted by JasonB on 11/07/2016 07:17:58:

. It evidently works for you, Jason ... But I don't think I could bring myself to hold the material in a collet and then offset the free end. MichaelG. |

| peak4 | 11/07/2016 11:09:47 |

2207 forum posts 210 photos | I've done something similar to the above, but lacking a small rotating centre, I ground a conical end on a broken carbide centre drill. I then mounted this in a 1/2" bar and clamped it in the boring head. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in