Clarke Metal Lathe CL300M

Not working

| zak moussa | 24/06/2016 07:31:54 |

| 17 forum posts | Hi all Completely new to turning and engineering in general (from a medical background), in my spare time i wanted to learn how to mill and turn aluminium. Having done no research i decided to walk into machine mart have a few discussions with staff and decided on purchasing a Clarke CL300M . A local seller on gumtree was selling one so thought I would purchase it. Got it home watched some basics on youtube, then thought ok lets get cracking. I was experimenting and playing around with the tools and its effects, i used it on low then switched to high, after about 30 seconds poof a tiny bit of smoke and my fuse box tripped. Reset my fusebox returned to the lathe, checked the fuse intact and working, the lathe not so much, my guess is that either the speed controller or motor is kaput. I am ok with electronics and like for like replacements, or can follow instructions. What are my options ?

Edited By Neil Wyatt on 24/06/2016 21:27:46 |

| Anthony Knights | 24/06/2016 18:52:03 |

| 681 forum posts 260 photos | Hi there Zak. I suggest you enter "CL300" into the SEARCH THIS SITE box which will show you previous threads on this subject. |

| john swift 1 | 24/06/2016 20:47:02 |

318 forum posts 183 photos | Hi Zak have a look at this post six years ago I ended up tracing the circuit for the old version of the speed control board for CL300M as the service information was not available

John PS the photo bucket link didn't work for me

Edited By john swift 1 on 24/06/2016 20:53:04 |

| Neil Wyatt | 24/06/2016 21:29:38 |

19226 forum posts 749 photos 86 articles | I fixed the photo although I'm a bit confused what it is meant to show... See here for info on posting from Photobucket. Neil |

| zak moussa | 25/06/2016 02:52:42 |

| 17 forum posts | Posted by Neil Wyatt on 24/06/2016 21:29:38:

I fixed the photo although I'm a bit confused what it is meant to show... See here for info on posting from Photobucket. Neil its the work I did experimenting with the Lathe which broke the lathe (maybe indicating stress etc which could have broken the lathe) |

| zak moussa | 25/06/2016 02:53:39 |

| 17 forum posts | Posted by john swift 1 on 24/06/2016 20:47:02:

Hi Zak have a look at this post six years ago I ended up tracing the circuit for the old version of the speed control board for CL300M as the service information was not available

John PS the photo bucket link didn't work for me

Edited By john swift 1 on 24/06/2016 20:53:04 Thanks for replying, i am not sure whats blown in my lathe how i can i tell if its the controller or the motor what tests am i looking to run ? |

| zak moussa | 25/06/2016 03:00:35 |

| 17 forum posts | Posted by Anthony Knights on 24/06/2016 18:52:03:

Hi there Zak. I suggest you enter "CL300" into the SEARCH THIS SITE box which will show you previous threads on this subject. I saw many threads (buzzing sound, pcb repair, motor repair etc ) |

| John Rudd | 25/06/2016 06:24:32 |

| 1479 forum posts 1 photos | Firstly look for any visible signs of damage inside the control box, should give you an idea of what has expired. Disconnect the motor, then connect a 100 watt household light bulb in place of the motor. If the light bulb brightness varies when you adjust the speed pot, chances are the control board is ok. Try running the motor from a 12volt car battery ( again disconnect rhe motor first from the controller). |

| zak moussa | 25/06/2016 13:57:04 |

| 17 forum posts | Posted by John Rudd on 25/06/2016 06:24:32:

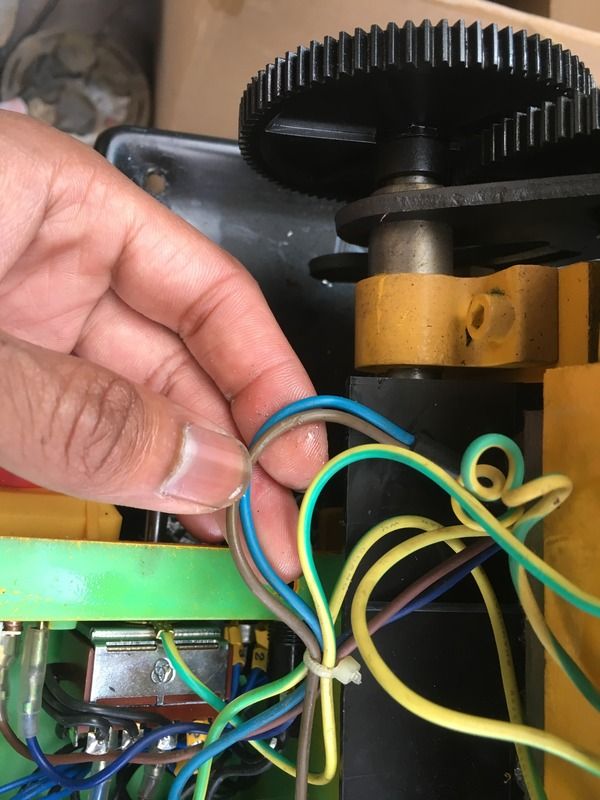

Firstly look for any visible signs of damage inside the control box, should give you an idea of what has expired. Disconnect the motor, then connect a 100 watt household light bulb in place of the motor. If the light bulb brightness varies when you adjust the speed pot, chances are the control board is ok. Try running the motor from a 12volt car battery ( again disconnect rhe motor first from the controller). Thanks for replying: Ok purchased a car battery (cant be bothered using mine from my car was only £20 anyway ) My guess for the motor is : Yellow is -

Edited By zak moussa on 25/06/2016 14:01:00 |

| John Rudd | 25/06/2016 14:18:00 |

| 1479 forum posts 1 photos | These mini lathes are prone to destroying themselves.....just be careful in what you replace....there's always a possibility that although you are replacing say a blown pcb, the underlying cause may not have been found. So, on to testing ..... Follow the wires from the motor back to where they connect to the control box. Disconnect it, remove from the lathe, check the brushes first and the condition of the commutator.......before doing anything else.If all is well, connect to your battery, doesn't matter way round the wires are connected.....the motor needs to turn freely and smoothly with little or no sparking from the brushes. Next, connect a mains domestic light bulb to the wires where the motor was connected. Does the bulb light up full when power is applied or can you vary the brightness with the speed pot? Conduct these two tests and feedback your results.....please. Edited By John Rudd on 25/06/2016 14:19:46 |

| john swift 1 | 25/06/2016 14:36:47 |

318 forum posts 183 photos | Hi Zak I see from the photos your lathe has the FC250J speed control board they have two FET's on the heat sink that have a habit of going short circuit if you over load the motor

John

|

| John Rudd | 25/06/2016 16:20:24 |

| 1479 forum posts 1 photos | Zak, Do you have anything from the motor at all? Does it run at all/ slowly/fast/no control ...? Edited By John Rudd on 25/06/2016 16:20:54 |

| zak moussa | 25/06/2016 16:56:40 |

| 17 forum posts | Posted by John Rudd on 25/06/2016 14:18:00:

These mini lathes are prone to destroying themselves.....just be careful in what you replace....there's always a possibility that although you are replacing say a blown pcb, the underlying cause may not have been found. So, on to testing ..... Follow the wires from the motor back to where they connect to the control box. Disconnect it, remove from the lathe, check the brushes first and the condition of the commutator.......before doing anything else.If all is well, connect to your battery, doesn't matter way round the wires are connected.....the motor needs to turn freely and smoothly with little or no sparking from the brushes. Next, connect a mains domestic light bulb to the wires where the motor was connected. Does the bulb light up full when power is applied or can you vary the brightness with the speed pot? Conduct these two tests and feedback your results.....please. Edited By John Rudd on 25/06/2016 14:19:46 Ok so no power to the light switch

Edited By zak moussa on 25/06/2016 16:56:48 |

| zak moussa | 25/06/2016 16:57:54 |

| 17 forum posts | Posted by john swift 1 on 25/06/2016 14:36:47:

Hi Zak I see from the photos your lathe has the FC250J speed control board they have two FET's on the heat sink that have a habit of going short circuit if you over load the motor

John

so the motor works fine the controller was hooked up to the light and did not work could this be the FETs ? |

| zak moussa | 25/06/2016 16:58:35 |

| 17 forum posts | Posted by John Rudd on 25/06/2016 16:20:24:

Zak, Do you have anything from the motor at all? Does it run at all/ slowly/fast/no control ...? Edited By John Rudd on 25/06/2016 16:20:54 the motor appears to work when hooked up to the small battery see the last picture |

| john carruthers | 25/06/2016 16:59:55 |

617 forum posts 180 photos | deleted post, I see you've sorted it. Edited By john carruthers on 25/06/2016 17:01:17 |

| zak moussa | 25/06/2016 17:42:18 |

| 17 forum posts | Posted by john carruthers on 25/06/2016 16:59:55:

deleted post, I see you've sorted it. Edited By john carruthers on 25/06/2016 17:01:17 I have not sorted the problem- just thanking people for the help so far Edited By zak moussa on 25/06/2016 17:42:49 |

| John Rudd | 25/06/2016 18:18:17 |

| 1479 forum posts 1 photos | Posted by zak moussa on 25/06/2016 16:57:54

so the motor works fine the controller was hooked up to the light and did not work could this be the FETs ? It could be, but it could be something else........ Have you examined the board for any burning? Do you have a multimeter and know how to use it?

|

| zak moussa | 25/06/2016 18:45:34 |

| 17 forum posts | Posted by John Rudd on 25/06/2016 18:18:17:

Posted by zak moussa on 25/06/2016 16:57:54

so the motor works fine the controller was hooked up to the light and did not work could this be the FETs ? It could be, but it could be something else........ Have you examined the board for any burning? Do you have a multimeter and know how to use it?

no i have not examined the board ,my brother has one i can borrow |

| SillyOldDuffer | 25/06/2016 18:49:34 |

| 10668 forum posts 2415 photos | Hi Zak, Bad luck! I had a near miss with my similar mini-lathe when a length of swarf found its way along the lead-screw and into the electronics. There was a blue flash and smoke. I was lucky and the lathe still worked. I notice that your pictures seem to show a lot of swarf inside the control box. It looks as if there's a quite a pile on the right hand side under the lead-screw and other bits scattered around. If it is swarf, the first thing to do is to remove it. You should also remove the clear plastic bag that protects the circuit board and carefully remove any metal shreds that might have found their way inside. It's possible that there's swarf under the board as well. Then you can start debugging the electronics. I can't help with that because I upgraded from a mini-lathe and no longer have it or the manuals. I remember that the most common fault is blown FETS, but f necessary you can buy a replacement board. I stopped more swarf getting in by reducing the gap between the lead-crew and control box with some electrical tape. Cheers, Dave |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in